You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Troubleshooting Starting Issue?

#1

L

LeakyBriggs

L

LeakyBriggs

Hello lawn and engine folks. Having an issue now with my lawn tractor starting

Details:

Older Simplicity Regency (20 years? Not sure. Time and memory gets away...)

Briggs & Stratton 22HP Intel V-Twin

Valve cover stamp:

Model 44K777

Type 0115 E1

Code 071015YG.

Issue I'm having is a no start situation. Meaning the engine does not turn over when turning the key to on.

Things I've confirmed:

Battery is good.

Foot pedal switch is not blocked and presses in normally.

When turning the switch to "On", the fuel cutoff solenoid clicks.

But that's it. Not sure where to start for troubleshooting. You know, test here first, if good, move to here, test, if good, move to here.

Thanks for any input & help.

LeakyBriggs.

Details:

Older Simplicity Regency (20 years? Not sure. Time and memory gets away...)

Briggs & Stratton 22HP Intel V-Twin

Valve cover stamp:

Model 44K777

Type 0115 E1

Code 071015YG.

Issue I'm having is a no start situation. Meaning the engine does not turn over when turning the key to on.

Things I've confirmed:

Battery is good.

Foot pedal switch is not blocked and presses in normally.

When turning the switch to "On", the fuel cutoff solenoid clicks.

But that's it. Not sure where to start for troubleshooting. You know, test here first, if good, move to here, test, if good, move to here.

Thanks for any input & help.

LeakyBriggs.

#2

M

mechanic mark

www.briggsandstratton.com

Post 7 digit Simplicity Model Number. Start with battery load test, hands on all electrical connections including ignition switch etc.

www.briggsandstratton.com

Post 7 digit Simplicity Model Number. Start with battery load test, hands on all electrical connections including ignition switch etc.

M

mechanic mark

Results

#3

R

Rivets

R

Rivets

Here is the procedure I use and have posted many times. Each tech on this site has their own so you might have to pick the one which works best for you. Simplicity model is on the frame, under the foot rest.

Electrical problems can be very easy or very difficult, depending on four things.

1. How well you understand basic electricity.

2. What tools you have and know how to use.

3. How well you follow directions.

4. You don't overlook or assume anything and verify everything.

Remember we cannot see what you are doing. You are our eyes, ears and fingers in solving this problem. You must be as accurate as you can when you report back. The two basic tools we will ask you to use are a test light and a multi-meter. If you have an assistant when going through these tests it would be very helpful. These steps work the best when done in order, so please don't jump around. Now let's solve this problem.

First, check the fuse(s), check battery connections for corrosion (clean if necessary) and voltage - above 12.5 volts should be good. Check and make sure the chassis ground is clean and tight.

Second, check for power from the battery to one of the large terminals on the solenoid. One of the wires is connected directly to the battery and has power all the time so one of the large terminals should light a test light or show 12 volts on a meter at all times.

Third, check for power at the small terminal of the solenoid while depressing the clutch/brake pedal and holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch). If your solenoid is a four wire solenoid, check both small wire terminals as one is ground and the other is power from the ignition switch. If your solenoid is a three wire solenoid, make sure the solenoid body is not corroded where it bolts to the chassis of the mower as this is your ground path back to the battery. If in doubt, remove the solenoid and clean the mounting area down to bare metal. If there is no power to the small terminal then your problem is most likely a safety switch, ignition switch or in the wiring.

Fourth, check for power on the other large terminal of the solenoid while holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch).

Fifth, check for power at the starter while holding the key in the start position (assistant again).

Sixth, check your ground circuit back to the battery.

After you have gone through each of the above steps, let us know what happened when you did each step. At that point we will have great info to tell you how to proceed. Remember you are our eyes, ears, and fingers, so please be as accurate as possible.

Be as specific as possible with voltage readings as this will help diagnose your problem quicker. If you do not know how to perform the above checks, just ask and I will try to guide you through it. Youtube also has some videos and as you know a picture is worth a thousand words.

Electrical problems can be very easy or very difficult, depending on four things.

1. How well you understand basic electricity.

2. What tools you have and know how to use.

3. How well you follow directions.

4. You don't overlook or assume anything and verify everything.

Remember we cannot see what you are doing. You are our eyes, ears and fingers in solving this problem. You must be as accurate as you can when you report back. The two basic tools we will ask you to use are a test light and a multi-meter. If you have an assistant when going through these tests it would be very helpful. These steps work the best when done in order, so please don't jump around. Now let's solve this problem.

First, check the fuse(s), check battery connections for corrosion (clean if necessary) and voltage - above 12.5 volts should be good. Check and make sure the chassis ground is clean and tight.

Second, check for power from the battery to one of the large terminals on the solenoid. One of the wires is connected directly to the battery and has power all the time so one of the large terminals should light a test light or show 12 volts on a meter at all times.

Third, check for power at the small terminal of the solenoid while depressing the clutch/brake pedal and holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch). If your solenoid is a four wire solenoid, check both small wire terminals as one is ground and the other is power from the ignition switch. If your solenoid is a three wire solenoid, make sure the solenoid body is not corroded where it bolts to the chassis of the mower as this is your ground path back to the battery. If in doubt, remove the solenoid and clean the mounting area down to bare metal. If there is no power to the small terminal then your problem is most likely a safety switch, ignition switch or in the wiring.

Fourth, check for power on the other large terminal of the solenoid while holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch).

Fifth, check for power at the starter while holding the key in the start position (assistant again).

Sixth, check your ground circuit back to the battery.

After you have gone through each of the above steps, let us know what happened when you did each step. At that point we will have great info to tell you how to proceed. Remember you are our eyes, ears, and fingers, so please be as accurate as possible.

Be as specific as possible with voltage readings as this will help diagnose your problem quicker. If you do not know how to perform the above checks, just ask and I will try to guide you through it. Youtube also has some videos and as you know a picture is worth a thousand words.

#4

L

LeakyBriggs

Thanks.

L

LeakyBriggs

Simplicity Part# 2690575 (How it's labeled on sticker on frame.)Post 7 digit Simplicity Model Number. Start with battery load test, hands on all electrical connections including ignition switch etc.Results

www.briggsandstratton.com

Thanks.

#5

L

LeakyBriggs

I have no assistant. But I do have a good meter and alligator test leads.

I will report back after going through your list.

Thanks again to both current replies and others are welcome.

LeakyBriggs.

L

LeakyBriggs

Thanks! I will be going through this with it soon. May take me a day or two with work and other things.Here is the procedure I use and have posted many times. Each tech on this site has their own so you might have to pick the one which works best for you. Simplicity model is on the frame, under the foot rest.

Electrical problems can be very easy or very difficult, depending on four things.

1. How well you understand basic electricity.

2. What tools you have and know how to use.

3. How well you follow directions.

4. You don't overlook or assume anything and verify everything.

Remember we cannot see what you are doing. You are our eyes, ears and fingers in solving this problem. You must be as accurate as you can when you report back. The two basic tools we will ask you to use are a test light and a multi-meter. If you have an assistant when going through these tests it would be very helpful. These steps work the best when done in order, so please don't jump around. Now let's solve this problem.

First, check the fuse(s), check battery connections for corrosion (clean if necessary) and voltage - above 12.5 volts should be good. Check and make sure the chassis ground is clean and tight.

Second, check for power from the battery to one of the large terminals on the solenoid. One of the wires is connected directly to the battery and has power all the time so one of the large terminals should light a test light or show 12 volts on a meter at all times.

Third, check for power at the small terminal of the solenoid while depressing the clutch/brake pedal and holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch). If your solenoid is a four wire solenoid, check both small wire terminals as one is ground and the other is power from the ignition switch. If your solenoid is a three wire solenoid, make sure the solenoid body is not corroded where it bolts to the chassis of the mower as this is your ground path back to the battery. If in doubt, remove the solenoid and clean the mounting area down to bare metal. If there is no power to the small terminal then your problem is most likely a safety switch, ignition switch or in the wiring.

Fourth, check for power on the other large terminal of the solenoid while holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch).

Fifth, check for power at the starter while holding the key in the start position (assistant again).

Sixth, check your ground circuit back to the battery.

After you have gone through each of the above steps, let us know what happened when you did each step. At that point we will have great info to tell you how to proceed. Remember you are our eyes, ears, and fingers, so please be as accurate as possible.

Be as specific as possible with voltage readings as this will help diagnose your problem quicker. If you do not know how to perform the above checks, just ask and I will try to guide you through it. Youtube also has some videos and as you know a picture is worth a thousand words.

I have no assistant. But I do have a good meter and alligator test leads.

I will report back after going through your list.

Thanks again to both current replies and others are welcome.

LeakyBriggs.

#6

P

packardv8

P

packardv8

Every rider I've owned in the past fifty years has eventually developed electrical problems. Nearly every time it was in the OEM wiring connections and safety switches. The path to the spark plugs and the PTO runs through so many cheapo connections, corrosion and heat combine to stop the flow.

The official fix is to find the offending article and replace it. Then soon after find and replace the next; a merry-go-round.

The unapproved fix is to simplify the wiring and use industrial quality switches for the few actually required to operate the machine.

jack vines

The official fix is to find the offending article and replace it. Then soon after find and replace the next; a merry-go-round.

The unapproved fix is to simplify the wiring and use industrial quality switches for the few actually required to operate the machine.

jack vines

#8

L

LeakyBriggs

L

LeakyBriggs

Awesome replies. Thanks to all. I will dive in fully with the meter this weekend and let ya'll know how things go.

One thing that I noticed but left out, (sorry) is that with the switch on, when you pull the PTO to engage the blade clutch, nothing happens.

Normally you can hear it engage even if the engine is off, no one is sitting in the seat, and no one is pressing the clutch pedal.

One thing that I noticed but left out, (sorry) is that with the switch on, when you pull the PTO to engage the blade clutch, nothing happens.

Normally you can hear it engage even if the engine is off, no one is sitting in the seat, and no one is pressing the clutch pedal.

#9

B

bertsmobile1

B

bertsmobile1

The PTO should not engage is there is no one in the seat , engine running or engine not running

Also note that if Star has posted the correct wiring diagram ( and he usually does ) that the seat switch plug has a anti-tamper shorting strip.

This type of plug is notorious for causing gries as on many of them the strip shorts out even when the plug is locked into the socket .

I have starteed to cut them off and fit standard sockets when I can get them because I am fed up with warranty call backs because of these garbage plugs .

To test your mower I use shart patch ( fancy name for jumper ) wires with a male on each end to connec the female terminals of the plugs as follows

Key, Red to Blue

Reverse blue to lue

PTO green to blue

Brake Green to yellow

IF the motor cranks when the Green to yellow is jumped ( do it last ) then the wires are good between the plugs

If not one of the plug wires is bad .

After that I use some longer ones to bypass each switch one at a time

so

Key blue at the reverse switch plug to solenoid Yellow engine should cank every time the key is on start , proves key switch is working

Reverse blue at PTO plug to solenoid as above proves reverse relay

PTO green to solenoid Yellow proves PTO switch is working

Note you may need to suspend yourself from the ceiling like a bat to get to some of the plugs

Also note that if Star has posted the correct wiring diagram ( and he usually does ) that the seat switch plug has a anti-tamper shorting strip.

This type of plug is notorious for causing gries as on many of them the strip shorts out even when the plug is locked into the socket .

I have starteed to cut them off and fit standard sockets when I can get them because I am fed up with warranty call backs because of these garbage plugs .

To test your mower I use shart patch ( fancy name for jumper ) wires with a male on each end to connec the female terminals of the plugs as follows

Key, Red to Blue

Reverse blue to lue

PTO green to blue

Brake Green to yellow

IF the motor cranks when the Green to yellow is jumped ( do it last ) then the wires are good between the plugs

If not one of the plug wires is bad .

After that I use some longer ones to bypass each switch one at a time

so

Key blue at the reverse switch plug to solenoid Yellow engine should cank every time the key is on start , proves key switch is working

Reverse blue at PTO plug to solenoid as above proves reverse relay

PTO green to solenoid Yellow proves PTO switch is working

Note you may need to suspend yourself from the ceiling like a bat to get to some of the plugs

#11

L

LeakyBriggs

L

LeakyBriggs

Thanks for the latest information. Working on wrapping my head around the schematics as I'm not that good at it.

One thing I will respectively disagree with is that the PTO should not engage if there is no one in the seat.

Maybe that is what StarTech is explaining above?

Normal operation from the factory has been:

-If the key is in the on position and you're even just standing beside it-pull the PTO button out and the PTO will engage with an audible click. This will occur without being in the seat and the clutch pedal not being depressed.

-If you leave the PTO in the on position in this scenario, and try to start, no power will be sent to the starter even if you're in the seat with the clutch pedal depressed.

My current situation just as a recap:

No start when turning key.

Fuel cutoff solenoid clicks.

PTO does not engage when pulling button out and start switch in on position.

Battery is good.

All the responses, directions, and diagrams have been extremely helpful. Will try to use details from all of them this weekend to see what the problem may be.

Leaky.

One thing I will respectively disagree with is that the PTO should not engage if there is no one in the seat.

Maybe that is what StarTech is explaining above?

Normal operation from the factory has been:

-If the key is in the on position and you're even just standing beside it-pull the PTO button out and the PTO will engage with an audible click. This will occur without being in the seat and the clutch pedal not being depressed.

-If you leave the PTO in the on position in this scenario, and try to start, no power will be sent to the starter even if you're in the seat with the clutch pedal depressed.

My current situation just as a recap:

No start when turning key.

Fuel cutoff solenoid clicks.

PTO does not engage when pulling button out and start switch in on position.

Battery is good.

All the responses, directions, and diagrams have been extremely helpful. Will try to use details from all of them this weekend to see what the problem may be.

Leaky.

#12

M

mechanic mark

www.simplicitymfg.com

OEM Simplicity Parts are listed above.

www.simplicitymfg.com

OEM Simplicity Parts are listed above.

Pick up a 12 volt test light at Harbor Freight, Auto Parts Store for troubleshooting. Clip to ground & test continuity at connections should light up.

M

mechanic mark

Manuals & Parts for your Simplicity machine – Simplicity

Need to find the owner's manual or small engine parts for your Simplicity lawn equipment? Simply use our search engine to find Simplicity parts and manuals.

Pick up a 12 volt test light at Harbor Freight, Auto Parts Store for troubleshooting. Clip to ground & test continuity at connections should light up.

#13

B

bertsmobile1

The PTO should not be on when you try to start the engine because it puts a bigger load on the mower and because the equally brain dead could crank the engine standing next to the mower with their toes under the deck and ger a pedicure at the anckle

OR standing on the deck and get tangled beteren belts & pulleys which can also remove a childs foot

These are the reasons why responsible techs never ever bypass a seat switch

B

bertsmobile1

The PTO should not engage when your bum is not in the seat to prevent the brain dead from getting a manicure at wrist level when clearin a blocked chute with the blades running.One thing I will respectively disagree with is that the PTO should not engage if there is no one in the seat.

Maybe that is what StarTech is explaining above?

The PTO should not be on when you try to start the engine because it puts a bigger load on the mower and because the equally brain dead could crank the engine standing next to the mower with their toes under the deck and ger a pedicure at the anckle

OR standing on the deck and get tangled beteren belts & pulleys which can also remove a childs foot

These are the reasons why responsible techs never ever bypass a seat switch

#14

StarTech

StarTech

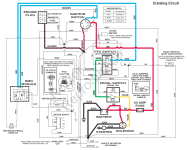

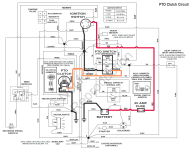

Bert, Your thinking is off on this one. The way this mower is wired it doesn't matter if your are on the seat or not except when the engine is running then the seat becomes involved it would shutdown the engine. But the PTO is live anytime the ignition is in run or start positions. It is just the engine will not crank if the PTO switch is on (in engaged position). Also the engine will crank with no one on the seat and the PTO is off but it will not run as long as the brake.clutch pedal is depressed.

This is why I posted the PTO circuit diagram.

This is why I posted the PTO circuit diagram.

#15

B

bertsmobile1

Obviously if the engine does not crank the blade can not lop your toes off

Not some thing I have ever come across so it may be they need to be wired differently down here .

B

bertsmobile1

Dunces cap is on and standing in the cornerBert, Your thinking is off on this one. The way this mower is wired it doesn't matter if your are on the seat or not except when the engine is running then the seat becomes involved it would shutdown the engine. But the PTO is live anytime the ignition is in run or start positions. It is just the engine will not crank if the PTO switch is on (in engaged position). Also the engine will crank with no one on the seat and the PTO is off but it will not run as long as the brake.clutch pedal is depressed.

This is why I posted the PTO circuit diagram.

Obviously if the engine does not crank the blade can not lop your toes off

Not some thing I have ever come across so it may be they need to be wired differently down here .

#16

StarTech

StarTech

Bert it just that wiring can be different. Plus electrical diagnostics it one of my strong points but 45+ years of reading these diagrams is major plus. All of us have different amounts of experience. There are things that I not able to do lack of knowledge or ability. One is no how much I try to learn to play the piano I just can't get it. I just keep trying to analysis it.

Wiring has changed over the years as manufactures as they become aware of different safety issues over time. It just they are getting better at preventing the consumer from bypassing safety switches. This usually involved more electronics or relays so they have more electrical issues over time.

But looking this Simplicity wiring it could be made to crank with the blades engaged if certain safety switches are bypassed. Personally I never recommend anyone other than a knowledgeable tech that knows to take extra safety precautions to prevent injury to bypass any safety switch.

Even when these decks are disengaged the blades could still turn if the deck has a malfunction. I saved a customer several years ago from getting his hand chopped up. We were unloading a mower when the deck hung on the tailgate of the truck. He started reaching to grab the deck when I grab him as I saw the rotating blades where he was trying to put his hands. I had the operator shut down the mower and we manually unloaded the mower. Later I found that someone had rigged up the deck which I corrected.

Wiring has changed over the years as manufactures as they become aware of different safety issues over time. It just they are getting better at preventing the consumer from bypassing safety switches. This usually involved more electronics or relays so they have more electrical issues over time.

But looking this Simplicity wiring it could be made to crank with the blades engaged if certain safety switches are bypassed. Personally I never recommend anyone other than a knowledgeable tech that knows to take extra safety precautions to prevent injury to bypass any safety switch.

Even when these decks are disengaged the blades could still turn if the deck has a malfunction. I saved a customer several years ago from getting his hand chopped up. We were unloading a mower when the deck hung on the tailgate of the truck. He started reaching to grab the deck when I grab him as I saw the rotating blades where he was trying to put his hands. I had the operator shut down the mower and we manually unloaded the mower. Later I found that someone had rigged up the deck which I corrected.

#17

Tiger Small Engine

Tiger Small Engine

Electrical issues continue to be somewhat intimidating to me, however, I have gotten a lot better. The multimeter and test light are your friends. Does anyone have any tips on electrical diagnostic problems? I can sort of read an electrical diagram, but rarely do.Bert it just that wiring can be different. Plus electrical diagnostics it one of my strong points but 45+ years of reading these diagrams is major plus. All of us have different amounts of experience. There are things that I not able to do lack of knowledge or ability. One is no how much I try to learn to play the piano I just can't get it. I just keep trying to analysis it.

Wiring has changed over the years as manufactures as they become aware of different safety issues over time. It just they are getting better at preventing the consumer from bypassing safety switches. This usually involved more electronics or relays so they have more electrical issues over time.

But looking this Simplicity wiring it could be made to crank with the blades engaged if certain safety switches are bypassed. Personally I never recommend anyone other than a knowledgeable tech that knows to take extra safety precautions to prevent injury to bypass any safety switch.

Even when these decks are disengaged the blades could still turn if the deck has a malfunction. I saved a customer several years ago from getting his hand chopped up. We were unloading a mower when the deck hung on the tailgate of the truck. He started reaching to grab the deck when I grab him as I saw the rotating blades where he was trying to put his hands. I had the operator shut down the mower and we manually unloaded the mower. Later I found that someone had rigged up the deck which I corrected.

#18

StarTech

StarTech

Just don't forget to do voltage drop tests when hunting a problem. Most problems are straight forward but some can be a royal pain to find without doing voltage drop tests.

#19

Japgolf

problem was nothing no clicks no nadda. While cleaning the engine I found a mouse nest between two metal plates, one plate

is for the lower frame and the other plate supports the battery, my wiring harness ran between those two metal plates. Almost

impossible to see but these critters chewed the wires in two between the plates. Disconnected the whole harness repaired

the open wires but rerouted the harness to the side instead of between the metal plates started right up and with a couple of

new deck pulleys runs fine. As Star Teck stated above take your measuremnts if the tests point to open or shorted wires check

to see if your wiring harness runs between the above mentioned plates.

Japgolf

I have the same simplicity machine that I got as a free be because it would chew up deck belts and would not startup. My no startJust don't forget to do voltage drop tests when hunting a problem. Most problems are straight forward but some can be a royal pain to find without doing voltage drop tests.

problem was nothing no clicks no nadda. While cleaning the engine I found a mouse nest between two metal plates, one plate

is for the lower frame and the other plate supports the battery, my wiring harness ran between those two metal plates. Almost

impossible to see but these critters chewed the wires in two between the plates. Disconnected the whole harness repaired

the open wires but rerouted the harness to the side instead of between the metal plates started right up and with a couple of

new deck pulleys runs fine. As Star Teck stated above take your measuremnts if the tests point to open or shorted wires check

to see if your wiring harness runs between the above mentioned plates.

#20

O

Oatsman

check for blown head gasket.

Could also be pressure release on the camshaft.

O

Oatsman

set the valves.Hello lawn and engine folks. Having an issue now with my lawn tractor starting

Details:

Older Simplicity Regency (20 years? Not sure. Time and memory gets away...)

Briggs & Stratton 22HP Intel V-Twin

Valve cover stamp:

Model 44K777

Type 0115 E1

Code 071015YG.

Issue I'm having is a no start situation. Meaning the engine does not turn over when turning the key to on.

Things I've confirmed:

Battery is good.

Foot pedal switch is not blocked and presses in normally.

When turning the switch to "On", the fuel cutoff solenoid clicks.

But that's it. Not sure where to start for troubleshooting. You know, test here first, if good, move to here, test, if good, move to here.

Thanks for any input & help.

LeakyBriggs.

check for blown head gasket.

Could also be pressure release on the camshaft.

#21

L

Laabk2

L

Laabk2

While working on an old Dixon Ram 50 I encountered a starting problem, chased my tail for a week only to finally figure out that there was a ground issue. Enough of a ground for everything to work but as soon as you tried to start it, nothing worked.

#22

L

LeakyBriggs

L

LeakyBriggs

Ok. I finally got a chance to check some things with my meter for further input.

Battery condition: 13.45 Volts (Just removed the charger.)

Pulled fuse and tested. It tones to be good. (Ohm continuity.)

Testing with meter:

-Black lead on negative/ground of battery-Red lead to first terminal of the solenoid block from battery with large red wire:

13.43 Volts

-Black lead on negative/ground of battery-Red lead to small terminal of solenoid block. It's the one nearest battery with a yellow wire:

0.00 Volts standing beside mower. (No one sitting on or doing anything related to mower operation.)

0.00 Volts sitting on mower, pressing clutch pedal, turning switch to on position, and turning switch to start position.

-Black lead on negative/ground of battery-Red lead to small terminal of solenoid block. It's the one nearest the steering wheel with a black wire.

.025 Volts standing beside the mower.

.070 Volts when sitting on mower and pressing clutch pedal.

12.94 Volts when sitting on mower, pressing clutch pedal, and turning key to start position.

-Black lead on negative/ground of battery-Red lead to terminal of solenoid block nearest steering wheel. Following it, wire appears to go to starter. Larger red wire like from battery.

0.00 Volts standing beside mower.

0.00 Volts sitting on mower, pressing clutch pedal, turning switch to on position, and turning switch to start position.

-Black lead on negative/ground of battery-Red lead to terminal of the starter.

0.00 Volts standing beside mower.

0.00 Volts sitting on mower, pressing clutch pedal, turning switch to on position, and turning switch to start position.

That's all my testing thus far. Will test further if this points to something or y'all have further ideas. She still no go!

(Hope coloring some words etc. in this post is ok. Just helps me read it easier and thought it might do the same for others.)

Thanks again all!

Leaky...

Battery condition: 13.45 Volts (Just removed the charger.)

Pulled fuse and tested. It tones to be good. (Ohm continuity.)

Testing with meter:

-Black lead on negative/ground of battery-Red lead to first terminal of the solenoid block from battery with large red wire:

13.43 Volts

-Black lead on negative/ground of battery-Red lead to small terminal of solenoid block. It's the one nearest battery with a yellow wire:

0.00 Volts standing beside mower. (No one sitting on or doing anything related to mower operation.)

0.00 Volts sitting on mower, pressing clutch pedal, turning switch to on position, and turning switch to start position.

-Black lead on negative/ground of battery-Red lead to small terminal of solenoid block. It's the one nearest the steering wheel with a black wire.

.025 Volts standing beside the mower.

.070 Volts when sitting on mower and pressing clutch pedal.

12.94 Volts when sitting on mower, pressing clutch pedal, and turning key to start position.

-Black lead on negative/ground of battery-Red lead to terminal of solenoid block nearest steering wheel. Following it, wire appears to go to starter. Larger red wire like from battery.

0.00 Volts standing beside mower.

0.00 Volts sitting on mower, pressing clutch pedal, turning switch to on position, and turning switch to start position.

-Black lead on negative/ground of battery-Red lead to terminal of the starter.

0.00 Volts standing beside mower.

0.00 Volts sitting on mower, pressing clutch pedal, turning switch to on position, and turning switch to start position.

That's all my testing thus far. Will test further if this points to something or y'all have further ideas. She still no go!

(Hope coloring some words etc. in this post is ok. Just helps me read it easier and thought it might do the same for others.)

Thanks again all!

Leaky...

#23

L

LeakyBriggs

L

LeakyBriggs

Here's a picture of my solenoid/terminal junction where the majority of the testing I'm referring too above is done if it helps.

Attachments

#24

R

Rivets

R

Rivets

Looking at the wiring diagram that Star posted, the picture you posted and your explanation, I would be replacing the solenoid. Reason I say this is you have voltage coming from the switch, yellow wire, but the solenoid is not engaging to send voltage to the starter. Before buying a new solenoid clean the solenoid mounting and the other small terminal on the solenoid black wire and retest. If the solenoid doesn’t engage again replace.

#26

R

Rivets

R

Rivets

I just reread your testing post and I made a mistake. I thought you had voltage at the yellow wire attached to the solenoid which you were on the seat, brake depressed, PTO off. This would have been my third test. If doing this test resulted in 0VDC you will then have to find where you are dropping your 12 VDC. At this point a good test light is better than a meter. This can be tedious, time consuming and drive a sane person crazy. Patience is your best friend at this time. Experienced techs who understand how the different switched work have figured out how to jump or bypass different switches, but I’m not going to get into that. I’ll try to help more if you have more questions.

#27

L

LeakyBriggs

L

LeakyBriggs

Thanks. I keep coming back to the PTO test as a way to chase the voltage loss.

Reason being is that the PTO will from the factory engage regardless of safety switches when the key is on in the "run" position. Don't have to be in the seat and don't have to press the brake/clutch/safety switch.

So if a safety switch was bad, in my head it wouldn't matter because they had no bearing on the PTO engaging.

But that may be wrong thinking....

Currently when the key is in the "run" position the PTO will not engage as it normally would.

Reason being is that the PTO will from the factory engage regardless of safety switches when the key is on in the "run" position. Don't have to be in the seat and don't have to press the brake/clutch/safety switch.

So if a safety switch was bad, in my head it wouldn't matter because they had no bearing on the PTO engaging.

But that may be wrong thinking....

Currently when the key is in the "run" position the PTO will not engage as it normally would.

#28

R

Rivets

R

Rivets

NUMBER 1 RULE IN ELECTRICAL TROUBLESHOOTING IS NEVER ASSUME ANYTHING!!! Yes PTO switches do go bad, but unless you full understand how your PTO switch works. First, question I want to answer before testing a PTO switch is, is the starting circuit of the switch I’m working on NC or NO? The switch in Star’s diagram is NC, so current should go straight through from the RMO MODULE to the PTO switch to the pedal switch.

#29

Tiger Small Engine

Tiger Small Engine

I have replaced 5 or 6 PTO switches this year. NC=normally closed, NO= normally open (for those not sure).NUMBER 1 RULE IN ELECTRICAL TROUBLESHOOTING IS NEVER ASSUME ANYTHING!!! Yes PTO switches do go bad, but unless you full understand how your PTO switch works. First, question I want to answer before testing a PTO switch is, is the starting circuit of the switch I’m working on NC or NO? The switch in Star’s diagram is NC, so current should go straight through from the RMO MODULE to the PTO switch to the pedal switch.

#31

L

LeakyBriggs

L

LeakyBriggs

Here's a dumb question: How do you disconnect the wiring harness from the foot pedal switch for testing?

I've disconnected various harnesses from various things & usually there's a clip you push down or pull up. Then wiggle and slide off.

This is on here pretty tight and I don't seem to see a clip to hold it.

Just don't want to unnecessarily break anything.

Thanks.

I've disconnected various harnesses from various things & usually there's a clip you push down or pull up. Then wiggle and slide off.

This is on here pretty tight and I don't seem to see a clip to hold it.

Just don't want to unnecessarily break anything.

Thanks.

#32

L

LeakyBriggs

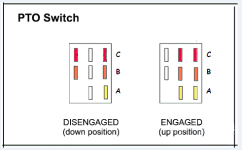

Other VOLTAGE tests I performed if it helps is to test the harness this attaches too in the following manner.

-Black Lead of the multimeter connected at the negative of the battery.

-Red Lead used to touch each connection point in the wiring harness.

-All points read 0.00 on the multimeter

Turn key to ON position

-Black Lead of the multimeter connected at the negative of the battery.

-Red Lead used to touch each connection point in the wiring harness.

-12.4 Volts found at position A of the wiring harness of the outside connection. It is yellow in the diagram above on the left. (Down Position)

-All other points read 0.00 on the multimeter.

(Remember though, I'm testing the wiring harness. Not the PTO switch above. Just using that diagram to indicate location on the harness.)

Turn key to START position and hold there

-Black Lead of the multimeter connected at the negative of the battery.

-Red Lead used to touch each connection point in the wiring harness.

-12.4 Volts found at position C of the wiring harness of the outside connection. It is white in the diagram above on the right. (Up Position)

-All other points read 0.00 on the multimeter.

(Again, I'm testing the wiring harness. Not the PTO switch above. Just using that diagram to indicate location on the harness.)

L

LeakyBriggs

Using this diagram. The switch tests to have continuity where it should in the positions noted.View attachment 67171

Colors just test points for continuity.

Other VOLTAGE tests I performed if it helps is to test the harness this attaches too in the following manner.

-Black Lead of the multimeter connected at the negative of the battery.

-Red Lead used to touch each connection point in the wiring harness.

-All points read 0.00 on the multimeter

Turn key to ON position

-Black Lead of the multimeter connected at the negative of the battery.

-Red Lead used to touch each connection point in the wiring harness.

-12.4 Volts found at position A of the wiring harness of the outside connection. It is yellow in the diagram above on the left. (Down Position)

-All other points read 0.00 on the multimeter.

(Remember though, I'm testing the wiring harness. Not the PTO switch above. Just using that diagram to indicate location on the harness.)

Turn key to START position and hold there

-Black Lead of the multimeter connected at the negative of the battery.

-Red Lead used to touch each connection point in the wiring harness.

-12.4 Volts found at position C of the wiring harness of the outside connection. It is white in the diagram above on the right. (Up Position)

-All other points read 0.00 on the multimeter.

(Again, I'm testing the wiring harness. Not the PTO switch above. Just using that diagram to indicate location on the harness.)

#33

L

LeakyBriggs

L

LeakyBriggs

I should have noted in the tests above that there was no one in the seat and the seat switch has always worked as designed fyi.

I got the foot switch wiring harness loose. The clasp is on the bottom on this one if anyone needs to know. And the switch is gray/white AND black plastic. The mistake I made was thinking the black part on the SWITCH was part of the harness. It's not. At least not on this one.

I'll try to attach a few pictures related to the footswitch.

One with a multimeter test lead showing the blade connections I have continuity with on the left if facing the blades.

One with a multimeter test lead showing the blade connections I have continuity with on the right if facing the blades.

One showing the connection point of the wiring harness.

And finally, one showing the blade on the wiring harness that I have 12.4 Volts at when switching the key to start.

-Black test lead on the negative battery cable during this test.

-No one in the seat.

-All other wiring harness connections here register low to no voltage regardless of key position.

Tell us anything? What to test next? Same problem persists.

Thanks,

Leaky.

I got the foot switch wiring harness loose. The clasp is on the bottom on this one if anyone needs to know. And the switch is gray/white AND black plastic. The mistake I made was thinking the black part on the SWITCH was part of the harness. It's not. At least not on this one.

I'll try to attach a few pictures related to the footswitch.

One with a multimeter test lead showing the blade connections I have continuity with on the left if facing the blades.

One with a multimeter test lead showing the blade connections I have continuity with on the right if facing the blades.

One showing the connection point of the wiring harness.

And finally, one showing the blade on the wiring harness that I have 12.4 Volts at when switching the key to start.

-Black test lead on the negative battery cable during this test.

-No one in the seat.

-All other wiring harness connections here register low to no voltage regardless of key position.

Tell us anything? What to test next? Same problem persists.

Thanks,

Leaky.

Attachments

#34

L

LeakyBriggs

L

LeakyBriggs

I jumpered the foot switch wiring harness from the point that has voltage to the one above it.

That's the way the foot switch seems to operate. When pushed in there is continuity between those terminal posts on the switch.

No change in problem. Still no start. Just an update.

Thanks.

That's the way the foot switch seems to operate. When pushed in there is continuity between those terminal posts on the switch.

No change in problem. Still no start. Just an update.

Thanks.

#35

L

LeakyBriggs

L

LeakyBriggs

Ok, as I ignorantly chase my tail back and forth....lol....

I pulled the solenoid. 4 point/post solenoid.

I put 12 Volts across the blades and it clicks solidly every time.

Put a meter on continuity on the screw terminals and it rings for continuity when I charge the solenoid at the blades.

Put it back on the mower.

Battery good.

Connections cleaned and triple checked.

12 Volts confirmed from battery to solenoid.

12 Volts confirmed to the starter side blade when turning the key to start with the clutch pedal pushed in.

However, turning the key with the clutch pedal pushed in and voltage confirmed at the starter side blade....

there is no voltage to the starter wire connection of the solenoid.

Any ideas what that tells us?

Thanks,

Leaky.

I pulled the solenoid. 4 point/post solenoid.

I put 12 Volts across the blades and it clicks solidly every time.

Put a meter on continuity on the screw terminals and it rings for continuity when I charge the solenoid at the blades.

Put it back on the mower.

Battery good.

Connections cleaned and triple checked.

12 Volts confirmed from battery to solenoid.

12 Volts confirmed to the starter side blade when turning the key to start with the clutch pedal pushed in.

However, turning the key with the clutch pedal pushed in and voltage confirmed at the starter side blade....

there is no voltage to the starter wire connection of the solenoid.

Any ideas what that tells us?

Thanks,

Leaky.

#36

L

LeakyBriggs

L

LeakyBriggs

Well, well, well....ya'll didn't think I was one of those that got a little information and disappeared without a conclusion did ya'?

I got fed up with this mower and shoved it in the shed, put a tarp on it, and waited for warmer weather. Spring has come and I started going through things again.

Long story short, I found the footswitch has an intermittent break in it. A smallish "Sweet Spot" where it starts and operates as it should.

Still leaks oil though.

I got fed up with this mower and shoved it in the shed, put a tarp on it, and waited for warmer weather. Spring has come and I started going through things again.

Long story short, I found the footswitch has an intermittent break in it. A smallish "Sweet Spot" where it starts and operates as it should.

Still leaks oil though.