- Joined

- Feb 19, 2020

- Threads

- 79

- Messages

- 10,274

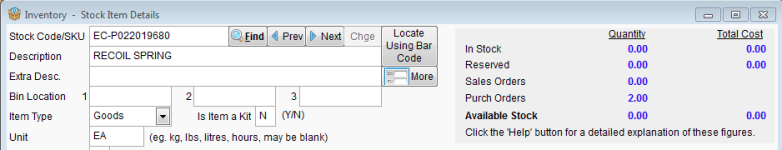

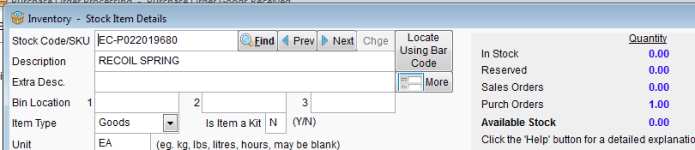

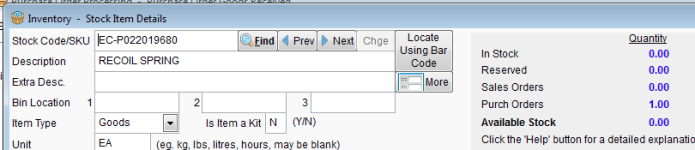

Well last I order some Echo screws and a recoil spring. Then I get an email saying one of four screws was b/o. So I called them and dropped off the b/o screw and was verbally told everything was in stock. The order should shipped out Friday. Well it didn't so I email them and finally late today got a generic email back saying to check order status online.

Well I did and found that now everything is on b/o. Well basically I was lied to by their customer service Thursday last week. They apparently decided to pull a SearsPartsDirect trick on me. I emailed back, cancelled the order, and ordered from PartsTree.

Moral here is you don't lie to me and get by with it. Yes it cost me a couple dollars more but at least I get the parts this week and not several weeks down the road.

Well I did and found that now everything is on b/o. Well basically I was lied to by their customer service Thursday last week. They apparently decided to pull a SearsPartsDirect trick on me. I emailed back, cancelled the order, and ordered from PartsTree.

Moral here is you don't lie to me and get by with it. Yes it cost me a couple dollars more but at least I get the parts this week and not several weeks down the road.

Last edited: