Turbodriven

Active Member

- Joined

- Aug 18, 2023

- Threads

- 11

- Messages

- 84

The short video attached should explain it better than I can.

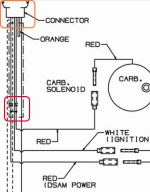

Essentially I'm not getting 12v to my fuel shutoff solenoid unless I unplug the 12 volt lead to my DSAM.

One thing to note in addition to what I mentioned in the video about unplugging the other leads to see if anything changed, is that I've continuity checked the 12 volt source to the d-sam with all the 6 other leads and I'm not getting any registered shorts.

Essentially I'm not getting 12v to my fuel shutoff solenoid unless I unplug the 12 volt lead to my DSAM.

One thing to note in addition to what I mentioned in the video about unplugging the other leads to see if anything changed, is that I've continuity checked the 12 volt source to the d-sam with all the 6 other leads and I'm not getting any registered shorts.