You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Well, my X360 blew up....

- Thread starter lkaskel

- Start date

More options

Export threadAuto Doc's

Lawn Addict

- Joined

- Sep 7, 2024

- Threads

- 19

- Messages

- 1,799

Hello L.,Hi Everyone,

This is just a note for everyone regarding my experience. I wish I had more to share...

I have a 2013 JD X360 that mainly gets used to cut my 1-acre lot on a slight hill. The hill is so slight that I can cut up and down or across with no issues. The only other thing I use it for is to pull my Agrifab leaf vac (I got this in 2024) in the fall. On Saturday, I was cutting the grass and something violent and tragic happened inside the engine. It came apart big time. It did not come through the side of the block but the engine was seized at that point. I do have a local small engine shop/lawn mower junk yard and he had an X320 with a 22hp engine (slightly more hours) so I was able to get it replaced with that one. A new one was $3500 so that was not an option. He has not taken the engine apart yet but said that he found the oil at a normal level and looked like it was ready to be changed. That makes sense as it would have been done in the next few weeks before winter storage. I pick it up tomorow so we shall see.

For some stats:

2013 X360 with the 22hp motor

545 hours

Oil and filter every year as I store it in the fall. I use the the JD LG265 service kit

If anyone has had a similar experience I would be interested in knowing more for interested than anything. It’s one of those things I could not do anything about. I had the mower serviced for the 1st 5 years by the local JD shop where it was purchased. I change the oil, air filter, plugs and fuel filter annually as they all come with the service kit. I only put about 40-50 hours on it each year. I did the transmission/steering filter service at ~200 and 400 hours as well (longer than recommended I know).

545 hrs. and about 12 seasons of use. I think you discovered the "lifetime" limit of that particular engine. I see similar models around here that seldom survive over 350 hrs. It is mostly due to lots of sand and poor customer maintenance habits.

I recently had a fairly new Cub Cadet that did not make it 100 hours because nothing was maintained except refilling it with fuel. The crank was seized in the top crank journal of the engine block so bad it could not even be pressed out.

Tiger Small Engine

Lawn Addict

- Joined

- Dec 7, 2022

- Threads

- 3

- Messages

- 1,623

The Kawasaki FH series engine puts it at about 20 years old, must be new old stock. Look on the silver sticker for date of manufacture. Unless it is a used engine. The Kawasaki FS series engine is basically the FR series with a better air filter and something else minor. No reason you can’t get closer to 2000 hours on the FS series with proper maintenance. I would say it was infrequent oil changes and run low on oil over an extended period of time to cause the connecting rod to break.Well, here is the update. I picked the mower up and it, of course, runs great with the replacement engine. The guy at the shop did say that there was not a nest or any debris under the shroud or in the fins. It was a connecting rod that broke and he said that he had seen this before engines. He also said that the replacement engine was one that he sees a lot of in commercial equipment vs the engine that blew seems to be more for lawn tractor use. The engine that he put in it is a Kawasaki FH661V and the engine that blew is a Kawasaki FS651V. Not that any of this means anything. I just cut my grass with it and was greatful to find a local shop that could help out.......

- Joined

- Feb 19, 2020

- Threads

- 118

- Messages

- 12,716

And the FX has a even better filter system. The FS uses the same filter system as the FR. I got one customer that has well over 3000 hrs on several of engines with one that just pass 4000 hrs. The only internal work so far has been an oil pump replacement. Now one did bite the dust but it had an oil drain leaking and his nephew didn't to take of the mower at all. The third time was the charm as the owner no longer loans his ZTRs to the nephew. He runs these Z900 mowers series commercially.

I actually have a parts list to make up the filter conversion kits to upgrade the FR/FS to FX filter system thanks to some Australian friends.

I actually have a parts list to make up the filter conversion kits to upgrade the FR/FS to FX filter system thanks to some Australian friends.

Last edited:

These are mower engines not the space shuttle.What RPM was the engine ran at, ALL the time. Idle down for warm ups? Idle down for cool off's? Low RPM's to save gas?

Regarding the oil change frequency and low oil. I changed the oil and filter, air filter and fuel filter every year and I averaged 40-50 hours a year so I am well within the hours requirement (listed at 100 hours). I also had recently checked the oil and it was good. I know it's super easy to "blame" the operator as we do not care but that's not me.The Kawasaki FH series engine puts it at about 20 years old, must be new old stock. Look on the silver sticker for date of manufacture. Unless it is a used engine. The Kawasaki FS series engine is basically the FR series with a better air filter and something else minor. No reason you can’t get closer to 2000 hours on the FS series with proper maintenance. I would say it was infrequent oil changes and run low on oil over an extended period of time to cause the connecting rod to break.

Auto Doc's

Lawn Addict

- Joined

- Sep 7, 2024

- Threads

- 19

- Messages

- 1,799

Hi L.,

These days (and for the past 20+ years), machines are manufactured to minimum specifications to save money. That means they are keeping figures on what will make it just past the expected warranty period before the manufacturer is no longer liable.

It is not a matter of oil changes in this case. It is a matter of how it was manufactured.

Personally, I would rather repower an older machine and revive it than I would to buy a new overpriced one. The addition of fuel injection, electronics and "smart controls" are just making matters worse.

These days (and for the past 20+ years), machines are manufactured to minimum specifications to save money. That means they are keeping figures on what will make it just past the expected warranty period before the manufacturer is no longer liable.

It is not a matter of oil changes in this case. It is a matter of how it was manufactured.

Personally, I would rather repower an older machine and revive it than I would to buy a new overpriced one. The addition of fuel injection, electronics and "smart controls" are just making matters worse.

FR FS AND FX engines are all the same basic engines. Air filters are different Carbs are different between HPs. Seems to be a reliable engine if maintained properly. Worse thing I see is the valve train.

Funky setup. Had a FX 850 in the shop for service. Don't remember the hours but well past the 300 hours they recommend adjusting the valves.The EX-valve had .080 clearance. Went to adjust it and the valve train was worn out. Sorry set up. If you have never seen the setup, it has two ears that stick up and a pin goes through the two ears and the rocker arms ride on the pin between the ears. There is a tab that sticks down from the valve cover to hold the pin in place. The tab is too far from the end of the pin and allows the pin to work out far enough that the end of the pin is not supported enough to keep it from wallowing the ear out and thus allowing the clearance to increase. Had to replace both heads.

Funky setup. Had a FX 850 in the shop for service. Don't remember the hours but well past the 300 hours they recommend adjusting the valves.The EX-valve had .080 clearance. Went to adjust it and the valve train was worn out. Sorry set up. If you have never seen the setup, it has two ears that stick up and a pin goes through the two ears and the rocker arms ride on the pin between the ears. There is a tab that sticks down from the valve cover to hold the pin in place. The tab is too far from the end of the pin and allows the pin to work out far enough that the end of the pin is not supported enough to keep it from wallowing the ear out and thus allowing the clearance to increase. Had to replace both heads.

- Joined

- Feb 19, 2020

- Threads

- 118

- Messages

- 12,716

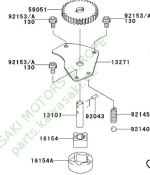

Question just where is the pin on the 11022-7025 rocker cover? I don't see one. Now the heads do have pin to keep the rocker bracket from turning on the screw and they do break off requiring a head replacement.If you have never seen the setup, it has two ears that stick up and a pin goes through the two ears and the rocker arms ride on the pin between the ears. There is a tab that sticks down from the valve cover to hold the pin in place. The tab is too far from the end of the pin and allows the pin to work out far enough that the end of the pin is not supported enough to keep it from wallowing the ear out and thus allowing the clearance to increase. Had to replace both heads.

.

It was a serious question. Wondering if he lugged it around the yard every mow killing the cooling and lubrication.These are mower engines not the space shuttle.

Fully agree, not the space shuttle LOL.