GeorgiaDave

Forum Newbie

- Joined

- May 4, 2025

- Threads

- 1

- Messages

- 9

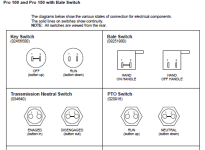

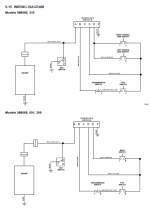

I have just resurrected a Gravely 150 PRO - this is a recoil, not battery start engine. Can anyone tell me or give me a functional schematic of an interlock module for a non-battery powered engine. I understand that the interlock is powered from the ignition coil primary, but I've looked and looked, and can't find any documentation for any module that runs from the primary side of the coil. The interlock is bad, I hate bypassing it, but I also hate that the cost for the interlock is a bit higher than I want to spend (just shy of $200). I have quite a bit of experience with circuit design, but I don't know much about the voltage(s) on the primary side. I suppose I can dig out my o-scope and see for myself, but if anyone here has knowledge regarding this, or an example circuit, I would sincerely appreciate it !

Worst case, I'll buy the interlock, but I'd have a lot more fun building my own...

Worst case, I'll buy the interlock, but I'd have a lot more fun building my own...