I have a Toro Timecutter MX5060. I just had the transaxle oil and filter changed. I was going to do it myself but medical issues suggested I better just let a shop do it. When I got home I was adding a little more oil to the reservoir to bring it to the Cold line and then I'd purge. I disconnected the switch under the seat so I wouldn't have to get on and off while purging the trans. I was trying to free up the bypass lever on one side. [I've had this issue before]. When I pushed in the right side control arm (me not sitting in the seat) the engine shuts off even with the seat switch disconnected. I don't understand that -- by disconnecting that switch shouldn't I be able to push the control arm in and the engine still run?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Under the Seat switch issue

- Thread starter jcworks

- Start date

More options

Export thread- Joined

- Feb 19, 2020

- Threads

- 79

- Messages

- 10,274

Now would adding a jumper be the same as closing the switch?May need a jumper wire

Star, by "closed" I assume you mean placing a short piece of wire in the two holes once the switch is pulled out ??Seat switch must be be closed as if the operator is on the seat. Just disconnecting it makes open as if the operator is not on the seat.

- Joined

- Feb 19, 2020

- Threads

- 79

- Messages

- 10,274

That why you must look-up the equipment wiring schematics. Some uses grounding circuit and others uses +12vdc depending the design.Yes if you connect the two wires it should jump it most of the time. I have seen a few machines that that may not work on.

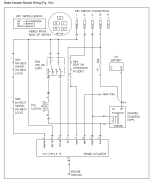

The following is the wiring schematic for the 74641 mower. As you will see 12vdc must be applied to the electric brake control module.

SeniorCitizen

Lawn Addict

- Joined

- Aug 28, 2010

- Threads

- 125

- Messages

- 2,118

So you had to complete the job you paid to have done . But at least you've learned they can be built to open or close to function .

Senior, yes that's right. This was a Scag dealer. Two Toro dealers had both told me they wouldn't do it till it had 500 hrs on it. Hydro Gear representatives i called laughed at that. The Scag dealer wasn't the most customer friendly but he agreed to do it for me as it's winter. He told me I would probably need to add a half qt but he had let it sit and run it about 15 mins. So I got home and added oil and purged it myself. I just kept watching the oil in the reservoir air bubbles trickle out slowly till it was done. Toward the end of that I drove around the yard a couple mins. That finished it up. But yes, I had to finish it up to make it right. Shops around here are not what I'd call good and they have less-thans doing the work. I do most what i can bc of that.So you had to complete the job you paid to have done . But at least you've learned they can be built to open or close to function .

Last edited: