warreng5995

Member

- Joined

- Jan 26, 2021

- Threads

- 1

- Messages

- 22

Hey all, first time poster.

My Dad has a Dixon 4515B ZTR mower that he got from his nephew... yeah its about 20 years old, I believe it to be a 2000 model

It has a Vanguard 15.5hp OHV engine #28Q777-0691-E1 (photo attached)

It all started... thats how most projects begin right ... with repairing the mower deck where it was rusting out only in the front section, and I welded in new sheet metal and etc etc...

... with repairing the mower deck where it was rusting out only in the front section, and I welded in new sheet metal and etc etc...

In any case, engine had an oil leak that had kept slowly getting worse, so wanted to get that fixed too. Appeared to be dipstick tube seal. Went to replace it, and when doing so I began cleaning all the old oil off the mower frame etc. Began to see oil going up the side of the block up under the engine cover, realized it must be the crankshaft seal under flywheel. Went to replace that, while doing so had the carb and air intake off. Happened to look into the intake side of the head and saw it was thickly coated in baked on oil . Long story short, ended up removing engine, complete tear down, found a thick layer of baked on oil (carbon buildup) all inside of head, top of piston, valves covered (not even sure if they were closing fully) etc. Oil in bottom of case was about a 1/2" of thick gel like sludge.The apparent problem was the bottom piston ring was stuck bad with a good amount of carbon build up, oil ring was stuck but came lose fairly easily when I began to mess with it.Top ring was moved ok, but there was build up in the groove. Seemed obvious that oil had been blowing by up into head.

. Long story short, ended up removing engine, complete tear down, found a thick layer of baked on oil (carbon buildup) all inside of head, top of piston, valves covered (not even sure if they were closing fully) etc. Oil in bottom of case was about a 1/2" of thick gel like sludge.The apparent problem was the bottom piston ring was stuck bad with a good amount of carbon build up, oil ring was stuck but came lose fairly easily when I began to mess with it.Top ring was moved ok, but there was build up in the groove. Seemed obvious that oil had been blowing by up into head.

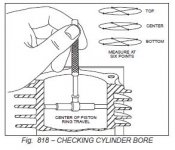

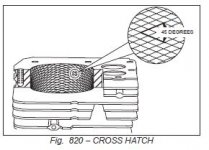

After getting everything completely disassembled and several days worth of cleaning until all parts were spotless... all internal parts looked good. No scoring on cylinder sleeve nor piston, crank and cam had no scoring and no real wear, all teeth were sharp and square (not worn). Cam pressure release looked and operated just fine. Governor gearing was perfect, no wear, operated fine. etc etc .Got full engine gasket and seal kit, ring set, full carb rebuild kit including new float and float bowl (after cleaning found a tiny pin hole in old bowl). Rebuilt entire engine, including deglazing cylinder sleeve, lapping valves, as well as checking head and block for "flatness" using a slab of granite I keep in the shop. Used engine assembly lube on crank, cam, rod connector, pin, etc etc etc. Torqed everything to B&S specs as listed in their service manual, including the head in correct 3 rounds of increasing torque to final spec, and in correct order.

Reinstalled engine onto mower, and finished up installing carb, starter ect. Filled with conventional 10w30 oil and new B&S filter.

Took mower out for a short run, seemed to run good but not the power that it should have had. When engaging electric clutch for mower deck, engine bogged down significantly before coming back up to speed. When cutting any grass that was thick at all or "taller" than the rest, could hear the engine bog. At first thought maybe governor tab might needed adjusting (carb doesn't really have any adjustments but one) etc. Brought mower in and parked it as I didn't have the time that day.

Fast forward to two days ago, my Dad took mower out cut for about 20 min (just to test as grass isn't tall just beginning to grow), I could hear the mower bogging some as before etc. UPS truck shows up at our gate, my Dad drives down shuts mower off. UPS leaves, mower cranks but will not restart, doesn't even try to hit. I was in the shop, heard it, walked down to see what the problem was. Couldn't see any reason, thought maybe it either wasn't getting fuel or it was flooded. Tried some starter fluid in the air intake, nothing... must be flooded. Towed it back up to the shop. Started to pull plug when I noticed some fluid in the vacuum line going from crankcase breather to the fuel pump (I use the 1/4" silicone transparent fuel lines on anything I replace now days due to issues I've had with the old style lines, which is why I could see the fluid in the line). Took line off fuel pump, poured it out into my hand and it appears to be a mix of oil and gas. Ok... fuel pump membrane must have a hole in it. Checked oil, level was good and no indication of the presence of gas. Bought new fuel pump and air filter (even though the one on it was fairly new). Ran again... more fluid in vacuum line, but this time it was only oil.

Spoke again with Kevin who owns my local Stihl dealer, I buy most of my small engines parts, saws, etc from him as they are good people to work with and knowledgeable.The only other thing he (and myself) could think of is if the crank case breather spring was broke or something blocking it etc. Replaced crankcase breather with new. Ran again for a few min, line clear. Seemed like it fixed that issue, but engine still didn't have the power it should.

Today decided to recheck valve clearances, they were a bit off, and I will say they sure are touchy... finally was satisfied I had the clearances correct. Took mower out, power was much improved... but still bogged some. Wanted to run it longer, get engine up to full temp etc. Mowed about 20 min or so. Brought back into shop, oil was back in the vacuum line yet again, and engine would not restart.

I'm out of ideas... just doesn't make sense to me. If I hadn't just replaced the head gasket and etc, I would say a blown head gasket was possibly the issues. And that it was pushing a bit of pressure into crankcase. which in turn was pushing the oil through the breather. But I just did the headgasket with everything else with all brand new B&S parts.

Any input would be much appreciated

Edit: Just thought I would note that Italics button works, but "Bold" text doesn't appear to be working on here for some reason...

My Dad has a Dixon 4515B ZTR mower that he got from his nephew... yeah its about 20 years old, I believe it to be a 2000 model

It has a Vanguard 15.5hp OHV engine #28Q777-0691-E1 (photo attached)

It all started... thats how most projects begin right

In any case, engine had an oil leak that had kept slowly getting worse, so wanted to get that fixed too. Appeared to be dipstick tube seal. Went to replace it, and when doing so I began cleaning all the old oil off the mower frame etc. Began to see oil going up the side of the block up under the engine cover, realized it must be the crankshaft seal under flywheel. Went to replace that, while doing so had the carb and air intake off. Happened to look into the intake side of the head and saw it was thickly coated in baked on oil

After getting everything completely disassembled and several days worth of cleaning until all parts were spotless... all internal parts looked good. No scoring on cylinder sleeve nor piston, crank and cam had no scoring and no real wear, all teeth were sharp and square (not worn). Cam pressure release looked and operated just fine. Governor gearing was perfect, no wear, operated fine. etc etc .Got full engine gasket and seal kit, ring set, full carb rebuild kit including new float and float bowl (after cleaning found a tiny pin hole in old bowl). Rebuilt entire engine, including deglazing cylinder sleeve, lapping valves, as well as checking head and block for "flatness" using a slab of granite I keep in the shop. Used engine assembly lube on crank, cam, rod connector, pin, etc etc etc. Torqed everything to B&S specs as listed in their service manual, including the head in correct 3 rounds of increasing torque to final spec, and in correct order.

Reinstalled engine onto mower, and finished up installing carb, starter ect. Filled with conventional 10w30 oil and new B&S filter.

Took mower out for a short run, seemed to run good but not the power that it should have had. When engaging electric clutch for mower deck, engine bogged down significantly before coming back up to speed. When cutting any grass that was thick at all or "taller" than the rest, could hear the engine bog. At first thought maybe governor tab might needed adjusting (carb doesn't really have any adjustments but one) etc. Brought mower in and parked it as I didn't have the time that day.

Fast forward to two days ago, my Dad took mower out cut for about 20 min (just to test as grass isn't tall just beginning to grow), I could hear the mower bogging some as before etc. UPS truck shows up at our gate, my Dad drives down shuts mower off. UPS leaves, mower cranks but will not restart, doesn't even try to hit. I was in the shop, heard it, walked down to see what the problem was. Couldn't see any reason, thought maybe it either wasn't getting fuel or it was flooded. Tried some starter fluid in the air intake, nothing... must be flooded. Towed it back up to the shop. Started to pull plug when I noticed some fluid in the vacuum line going from crankcase breather to the fuel pump (I use the 1/4" silicone transparent fuel lines on anything I replace now days due to issues I've had with the old style lines, which is why I could see the fluid in the line). Took line off fuel pump, poured it out into my hand and it appears to be a mix of oil and gas. Ok... fuel pump membrane must have a hole in it. Checked oil, level was good and no indication of the presence of gas. Bought new fuel pump and air filter (even though the one on it was fairly new). Ran again... more fluid in vacuum line, but this time it was only oil.

Spoke again with Kevin who owns my local Stihl dealer, I buy most of my small engines parts, saws, etc from him as they are good people to work with and knowledgeable.The only other thing he (and myself) could think of is if the crank case breather spring was broke or something blocking it etc. Replaced crankcase breather with new. Ran again for a few min, line clear. Seemed like it fixed that issue, but engine still didn't have the power it should.

Today decided to recheck valve clearances, they were a bit off, and I will say they sure are touchy... finally was satisfied I had the clearances correct. Took mower out, power was much improved... but still bogged some. Wanted to run it longer, get engine up to full temp etc. Mowed about 20 min or so. Brought back into shop, oil was back in the vacuum line yet again, and engine would not restart.

I'm out of ideas... just doesn't make sense to me. If I hadn't just replaced the head gasket and etc, I would say a blown head gasket was possibly the issues. And that it was pushing a bit of pressure into crankcase. which in turn was pushing the oil through the breather. But I just did the headgasket with everything else with all brand new B&S parts.

Any input would be much appreciated

Edit: Just thought I would note that Italics button works, but "Bold" text doesn't appear to be working on here for some reason...

Attachments

Last edited: