You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

What's best way to tie down lawntractor on trailer?

#1

Maxrevs

Maxrevs

Hi all,

How do you guys tie down lawntractors on a trailer so the tie-down straps don't bounce loose?

No matter how tight I get the ratchet straps, one or two always seem to come loose.

I know how they're coming loose but I can't find a way to prevent it. The trailer is a 7x4 with sides & loading ramp, it has balloon tyres, no suspension - bumps in the road make the trailer bounce, the mower's tyres compress, creating a momentary slack in the strap tension which can cause the strap hooks to unhook from the trailer hooks/cleats.

I currently use three ratchet straps from side to side: over & around the front and rear axles, and one over the driver's footwell.

How do you guys tie down lawntractors on a trailer so the tie-down straps don't bounce loose?

No matter how tight I get the ratchet straps, one or two always seem to come loose.

I know how they're coming loose but I can't find a way to prevent it. The trailer is a 7x4 with sides & loading ramp, it has balloon tyres, no suspension - bumps in the road make the trailer bounce, the mower's tyres compress, creating a momentary slack in the strap tension which can cause the strap hooks to unhook from the trailer hooks/cleats.

I currently use three ratchet straps from side to side: over & around the front and rear axles, and one over the driver's footwell.

#2

R

Rivets

R

Rivets

I always use either 2 or 4 straps, depending on the distance I have to go for delivery. State law here requires a 4 point holddown if you have no sides to your trailer. Four good quality straps are cheaper than $175 fine per unit on your trailer. When going a long distance use 4 straps going 4 corner method. Tighten the two front first as tight as possible, then the two rear, pulling to the back more than down. With two straps, first the front as close to the center as possible very tight and then the back in the center through the trailer tow hole. If your straps come loose, you are not getting them tight to start or you need to slow down. Going through the step through area normally does not hold much, too easy to slide around.

#3

reynoldston

reynoldston

It sound to me like you have more of a trailer problem then a tie down problem. You can buy a new trailer with a suspension from HF for 200 dollars or maybe less if used. Maybe let some air out of the trailer tires? might help.

#4

B

bertsmobile1

B

bertsmobile1

There is this stuff called rope and a knot called a trailer hitch or truckies hitch , waggon hitch or down here a sheep shank.

This knot system was invented to stop things falling off horse / bullock drawn waggons with steel tyres and no suspension.

So there must be an equivalent in the USA.

The one I use has 2 loopes in it so you can get a 4 times leverage if you really need to pull down tight, Knot ca be tied one handed and is undone by pulling on the middle run so just about falls off when finished with.

It also works with motorcycles and mowers on trailers.

Next best, but a long way down is to get some better quality tie downs that have a 2 part hook.

And by that I mean two part steel hook, not a sliver of plastic to close over the open end.

It is impossible for these to fall off which is why they were invented however they will cost twice as much as cheap open hook tie downs.

Next best is to use motorcycle tie downs that have "soft hooks" where the hook loops around the vehicle and slots back into a stitched loop in the strap.

These do not fall off when momentarily slakening happens and you do a similar thing at the trailer end if you have a loop or rail anchor point.Rune the hook under the loop/rail then hook it back over the strap and if you want to be doubly sure run it around the strap once then hook it onto the strap.

Finally there is an extreamy simple knot which you have probably been using for years without knowing it called a crane hitch or hook hitch where you make 2 eyes then bend the rope to make a single double eye and slip that over a hook, post etc or make a loop in the rope, slip in under the anchor point then run the rope back through itself.

If you can run the tie down from the trailer anchor point around the mower then back to the anchor point thus you have doubled the effective tie down pressure the ratchet can provide.

As for where to put them, that will depend upon how you have set up the trailer, weather you have some sort of wheel chocks or a backing board you can pull the mower into.

This is always the best way to go as it gives the mower something solid to be anchored against.

For pick up & delivery of cusomers mowers I use an old motorcycle trailer and run a single rope from an anchor point at the front around the back of the mower to another front anchor point .

But then I am only towing the mower 12 miles max which is the limit of my service zone.

This knot system was invented to stop things falling off horse / bullock drawn waggons with steel tyres and no suspension.

So there must be an equivalent in the USA.

The one I use has 2 loopes in it so you can get a 4 times leverage if you really need to pull down tight, Knot ca be tied one handed and is undone by pulling on the middle run so just about falls off when finished with.

It also works with motorcycles and mowers on trailers.

Next best, but a long way down is to get some better quality tie downs that have a 2 part hook.

And by that I mean two part steel hook, not a sliver of plastic to close over the open end.

It is impossible for these to fall off which is why they were invented however they will cost twice as much as cheap open hook tie downs.

Next best is to use motorcycle tie downs that have "soft hooks" where the hook loops around the vehicle and slots back into a stitched loop in the strap.

These do not fall off when momentarily slakening happens and you do a similar thing at the trailer end if you have a loop or rail anchor point.Rune the hook under the loop/rail then hook it back over the strap and if you want to be doubly sure run it around the strap once then hook it onto the strap.

Finally there is an extreamy simple knot which you have probably been using for years without knowing it called a crane hitch or hook hitch where you make 2 eyes then bend the rope to make a single double eye and slip that over a hook, post etc or make a loop in the rope, slip in under the anchor point then run the rope back through itself.

If you can run the tie down from the trailer anchor point around the mower then back to the anchor point thus you have doubled the effective tie down pressure the ratchet can provide.

As for where to put them, that will depend upon how you have set up the trailer, weather you have some sort of wheel chocks or a backing board you can pull the mower into.

This is always the best way to go as it gives the mower something solid to be anchored against.

For pick up & delivery of cusomers mowers I use an old motorcycle trailer and run a single rope from an anchor point at the front around the back of the mower to another front anchor point .

But then I am only towing the mower 12 miles max which is the limit of my service zone.

#7

reynoldston

reynoldston

For some reason everybody is missing he has no suspension on his trailer. That in my eyes would be no springs. I just don't care as to how you would tie something down it just would be putting a over amount of force on his lawn tractor plus the tie downs. So much force he said that his tractor tires are compressing. He needs a different trailer or add some kind of suspension to what he has. Just think what damage that is doing??? Or am I missing something here? Yes all the things that you have suggested to him would work if he had a trailer with springs. Or as suggested earlier slow down. It has to be like one of the old farm wagons/ trailers like when I was a youngster back on the farm. By the way the farm tractor only went about 5 MPH not 50 MPH down the road.

#8

B

bertsmobile1

Not quite

You have the right idea.

To be unable to move the tie downs need to pull against each other so your lay out will work fine however if the back 2 go off the rear axels it will work better.

The wheel ties will not work on your trailer.

They are designed specifically to clip over rails fitted to tow trucks and need to be pulled almost strait down.

Those types of hooks have come from the airfreight industry and are desied to latch over thin high strength alloy steel rings fitted in fuselarge load bays. They will not go around a regular trailer tie down rail.

However as has already been pointed out to you without any suspension on the trailer, keeping things in place will not be easy.

Considering that even some garden trailers come with suspension I can understand why you would want a car trailer without suspension

B

bertsmobile1

Ok so as I see it and I see things different.

If you want to tie it down there is only one way and that is with these.

View attachment 27959

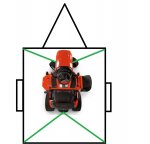

If you want to transport it the use 4 straps and attach them like the picture I created. You are not strapping down. It is more like stretching it in between 4 corners.

View attachment 27960

Not quite

You have the right idea.

To be unable to move the tie downs need to pull against each other so your lay out will work fine however if the back 2 go off the rear axels it will work better.

The wheel ties will not work on your trailer.

They are designed specifically to clip over rails fitted to tow trucks and need to be pulled almost strait down.

Those types of hooks have come from the airfreight industry and are desied to latch over thin high strength alloy steel rings fitted in fuselarge load bays. They will not go around a regular trailer tie down rail.

However as has already been pointed out to you without any suspension on the trailer, keeping things in place will not be easy.

Considering that even some garden trailers come with suspension I can understand why you would want a car trailer without suspension

#9

Maxrevs

Maxrevs

The advice offered in all your combined postings has really stimulated my thinking on this problem. Thanks!

I now reckon the main problem is with my trailer having built-up sides about a foot high, any straps or ropes that come over the sides are already a foot high before I secure them to any part of the mower. This means they're pulling ACROSS rather than pulling DOWN.

I think the answer might be to install some kind of floor-mounted D-rings. Attaching the tie-downs to these would pull the tractor DOWN to the floor and prevent it hopping around. What do you think?

I now reckon the main problem is with my trailer having built-up sides about a foot high, any straps or ropes that come over the sides are already a foot high before I secure them to any part of the mower. This means they're pulling ACROSS rather than pulling DOWN.

I think the answer might be to install some kind of floor-mounted D-rings. Attaching the tie-downs to these would pull the tractor DOWN to the floor and prevent it hopping around. What do you think?

#10

Ric

I don't think any type of d rings are going to help. I have front and rear rings on my trailer and tie down straps of any type always end up loose by the time I get to where ever it is I'm going to, the trailer mounted tie downs never helped me. I think the photo below is the way to go. The floor bracket helps keep the mower in place and the straps hold it in place. JMO

Ric

The advice offered in all your combined postings has really stimulated my thinking on this problem. Thanks!

I now reckon the main problem is with my trailer having built-up sides about a foot high, any straps or ropes that come over the sides are already a foot high before I secure them to any part of the mower. This means they're pulling ACROSS rather than pulling DOWN.

I think the answer might be to install some kind of floor-mounted D-rings. Attaching the tie-downs to these would pull the tractor DOWN to the floor and prevent it hopping around. What do you think?

I don't think any type of d rings are going to help. I have front and rear rings on my trailer and tie down straps of any type always end up loose by the time I get to where ever it is I'm going to, the trailer mounted tie downs never helped me. I think the photo below is the way to go. The floor bracket helps keep the mower in place and the straps hold it in place. JMO

#11

Maxrevs

Maxrevs

They do look good, Ric. Tell me, are they adjustable for position, because I carry a variety of lawntractors of various sizes so I'd need to be able to reposition for each.

#12

Ric

Yes there adjustable and can be mounted anywhere in the trailer you prefer, they will come with all the mounting hardware.

Ric

They do look good, Ric. Tell me, are they adjustable for position, because I carry a variety of lawntractors of various sizes so I'd need to be able to reposition for each.

Yes there adjustable and can be mounted anywhere in the trailer you prefer, they will come with all the mounting hardware.

#13

M

Marty013

M

Marty013

i kno its an older thread.. but if your taking a mower to the shop.. air up! cars traveling to dealerships have ove 40psi in heir tires for tha reason.. once tied down.. tires wont compress when driving the trailer over bumps  hope it helps! check the tires to see if they have a max preassure.. go to that number... just remember what it had so u can go back to it

hope it helps! check the tires to see if they have a max preassure.. go to that number... just remember what it had so u can go back to it

if yoru loading and unloading from yar to yard as a lawncare contactor.. then airing up and down will get old fast soo.. not sure then

if yoru loading and unloading from yar to yard as a lawncare contactor.. then airing up and down will get old fast soo.. not sure then

#14

P

Pumper54

P

Pumper54

When I have to haul my mowers around I use the trailer I use for transporting motorcycles. I found out one day by accident the spacing of the two wheel chocks is perfect for the two mowers that I need to haul. Bought these at Northern Tool on sale. http://www.northerntool.com/shop/tools/product_200409163_200409163

Drive into the chocks, run a strap through the trailer hitch on the back of the mower and I am good to go.

Tom

Drive into the chocks, run a strap through the trailer hitch on the back of the mower and I am good to go.

Tom