You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Honda HRR Models: Rear Wheels Locking Up When Pulling Backwards

#1

robert@honda

robert@honda

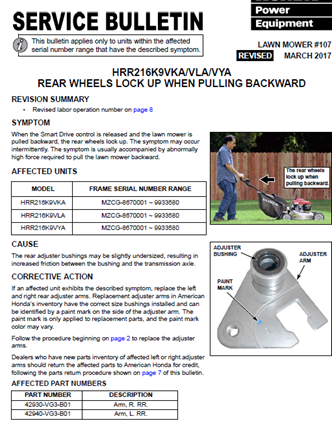

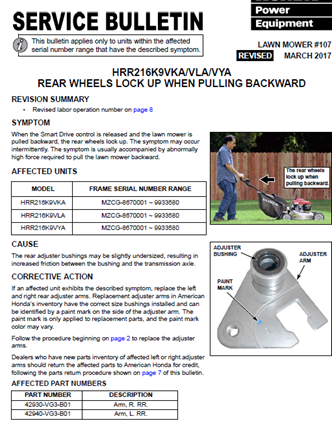

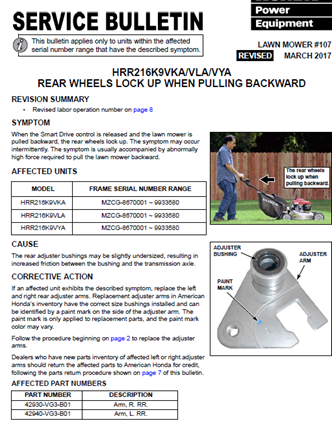

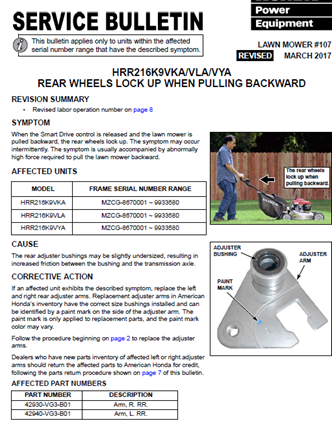

Honda issued a Service Bulletin on this problem earlier this spring; the issue is the bushings may be undersized, causing increased friction between the bushing the the transmision's axle.

The fix is to replace the adjuster arms, which have countermeasure bushings.

Step 1: First, verify your mower is in the affected range; if it is NOT, you have a different problem.

Affected model list is as follows:

HRR216K9VKA serial numbers MZCG-8670001-9933580

HRR216K9VLA serial numbers MZCG-8670001-9933580

HRR216K9VYA serial numbers MZCG-8670001-9933580

Step 2: Normal warranty applies; if your mower is still under warranty, is having a pull-back issue, and is in the above range, Honda will replace the adjusters under warranty. All Honda dealers are authorized to do this warranty repair, even if you didn't buy it from them. Beware that some dealers may offer more flexible repair schedules for those customer who did.

Find A Honda Dealer

If the dealer doesn't seem aware, tell him to look at Honda Power Equipment Lawn Mower Service Bulletin #107.

Step 3: If you're out of warranty, a dealer can still do the repair. Most will charge about 45 minutes to 1 hour of shop time for this job, but that's totally up to them. List price for each adjuster is $12.10.

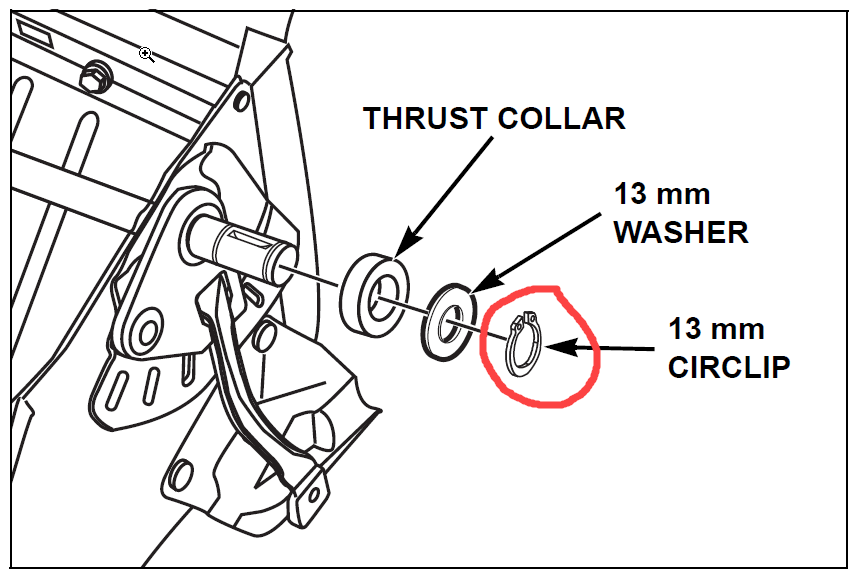

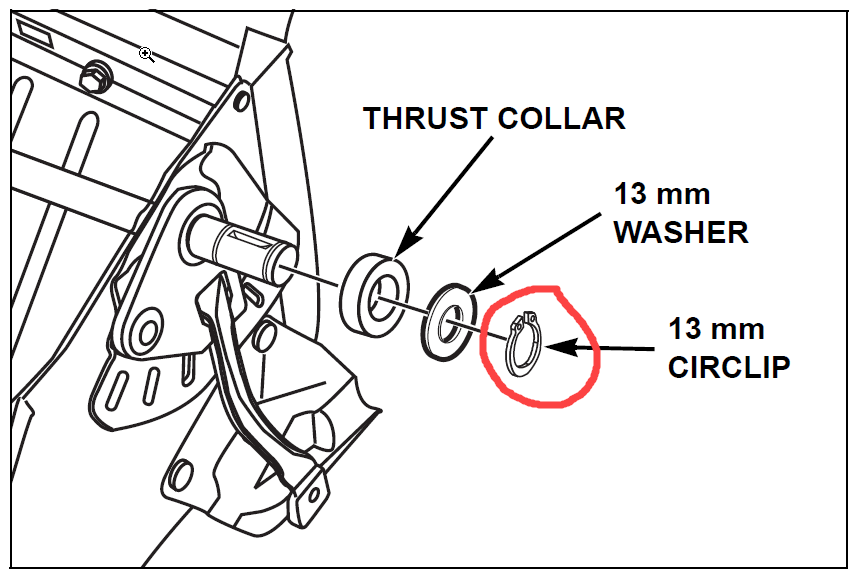

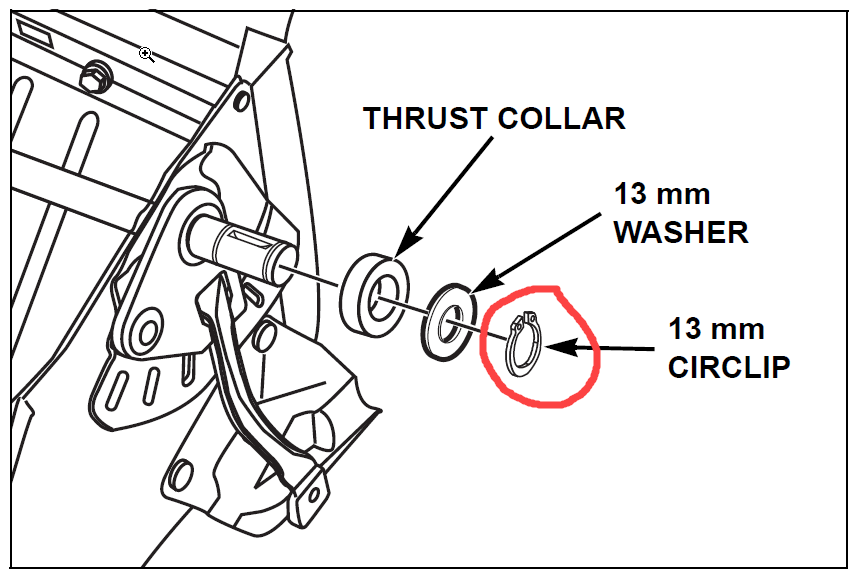

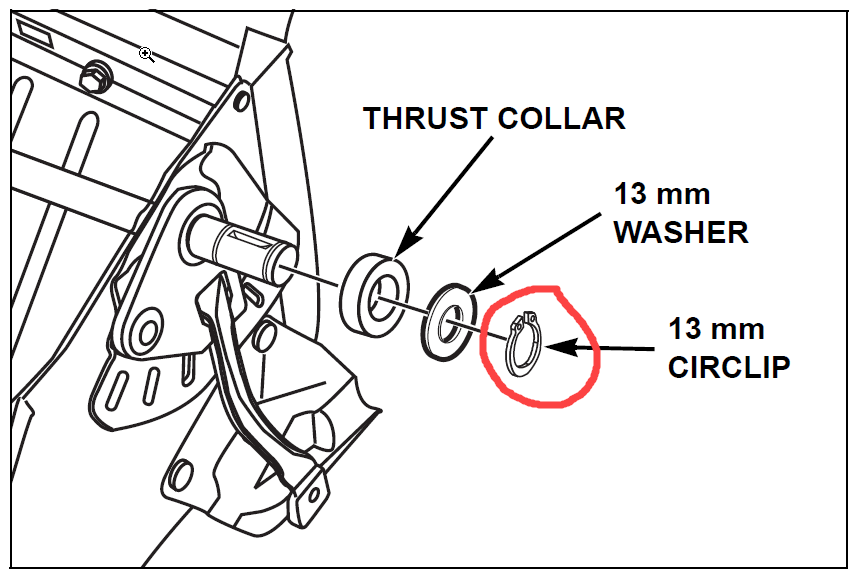

Step 4: If you'd like to DIY, it's not a bad job. You need to remove the rear wheels and all the parts on the drive axle, which include a couple of circlips, so you may need to buy a circlip pliers. A bench is a big help to hold the mower in an easy-to-work-on position; note this requires the fuel and oil to be drained:

I'd be happy to share some detailed instructions, just drop me a PM with your full email address.

The fix is to replace the adjuster arms, which have countermeasure bushings.

Step 1: First, verify your mower is in the affected range; if it is NOT, you have a different problem.

Affected model list is as follows:

HRR216K9VKA serial numbers MZCG-8670001-9933580

HRR216K9VLA serial numbers MZCG-8670001-9933580

HRR216K9VYA serial numbers MZCG-8670001-9933580

Step 2: Normal warranty applies; if your mower is still under warranty, is having a pull-back issue, and is in the above range, Honda will replace the adjusters under warranty. All Honda dealers are authorized to do this warranty repair, even if you didn't buy it from them. Beware that some dealers may offer more flexible repair schedules for those customer who did.

Find A Honda Dealer

If the dealer doesn't seem aware, tell him to look at Honda Power Equipment Lawn Mower Service Bulletin #107.

Step 3: If you're out of warranty, a dealer can still do the repair. Most will charge about 45 minutes to 1 hour of shop time for this job, but that's totally up to them. List price for each adjuster is $12.10.

Step 4: If you'd like to DIY, it's not a bad job. You need to remove the rear wheels and all the parts on the drive axle, which include a couple of circlips, so you may need to buy a circlip pliers. A bench is a big help to hold the mower in an easy-to-work-on position; note this requires the fuel and oil to be drained:

I'd be happy to share some detailed instructions, just drop me a PM with your full email address.

#2

B

BillE507

B

BillE507

Robert,

Thanx for posting this!

I've been having to "R & R" the rear wheel assembly about every 6-10 weeks to clean and re-lube (got it down to about 15-20 min a side). Even though I'm still under warranty, I'll just drop the $25 and do it my self to save time.

Some fool over fed the lawn and its mow every 3-4 days (daze?)!

Bill

Thanx for posting this!

I've been having to "R & R" the rear wheel assembly about every 6-10 weeks to clean and re-lube (got it down to about 15-20 min a side). Even though I'm still under warranty, I'll just drop the $25 and do it my self to save time.

Some fool over fed the lawn and its mow every 3-4 days (daze?)!

Bill

#3

B

BillE507

B

BillE507

Forgot to ask this last night...How much under size are the "old" bearings? Maybe a better way to say it, What is the internal diameter supposed to be?

I have access to a machine shop and their tools, I may just try and mill them out to the proper specs.

Thanx...

Bill

I have access to a machine shop and their tools, I may just try and mill them out to the proper specs.

Thanx...

Bill

#4

robert@honda

Don't have that spec, sorry. All they tell me is some bushings were mfg. just a bit too small I.D.

robert@honda

Forgot to ask this last night...How much under size are the "old" bearings? Maybe a better way to say it, What is the internal diameter supposed to be?

I have access to a machine shop and their tools, I may just try and mill them out to the proper specs.

Thanx...

Bill

Don't have that spec, sorry. All they tell me is some bushings were mfg. just a bit too small I.D.

#5

B

BillE507

Thanx for looking, much appreciated.

I MAY just try and hone them out about .010" (max) and see it that just may help.

Thanx again...Bill

B

BillE507

Don't have that spec, sorry. All they tell me is some bushings were mfg. just a bit too small I.D.

Thanx for looking, much appreciated.

I MAY just try and hone them out about .010" (max) and see it that just may help.

Thanx again...Bill

#6

primerbulb120

I checked my two HRRs, and both of them fall within the affected range. However, I ordered sets of replacement bushings on 9/9/2016 and installed them, and the issues returned a month later. Were the replacement bushings also undersized?

primerbulb120

Don't have that spec, sorry. All they tell me is some bushings were mfg. just a bit too small I.D.

I checked my two HRRs, and both of them fall within the affected range. However, I ordered sets of replacement bushings on 9/9/2016 and installed them, and the issues returned a month later. Were the replacement bushings also undersized?

#7

robert@honda

The bulletin says to replace the adjuster AND the bushing, not just the bushing. It it totally possible the dealer that sold you the loose bushings-only sold you some older ones (that may have been undersized). The part number for the bushing alone did not change, although old stock of bushings and adjusters/bushing assemblies were purged from Honda warehouses. Of course, your dealer may have sold you a set he had sitting on the self.

If you purchase the complete adjuster (using the part numbers in the bulletin) it will already have a properly fitted bushing installed. I'd strongly recommend you replace the adjuster/bushing assembly as outlined in the bulletin. A pair of new adjusters/bushing are about $22 list price. See the bulletin for the part numbers, and Google them to find a dealer selling online.

robert@honda

I checked my two HRRs, and both of them fall within the affected range. However, I ordered sets of replacement bushings on 9/9/2016 and installed them, and the issues returned a month later. Were the replacement bushings also undersized?

The bulletin says to replace the adjuster AND the bushing, not just the bushing. It it totally possible the dealer that sold you the loose bushings-only sold you some older ones (that may have been undersized). The part number for the bushing alone did not change, although old stock of bushings and adjusters/bushing assemblies were purged from Honda warehouses. Of course, your dealer may have sold you a set he had sitting on the self.

If you purchase the complete adjuster (using the part numbers in the bulletin) it will already have a properly fitted bushing installed. I'd strongly recommend you replace the adjuster/bushing assembly as outlined in the bulletin. A pair of new adjusters/bushing are about $22 list price. See the bulletin for the part numbers, and Google them to find a dealer selling online.

#8

D

de3

what i noticed is that a person needs to take apart and clean the keyway and spring in the axle and make sure you can hear it click.....

D

de3

The bulletin says to replace the adjuster AND the bushing, not just the bushing. It it totally possible the dealer that sold you the loose bushings-only sold you some older ones (that may have been undersized). The part number for the bushing alone did not change, although old stock of bushings and adjusters/bushing assemblies were purged from Honda warehouses. Of course, your dealer may have sold you a set he had sitting on the self.

If you purchase the complete adjuster (using the part numbers in the bulletin) it will already have a properly fitted bushing installed. I'd strongly recommend you replace the adjuster/bushing assembly as outlined in the bulletin. A pair of new adjusters/bushing are about $22 list price. See the bulletin for the part numbers, and Google them to find a dealer selling online.

what i noticed is that a person needs to take apart and clean the keyway and spring in the axle and make sure you can hear it click.....

#9

T

Themus

T

Themus

I too have the problem with my Honda mower locking up its back wheels when pulling backwards. I have in the not-to-distant past, replaced the bushings with the adjuster arms. Seemed to work a few times while cutting the yard and then right back at the same stubborn hard-to-pull backwards issue. Just recently I took both assemblies off, cleaned the entire gears, springs and assembly and added lubricant. Worked well for just one mowing job.

Weird thing is, I have noticed the wheels seem to roll backwards when sitting in the garage and I need to pull it out to mow. Or sometimes, but not always, when I empty the bagger of clippings.

I have almost sold it. Indeed I had it on Craigslist and couldn't get my asking price so I pulled it off. I have also seen a YouTube video where a post shows my problem exactly and what he suggested was to take it all apart and sand the shaft on both sides where the bushings slide.

Anyone really have this problem and get a long-term solution?

Weird thing is, I have noticed the wheels seem to roll backwards when sitting in the garage and I need to pull it out to mow. Or sometimes, but not always, when I empty the bagger of clippings.

I have almost sold it. Indeed I had it on Craigslist and couldn't get my asking price so I pulled it off. I have also seen a YouTube video where a post shows my problem exactly and what he suggested was to take it all apart and sand the shaft on both sides where the bushings slide.

Anyone really have this problem and get a long-term solution?

Attachments

#10

W

wcmiii

W

wcmiii

Hello: I have HRR216K9VLAA S/N-MZCG-9780304 purchased summer of 2016 from Home Depot. Summer of 2017 the rear wheels locked, and following the service bulletin, I had a local dealer fix it for no charge. June 9th, 2018 the rear wheels locked up again, so I took the mower to the same dealer. Dealer called today Monday June 11, 2018, said it was fixed and the cause of the wheel lock, was due to "rust on the diag Drive System." I always clean out the undercarriage after each mowing with water hose and scrubber. After the engine has cooled, I turn the mower over on the right side, cut fuel line off, and I am very careful to not get water on the filter, or engine. I then use the water hose and scrubber to clean the under carriage.

I've mowed lawns for many decades and I have never heard of RUST ON A DRIVE SYSTEM causing the rear wheels to lock up. I have read the recall bulletin and watched a YouTube video on sanding the shaft. Anyway, for $32.00 the dealer removed the rust, and I was told to not get water in the drive system and to use a air blower not hose or pressure washer, which I never have used, to clean the under carriage.

Any suggestions would be greatly appreciated! Thanks!

I've mowed lawns for many decades and I have never heard of RUST ON A DRIVE SYSTEM causing the rear wheels to lock up. I have read the recall bulletin and watched a YouTube video on sanding the shaft. Anyway, for $32.00 the dealer removed the rust, and I was told to not get water in the drive system and to use a air blower not hose or pressure washer, which I never have used, to clean the under carriage.

Any suggestions would be greatly appreciated! Thanks!

#11

Mow'N Weeds

Mow'N Weeds

I have a question I'm hoping someone can answer for me, derived from this exact topic (rear wheels locking up on an HRR216VKR)..

- How do you tell what year HRR216 you have? I'd assume it's in the model #, but can someone confirm this for me?

As an example.. I have an HRR2169VKR. Does that indicate anything? This just happened to me with this model, and the serial # falls within the ones Robert listed, so I'm trying to determine if mine would be under this service bulletin as warranty work or not, and just in general I'd like to know how to tell the years of these.

Thanks!

- How do you tell what year HRR216 you have? I'd assume it's in the model #, but can someone confirm this for me?

As an example.. I have an HRR2169VKR. Does that indicate anything? This just happened to me with this model, and the serial # falls within the ones Robert listed, so I'm trying to determine if mine would be under this service bulletin as warranty work or not, and just in general I'd like to know how to tell the years of these.

Thanks!

#12

gotomow

HHR's are covered under Honda's 3 year warranty. You would need to look at your receipt for the date of purchase. Here's how Honda lists it on their site:

To Obtain Warranty Service:

"You must, at your expense, take the Honda Power Equipment product, accessory, replacement part, apparel, or the power equipment on which the accessory or replacement part is installed, and proof of purchase to any Honda Power Equipment dealer in the United States, Puerto Rico, or the U.S. Virgin Islands who is authorized to sell and/or

service that product, during the dealer’s normal business hours. To locate a dealer near you, visit our web site at http://powerequipment.honda.com and click on Find a Dealer.

If you are unable to obtain warranty service or are dissatisfied with the warranty service you receive, contact the owner of the dealership involved;

normally this will resolve the problem."

Honda charges $12.10 for each adjuster, so a total of $24.20. Each bushing is $.91 with 4 required so a total of $3.64 per machine. That's more than $20 per machine, at retail of course. Thus saving Honda quite a bit of coinage per how many hundred of thousand/millions of machines manufactured.

What's interesting is that my HRX217 started almost locking up when I tried to pull it back. That's when I began to search the web for answers. I found Dave's video on his HHR and I wondered if the same thing was happening to my machine. Here is Dave's video:https://www.youtube.com/watch?v=ubnpTirPBu4

On my machine I thought I would first try spraying the bushing area with Motorkote spray lube. I've had great success with Motorkote spray in the past so I thought what the heck. I removed the wheels and the pinion gears so I could get right at the bushing. On the inside I removed the circlip and sprayed there also. I tipped the machine on each side so the Motorkote could soak well into the bushings. The results were amazing. Now I could easily reverse my mower. Not only that, in forward my machine was moving much faster at a lower speed setting.

Now you may think, "what do I care I don't reverse my machine at all". The problem is that over time your gearbox has to work harder and harder to overcome the increased friction from the shaft on the bushings. Could that lead to premature gearbox failure? Hmmm who knows, but I could see it happening.

gotomow

I have a question I'm hoping someone can answer for me, derived from this exact topic (rear wheels locking up on an HRR216VKR)..

- How do you tell what year HRR216 you have? I'd assume it's in the model #, but can someone confirm this for me?

As an example.. I have an HRR2169VKR. Does that indicate anything? This just happened to me with this model, and the serial # falls within the ones Robert listed, so I'm trying to determine if mine would be under this service bulletin as warranty work or not, and just in general I'd like to know how to tell the years of these.

Thanks!

HHR's are covered under Honda's 3 year warranty. You would need to look at your receipt for the date of purchase. Here's how Honda lists it on their site:

To Obtain Warranty Service:

"You must, at your expense, take the Honda Power Equipment product, accessory, replacement part, apparel, or the power equipment on which the accessory or replacement part is installed, and proof of purchase to any Honda Power Equipment dealer in the United States, Puerto Rico, or the U.S. Virgin Islands who is authorized to sell and/or

service that product, during the dealer’s normal business hours. To locate a dealer near you, visit our web site at http://powerequipment.honda.com and click on Find a Dealer.

If you are unable to obtain warranty service or are dissatisfied with the warranty service you receive, contact the owner of the dealership involved;

normally this will resolve the problem."

Honda charges $12.10 for each adjuster, so a total of $24.20. Each bushing is $.91 with 4 required so a total of $3.64 per machine. That's more than $20 per machine, at retail of course. Thus saving Honda quite a bit of coinage per how many hundred of thousand/millions of machines manufactured.

What's interesting is that my HRX217 started almost locking up when I tried to pull it back. That's when I began to search the web for answers. I found Dave's video on his HHR and I wondered if the same thing was happening to my machine. Here is Dave's video:https://www.youtube.com/watch?v=ubnpTirPBu4

On my machine I thought I would first try spraying the bushing area with Motorkote spray lube. I've had great success with Motorkote spray in the past so I thought what the heck. I removed the wheels and the pinion gears so I could get right at the bushing. On the inside I removed the circlip and sprayed there also. I tipped the machine on each side so the Motorkote could soak well into the bushings. The results were amazing. Now I could easily reverse my mower. Not only that, in forward my machine was moving much faster at a lower speed setting.

Now you may think, "what do I care I don't reverse my machine at all". The problem is that over time your gearbox has to work harder and harder to overcome the increased friction from the shaft on the bushings. Could that lead to premature gearbox failure? Hmmm who knows, but I could see it happening.

#13

H

Horsehockey

H

Horsehockey

Link to Dave's video didn't work for me for some reason. Alternative link or search ideas? Thank you.

#14

Mow'N Weeds

Mow'N Weeds

I swung into my local dealer the other day and mentioned this service bulletin (though I didn't have the bulletin # handy with me) and tried to get somewhere with this.

He couldn't find anything pertaining to wheels locking up while pulling backwards. Only thing I got was I found out the mower in question was on a showroom floor in 2014 and was told the only way to figure out the year was to run the serial # in their system. Either way, I'm not the original owner, I don't have a purchase receipt, the mower was never registered.. guess who's SOL for a no-charge dealer fix, but of course they could look at it for me if I wanted. I'm into this thing for too much as it is and selling it. Actually I have it sold, contingent on getting this issue fixed. Now I gotta deal with this myself to attempt to not lose money on it. Sticking another $24.20 into it will put me pretty close to being in the red vs what the used market value is on it. That's assuming I'm not even paying myself for time into it.

I messed around with it last night and on mine the bushings don't really seem to be hanging up on the shaft, from what I can tell at least. There's a short plastic 'bushing' I guess you could call it, that I'm able to pry down onto the shaft from the bottom portion of the shaft (so from the under-deck side), is this the bushing thought to be the ones associated with the wheels locking up? I got one wheel & gear off, woodruff seems fine, and I'm at the point of trying to get the bottom snap ring off, the one on the flip side didn't come off so nicely. The very first one did (outer most on the shaft) and that was the only one that did. At that point penetratant was put on both sides of the shaft at both wheels and after a bit, they were able to move backwards again, but still with too much resistance, one maybe more so than the other. Something doesn't sound right when rotating them backwards. Not sure what the hangup on mine is yet. Planning on digging deeper tonight yet, just what I wanna do on my Friday evening. I actually called a buddy and asked 'em if he wants to come over and help me wreck a $400 2014 Honda mower. Wish me luck! :laughing:

That last vid link doesn't work for me either. Just winds up going back to a non-specific youtube link.

He couldn't find anything pertaining to wheels locking up while pulling backwards. Only thing I got was I found out the mower in question was on a showroom floor in 2014 and was told the only way to figure out the year was to run the serial # in their system. Either way, I'm not the original owner, I don't have a purchase receipt, the mower was never registered.. guess who's SOL for a no-charge dealer fix, but of course they could look at it for me if I wanted. I'm into this thing for too much as it is and selling it. Actually I have it sold, contingent on getting this issue fixed. Now I gotta deal with this myself to attempt to not lose money on it. Sticking another $24.20 into it will put me pretty close to being in the red vs what the used market value is on it. That's assuming I'm not even paying myself for time into it.

I messed around with it last night and on mine the bushings don't really seem to be hanging up on the shaft, from what I can tell at least. There's a short plastic 'bushing' I guess you could call it, that I'm able to pry down onto the shaft from the bottom portion of the shaft (so from the under-deck side), is this the bushing thought to be the ones associated with the wheels locking up? I got one wheel & gear off, woodruff seems fine, and I'm at the point of trying to get the bottom snap ring off, the one on the flip side didn't come off so nicely. The very first one did (outer most on the shaft) and that was the only one that did. At that point penetratant was put on both sides of the shaft at both wheels and after a bit, they were able to move backwards again, but still with too much resistance, one maybe more so than the other. Something doesn't sound right when rotating them backwards. Not sure what the hangup on mine is yet. Planning on digging deeper tonight yet, just what I wanna do on my Friday evening. I actually called a buddy and asked 'em if he wants to come over and help me wreck a $400 2014 Honda mower. Wish me luck! :laughing:

That last vid link doesn't work for me either. Just winds up going back to a non-specific youtube link.

#16

gotomow

gotomow

You have to remove both the outer circlip, (right at the bushing) and the inner circlip to get the adjuster off so you check the drive shaft. If your's is rusty it will need sanding to make it easier to pull backwards. Kind of crazy to think that the shaft rusts so easily and that your expensive Honda mower is dependent on four .91 cent plastic bushings to make it run smooth.

#17

Mow'N Weeds

Mow'N Weeds

That link works. I've watched that one previously, good vid.. outside of I wish it was more detailed, like step by step. It would take at least twice as long to do the job understandably trying to document each little step, but it would have helped me at least a good bit more. But at least it gave me an idea of what I'm doing/looking for/trying to accomplish.

At any rate.. that was fun! Those little snap rings/circlips are a bit of a pain to deal with. One of 'em took flight, ricocheted off a couple things in the garage - never to be seen again . My 'bushings' were a little different than what I thought they'd be going off what I've read and watched. For some reason.. mine were a 2-pc design. At first I thought one had ripped or something, but that wasn't the case. That little part of a bushing I was pulling out on the underside of shaft was more like a 'hat'. Then there was a space between that and the other end of the bushing that just seemed to be a void space filled with grease and whatever else gunk got in there. The other longer part of the bushing wasn't interested in coming out of the bracket at all. Didn't look like it needed to for that matter either from what I could tell. So, everything was taken apart, without removing the axle from the deck (which was probably only one more step away), cleaned of debris and old grease, then re-greased with blue marine grease. My axle ends where these bushings ride on weren't super corroded, but they got touched up anyway since we were down that far. Got that whole assy back together, wheels back on, flipped 'er over and set 'er down to the ground to see if that was the issue, and it It appears to be a successful adventure. Pulls back now with little effort, with that little bit of resistance per design evidently. I'm still not quite sure what was hanging them up from freewheeling backwards other than old grease and/or maybe lack of grease. From what I could tell it almost looked like a white lithium grease was the old grease, be it from the factory or a possible previous person servicing I'm not sure. There wasn't much white left to it, it looked mostly like dirt/graphite color but I found a little bit of white left while cleaning. Hopefully this 'fix' will last a good while for the guy buying this. At this point I'll say he's gonna be pretty happy with his purchase. I messed around with this 'till late last night so there's small stuff to put back together later today, like the little bolts & matching retainers that hold the plastic part of the under-deck in, which are a pain to deal with too. All in all, an interesting adventure.

. My 'bushings' were a little different than what I thought they'd be going off what I've read and watched. For some reason.. mine were a 2-pc design. At first I thought one had ripped or something, but that wasn't the case. That little part of a bushing I was pulling out on the underside of shaft was more like a 'hat'. Then there was a space between that and the other end of the bushing that just seemed to be a void space filled with grease and whatever else gunk got in there. The other longer part of the bushing wasn't interested in coming out of the bracket at all. Didn't look like it needed to for that matter either from what I could tell. So, everything was taken apart, without removing the axle from the deck (which was probably only one more step away), cleaned of debris and old grease, then re-greased with blue marine grease. My axle ends where these bushings ride on weren't super corroded, but they got touched up anyway since we were down that far. Got that whole assy back together, wheels back on, flipped 'er over and set 'er down to the ground to see if that was the issue, and it It appears to be a successful adventure. Pulls back now with little effort, with that little bit of resistance per design evidently. I'm still not quite sure what was hanging them up from freewheeling backwards other than old grease and/or maybe lack of grease. From what I could tell it almost looked like a white lithium grease was the old grease, be it from the factory or a possible previous person servicing I'm not sure. There wasn't much white left to it, it looked mostly like dirt/graphite color but I found a little bit of white left while cleaning. Hopefully this 'fix' will last a good while for the guy buying this. At this point I'll say he's gonna be pretty happy with his purchase. I messed around with this 'till late last night so there's small stuff to put back together later today, like the little bolts & matching retainers that hold the plastic part of the under-deck in, which are a pain to deal with too. All in all, an interesting adventure.

At any rate.. that was fun! Those little snap rings/circlips are a bit of a pain to deal with. One of 'em took flight, ricocheted off a couple things in the garage - never to be seen again

#18

D

DUSlider

D

DUSlider

Hello,

I have an HRR216K5VKA. My issue is with the wheels not rolling while pulling the mower backwards. I removed everything down to the axel on both sides. The right side wheel height adjuster was easily removed. The left I had to use an axle puller to remove, which left the plastic bearing on the axle, stuck on there really good.

I saw the service bulletin released for the K9. Curiously, I checked peparts.honda.com and the height adjusters part numbers for both the K5 and K9 are identical.

It seems this issue may have been around for awhile and Honda didn't do anything about it until the K9 series was released? Has anyone with a model older than the K9 been able to get Honda to goodwill the repair or parts? I think I'm just going to order new wheel height adjusters with hopefully revised bearings instead of messing with the old bearings as I'm not sure I can get the bearing out of the right height adjuster to replace it with the new one.

Also, what type (if any) of grease are you using inside the wheel height adjuster for the bearings? I was doing some research and (I can't remember where) I saw someone had used Molykote.

I have an HRR216K5VKA. My issue is with the wheels not rolling while pulling the mower backwards. I removed everything down to the axel on both sides. The right side wheel height adjuster was easily removed. The left I had to use an axle puller to remove, which left the plastic bearing on the axle, stuck on there really good.

I saw the service bulletin released for the K9. Curiously, I checked peparts.honda.com and the height adjusters part numbers for both the K5 and K9 are identical.

It seems this issue may have been around for awhile and Honda didn't do anything about it until the K9 series was released? Has anyone with a model older than the K9 been able to get Honda to goodwill the repair or parts? I think I'm just going to order new wheel height adjusters with hopefully revised bearings instead of messing with the old bearings as I'm not sure I can get the bearing out of the right height adjuster to replace it with the new one.

Also, what type (if any) of grease are you using inside the wheel height adjuster for the bearings? I was doing some research and (I can't remember where) I saw someone had used Molykote.

#19

gotomow

gotomow

I used Motorkote spray because I wanted to mow right away and didn't want to fully disassemble. The Motorkote worked it's way into the shaft good enough for right now. When I have enough time to get everything apart I'll probably use bike chain lube or garage door lube and see how that works. Grease tends to hold dirt and dust in suspension so that's why I'm going with the lubes. However, anything is better than nothing so use what you've got.

#20

D

DUSlider

I got mine all apart and re-assembled with new wheel height adjusters and bearings. I sanded down the axle but to be honest I don't think it really needed it. I think what is happening is the rubber dust seal is breaking down letting gunk in and possible parts of the seal inside the bearing, freezing it up. The right side was actually fine, it was the left side, closest to the transmission. It also had some odd wear on the plastic dust shield for the hole that the transmission axle goes through so I replaced that as well. (Hole was worn out and elongated).

Getting the spring back on the transmission was a PITA.

I've had this mower for 10 years at least. If I don't have to do this for another 5 I'll be happy.

I used some DuPont teflon non-stick dry-film lubricant on the axle where the bearing was contacting the axle and some multi purpose grease for the gear/key.

D

DUSlider

I used Motorkote spray because I wanted to mow right away and didn't want to fully disassemble. The Motorkote worked it's way into the shaft good enough for right now. When I have enough time to get everything apart I'll probably use bike chain lube or garage door lube and see how that works. Grease tends to hold dirt and dust in suspension so that's why I'm going with the lubes. However, anything is better than nothing so use what you've got.

I got mine all apart and re-assembled with new wheel height adjusters and bearings. I sanded down the axle but to be honest I don't think it really needed it. I think what is happening is the rubber dust seal is breaking down letting gunk in and possible parts of the seal inside the bearing, freezing it up. The right side was actually fine, it was the left side, closest to the transmission. It also had some odd wear on the plastic dust shield for the hole that the transmission axle goes through so I replaced that as well. (Hole was worn out and elongated).

Getting the spring back on the transmission was a PITA.

I've had this mower for 10 years at least. If I don't have to do this for another 5 I'll be happy.

I used some DuPont teflon non-stick dry-film lubricant on the axle where the bearing was contacting the axle and some multi purpose grease for the gear/key.

#21

R

Roymg

R

Roymg

I can't take ownership for this fix and I can't find where I got this article from to be able to give credit to the originator. But I tried the fix he suggested and it worked for me. Why I'm not sure, but heck I was willing to try something to take care of the problem. I have a HRR216K9VKA Honda mower. I got my thrust washers from ACE and even though they were not an exact match, they worked. So far I cut my yard only once with this fix and ran this mower for an hour and one half, with good results.

14 year old HRT216 would no longer backup (rear wheels would not release when the drive handle was released, and the wheels just "locked". My remedy below is uniquely different from any others I have seen on this subject. Honda Mower Rear wheel xmission has a unique design that uses Thrust Washers to help release the drive from the rear wheels so that the operator can easily back up the mower when the Drive Handle is released.

As the machine ages, these washers lose their load Thrust and the rear wheels will not properly release to enable an easy back up. This makes the mower very hard to operate due to its "braking weight in reverse". A Simple Fix in lieu of replacing the entire transmission ($175 or so) and repair bill of $175 (total xmission repair is very difficult and time consuming) is to place two thrust washers (Pt # 90505-VG3-000) (13 x 27mm) in series and add one more spacing wheel washer (Pt # 90455-VA2-000 (13 x 27 x 1mm) to each Rear Wheel Assembly instead of just one thrust washer and spacer washer.

These are items #16 and #19 in Jacks-Parts-Lookup/Model-Diagram. Adding these washers "in series" will double the Thrust Force and aid the wheels to release. I used the existing Thrust Washer and Spacing Washer from the existing mower and added one Thrust Washer and One more Spacing Washer to each Wheel Assembly and got excellent results. Put the Spacing Plain Washers on each end of the Series Assembly of two Thrust Washers (i.e. Top and Bottom Sandwich with Thrust Washers "back to back" as shown in the Solon diagram referenced below: **. Be sure to orient the Washer Assembly as shown in Solon Belleville Spring Features via **.

One of the Thrust Washers Convex Head must be oriented to point towards the Wheel Axles Bolt Head, the other Trust washer Convex Head must point towards the Wheel Cover Item #6. Two Thrust Washers and two Wheel Washers will cost about $6.00. Time to un-assemble and re-assemble each wheel is about ten minutes each. Clean the large driver perimeter gear(s) on each inner wheel if badly caked with lubricant, grass, and dirt. Apply a thin coating of Gear Grease or Heavy Motor Oil to each driving gear

14 year old HRT216 would no longer backup (rear wheels would not release when the drive handle was released, and the wheels just "locked". My remedy below is uniquely different from any others I have seen on this subject. Honda Mower Rear wheel xmission has a unique design that uses Thrust Washers to help release the drive from the rear wheels so that the operator can easily back up the mower when the Drive Handle is released.

As the machine ages, these washers lose their load Thrust and the rear wheels will not properly release to enable an easy back up. This makes the mower very hard to operate due to its "braking weight in reverse". A Simple Fix in lieu of replacing the entire transmission ($175 or so) and repair bill of $175 (total xmission repair is very difficult and time consuming) is to place two thrust washers (Pt # 90505-VG3-000) (13 x 27mm) in series and add one more spacing wheel washer (Pt # 90455-VA2-000 (13 x 27 x 1mm) to each Rear Wheel Assembly instead of just one thrust washer and spacer washer.

These are items #16 and #19 in Jacks-Parts-Lookup/Model-Diagram. Adding these washers "in series" will double the Thrust Force and aid the wheels to release. I used the existing Thrust Washer and Spacing Washer from the existing mower and added one Thrust Washer and One more Spacing Washer to each Wheel Assembly and got excellent results. Put the Spacing Plain Washers on each end of the Series Assembly of two Thrust Washers (i.e. Top and Bottom Sandwich with Thrust Washers "back to back" as shown in the Solon diagram referenced below: **. Be sure to orient the Washer Assembly as shown in Solon Belleville Spring Features via **.

One of the Thrust Washers Convex Head must be oriented to point towards the Wheel Axles Bolt Head, the other Trust washer Convex Head must point towards the Wheel Cover Item #6. Two Thrust Washers and two Wheel Washers will cost about $6.00. Time to un-assemble and re-assemble each wheel is about ten minutes each. Clean the large driver perimeter gear(s) on each inner wheel if badly caked with lubricant, grass, and dirt. Apply a thin coating of Gear Grease or Heavy Motor Oil to each driving gear

#22

B

Briantii

B

Briantii

Is there any definitive best lube for these? I’ve been using grease and frankly it cakes up with dirt and gunk and I’m back to the same old infuriating lawn mower again. I get about a years worth of homeowner use no matter what. I’ve replaced the bushings 2 or 3 times too and the latest version even has been locking up... just like all the prior ones. I took it apart and cleaned them all out again this weekend and reassembled with powdered graphite this time. Feels great right now, but as always, who knows how long it will last. These mowers are awesome except for this stupid design. Why they didn’t use a sealed ball bearing is beyond me.

Robert, any chance you can comment about what lube (if any) is supposed to go in these bushings? I literally installed the new bushings last August and come July 2018 I’m ready to throw this thing off a cliff again. I can’t help but think it’s somehow me and using the wrong lube.

Robert, any chance you can comment about what lube (if any) is supposed to go in these bushings? I literally installed the new bushings last August and come July 2018 I’m ready to throw this thing off a cliff again. I can’t help but think it’s somehow me and using the wrong lube.

#23

gotomow

gotomow

I used Motorkote spray with good results. You could also try a graphite based spray like EZ-Slide. I picked up a can of EZ-Slide at an estate sale for a great price so I'm going to try that if the Motorkote is no longer effective. Honda chose to save $$$ on cheap bushings instead of putting bearings in. On a trip to Home Depot I noticed a HRX217 reduced on the sales floor so I thought I'd pull back on it and WOW that thing was hard to pull back practically brand new! If I had a lot of pulling back to do with a mower the Honda's would not be on my list.

#24

B

Briantii

B

Briantii

Thanks, I may have to try one of those if the graphite powder doesn’t hold up. I’ll update the thread when I know. In a year if graphite still works I’ll sing it’s praises here.

This design is just so infuriating. It’s literally the only part of this mower that’s substandard. I can’t help but wonder how hard it’d be to machine the adjusters to accept a standard ball bearing. Looks like all current non-commercial models use the same design. I guess as always if you want the good stuff gotta pay for commercial grade, though my yard really shouldn’t need it. And I agree, half the brand new ones are hard to pull backwards too.... insane.

This design is just so infuriating. It’s literally the only part of this mower that’s substandard. I can’t help but wonder how hard it’d be to machine the adjusters to accept a standard ball bearing. Looks like all current non-commercial models use the same design. I guess as always if you want the good stuff gotta pay for commercial grade, though my yard really shouldn’t need it. And I agree, half the brand new ones are hard to pull backwards too.... insane.

#25

B

bertsmobile1

B

bertsmobile1

Go to a push bike shop, the ones inhabited by MAMILS and get some DRY cable lube.

The stuff is expensive but you will only use a few drops.

I use Tri-FLow.

Do not get the spray cans.

When I started in the repair business 5 years ago I had 1/2 a 4oz bottle because I use it for lubing motorcycle control cables

Despite using it on mowers & bikes I still have about 1/10 of the bottle left.

Just give it a really good shake before you apply 2 to 3 drops then assemble and roll the mower a few feet to distribute the lube.

leave it for about 1/2 hour for the solvent to evaporate before you mow.

Do it every season as part of your annual season end service and you will never have to replace them again.

The stuff is expensive but you will only use a few drops.

I use Tri-FLow.

Do not get the spray cans.

When I started in the repair business 5 years ago I had 1/2 a 4oz bottle because I use it for lubing motorcycle control cables

Despite using it on mowers & bikes I still have about 1/10 of the bottle left.

Just give it a really good shake before you apply 2 to 3 drops then assemble and roll the mower a few feet to distribute the lube.

leave it for about 1/2 hour for the solvent to evaporate before you mow.

Do it every season as part of your annual season end service and you will never have to replace them again.

#26

B

Briantii

Awesome, sounds like the perfect product. I'llpick sone up if graphite fails me. Disappointing the labor to get to them though and that it's required. Thanks!

B

Briantii

Go to a push bike shop, the ones inhabited by MAMILS and get some DRY cable lube.

The stuff is expensive but you will only use a few drops.

I use Tri-FLow.

Do not get the spray cans.

When I started in the repair business 5 years ago I had 1/2 a 4oz bottle because I use it for lubing motorcycle control cables

Despite using it on mowers & bikes I still have about 1/10 of the bottle left.

Just give it a really good shake before you apply 2 to 3 drops then assemble and roll the mower a few feet to distribute the lube.

leave it for about 1/2 hour for the solvent to evaporate before you mow.

Do it every season as part of your annual season end service and you will never have to replace them again.

Awesome, sounds like the perfect product. I'llpick sone up if graphite fails me. Disappointing the labor to get to them though and that it's required. Thanks!

#27

R

Roymg

Update:

I guess it was too good to be true. Second go around cutting my yard the problem returned. I had high hopes this would work. I did not use the exact parts he did in his fix but should not have mattered.

R

Roymg

I can't take ownership for this fix and I can't find where I got this article from to be able to give credit to the originator. But I tried the fix he suggested and it worked for me. Why I'm not sure, but heck I was willing to try something to take care of the problem. I have a HRR216K9VKA Honda mower. I got my thrust washers from ACE and even though they were not an exact match, they worked. So far I cut my yard only once with this fix and ran this mower for an hour and one half, with good results.

14 year old HRT216 would no longer backup (rear wheels would not release when the drive handle was released, and the wheels just "locked". My remedy below is uniquely different from any others I have seen on this subject. Honda Mower Rear wheel xmission has a unique design that uses Thrust Washers to help release the drive from the rear wheels so that the operator can easily back up the mower when the Drive Handle is released.

As the machine ages, these washers lose their load Thrust and the rear wheels will not properly release to enable an easy back up. This makes the mower very hard to operate due to its "braking weight in reverse". A Simple Fix in lieu of replacing the entire transmission ($175 or so) and repair bill of $175 (total xmission repair is very difficult and time consuming) is to place two thrust washers (Pt # 90505-VG3-000) (13 x 27mm) in series and add one more spacing wheel washer (Pt # 90455-VA2-000 (13 x 27 x 1mm) to each Rear Wheel Assembly instead of just one thrust washer and spacer washer.

These are items #16 and #19 in Jacks-Parts-Lookup/Model-Diagram. Adding these washers "in series" will double the Thrust Force and aid the wheels to release. I used the existing Thrust Washer and Spacing Washer from the existing mower and added one Thrust Washer and One more Spacing Washer to each Wheel Assembly and got excellent results. Put the Spacing Plain Washers on each end of the Series Assembly of two Thrust Washers (i.e. Top and Bottom Sandwich with Thrust Washers "back to back" as shown in the Solon diagram referenced below: **. Be sure to orient the Washer Assembly as shown in Solon Belleville Spring Features via **.

One of the Thrust Washers Convex Head must be oriented to point towards the Wheel Axles Bolt Head, the other Trust washer Convex Head must point towards the Wheel Cover Item #6. Two Thrust Washers and two Wheel Washers will cost about $6.00. Time to un-assemble and re-assemble each wheel is about ten minutes each. Clean the large driver perimeter gear(s) on each inner wheel if badly caked with lubricant, grass, and dirt. Apply a thin coating of Gear Grease or Heavy Motor Oil to each driving gear

Update:

I guess it was too good to be true. Second go around cutting my yard the problem returned. I had high hopes this would work. I did not use the exact parts he did in his fix but should not have mattered.

#28

B

Briantii

Yeah, sorry it didn’t work. If that model is like most Honda’s then I believe the theory of operation is quite wrong. The wheels don’t release at all ever. The ratcheting pinion gear allows the wheel to “overrun” the speed of the drive shaft but only in the forward direction. This allows you to turn the mower to turn while self propelled is engaged. If the wheels were locked to the shaft always then there would be no turning since I think most are like mine and have no differential in the transmission. Pulling backwards allows you to see ALL the drag in the driveline assembly.

I believe those washers on the wheels simply help keep it on tight as well as ensure the plastic guard doesn’t interfere with the wheel.

So far have one mow completed with graphite in the bushings. So far so good.

B

Briantii

Update:

I guess it was too good to be true. Second go around cutting my yard the problem returned. I had high hopes this would work. I did not use the exact parts he did in his fix but should not have mattered.

Yeah, sorry it didn’t work. If that model is like most Honda’s then I believe the theory of operation is quite wrong. The wheels don’t release at all ever. The ratcheting pinion gear allows the wheel to “overrun” the speed of the drive shaft but only in the forward direction. This allows you to turn the mower to turn while self propelled is engaged. If the wheels were locked to the shaft always then there would be no turning since I think most are like mine and have no differential in the transmission. Pulling backwards allows you to see ALL the drag in the driveline assembly.

I believe those washers on the wheels simply help keep it on tight as well as ensure the plastic guard doesn’t interfere with the wheel.

So far have one mow completed with graphite in the bushings. So far so good.

#30

B

Briantii

B

Briantii

So quick update. 2 - 3 hours in on ONLY cleaning and re-lubing with powdered graphite and we're sticking again when hot. Guess it's new adjuster / bushing time. I wonder if Amazon has a "Subscribe and Save" option for adjusters / bushings... I swear it's an annual deal it seems. SO ANNOYING.

#31

D

DUSlider

D

DUSlider

When you guys lube the new bushings, make sure you use something safe for rubber/plastic. If you use the same grease you put on the pinion gear you're probably asking for trouble.

I used DuPont Teflon Non-Stick Dry-Film Lubricant. Its supposed to lube and repel dirt/grime. The one bearing has a rubber seal on one side that is supposed to help keep gunk out. However if you use grease that isn't compatible with rubber/plastic, that seal will break down and let gunk in and will freeze the bushing on the axle.

I replaced my height adjusters and got new bushings this summer and so far its working perfectly. I'll update after the cutting season next year.

I used DuPont Teflon Non-Stick Dry-Film Lubricant. Its supposed to lube and repel dirt/grime. The one bearing has a rubber seal on one side that is supposed to help keep gunk out. However if you use grease that isn't compatible with rubber/plastic, that seal will break down and let gunk in and will freeze the bushing on the axle.

I replaced my height adjusters and got new bushings this summer and so far its working perfectly. I'll update after the cutting season next year.

#32

B

Briantii

Yeah I think that's a very valid point and why I'd love to know what Honda recommends. The Dupont Dry Lube sounds like a good option.

B

Briantii

When you guys lube the new bushings, make sure you use something safe for rubber/plastic. If you use the same grease you put on the pinion gear you're probably asking for trouble.

I used DuPont Teflon Non-Stick Dry-Film Lubricant. Its supposed to lube and repel dirt/grime. The one bearing has a rubber seal on one side that is supposed to help keep gunk out. However if you use grease that isn't compatible with rubber/plastic, that seal will break down and let gunk in and will freeze the bushing on the axle.

I replaced my height adjusters and got new bushings this summer and so far its working perfectly. I'll update after the cutting season next year.

Yeah I think that's a very valid point and why I'd love to know what Honda recommends. The Dupont Dry Lube sounds like a good option.

#33

J

JHead

J

JHead

I purchased my HRR216VKA in May 2018 and have already begun experiencing this problem. Mower works OK at first and as it heats up, drive essentially stops working and wheels won’t roll backward. From what I’ve read on this forum, this is a design deficiency on the part of Honda which they didn’t fix after the Service Bulletin #107 in March 2017. I’ll be taking my mower back to the dealer tomorrow.

#35

G

Gatafly

G

Gatafly

Took mine to the dealer to be fixed for this and also high oil consumption. He claims he can do the fix, but that it won't fix it as that is just the way they are. We will see, but not sure I believe him. Anyone else have this done and not work?

#36

B

Bobz1

B

Bobz1

Mine was supposedly fixed but after 2 uses just the same. The dealer said they used new bushings. I think they got old ones. Will take back again in spring. If They don't resole it I will go directly to Honda as is useless if wheels lock up.

#37

T

Thoffm99

T

Thoffm99

Re: Honda HRR Models: Rear Wheels Locking Up When Pulling Backward.

Same exact problem. Replaced the adjuster assembly using the part numbers from the bulletin, lubed it with lithium grease. Worked for one time and problem is back. It will backup but is harder than just after I reassembled it.

I too have the problem with my Honda mower locking up its back wheels when pulling backwards. I have in the not-to-distant past, replaced the bushings with the adjuster arms. Seemed to work a few times while cutting the yard and then right back at the same stubborn hard-to-pull backwards issue. Just recently I took both assemblies off, cleaned the entire gears, springs and assembly and added lubricant. Worked well for just one mowing job.

Weird thing is, I have noticed the wheels seem to roll backwards when sitting in the garage and I need to pull it out to mow. Or sometimes, but not always, when I empty the bagger of clippings.

I have almost sold it. Indeed I had it on Craigslist and couldn't get my asking price so I pulled it off. I have also seen a YouTube video where a post shows my problem exactly and what he suggested was to take it all apart and sand the shaft on both sides where the bushings slide.

Anyone really have this problem and get a long-term solution?

Same exact problem. Replaced the adjuster assembly using the part numbers from the bulletin, lubed it with lithium grease. Worked for one time and problem is back. It will backup but is harder than just after I reassembled it.

#38

O

Opfoto

Interesting that Honda refuses to correct this issue. I have an 2012 HRR and I experienced this exact issue issue a number of times, I was told to make sure the gears are cleaned and lubed. No part replacements were ever offered either under warranty or not. I spent damn good money on a "better" mower. Found out rather quickly that I could have purchased a couple of other mowers instead for a lot less but I tought you get what you pay for. C'mon Honda are ya listening yet???

O

Opfoto

Honda issued a Service Bulletin on this problem earlier this spring; the issue is the bushings may be undersized, causing increased friction between the bushing the the transmision's axle.

The fix is to replace the adjuster arms, which have countermeasure bushings.

Step 1: First, verify your mower is in the affected range; if it is NOT, you have a different problem.

Affected model list is as follows:

HRR216K9VKA serial numbers MZCG-8670001-9933580

HRR216K9VLA serial numbers MZCG-8670001-9933580

HRR216K9VYA serial numbers MZCG-8670001-9933580

Step 2: Normal warranty applies; if your mower is still under warranty, is having a pull-back issue, and is in the above range, Honda will replace the adjusters under warranty. All Honda dealers are authorized to do this warranty repair, even if you didn't buy it from them. Beware that some dealers may offer more flexible repair schedules for those customer who did.

Find A Honda Dealer

If the dealer doesn't seem aware, tell him to look at Honda Power Equipment Lawn Mower Service Bulletin #107.

Step 3: If you're out of warranty, a dealer can still do the repair. Most will charge about 45 minutes to 1 hour of shop time for this job, but that's totally up to them. List price for each adjuster is $12.10.

Step 4: If you'd like to DIY, it's not a bad job. You need to remove the rear wheels and all the parts on the drive axle, which include a couple of circlips, so you may need to buy a circlip pliers. A bench is a big help to hold the mower in an easy-to-work-on position; note this requires the fuel and oil to be drained:

I'd be happy to share some detailed instructions, just drop me a PM with your full email address.

Interesting that Honda refuses to correct this issue. I have an 2012 HRR and I experienced this exact issue issue a number of times, I was told to make sure the gears are cleaned and lubed. No part replacements were ever offered either under warranty or not. I spent damn good money on a "better" mower. Found out rather quickly that I could have purchased a couple of other mowers instead for a lot less but I tought you get what you pay for. C'mon Honda are ya listening yet???

#39

D

de3

D

de3

I bought a new HRR 3 years ago,I used it for 1 summer and replaced both pinion gears twice,the reason for them wearing out was that the rear wheels got so much play that the gear on the wheel wasn't lined up with the pinion gears and was wearing one side of the pinion gear real bad,to correct the issue i used thin wave washers to get the back and forth play out of the wheels,but you can only get by with doing that maybe twice.....Needless to say after 1 summer of using it i sold it,I average 75 hours or more a summer,The HRR Is pretty much a small town yard lawn mower,I've now been using a HRX 217 that I bought new,it now has around 400 hours and this is my 6th summer for it,i've replaced the blade stop hub bearing and I upgraded the wheel bearings with real bearings and replaced the pinion gears twice,so its been a good mower///I also have a HRC216 Commercial with 45 hours,this mower is in a class of its own,very well built including good bearings in the wheels and a few other things

Attachments

#40

B

Briantii

Dry Lube did NOT work for me. Lasted less time than traditional grease. This is the “fix” I’m trying right now, that I think may hold some promise. I love the mower, just hate this insanely stupid design.

B

Briantii

Yeah I think that's a very valid point and why I'd love to know what Honda recommends. The Dupont Dry Lube sounds like a good option.

Dry Lube did NOT work for me. Lasted less time than traditional grease. This is the “fix” I’m trying right now, that I think may hold some promise. I love the mower, just hate this insanely stupid design.

#41

B

Briantii

B

Briantii

The idea is that I should be able to periodically push fresh grease into the bushing hopefully keeping most dirt and grit out. I aligned the fitting with the wheel mount on the adjuster so that if you adjust the wheels to the highest setting then the fitting points down and is easily accessible to pump grease into, otherwise it just points sideways/ up during normal use. I disassembled drilled and tapped it the put it back together and installed the zerk fitting with locktite. It’s a pain, but fingers crossed it’ll work well for a while.

#42

B

Briantii

B

Briantii

Re: Honda HRR Models: Rear Wheels Locking Up When Pulling Backward.

Yep, and will only get worse. I’m on my 2nd set of the “new” bushings that comply with the bulletin. Honda should have used sealed bearings IMHO.

Same exact problem. Replaced the adjuster assembly using the part numbers from the bulletin, lubed it with lithium grease. Worked for one time and problem is back. It will backup but is harder than just after I reassembled it.

Yep, and will only get worse. I’m on my 2nd set of the “new” bushings that comply with the bulletin. Honda should have used sealed bearings IMHO.

#43

B

Briantii

B

Briantii

Took mine out for it’s first mow with the zerk fittings pumped up with some really old Yamaha Marine grease (just what was in my gun). Wow! So much better. I could turn on a dime, self propelled was faster, whole thing felt lighter and more maneuverable. Fingers crossed that shooting grease in there once a month or so will keep it like this. I forgot how good these things are on the rare occasion they’re actually working correctly. Will update everyone later this season with status. Hopefully this is a long term solution since Honda sure doesn’t give us one.

#44

Mow'N Weeds

Mow'N Weeds

I like that grease fitting idea, that should have been a factory installed deal, for as over-complicated design of those things.. why wasn't it??

I shy away from Honda mowers, do not like. Motors yeah of course, everything else, not one bit. I got another one laying about, but I have no money invested into it thus far, it was a freebie someone beat to snot then finally pushed to the curb. Motor may be a runner, it's free at least. That's the most I'll pay for an actual Honda mower though

I shy away from Honda mowers, do not like. Motors yeah of course, everything else, not one bit. I got another one laying about, but I have no money invested into it thus far, it was a freebie someone beat to snot then finally pushed to the curb. Motor may be a runner, it's free at least. That's the most I'll pay for an actual Honda mower though

#45

B

Briantii

I wish they would have used sealed ball bearings. The zerk fitting for the non sealed bushing seemed like the next best thing. I like my mower when the self propelled isn’t messed up. Unfortunately due to their horrible design I feel like I’m re-engineering more than mowing. So frustrating. If this continues to work I’ll be happy though.... just not with Honda.

B

Briantii

I like that grease fitting idea, that should have been a factory installed deal, for as over-complicated design of those things.. why wasn't it??

I shy away from Honda mowers, do not like. Motors yeah of course, everything else, not one bit. I got another one laying about, but I have no money invested into it thus far, it was a freebie someone beat to snot then finally pushed to the curb. Motor may be a runner, it's free at least. That's the most I'll pay for an actual Honda mower though

I wish they would have used sealed ball bearings. The zerk fitting for the non sealed bushing seemed like the next best thing. I like my mower when the self propelled isn’t messed up. Unfortunately due to their horrible design I feel like I’m re-engineering more than mowing. So frustrating. If this continues to work I’ll be happy though.... just not with Honda.

#46

M

minndogs

M

minndogs

Seems to me this lock up of the rear wheels is a design problem.

I have experienced it on 2 hrr216 series mowers and my brother has the exact problem on his hrr216 series mower. THe Honda dealer recently replaced the bushings on one of mine under warranty. The mower still has the issue.

My thoughts are that when the clutch is adjusted so that the rear wheels do not lock up, the mower does not have enough torque on the rear wheels to go up steeper hills. Fine for flat lawns with mild hill angles.

If the clutch is adjusted so that there is enough clutch tension to keep the wheels going for steep hills, the rear wheels lock up when pulling the mower backwards with the engine running.

I think this is due to the stiffer tension adjustment needed for steeper hills. With the stiffer tension, when the clutch is released to pull the mower backwards, there is still slight tension on the transmission pulley so the rear wheels will not turn freely when pulling backwards.

I tested this out by changing clutch adjustments in my driveway and sure enough, the rear wheels lock when the clutch adjustment is tightened adequately for steeper hills. There does not seem be solution to this issue. It is caused by the design of the drive system.

I have experienced it on 2 hrr216 series mowers and my brother has the exact problem on his hrr216 series mower. THe Honda dealer recently replaced the bushings on one of mine under warranty. The mower still has the issue.

My thoughts are that when the clutch is adjusted so that the rear wheels do not lock up, the mower does not have enough torque on the rear wheels to go up steeper hills. Fine for flat lawns with mild hill angles.

If the clutch is adjusted so that there is enough clutch tension to keep the wheels going for steep hills, the rear wheels lock up when pulling the mower backwards with the engine running.

I think this is due to the stiffer tension adjustment needed for steeper hills. With the stiffer tension, when the clutch is released to pull the mower backwards, there is still slight tension on the transmission pulley so the rear wheels will not turn freely when pulling backwards.

I tested this out by changing clutch adjustments in my driveway and sure enough, the rear wheels lock when the clutch adjustment is tightened adequately for steeper hills. There does not seem be solution to this issue. It is caused by the design of the drive system.

#47

Mow'N Weeds

Mow'N Weeds

Sealed bearings sound like a better idea too. I had the joy of tearing one down on both rear wheels, cleaning/sanding down parts, cleaning every bit of old grease and re-greasing w/new blue marine grease. It worked again when finished (wheels didn't lock up anymore), but it was a PITA job and I honestly don't know if it was any sort of permanent fix to the issue or not. I sold it before I found out yes or no. The buyer asked if the wheels locking up would come back and I told 'em IDK, but that if he had a problem with them doing that anytime soon, that he could get in contact with me and I could do the job again if need be. I wouldn't have charged 'em to do it, would have just been a courtesy. Thankfully I never heard from him again, so I'm also hoping it's still mowin' along just fine for 'em. I've read that bushings were made too small from the factory (or wheel shafts too big, depending on how you wanna look at it), and if still under warranty they'd replace with new up-sized bushings and that was supposed to fix it. But here we have testimony of that still not fixing the issue. Though I'm no official Engineer, I don't think it's the best design either, clearly. If they were cheapie mowers a guy might not gripe so much, but these things purchased new are far from 'cheap' in price for a walk behind mower IMO.Briantii said:I wish they would have used sealed ball bearings. The zerk fitting for the non sealed bushing seemed like the next best thing. I like my mower when the self propelled isn’t messed up. Unfortunately due to their horrible design I feel like I’m re-engineering more than mowing. So frustrating. If this continues to work I’ll be happy though.... just not with Honda.

#48

B

Briantii

Yep, EXACTLY. It seems to me to be related to how much dust you have. It gums up pretty quickly if there is a lot of dust. If it's damp or I stick with the front yard where the grass is in a lot better shape, then it's fine. The zerk fittings so far are still working great. Just hit them with a shot of grease any time I start to feel any drag. This is the best the mower has EVER been, even new. I'd highly recommend the "zerk fitting mod" as it seems to be the only real way to maintain them without tearing the whole thing apart each time.

B

Briantii

Sealed bearings sound like a better idea too. I had the joy of tearing one down on both rear wheels, cleaning/sanding down parts, cleaning every bit of old grease and re-greasing w/new blue marine grease. It worked again when finished (wheels didn't lock up anymore), but it was a PITA job and I honestly don't know if it was any sort of permanent fix to the issue or not. I sold it before I found out yes or no. The buyer asked if the wheels locking up would come back and I told 'em IDK, but that if he had a problem with them doing that anytime soon, that he could get in contact with me and I could do the job again if need be. I wouldn't have charged 'em to do it, would have just been a courtesy. Thankfully I never heard from him again, so I'm also hoping it's still mowin' along just fine for 'em. I've read that bushings were made too small from the factory (or wheel shafts too big, depending on how you wanna look at it), and if still under warranty they'd replace with new up-sized bushings and that was supposed to fix it. But here we have testimony of that still not fixing the issue. Though I'm no official Engineer, I don't think it's the best design either, clearly. If they were cheapie mowers a guy might not gripe so much, but these things purchased new are far from 'cheap' in price for a walk behind mower IMO.

Yep, EXACTLY. It seems to me to be related to how much dust you have. It gums up pretty quickly if there is a lot of dust. If it's damp or I stick with the front yard where the grass is in a lot better shape, then it's fine. The zerk fittings so far are still working great. Just hit them with a shot of grease any time I start to feel any drag. This is the best the mower has EVER been, even new. I'd highly recommend the "zerk fitting mod" as it seems to be the only real way to maintain them without tearing the whole thing apart each time.

#49

B

Briantii

Assuming you're talking about the newer versions there really isn't a "clutch" per say - the cable pulls up on the transmission which rotates and tightens the belt. I always thought it might be drag from the belt and did similar experiments to yours, but it's really drag from those stupid bushings. It also can be affected by heat. As the plastic bushings inside the metal adjuster heat up then it gets tighter, causing more friction and heat and drags even more. It actually seems to put a pretty big load on the transmission from the drag and friction. I overheated / locked up my transmission with the bushings dragging so much one time. The temp differences do lead to inconsistent results of the tests as well. I HIGHLY suggest trying the zerk fitting mod that I showed in the picture. It's really working great with the bushings remaining well lubed. Like, it freely rolls backwards down hills without ANY hint of tearing up grass! How sad that they couldn't get this right from the factory. The only thing I'd do differently is epoxy the inside dust shield to the metal adjuster to keep the pressure from the grease from wanting to pop it out which can happen if you pump a shot of grease in them quickly.

B

Briantii

Seems to me this lock up of the rear wheels is a design problem.

I have experienced it on 2 hrr216 series mowers and my brother has the exact problem on his hrr216 series mower. THe Honda dealer recently replaced the bushings on one of mine under warranty. The mower still has the issue.

My thoughts are that when the clutch is adjusted so that the rear wheels do not lock up, the mower does not have enough torque on the rear wheels to go up steeper hills. Fine for flat lawns with mild hill angles.

If the clutch is adjusted so that there is enough clutch tension to keep the wheels going for steep hills, the rear wheels lock up when pulling the mower backwards with the engine running.

I think this is due to the stiffer tension adjustment needed for steeper hills. With the stiffer tension, when the clutch is released to pull the mower backwards, there is still slight tension on the transmission pulley so the rear wheels will not turn freely when pulling backwards.

I tested this out by changing clutch adjustments in my driveway and sure enough, the rear wheels lock when the clutch adjustment is tightened adequately for steeper hills. There does not seem be solution to this issue. It is caused by the design of the drive system.

Assuming you're talking about the newer versions there really isn't a "clutch" per say - the cable pulls up on the transmission which rotates and tightens the belt. I always thought it might be drag from the belt and did similar experiments to yours, but it's really drag from those stupid bushings. It also can be affected by heat. As the plastic bushings inside the metal adjuster heat up then it gets tighter, causing more friction and heat and drags even more. It actually seems to put a pretty big load on the transmission from the drag and friction. I overheated / locked up my transmission with the bushings dragging so much one time. The temp differences do lead to inconsistent results of the tests as well. I HIGHLY suggest trying the zerk fitting mod that I showed in the picture. It's really working great with the bushings remaining well lubed. Like, it freely rolls backwards down hills without ANY hint of tearing up grass! How sad that they couldn't get this right from the factory. The only thing I'd do differently is epoxy the inside dust shield to the metal adjuster to keep the pressure from the grease from wanting to pop it out which can happen if you pump a shot of grease in them quickly.

#50

J

jahn

I had my mower parts replaced and after 2 weeks it still won't pull backwards..........I bought a Toro that always works.

J

jahn

Honda issued a Service Bulletin on this problem earlier this spring; the issue is the bushings may be undersized, causing increased friction between the bushing the the transmision's axle.

The fix is to replace the adjuster arms, which have countermeasure bushings.

Step 1: First, verify your mower is in the affected range; if it is NOT, you have a different problem.

Affected model list is as follows:

HRR216K9VKA serial numbers MZCG-8670001-9933580

HRR216K9VLA serial numbers MZCG-8670001-9933580

HRR216K9VYA serial numbers MZCG-8670001-9933580

Step 2: Normal warranty applies; if your mower is still under warranty, is having a pull-back issue, and is in the above range, Honda will replace the adjusters under warranty. All Honda dealers are authorized to do this warranty repair, even if you didn't buy it from them. Beware that some dealers may offer more flexible repair schedules for those customer who did.

Find A Honda Dealer

If the dealer doesn't seem aware, tell him to look at Honda Power Equipment Lawn Mower Service Bulletin #107.

Step 3: If you're out of warranty, a dealer can still do the repair. Most will charge about 45 minutes to 1 hour of shop time for this job, but that's totally up to them. List price for each adjuster is $12.10.

Step 4: If you'd like to DIY, it's not a bad job. You need to remove the rear wheels and all the parts on the drive axle, which include a couple of circlips, so you may need to buy a circlip pliers. A bench is a big help to hold the mower in an easy-to-work-on position; note this requires the fuel and oil to be drained:

I'd be happy to share some detailed instructions, just drop me a PM with your full email address.

I had my mower parts replaced and after 2 weeks it still won't pull backwards..........I bought a Toro that always works.

#51

G

Gatafly

I did too, but also because it burns oil and Honda won't do anything even under warranty. Love my Toro, better self propel, lighter and easier to mow with and doesn't leave built up grass by the left rear wheel if mowing gets delayed a couple days because of rain.

G

Gatafly

I had my mower parts replaced and after 2 weeks it still won't pull backwards..........I bought a Toro that always works.

I did too, but also because it burns oil and Honda won't do anything even under warranty. Love my Toro, better self propel, lighter and easier to mow with and doesn't leave built up grass by the left rear wheel if mowing gets delayed a couple days because of rain.

#52

J

jahn

Don't get any better than a Toro........my last one which I used for 15 years, I just gave it to my brother and like a Timex it takes a lickin' & keeps on tickin'......

J

jahn

I did too, but also because it burns oil and Honda won't do anything even under warranty. Love my Toro, better self propel, lighter and easier to mow with and doesn't leave built up grass by the left rear wheel if mowing gets delayed a couple days because of rain.

Don't get any better than a Toro........my last one which I used for 15 years, I just gave it to my brother and like a Timex it takes a lickin' & keeps on tickin'......

#53

D

DUSlider

D

DUSlider

Just to update on my mower. Still no issues with the original problem, however one of the rear wheel height adjuster handles broke while I was mowing today, unexpectedly. So it looks like I'll get to see how that bearing and the axle is holding up on that side. Now to order the replacement part.

#54

Mow'N Weeds

Mow'N Weeds

I see 'em free with issues on local CL almost daily, lol. Usually the 6.5 Tecumseh models. As soon as they go up, someone is on 'em. I've only scored one and honestly I didn't even really want it, I was just getting irritated about not getting the ones I wanted to so when that one came up near me I ran to get it just to piss everyone else off, lol!Don't get any better than a Toro........my last one which I used for 15 years, I just gave it to my brother and like a Timex it takes a lickin' & keeps on tickin'......

#55

B

Briantii

B

Briantii

Hey guys just an update on the zerk fittings. They work, but I still was getting enough gunk build up in the adjusters that eventually more grease would just push the dust seal out. If you're going to do it, I'd suggest getting an extra dust seal for the inside of the wheel and epoxying the dust seals - it may require trimming the bushing to make enough room for 2 dust seals.

I started a new thread showing my latest experiment - converting to bearings.

https://www.lawnmowerforum.com/show...wer-Backwards-HRR216VLA-to-bearing-conversion

Frankly I'm about done trying to re-engineer Honda's mistakes on this stuff. I may go Honda Commercial or Toro if this doesn't work.