Florida

Member

- Joined

- Aug 3, 2017

- Threads

- 6

- Messages

- 18

Hello all, been searching the forums and found tons of great info getting me closer to my answer.

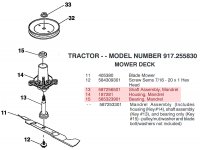

My 2017 craftsman (917.255830) is in good shape but I thought it may be wise to have some spare mandrel bearings on hand after using it for the past years.

Is replacing the bearings in the mandrel a reasonable idea? Instead of buying an entire complete mandrel assembly?

I've been trying to track down the bearing specs / P#s but I can't find the bottom bearing listed except when sold with the mandrel shaft.

Here are the current parts and cross referenced numbers I could find:

Non-electric PTO

Deck (46" Mower Complete Assy.): 583477401, 432250

Mandrel complete assy.: 587253301

Mandrel housing: 187281

Mandrel top bearing: 585323901

Mandrel shaft (w/ bottom bearing): 587256501

I did manage to find one website store that mentioned bearings for their assembly which looked like it may be the same as mine, they listed the bearings as:

TOP: 6203-2RS

BOTTOM: 6204-2RS

I figured i'd look around/ask online before tearing down and inspecting the bearings for markings.

Will update.

Cheers fellas!

My 2017 craftsman (917.255830) is in good shape but I thought it may be wise to have some spare mandrel bearings on hand after using it for the past years.

Is replacing the bearings in the mandrel a reasonable idea? Instead of buying an entire complete mandrel assembly?

I've been trying to track down the bearing specs / P#s but I can't find the bottom bearing listed except when sold with the mandrel shaft.

Here are the current parts and cross referenced numbers I could find:

Non-electric PTO

Deck (46" Mower Complete Assy.): 583477401, 432250

Mandrel complete assy.: 587253301

Mandrel housing: 187281

Mandrel top bearing: 585323901

Mandrel shaft (w/ bottom bearing): 587256501

I did manage to find one website store that mentioned bearings for their assembly which looked like it may be the same as mine, they listed the bearings as:

TOP: 6203-2RS

BOTTOM: 6204-2RS

I figured i'd look around/ask online before tearing down and inspecting the bearings for markings.

Will update.

Cheers fellas!