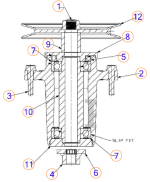

Looking for some guidance on how to disassemble this MTD spindle from a Dewalt Z254 (similar to CubCadet ZTX4 54).

Part number in the spindle housing reads "714-054", but I didn't find any reasonable hits for a search of the pn.

Parts diagram shows that this spindle has part numbers 490-130-C022 | 918-07416 | 618-07416 , latest revision to earliest.

This is the same spindle used in CubCadet ZTX4 and some other MTD mowers - pulley size varies for blade length :

cubcadet.com

cubcadet.com

mtdparts.com

mtdparts.com

mtdparts.com

mtdparts.com

I saw one of the advertised features was "Triple sealed bearings ensure maximum life". So, maybe they designed it to be difficult to disassemble ?

After looking at the spindle with nut, washer, and shaft removed , it's non-intuitive (to me) how to take it apart to get to the bearings so as to grease them up. I can't imagine that the top seal would be the only thing holding the axel tube and bearings in place.

Would appreciate hearing from anyone having dissected one of these and can give a few pointers on how to do it ?

=====

Part number in the spindle housing reads "714-054", but I didn't find any reasonable hits for a search of the pn.

Parts diagram shows that this spindle has part numbers 490-130-C022 | 918-07416 | 618-07416 , latest revision to earliest.

This is the same spindle used in CubCadet ZTX4 and some other MTD mowers - pulley size varies for blade length :

Spindle Assembly- 5.76" Dia. Pulley - 918-07416 | Cub Cadet US

Read reviews and buy Spindle Assembly- 5.76" Dia. Pulley918-07416. Free shipping on parts orders over $45.

918-07417A - 918-07417 | MTD Parts

Buy the 918-07417A online and get your OEM parts quick! Orders over $45 qualify for Free Shipping.

Spindle Assembly- 5.76" Dia. Pulley - 918-07416 | MTD Parts

Buy the Spindle Assembly- 5.76" Dia. Pulley online and get your OEM parts quick! Orders over $45 qualify for Free Shipping.

I saw one of the advertised features was "Triple sealed bearings ensure maximum life". So, maybe they designed it to be difficult to disassemble ?

After looking at the spindle with nut, washer, and shaft removed , it's non-intuitive (to me) how to take it apart to get to the bearings so as to grease them up. I can't imagine that the top seal would be the only thing holding the axel tube and bearings in place.

Would appreciate hearing from anyone having dissected one of these and can give a few pointers on how to do it ?

=====