You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More options

Export threadLOL soooooo on to my next installment of the process to fix this thing. After failed attempts to get the back wheel off, I started to look forward to where the clutch/ brake linkage connects to the peddle. As soon as I got this thing I noticed the clutch peddle was really far forward and difficult to reach. I'm 5'8" so I'm sure Craftsman (or whoever makes these things) intended for someone my height could use these and not someone 6'2". So I started thinking maybe there is an adjustment up front and no need to mess with the rear wheel at this time. I found two bolts under the clutch peddle and it looked like I could make an adjustment from there. I loosened the two bolts and tried to maneuver the plate behind the bolts as best I could (of course I have no idea what I'm doing) I started the mower, put it in gear and rode around the yard and I'm able the shift a bit better but, I don't have either a main brake or an emergency brake. I feel like I'm getting closer to solving the problem... I just need to get over the hump. Looking at where the clutch comes up from under the frame It seems to me that it should be closer to my feet.

Attachments

soooooo on to my next installment of the process to fix this thing. After failed attempts to get the back wheel off, I started to look forward to where the clutch/ brake linkage connects to the peddle. As soon as I got this thing I noticed the clutch peddle was really far forward and difficult to reach. I'm 5'8" so I'm sure Craftsman (or whoever makes these things) intended for someone my height could use these and not someone 6'2". So I started thinking maybe there is an adjustment up front and no need to mess with the rear wheel at this time. I found two bolts under the clutch peddle and it looked like I could make an adjustment from there. I loosened the two bolts and tried to maneuver the plate behind the bolts as best I could (of course I have no idea what I'm doing) I started the mower, put it in gear and rode around the yard and I'm able the shift a bit better but, I don't have either a main brake or an emergency brake. I feel like I'm getting closer to solving the problem... I just need to get over the hump. Looking at where the clutch comes up from under the frame It seems to me that it should be closer to my feet.If you can find an inexpensive replacement rim, you can always Sawzall the wheel to make a slit, then pry to widen the slit and pull it off.

As to your original problem. Have you checked the brake pads and cable / bar tension? Lots of mowers use a pad that wears, and when it does the belt geometry and behavior changes. Sometimes it will cause slippage, sometimes it will fail to brake the pulleys.

Attachments

- Joined

- Feb 19, 2020

- Threads

- 119

- Messages

- 12,777

I can't prove by it my results and that's what counts to me....Of course people swear by JB Weld too and I have try them and they fail to live up to hype.

Last edited:

sgkent

Lawn Addict

- Joined

- Sep 27, 2017

- Threads

- 35

- Messages

- 1,976

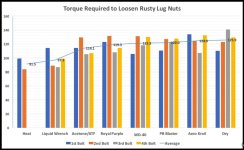

Trash? A mentor, who was engineer and machinist known for building winning Formula One and Indy engines, once suggested I try Liquid Wrench on some exhaust studs that were frozen solid. I laughed but tried it. I had already snapped one double nutted. Came back the next morning and all but one unscrewed by finger. The other one took a grab with a pair of pliers. Here is what Project Farm discovered in his testing of Penetrating Oils.

Last edited:

- Joined

- Feb 19, 2020

- Threads

- 119

- Messages

- 12,777

Now that is more believable when actually someone took time to do the testing head to head but just how rusty were the fasteners. And also proves that the home brew works better than most of commercial penetrating fluids. As shown heat is still the best for many applications. Probably why I still use a torch at times.

I give Liquid Wench a try as there got to be something that actually halfway works but I won't be holding my breathe until I prove it myself. I have had to use Muriatic Acid on steel on steel and Sulfuric Acid to remove steel fasteners out of aluminum. And I have even used Sulfuric Acid to clean some carburetors.

Whatever anyone does DON'T use Muriatic Acid on anything aluminum or you won't have it long.

I give Liquid Wench a try as there got to be something that actually halfway works but I won't be holding my breathe until I prove it myself. I have had to use Muriatic Acid on steel on steel and Sulfuric Acid to remove steel fasteners out of aluminum. And I have even used Sulfuric Acid to clean some carburetors.

Whatever anyone does DON'T use Muriatic Acid on anything aluminum or you won't have it long.

Thanks for the heads up on Kroil I'll pick some up the next time I'm at Lowes

Now that is more believable when actually someone took time to do the testing head to head but just how rusty were the fasteners. And also proves that the home brew works better than most of commercial penetrating fluids. As shown heat is still the best for many applications. Probably why I still use a torch at times.

I give Liquid Wench a try as there got to be something that actually halfway works but I won't be holding my breathe until I prove it myself. I have had to use Muriatic Acid on steel on steel and Sulfuric Acid to remove steel fasteners out of aluminum. And I have even used Sulfuric Acid to clean some carburetors.

Whatever anyone does DON'T use Muriatic Acid on anything aluminum or you won't have it long.

I can't prove by it my results and that's what counts to me....Of course people swear by JB Weld too and I have try them and they fail to live up to hype.