Sorry the wiring posted is incorrect.

Personally I highly suggest the OP get a copy of the service manual.

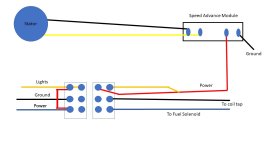

Wiring per the service manual for 3 amp system.

View attachment 62638

B+ Lead will have one 200v 3-5 amp diode in it. These do short out at times and need replacing.

Also note the stator brake is optional and may not even be wired. IE No green wire.

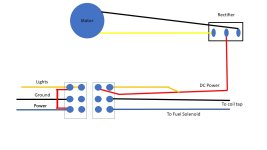

Wiring per Service manual for 15 amp system.

View attachment 62639

I hate to point this out but engine doesn't have the same flywheel as the CV11-CV15. Which is why the coil is not matching up.

With all the time wasted here it can be more productive just to dig out the high tension lead and replace it in the Tecumseh coil. It is replaceable with patience. Use a 7mm lead and a new terminal. straight or 90 degree version. Places like Oreilly's has the terminals. And probably one of local mower shops with have the lead. I know I buy all three in bulk here. Exacto knife is one of the tools needed along epoxy to seal the new lead.