The bottom hole in the deck wheel bracket on my z540m is rounded and I’m unable to to tighten the 13mm nut without it spinning. I know I could move it up one but I mow between 3 - 3 1/2” height. Any suggestions on how to repair it ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Z540m Deck Wheel Bracket ?

- Thread starter beretta22

- Start date

More options

Export thread- Joined

- Feb 19, 2020

- Threads

- 79

- Messages

- 10,274

The wear is usually from the spacer and gauge being left loose. They seize on the screw and then they spin together wearing the mating area.

It will someone with a welder, grinder (or file), and drill to repair the damage. Or a very heavy (extra thick) tight fitting washer and longer screw might work but finding one is problemic as very few are size for such a tight fitting.

It will someone with a welder, grinder (or file), and drill to repair the damage. Or a very heavy (extra thick) tight fitting washer and longer screw might work but finding one is problemic as very few are size for such a tight fitting.

- Joined

- Feb 19, 2020

- Threads

- 79

- Messages

- 10,274

JD is using a sleeve on the current screw to make it into a shoulder screw. If you try going to the next size you need do something like Hustler does on their Super Z gauge where they a partially threaded screw and a couple nuts.

Now those bushings (JD calls them axles) are .492 x 3.388 x .321 (12.5mm x 86mm x 8.25mm). You probably delete the axle and go with a grade 5 or better 1/2" screw that has 3-3/8 unthreaded section with nut up against the unthreaded section and one on the side lock the screw on the deck mounting ear.

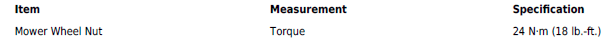

As for torquing the M8 screw nut this is what is in the service manual.

Now those bushings (JD calls them axles) are .492 x 3.388 x .321 (12.5mm x 86mm x 8.25mm). You probably delete the axle and go with a grade 5 or better 1/2" screw that has 3-3/8 unthreaded section with nut up against the unthreaded section and one on the side lock the screw on the deck mounting ear.

As for torquing the M8 screw nut this is what is in the service manual.

I purchased a new JD bolt and the square shoulders are holding much better. I noticed the old bolt shoulders were a little rounded which was causing it not to hold very well. Also the bolt description stated a square short neck. Does that mean a non JD bolt might work with a little longer square neck, or, would it make contact with the inner bushing, due to a little extra length? Hope I’m making sense. Thanks

There’s your answer. 3/4” off of the ground at 3” is too low. Raise those anti-scalp wheels. The bottom hole is when you are cutting at the highest deck setting. With the deck set at 3”, the anti-scalp wheels should be about 2 1/2” off of the ground. The anti-scalp wheels are to prevent the deck and blades from contacting the ground. They are not designed to support the deck.Installed new hardware and leveled the deck on the 3” setting. However, with the bolt in the bottom hole, the deck wheel is about 3/4” off the ground. This is as low as it will go. What am I doing wrong?

I’m sorry, you’ve lost me. Deere recommends to place your deck at preferred cutting height (3”) and adjust gauge wheel to 1/4” from the bottom of the wheel to the ground. I can’t get 2 1/2” even if I raise it to the top hole. Thanks