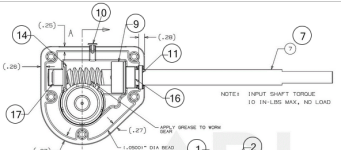

In the recent round of snowstorms here in Wisconsin, the brass auger gear inside the worm drive shredded. I got a new gear and ran into what I think is a problem with the reassembly. The collar on one side of the worm gear is not held in tightly. I've marked the area in blue in the picture. It looks like there's a flange missing. I'm sure I didn't lose any parts, but just in case I've looked all over my workspace and can't find anything that might remotely resemble a flange. Of course, there isn't a schematic for this particular assembly for me to be sure it is missingView attachment 67649. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.