Ok, this will be my last post to this thread. I've laid out the specifics and I'm sorry Star but you are wrong also. Making it so you have to drop the deck to grease is well, foolish and mostly a waste of time if all you want to do is hit them with a shot of grease. For God's sake, JD put those openings there for a reason, and in the process made it super fast and easy to do. I agree on the cleaning aspect but an air compressor does a lovely job as well. But I'm not going to argue any more. Just the facts...

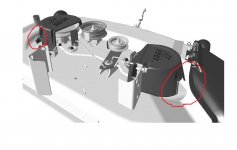

Bio, please look at the attached. I have circled the openings in the plastic covers which were specifically put there to facilitate reaching the grease fittings straight on, with no extra work. All you have to do is place your plastic covers on and look through openings I've circled. When your spindles are in the right location, you'll have an extremely simple, straight shot to hit them with the grease gun, as the tractor comes brand new. Please do that simple test. Then I think you'll see why JD put those openings there and why you need to rotate the one on the left 90 deg and the one on the right all the way around to line up with its opening.

Nuff said...