You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

New to me 13ag601h729 in good condition but neglected.

#1

R

ritalz

R

ritalz

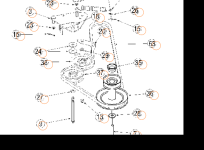

Will run on starting fluid but not on its own. Checked the fuel pump and it seems to work. Pictures show a electrical plug on the bottom of the carb that I'm not sure what it is supposed to do. If that checks out my next idea is to pull the carb for cleaning. Printed a user manual for reference and would like to find a service manual. New tires and battery are worth more than I paid for it. Also, how can I tell when it was made?

#2

ILENGINE

ILENGINE

The solenoid on the bottom of the carb should hear feel it click when you turn the key on and off. It looks like that model number was made in 2005 only. And the Engine service manual is part number 273521. MTD is not real real good with their mower service manuals and leave a lot to desire if they even have the manual for your mower.

#3

Tiger Small Engine

Tiger Small Engine

If anti afterfire carburetor solenoid is working correctly, then most likely, the carburetor will need to be removed and thoroughly cleaned to have engine to run .The solenoid on the bottom of the carb should hear feel it click when you turn the key on and off. It looks like that model number was made in 2005 only. And the Engine service manual is part number 273521. MTD is not real real good with their mower service manuals and leave a lot to desire if they even have the manual for your mower.

#5

R

ritalz

R

ritalz

Good catch on the solenoid working. Could not detect any clicking while turning the key off and on. Checked the plug and it did show 12 volts but it was rather crusty. Sprayed some contact cleaner and worked plug a couple of times and it started clicking. Hit the starter again and after a few cranks she started and stayed running. Ran around my tiny yard and down the alley to mulch some leaves. Day 2 was a win.

#6

R

ritalz

R

ritalz

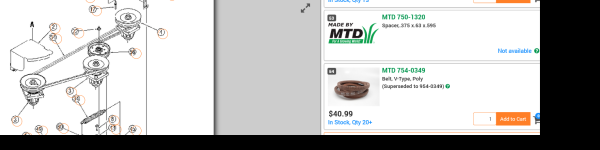

Broke the deck belt which was already badly worn. Book calls for 954-0349 but that is way too long at 79". I took some string and wrapped it around the pulleys ant it was closer to 60". This deck has 2 belts to run the blades, Top belt from the motor, around the tensioner pulleys and the left most spindle. The other belt ties all 3 spindles together. Now I don't know what length belt to buy or how to look it up.

#8

R

ritalz

R

ritalz

Thanks for the reply but 68" still seems to be a bit long. The old belt is closer to 63" and unless it was routed wrong (doubt since the routing is pretty straight forward) the 68" would never engage. There are no visible numbers on the old belt. Makes me wonder if something was swapped out somewhere along its life. Trying to make sure I get the correct belt before purchasing.

#9

Scrubcadet10

Scrubcadet10

so the 0349 deck belt is 1/2" wide, And since the shorter belt that was on it, seemed to work properly, i'd buy a 1/2" x63" belt and see where that gets you

a Stens 266-155 would be a well made, but cheap, alternative.

a heavy duty alternative would be the True Blue

a Stens 266-155 would be a well made, but cheap, alternative.

a heavy duty alternative would be the True Blue

#10

R

ritalz

R

ritalz

I think the 63" is the way to go and I ordered one. Should be here in a couple of days. Thanks for all your help.

#11

R

ritalz

R

ritalz

The 63" belt is too short. I can force it onto the pulleys but there is no slack at all to disengage the blades. Still cannot find any data to give me the correct length to buy. Trying to decide on the next length to try, leaning towards a 65" but not sure.

#12

R

ritalz

R

ritalz

Found it. The belt I'm looking for is the 68.25" by .63". I kept calling it the deck belt but the diagrams list it as the PTO belt. You had it right but I couldn't see it. Thanks

#14

R

ritalz

R

ritalz

Spent some time over the past couple of days doing some small things. Oil and filter, adjusted the valves, air in the tires, rubbed some plastic restorer on some parts, tried buffing out some of the sun fade and oxidation, a little paint touch up and some general cleaning. Still waiting on the new belt to arrive. One big thing left to do is the seat. The old cover is split in several places and the foam is questionable. Considering a new aftermarket seat but that will have to wait a bit. Not sure if or how the seat comes apart to do some repair work instead of new.

#15

F

Forest#2

F

Forest#2

The length spec of lawn tractor v -belts is the OD of the belt.

You can take a piece of string and measure the length of the old broken belt.

I also keep a upholstery cloth tape measure handy (from wal mart sewing section for about $3) and BEFORE installing a new belt I measure the OD with the upholstery tape. I've found lots of new belts that are not the length specified when ordered.

When replacing v belts I measure the OD length of the old belt in use and compare it to the part number length and then measure the new belt length when received. At the price of V-belts it saves $$'s to keep a constant heads up.

While the belt if off is a good time to check the pulley and spindle bearings to make sure they are Ok.

A owners manual surfaced over at sears parts direct at this link.

You might want to investigate such. I seen couple other downloads but I did not view them.

Also you need to keep a heads up about that type drive (variator type)requires that both drive belts be replaced as a set to get proper drive travel. I did not read the manual but this is usually so with that type drive.

Link at sears parts direct.

click on manual and then the 769-01XXXX

www.mtdparts.com

www.mtdparts.com

You can take a piece of string and measure the length of the old broken belt.

I also keep a upholstery cloth tape measure handy (from wal mart sewing section for about $3) and BEFORE installing a new belt I measure the OD with the upholstery tape. I've found lots of new belts that are not the length specified when ordered.

When replacing v belts I measure the OD length of the old belt in use and compare it to the part number length and then measure the new belt length when received. At the price of V-belts it saves $$'s to keep a constant heads up.

While the belt if off is a good time to check the pulley and spindle bearings to make sure they are Ok.

A owners manual surfaced over at sears parts direct at this link.

You might want to investigate such. I seen couple other downloads but I did not view them.

Also you need to keep a heads up about that type drive (variator type)requires that both drive belts be replaced as a set to get proper drive travel. I did not read the manual but this is usually so with that type drive.

Link at sears parts direct.

click on manual and then the 769-01XXXX

Yard Machines Riding Lawn Mower - Model 13AG601H729 | MTD Parts

Find parts and product manuals for your Yard Machines Riding Lawn Mower Model 13AG601H729. Free shipping on parts orders over $45.

#16

R

ritalz

R

ritalz

New belt is installed and seems to engage the blades properly. Next up is going to be the spindles. The noise level is very high when the blades are turning. I'll take the belts off the pulleys and spin each spindle and pulley till I find the culprit. Maybe just plan on some new bearings while I'm spending time on this one. Anyone know the specs of the spindle bearings?

#18

R

ritalz

R

ritalz

Pulled the spindles off today and yes the bearings are growling. The numbers on the old bearings do indeed match as stated above. This should make quite a difference in noise levels when I get it back together.

#19

R

ritalz

R

ritalz

Got it all back together today and everything seems to fine. The muffler is shot so the motor makes more noise than the deck. Probably won't do anything about that. Blades are chewed up some so I ground some material from the opposite ends to balance them a bit. Next big thing is to work on the seat. Lookin pretty good. I should take some pictures of my work.

#21

F

Forest#2

F

Forest#2

Is that where an animal has chewed on the shifter and a pedal?

Your seat would last awhile with a cover.

I've used contact cement and indoor outdoor carpet and fixed lawn tractor seats with good results. Weldwood is the best contact cement and the spray one is more user friendly.

i just cover all, including the back. (after removing the bottom bracket.

I've have some that are going on 8 years old and still look good.

Shoo goo is really good for re-glueing if the seat cover is still good but coming loose from the plastic backing. (but not needed if covering all with indoor/outdoor carpet)

After removing the deck you can replace the spindle bearings without removing the spindle housing. Take the top pulley off and drive the spindle shaft out the bottom, then remove the bearings. You tube videos about such. Just leave the blade on the shaft if desired. I usually re-pack new bearings if they have the removeable plastic seals.

Nice old machine, might be a keeper.

Your seat would last awhile with a cover.

I've used contact cement and indoor outdoor carpet and fixed lawn tractor seats with good results. Weldwood is the best contact cement and the spray one is more user friendly.

i just cover all, including the back. (after removing the bottom bracket.

I've have some that are going on 8 years old and still look good.

Shoo goo is really good for re-glueing if the seat cover is still good but coming loose from the plastic backing. (but not needed if covering all with indoor/outdoor carpet)

After removing the deck you can replace the spindle bearings without removing the spindle housing. Take the top pulley off and drive the spindle shaft out the bottom, then remove the bearings. You tube videos about such. Just leave the blade on the shaft if desired. I usually re-pack new bearings if they have the removeable plastic seals.

Nice old machine, might be a keeper.

#22

R

ritalz

Thanks for the reply.

R

ritalz

Not sure what those marks are from. Came to me that way.Is that where an animal has chewed on the shifter and a pedal?

Plan is to either cover or replace the seat sometime before May. This whole project is for someone else.Your seat would last awhile with a cover.

I removed the spindles without removing the deck. Easy enough to replace the bearings on the workbench then bolt the spindles back in place. Also much warmer and more light working in the basement.I've used contact cement and indoor outdoor carpet and fixed lawn tractor seats with good results. Weldwood is the best contact cement and the spray one is more user friendly.

i just cover all, including the back. (after removing the bottom bracket.

I've have some that are going on 8 years old and still look good.

Shoo goo is really good for re-glueing if the seat cover is still good but coming loose from the plastic backing. (but not needed if covering all with indoor/outdoor carpet)

After removing the deck you can replace the spindle bearings without removing the spindle housing. Take the top pulley off and drive the spindle shaft out the bottom, then remove the bearings. You tube videos about such. Just leave the blade on the shaft if desired. I usually re-pack new bearings if they have the removeable plastic seals.

Sort of a keeper, it will be staying in the family.Nice old machine, might be a keeper.

Thanks for the reply.

#23

C

Charles Edward

Step 2 - Then add up the circumferences of all the pulley's - and divide the number in half.

Step 3 - Add the result of step 1 to the result of step 2 - and that will usually get you pretty close to the required belt length.

100% accurate with two pulley's - the greater the number of pulley's the greater the potential error.

C

Charles Edward

Step 1 - Measure the shaft centers along each part of the correct belt run and add them together - double the total.Broke the deck belt which was already badly worn. Book calls for 954-0349 but that is way too long at 79". I took some string and wrapped it around the pulleys ant it was closer to 60". This deck has 2 belts to run the blades, Top belt from the motor, around the tensioner pulleys and the left most spindle. The other belt ties all 3 spindles together. Now I don't know what length belt to buy or how to look it up.

Step 2 - Then add up the circumferences of all the pulley's - and divide the number in half.

Step 3 - Add the result of step 1 to the result of step 2 - and that will usually get you pretty close to the required belt length.

100% accurate with two pulley's - the greater the number of pulley's the greater the potential error.

#24

D

Digiacomo

D

Digiacomo

I hope that you checked the oil carefully before you ran it......if that carburetor solenoid was stuck in the down position .......you could have oil and gas mixed........if you have ran it a while chances are that it is ok.........It happened to me, but I was lucky enough that I got so much gas in the crank case that it locked up and wouldn't turn over.......I have a twin 22 horse with fuel pump......

#25

R

ritalz

R

ritalz

Thanks for the reminder. Actually I did check the oil first. It was a bit dirty but still free of any gas smells. I have since changed and installed a new filter and will probably change it again before turning it over to its new owner. Kind of used to checking things as I frequently work on older motors.

#26

R

ritalz

R

ritalz

Was reading somewhere that steel wool can be loosely packed in the muffler to deaden the noise a bit. Some #3 steel wool for a couple dollars did a pretty good job. Quiet enough that now I can hear more deck noise. I'm gonna pull the belts off again and check all the pulleys one by one till I find the culprit. I have attached a pulley to my electric drill and will use a belt to spin each pulley while listening for the noisy one. I think there are 7 pulleys on the deck and I've already replaced the bearings on the 3 spindles. It could still be one of the spindles if I messed up on reassembly.

#27

R

ritalz

R

ritalz

Idler pulley was the culprit. Bad news is the prices for this pulley are outrageous and out of stock in most places. Found one online for a favorable price and placed the order. Now I have to wait several days before I can start working again. In the meantime I will work on the seat. Covered it with some vinyl from the fabric store and pulled most of the wrinkles smooth by hand. Glued the newly covered foam to the pan and it looks ok at best. Also working on some nice emblems to attach to the hood (see pic). This is the first draft and was made on a 3D printer.

Attachments

#28

R

ritalz

R

ritalz

Not much to add since the last update. Found a brand new set of blades on marketplace for $10, deal. Got the new idler pulley mounted and the deck is still has more noise than I like. Still working on the emblems and doing some touch ups on the paint. Had to stop to take care of some other projects.

#29

R

ritalz

R

ritalz

Another issue popped up that I'm puzzled about. Had to replace the drive belt recently and since then the mower wants to start moving soon as I select forward or reverse. Acts like either the belt is too tight or I have incorrect routing. Not sure if there is some adjustment I am missing or is there something else. The brakes are very weak and not able to keep the mower from (brakes to be done later) moving without shifting out of gear. I'm pretty sure I used the correct belt after much research. Drive belt was indeed a pain to install. Also forgot to include a picture of the finished machine. Not perfect by any means but a big hit and fun project.

#30

R

ritalz

R

ritalz

Found this thread and will check when I get a chance.

www.lawnmowerforum.com

www.lawnmowerforum.com

After changing all belts, riding mower moves on its own

Hi all. i just changed the 3 belts on my 2015 Troy Bilt Bronco riding mower. Now when i put it into gear (forward or reverse) it jerks forward (or backward) and starts moving without me pressing the pedal. The clutch/brake pedal has little effect is stopping it. Also, when i put it into...

#31

F

Forest#2

F

Forest#2

How was the drive motion acting before you changed the drive belts.

I seen a owners manual/parts list download at the sears link.

www.searspartsdirect.com

www.searspartsdirect.com

Keep a heads up when working on the brake if replacing the pucks. The steel bolts will twist off easily in the aluminum housing.

Try adjusting the brake first.

I seen a owners manual/parts list download at the sears link.

MTD 13AG601H729 front-engine lawn tractor manual

Download the manual for model MTD 13AG601H729 front-engine lawn tractor. Sears Parts Direct has parts, manuals & part diagrams for all types of repair projects to help you fix your front-engine lawn tractor!

Keep a heads up when working on the brake if replacing the pucks. The steel bolts will twist off easily in the aluminum housing.

Try adjusting the brake first.

#32

R

ritalz

R

ritalz

Drive motion was working as it should before the belt broke. I have printed off a copy of the manual and will look through it again. Thanks for the heads up on the brakes.

#33

F

Forest#2

F

Forest#2

Look at page 30 of the owners manual.

It appears that maybe on that machine:

When you are not on the forward or reverse pedal the belt going toward the engine pulley should be loose/slack enough that it slips on the engine pulley for neutral. Also make sure it's routed correctly per the diagram. Make sure the engine pulley motion drive belt is the correct length and width if you do not ever get it to be in Neutral.

The owners manual is not really any help for replacing the motion drive belts on your machine. They know it's not a easy user friendly thing, but a learning experience and requires patience and might involve sacrificing some skin and meat when doing the rear belt. Good to hear the drive was ok before new belt replacement. That lets us know that the double sheave vari speed variator pulley is most likely ok. (bearings ok and the center shaft not rusted)

I see the brake adjustment on pg 17.

A easy way to adjust the brake after you locate the 1/2 inch adjustment nut per page 17 is to put the non-running machine in neutral, lock the brake pedal down and try to push the machine forward with both rear tires on the ground.. If it rolls easily turn the 1/2 nut CW 1/2 turn and try again. You will eventually get brake if the brake pucks are not worn out or their push pins re not rust seized. When you get close to correct adjustment a 1/4 turn of the adjustment nut will be brake and no brake. I've made those pucks from old disc brake pads.

The brake system is the wimpy type, so do not expect the brake to slide the rear tires, it just kinda slows the machine down. Do not trust the brake when on a hill or steep slope.

I would leave the deck off and test drive the machine really good before re-installing the deck AND always use safety stands when laying under the elevate machine.

It appears that maybe on that machine:

When you are not on the forward or reverse pedal the belt going toward the engine pulley should be loose/slack enough that it slips on the engine pulley for neutral. Also make sure it's routed correctly per the diagram. Make sure the engine pulley motion drive belt is the correct length and width if you do not ever get it to be in Neutral.

The owners manual is not really any help for replacing the motion drive belts on your machine. They know it's not a easy user friendly thing, but a learning experience and requires patience and might involve sacrificing some skin and meat when doing the rear belt. Good to hear the drive was ok before new belt replacement. That lets us know that the double sheave vari speed variator pulley is most likely ok. (bearings ok and the center shaft not rusted)

I see the brake adjustment on pg 17.

A easy way to adjust the brake after you locate the 1/2 inch adjustment nut per page 17 is to put the non-running machine in neutral, lock the brake pedal down and try to push the machine forward with both rear tires on the ground.. If it rolls easily turn the 1/2 nut CW 1/2 turn and try again. You will eventually get brake if the brake pucks are not worn out or their push pins re not rust seized. When you get close to correct adjustment a 1/4 turn of the adjustment nut will be brake and no brake. I've made those pucks from old disc brake pads.

The brake system is the wimpy type, so do not expect the brake to slide the rear tires, it just kinda slows the machine down. Do not trust the brake when on a hill or steep slope.

I would leave the deck off and test drive the machine really good before re-installing the deck AND always use safety stands when laying under the elevate machine.

#34

R

ritalz

R

ritalz

Spent the afternoon working on this problem. Verified the belt routing and adjusted the idler all the way to the edge of the threads. It still pulls a little when put in gear but it is better. Moved on to the brakes and found the whole setup rusted and not moving. The slide pins were forced out and cleaned and lubed. The brake pad and holding piece was cleaned and reinstalled. Had a hard time getting the springs and pressure arm back in the right order. After several attempts the adjusting nut seems to be correct as the mower now stops when the pedal is pressed. Gonna leave it alone for now and hope the drive belt wears in.

#35

F

Forest#2

F

Forest#2

On your idlers make sure that they are the correct OD.

It's quite common now days to order the correct v belts by part number but the size you receive is not per specs for the tractor.

I use a upholstery tape measure, cloth type tape 1 inch wide and about 12 ft long from wal mart sewing section, low cost.

The cloth tape measure is more user friendly than trying to use a string or rope and then have to measure the rope. The cloth tape is also really accurate about v-belt lengths.

I also had a pile of unknown length V-belt and I now have them tagged/labeled as to their size.

When I take off a v belt I measure it's OD length and then compare to the belt being installed BEFORE I install the replacement belt.

This gives me a heads up as what to expect especially if the old belt has been operating correctly in the past.

I've seen several v belts from Randy engine repair on ebay that have the same part number but are not same size.

It's quite common now days to order the correct v belts by part number but the size you receive is not per specs for the tractor.

I use a upholstery tape measure, cloth type tape 1 inch wide and about 12 ft long from wal mart sewing section, low cost.

The cloth tape measure is more user friendly than trying to use a string or rope and then have to measure the rope. The cloth tape is also really accurate about v-belt lengths.

I also had a pile of unknown length V-belt and I now have them tagged/labeled as to their size.

When I take off a v belt I measure it's OD length and then compare to the belt being installed BEFORE I install the replacement belt.

This gives me a heads up as what to expect especially if the old belt has been operating correctly in the past.

I've seen several v belts from Randy engine repair on ebay that have the same part number but are not same size.