rajthepilot

Member

- Joined

- Jun 1, 2023

- Threads

- 8

- Messages

- 23

Hello,

The drive belt came off of my Snapper Pro S200XT. I'll be ordering a new belt today, but I still wanted to put the old one on, just so I understand the process. (When adding the new one, I know I'll have to remove the mower belt and clutch plate as well).

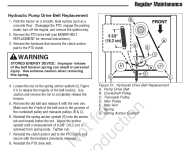

Using step 4 of the attached picture from the manual, I loosened the nut on the spring anchor eyebolt. I then removed the nut and the spring. The old belt took a lot of effort in getting back on, even though idler pulley was free to move around.

Is that supposed to happen or it should get on the idler pulley easily when the spring is not attached?

I finally used a flathead screw driver to help get the belt on, but now I cannot move the idler pulley forward enough to be able to put the spring anchor eyebolt back on. I'm attaching few pictures of what it looks like now. Is there any way in the world that the belt could have shrunk in size? Just wondering. I'm assuming it would stretch out over its life.

And also want to confirm that the clean side of belt should be on the outside and these grooves side should be on the inside on the transaxle and crankshaft pulley. (And on the idler pulley, the grooves should be outside and clean belt should be inside?)

Thank You

The drive belt came off of my Snapper Pro S200XT. I'll be ordering a new belt today, but I still wanted to put the old one on, just so I understand the process. (When adding the new one, I know I'll have to remove the mower belt and clutch plate as well).

Using step 4 of the attached picture from the manual, I loosened the nut on the spring anchor eyebolt. I then removed the nut and the spring. The old belt took a lot of effort in getting back on, even though idler pulley was free to move around.

Is that supposed to happen or it should get on the idler pulley easily when the spring is not attached?

I finally used a flathead screw driver to help get the belt on, but now I cannot move the idler pulley forward enough to be able to put the spring anchor eyebolt back on. I'm attaching few pictures of what it looks like now. Is there any way in the world that the belt could have shrunk in size? Just wondering. I'm assuming it would stretch out over its life.

And also want to confirm that the clean side of belt should be on the outside and these grooves side should be on the inside on the transaxle and crankshaft pulley. (And on the idler pulley, the grooves should be outside and clean belt should be inside?)

Thank You

Attachments

-

Hydraulic Pump Drive Belt Replacement.png129.1 KB · Views: 23

Hydraulic Pump Drive Belt Replacement.png129.1 KB · Views: 23 -

20230616_064904.jpg702 KB · Views: 22

20230616_064904.jpg702 KB · Views: 22 -

20230616_064921.jpg641.6 KB · Views: 21

20230616_064921.jpg641.6 KB · Views: 21 -

20230616_070355.jpg599.6 KB · Views: 20

20230616_070355.jpg599.6 KB · Views: 20 -

20230616_070416.jpg654.6 KB · Views: 20

20230616_070416.jpg654.6 KB · Views: 20 -

20230616_070452.jpg574.9 KB · Views: 19

20230616_070452.jpg574.9 KB · Views: 19 -

20230616_070455.jpg599.3 KB · Views: 21

20230616_070455.jpg599.3 KB · Views: 21