You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Swapping Kohler CV730S for a B&S 44N877 - can't figure out 6-pin harness

#1

C

cmrho

C

cmrho

Firstly, thanks for your help. I've been scouring the interweb but cannot find the info I need.

The old 26hp Kohler CV730 gave out so I replaced it with a Briggs & Stratton 24hp engine (model 44N877). The 6 pin connector on the mower side has the following color wires: orange, red, black, blue/red, white (5 wires). I cannot find anywhere what those wires correspond to. I've figured out that the Briggs & Stratton 6 pin connector on the engine side has the following wires: red + red (jumpered - alternator and light switch), black (magneto), grey (fuel solenoid), green (oil pressure).

I've looked through both the service and operations manual for the CV730 and nowhere can I find the description of the wires for the mower-side connector, just the description of the connector wiring on the engine side. Does anyone know what the wire colors on the mower side for the Kohler engine correspond to the B&S connector? I've attached what information I've been able to find.

The old 26hp Kohler CV730 gave out so I replaced it with a Briggs & Stratton 24hp engine (model 44N877). The 6 pin connector on the mower side has the following color wires: orange, red, black, blue/red, white (5 wires). I cannot find anywhere what those wires correspond to. I've figured out that the Briggs & Stratton 6 pin connector on the engine side has the following wires: red + red (jumpered - alternator and light switch), black (magneto), grey (fuel solenoid), green (oil pressure).

I've looked through both the service and operations manual for the CV730 and nowhere can I find the description of the wires for the mower-side connector, just the description of the connector wiring on the engine side. Does anyone know what the wire colors on the mower side for the Kohler engine correspond to the B&S connector? I've attached what information I've been able to find.

Attachments

#4

B

bertsmobile1

B

bertsmobile1

If you still have both mowers remove both blower housings

The only different thing will be the solenoid trigger wire

Mark the mowers wires where they went to on the old engine

Alternator, carb solenoid & magneto kill are the only connections you need

The blue wire that went to the starter will now have to go to the remote solenoid

And of course you will have to fit a remote solenoid.

The thin wire that went on the same starter terminal as the battery lead will go to the same place on the new solenoid as it powers the mower.

And of course you will need a starter cable to go from the new solenoid to the starter on the B & S engine.

The only different thing will be the solenoid trigger wire

Mark the mowers wires where they went to on the old engine

Alternator, carb solenoid & magneto kill are the only connections you need

The blue wire that went to the starter will now have to go to the remote solenoid

And of course you will have to fit a remote solenoid.

The thin wire that went on the same starter terminal as the battery lead will go to the same place on the new solenoid as it powers the mower.

And of course you will need a starter cable to go from the new solenoid to the starter on the B & S engine.

#5

H

hlw49

H

hlw49

The problem you could run into is the fuel solenoid wire. If you look at the Kohler engine harness you will notice a blue/red wire together the reason for this is that on the Kohler engine harness is that on some mowers the switch will drop the circuit that feeds the fuel shut off solenoid out when you turn the key to the start position. Thus the red and blue wire together so the exciter wire blue will feed the fuel solenoid in the start position. The Kohler engine harness runs a wire from the starter exciter with to the fuel shut off solenoid with a diode in it so it won't feed the starter exciter wire and run the starter all the time. If you cut the Kohler harness open you see it has two diodes in it. one to feed the fuel solenoid in the start circuit and one to run the solenoid in the run position. You will have to wire these into the gray wire on the Briggs that feeds the fuel solenoid in the start circuit and the single red or red/purple wire that feeds the solenoid in the run position. Purple wire is the charge lead wire on the Kohler it should only be hot when key is. Hope I didn't miss anything. WHEW

#7

C

cmrho

C

cmrho

Thanks. Pages 35 and 36 of what document?The info is on pages 35 and 36; just takes a little deciphering.

#8

C

cmrho

C

cmrho

Ok, I took the blower housing off the old CV730 and matched it to the mower-side harness:

Harness connection - blue-red -----> Engine connection (no wire)

Harness connection -black -----> Engine connection (white - alternator)

Harness connection - red -----> Engine connection (purple and orange, orange is jumpered to purple, purple goes to rectifier regulator)

Harness connection - white -----> Engine connection (blue and red, blue to starter solenoid, red to carb solenoid)

Harness connection - empty -----> Engine connection (green, not connected to anything but suspect it would go to oil level sensor)

Harness connection - orange -----> Engine connection (red and orange, orange is jumpered to red, red goes to carb solenoid)

The two red wires on the engine side appear to go to 2 diodes which meet to a single red wire going to the carb solenoid.

The B&S engine side connection was listed in the first post: red (alternator), red (jumpered from red - goes to light switch), black (magneto), green (oil level), grey (fuel solenoid). At least that's what I think. I didn't want to open up the blower housing on a brand new engine. The interesting thing is that there is a grey AND black wire going to the carb solenoid on the B&S engine.

I've installed a starter solenoid and wired to the white wire on the harness. And the black wire (harness connection) to the red wire (engine side connection). The rest, I don't know. There is no 'magneto' wire on the current mower-side harness.

Harness connection - blue-red -----> Engine connection (no wire)

Harness connection -black -----> Engine connection (white - alternator)

Harness connection - red -----> Engine connection (purple and orange, orange is jumpered to purple, purple goes to rectifier regulator)

Harness connection - white -----> Engine connection (blue and red, blue to starter solenoid, red to carb solenoid)

Harness connection - empty -----> Engine connection (green, not connected to anything but suspect it would go to oil level sensor)

Harness connection - orange -----> Engine connection (red and orange, orange is jumpered to red, red goes to carb solenoid)

The two red wires on the engine side appear to go to 2 diodes which meet to a single red wire going to the carb solenoid.

The B&S engine side connection was listed in the first post: red (alternator), red (jumpered from red - goes to light switch), black (magneto), green (oil level), grey (fuel solenoid). At least that's what I think. I didn't want to open up the blower housing on a brand new engine. The interesting thing is that there is a grey AND black wire going to the carb solenoid on the B&S engine.

I've installed a starter solenoid and wired to the white wire on the harness. And the black wire (harness connection) to the red wire (engine side connection). The rest, I don't know. There is no 'magneto' wire on the current mower-side harness.

#9

C

cmrho

Ok, I took the blower housing off the old CV730 and matched it to the mower-side harness:

Harness connection - blue-red -----> Engine connection (no wire)

Harness connection -black -----> Engine connection (white - alternator)

Harness connection - red -----> Engine connection (purple and orange, orange is jumpered to purple, purple goes to rectifier regulator)

Harness connection - white -----> Engine connection (blue and red, blue to starter solenoid, red to carb solenoid)

Harness connection - empty -----> Engine connection (green, not connected to anything but suspect it would go to oil level sensor)

Harness connection - orange -----> Engine connection (red and orange, orange is jumpered to red, red goes to carb solenoid)

The two red wires on the engine side appear to go to 2 diodes which meet to a single red wire going to the carb solenoid.

The B&S engine side connection was listed in the first post: red (alternator), red (jumpered from red - goes to light switch), black (magneto), green (oil level), grey (fuel solenoid). At least that's what I think. I didn't want to open up the blower housing on a brand new engine. The interesting thing is that there is a grey AND black wire going to the carb solenoid on the B&S engine.

I've installed a starter solenoid and wired to the white wire on the harness. And the black wire (harness connection) to the red wire (engine side connection). The rest, I don't know. There is no 'magneto' wire on the current mower-side harness.

C

cmrho

Replied to main thread but I did what you said:If you still have both mowers remove both blower housings

The only different thing will be the solenoid trigger wire

Mark the mowers wires where they went to on the old engine

Alternator, carb solenoid & magneto kill are the only connections you need

The blue wire that went to the starter will now have to go to the remote solenoid

And of course you will have to fit a remote solenoid.

The thin wire that went on the same starter terminal as the battery lead will go to the same place on the new solenoid as it powers the mower.

And of course you will need a starter cable to go from the new solenoid to the starter on the B & S engine.

Ok, I took the blower housing off the old CV730 and matched it to the mower-side harness:

Harness connection - blue-red -----> Engine connection (no wire)

Harness connection -black -----> Engine connection (white - alternator)

Harness connection - red -----> Engine connection (purple and orange, orange is jumpered to purple, purple goes to rectifier regulator)

Harness connection - white -----> Engine connection (blue and red, blue to starter solenoid, red to carb solenoid)

Harness connection - empty -----> Engine connection (green, not connected to anything but suspect it would go to oil level sensor)

Harness connection - orange -----> Engine connection (red and orange, orange is jumpered to red, red goes to carb solenoid)

The two red wires on the engine side appear to go to 2 diodes which meet to a single red wire going to the carb solenoid.

The B&S engine side connection was listed in the first post: red (alternator), red (jumpered from red - goes to light switch), black (magneto), green (oil level), grey (fuel solenoid). At least that's what I think. I didn't want to open up the blower housing on a brand new engine. The interesting thing is that there is a grey AND black wire going to the carb solenoid on the B&S engine.

I've installed a starter solenoid and wired to the white wire on the harness. And the black wire (harness connection) to the red wire (engine side connection). The rest, I don't know. There is no 'magneto' wire on the current mower-side harness.

#10

M

MParr

M

MParr

Flip up the seat and look on the bottom of the seat pan. You will see a model number and a serial number. Here’s the deal, some Craftsman mowers were made by MTD and some were made by AYP/Husqvarna.This is a Craftsman DYT4000

#11

C

cmrho

C

cmrho

It says Craftsman model 917.275901Flip up the seat and look on the bottom of the seat pan. You will see a model number and a serial number. Here’s the deal, some Craftsman mowers were made by MTD and some were made by AYP/Husqvarna.

#12

M

MParr

M

MParr

Get you some masking tape and label the wires coming off of the ignition switch to wiring harnesses of the Kohler engine. You may have to take the switch out and make note of the lettering on the back of the switch. This will go a long way in helping you to get you up and running.

#14

C

cmrho

C

cmrho

Thanks all. I cut open the harness on the CV730 and did confirm what y'all said. There are 2 red wires to the carb sol. One appears to be activated at the same time as the starter sol (so when the key is turned to the start position). But then that wire goes neutral when the key goes back to the on position. So then the other red wire, which is jumpered to the alternator, activates the carb sol.? The diodes in both the red wires eliminates current backfeed, particularly to the starter sol. I have everything figured out except: How does the old harness setup kill the new engine? I'm guessing that in the old engine, it cuts the connection to the red wire powering the carb sol. while the engine is running, which kills the engine. I don't have that on the new engine. All I have is a single grey wire that goes to the carb sol., not 2. Do I jumper the new carb sol. wire to the alternator in addition to the old harness starter wire?

#15

C

cmrho

C

cmrho

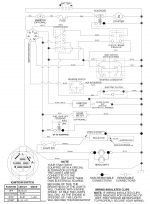

Thanks for this. I'm not an electronics technician by training, but see what you're talking about. So this means that the fuel solenoid needs to be jumpered to the alternator correct? So when the engine is running, the solenoid activates?Ahh now I see what is needed. Look at the fuel solenoid and regulator connection on the following diagram. They are tied together. Also the ignition switch is not wired the same as in the Kohler service manual.

Your mower wiring schematic

View attachment 57538

#16

H

hlw49

H

hlw49

Do you own a test light and a VOA meter is you do you can test the switch an each position as to what they do. Key off probe the wire for continuity to ground this would be the ignition kill circuit. Turn to run position and probe with test light that would be fuel solenoid and charge wire if you get two circuits. If just one fuel solenoid. Turn key to start position that one would be the starter exciter wire. If you have a blue wire with a red jumper that will be fuel solenoid wire and it has to have a diode in it when you connect it to the gray wire. Probe the wires that were hot in the run position and turn key to start position if one of them goes out that will be the fuel solenoid wire and you have to have a diode in wire and the blue wire with the red jumper so they will not feed back into the other circuits.

#17

C

cmrho

C

cmrho

Great tips. Thanks!Do you own a test light and a VOA meter is you do you can test the switch an each position as to what they do. Key off probe the wire for continuity to ground this would be the ignition kill circuit. Turn to run position and probe with test light that would be fuel solenoid and charge wire if you get two circuits. If just one fuel solenoid. Turn key to start position that one would be the starter exciter wire. If you have a blue wire with a red jumper that will be fuel solenoid wire and it has to have a diode in it when you connect it to the gray wire. Probe the wires that were hot in the run position and turn key to start position if one of them goes out that will be the fuel solenoid wire and you have to have a diode in wire and the blue wire with the red jumper so they will not feed back into the other circuits.

#18

C

cmrho

C

cmrho

Did as you said. Nothing is making sense. Even with the seat switch and brake switch activated, I'm getting no current on any of the wires coming off the harness in either the on or start position. But weirdly, I get current on a few of them when the key is completely off. I am completely stumped.Great tips. Thanks!

#19

C

cmrho

C

cmrho

Well, I'm at my wit's end. Nothing is making sense. I suspect there's a kill switch somewhere that I don't know about. But I'm not getting any current through any of the wires coming out of the switch when in the on position. I might throw in the towel and just buy a new mower. Anyone want to buy a brand new Briggs & Stratton engine, lol? Thanks for the help y'all.

#20

StarTech

StarTech

This why professional like me go to school when are young to learn things like how to read schematics. Personally I spent two year going to a technical school. Even many repair shops in my aread have techs that have no idea of what they are actually doing and just guess at it. Every year I get multiple jobs where the local shop have screwed up a customer's mower wiring. This includes the local JD dealer that cant find a bad oil pressure switch, loose connection, or even a bad spark plug.

No wonder one my customers brought a Z950M from the dealer but will not let them even touch it under warranty.

It is much cheaper to let a confident mechanic install your engine than buy a new mower since you have already gone the process of buying a new engine.

No wonder one my customers brought a Z950M from the dealer but will not let them even touch it under warranty.

It is much cheaper to let a confident mechanic install your engine than buy a new mower since you have already gone the process of buying a new engine.

#21

C

cmrho

C

cmrho

I get it. But some people like love doing this type of stuff. Yeah, we screw things up sometimes. But a lot times we don't. When we do, we learn from it, and it makes us better. I don't mind paying someone to do work. But if there's a challenge and I'm able, I'll try it first.This why professional like me go to school when are young to learn things like how to read schematics. Personally I spent two year going to a technical school. Even many repair shops in my aread have techs that have no idea of what they are actually doing and just guess at it. Every year I get multiple jobs where the local shop have screwed up a customer's mower wiring. This includes the local JD dealer that cant find a bad oil pressure switch, loose connection, or even a bad spark plug.

No wonder one my customers brought a Z950M from the dealer but will not let them even touch it under warranty.

It is much cheaper to let a confident mechanic install your engine than buy a new mower since you have already gone the process of buying a new engine.

#22

StarTech

StarTech

But there even time us techs got to admit we are in over our heads and ask for help. In this case it one of those things that must in front of me as i is hard to teach all the basics and then directly to advance level all with a few days.

I have been doing this since '79 when I graduated from tech school. Even then it was going other tech for in person training that got to where I am now. One of hte resource someone electronics which cover basic wiring is the ARRL Hardbook.

Even now I see service manual that are done so poorly that the need info is simply not available unless other tech are willing to part with their knowledge. The problem with me is that I run a full time shop and on top that I am past 60. I probably forgot more than most entry level techs ever knew to start with.

It is really embarrassing to me to have supposedly factory trained JD mechanic to tell a customer their does not have oil pump even it is glaring obvious when an oil is present and the IPL itself shows an oil pump.

I have been doing this since '79 when I graduated from tech school. Even then it was going other tech for in person training that got to where I am now. One of hte resource someone electronics which cover basic wiring is the ARRL Hardbook.

Even now I see service manual that are done so poorly that the need info is simply not available unless other tech are willing to part with their knowledge. The problem with me is that I run a full time shop and on top that I am past 60. I probably forgot more than most entry level techs ever knew to start with.

It is really embarrassing to me to have supposedly factory trained JD mechanic to tell a customer their does not have oil pump even it is glaring obvious when an oil is present and the IPL itself shows an oil pump.

#23

C

cmrho

C

cmrho

Ok, I got the engine running by using a separate start switch to energize the starter solenoid, and cutting the harness off the old engine and wiring to the new one. It runs perfectly for 38-43 seconds. Like clockwork. Every time it hits that time range, the engine cuts out. Any idea what could be causing it?

#24

C

cmrho

C

cmrho

Ok, final post, because I have it working. The issue with the engine cutting out after 40 seconds was in the PTO engage/disengage switch. Something in the switch was killing the engine even though it was disengaged. I put that switch completely out and put in a rocker switch to engage the clutch. I know I'll catch hell for this from some of you, because it bypasses the seat switch, but it is what it is.

For the record, I solved the electrical connection issues by cutting the connector off the old engine, cutting the connector off the new engine, then matching the wires on a 1-1 match from the old connection to new one. The only difference in the new engine wiring was the presence of the oil sensor wire, which the old one didn't have. So the engine-side harness didn't have a connection to it anyway.

I mounted and wired a new starter solenoid, which was not present on the B&S engine. I then wired a hot wire from the battery to the momentary switch, which went to the starter solenoid.

To activate the PTO, I mounted a panel-mount rocker switch that activated a hot wire. This was spliced into the PTO clutch hot wire.

Thanks for the help all. While it turned out to be a workable solution, next time I'll just buy a Kohler replacement engine. Since they were twice the cost of the B&S, I paid for it by doing that. Lesson learned.

For the record, I solved the electrical connection issues by cutting the connector off the old engine, cutting the connector off the new engine, then matching the wires on a 1-1 match from the old connection to new one. The only difference in the new engine wiring was the presence of the oil sensor wire, which the old one didn't have. So the engine-side harness didn't have a connection to it anyway.

I mounted and wired a new starter solenoid, which was not present on the B&S engine. I then wired a hot wire from the battery to the momentary switch, which went to the starter solenoid.

To activate the PTO, I mounted a panel-mount rocker switch that activated a hot wire. This was spliced into the PTO clutch hot wire.

Thanks for the help all. While it turned out to be a workable solution, next time I'll just buy a Kohler replacement engine. Since they were twice the cost of the B&S, I paid for it by doing that. Lesson learned.

#25

StarTech

StarTech

Just shows you when someone with the lack the knowledge they can still hack up a system in order to get to run, even it is in an unsafe condition now.

The OP saved a lot money by switching over to a Briggs engine but was such a tightwad that wasn't willing to pay a little to have it professionally wired. For under under $100 in my shop he could have saved all frayed nerves, cuss words, and the likes.

Just don't be so stubborn next time.

Also note this was an easy job for someone that knew what they were doing.

The OP saved a lot money by switching over to a Briggs engine but was such a tightwad that wasn't willing to pay a little to have it professionally wired. For under under $100 in my shop he could have saved all frayed nerves, cuss words, and the likes.

Just don't be so stubborn next time.

Also note this was an easy job for someone that knew what they were doing.

#26

M

MParr

M

MParr

Wouldn’t it have been easier to purchase a Briggs and Stratton ignition switch, wiring harness and solenoid to make it work correctly?Just shows you when someone with the lack the knowledge they can still hack up a system in order to get to run, even it is in an unsafe condition now.

The OP saved a lot money by switching over to a Briggs engine but was such a tightwad that wasn't willing to pay a little to have it professionally wired. For under under $100 in my shop he could have saved all frayed nerves, cuss words, and the likes.

Just don't be so stubborn next time.

Also note this was an easy job for someone that knew what they were doing.

#27

C

cmrho

If I experienced the attitude you display now as a potential customer, I wouldn't have used your shop anyway. Yeah, I'm sure you've seen a lot of stupid stuff. But it doesn't mean you show it. Thanks again for the schematic and the small assistance you provided. Have a nice day.

C

cmrho

I appreciated your assistance earlier in the thread. Your assumptive arrogance is certainly not appreciated now. I would've happily paid $100 to have this fixed by a 'pro'. I called 3 different shops. None of them would touch the electrical system. The mower isn't in an unsafe position. The seat switch still kills the engine. The only difference is that the PTO runs in reverse, which it didn't before. No biggie.Just shows you when someone with the lack the knowledge they can still hack up a system in order to get to run, even it is in an unsafe condition now.

The OP saved a lot money by switching over to a Briggs engine but was such a tightwad that wasn't willing to pay a little to have it professionally wired. For under under $100 in my shop he could have saved all frayed nerves, cuss words, and the likes.

Just don't be so stubborn next time.

Also note this was an easy job for someone that knew what they were doing.

If I experienced the attitude you display now as a potential customer, I wouldn't have used your shop anyway. Yeah, I'm sure you've seen a lot of stupid stuff. But it doesn't mean you show it. Thanks again for the schematic and the small assistance you provided. Have a nice day.

#28

C

cmrho

C

cmrho

Easier? I'm not sure. It should've worked with the current harness and switch. I wired the engine-side connector exactly the same as in the old engine. But it didn't work. After installing a separate starter solenoid wire, the PTO clutch wouldn't engage with that switch. I'm not sure a B&S harness would've addressed that. As I said, next time I'll replace the engine with the same brand engine. Presumably, that would've reduced the headache of the electrical system mismatch. Again, it's a lesson learned. Thanks for your help! And thanks for holding back the condescending attitude towards a DIYer. It takes a real pro to do that.Wouldn’t it have been easier to purchase a Briggs and Stratton ignition switch, wiring harness and solenoid to make it work correctly?

#29

M

MParr

Like you said, it is what it is. And, a direct Kohler switch would have save a lot of time and headache. ?

M

MParr

The B&S #591393 wiring harness should have plugged right up. You would likely have to change your starter switch to match the wiring harness.Easier? I'm not sure. It should've worked with the current harness and switch. I wired the engine-side connector exactly the same as in the old engine. But it didn't work. After installing a separate starter solenoid wire, the PTO clutch wouldn't engage with that switch. I'm not sure a B&S harness would've addressed that. As I said, next time I'll replace the engine with the same brand engine. Presumably, that would've reduced the headache of the electrical system mismatch. Again, it's a lesson learned. Thanks for your help! And thanks for holding back the condescending attitude towards a DIYer. It takes a real pro to do that.

Like you said, it is what it is. And, a direct Kohler switch would have save a lot of time and headache. ?

#30

StarTech

As for PTO operating in reverse without making someone isn't behind (and it does happen) as being no biggie tell that to numerous toddlers that have been injured or killed because of in attention of an operator mowing in reverse.

The main reason the other shops turned down the job they don't have the knowledge either. I deal with John Deere that can't even find a bad wire connection that is staring them in the face. Or to have them tell a customer that their engine doesn't have an oil pump and to ignore the oil pressure light when right in front of them is an oil filter. I even had one warranty case with the local Stihl dealer where they couldn't even find a bad spark plug. Sometimes I think the local JD dealer's techs couldn't find their way out of a wet paper bag with both ends open.

As for my attitude I do think people that are unwilling to admit they are in over their head are fools. I have been doing this work for over 40 yrs now. I have learn to admit my limits and to ask for plus pay for help. We all know some things but none of us will never know everything as we are humans not Gods. Most people like you are just wanting us to give you our knowledge for free but we do have families too that needs feeding and have other expenses too like the shop to be available for them to come to.

Plus employees usually draws a hourly wage. Do you work for free?

As for giving local advice I don't help others to cut my throat. I am not here to lose money; although, I am a near non profit business as it is. Ever seen the cost of a well written service manual? Or the cost of a lawyer to defend you against a claim by customer that you sold parts to that had bypassed things and had an accident?

What I know is hard earned and what you know was probably hard earn too. Natural ability to do some things are a talent just like being able to play a musical instrument which I am have no ability to do, just can't do it no matter how much a try with teachers.

All he needed was a starter solenoid, a few wire terminals, some jumper wire (various colors), a terminal housing or two and maybe a new fuse. These things I have on hand as I took the time to figure which one the OEMs used and found a resource that have them. The only things that were need was a pair of wire cutter, a wire stripper, and an open barrel terminal crimper; of course, normal hands are also required. Unlike other shops that sell complete harnesses I repair them most times as a savings for the customer and a profit for my shop.

As a shop it was worth it to invest $70 in the crimpers so I do professional factory style crimps. I actually brought a second one to have it modify for my needs. Those crimpers sold places like Walmart are just junk. Also needed is the extractor tools. The hardware is brought in 50-100 piece units except for the housing which I reason amount as I use most of the present ones. Most of terminals and housings are Molex Standard .084 in (MLX) and/or AMP versions. Actually the pins were only 0.10 ea the last time I brought them.

I did take the time to do a write up with part numbers and pictures of the commonly used terminals and housing for the PPETEN forum group. Those documents were posted in their download forum under the Briggs service info section but I recently removed them from the public forum when the Briggs crankshaft specs section. I still have the three documents available on my drive. I start writing up one for the weather pack terminals and connectors but that is a work in progress as get time and feel like working on it. Lots different ones so it is harder to figure out what the mower OEMs are using without actually seeing them.

StarTech

It wasn't assumed; you admitted that you couldn't read schematics.I appreciated your assistance earlier in the thread. Your assumptive arrogance is certainly not appreciated now. I would've happily paid $100 to have this fixed by a 'pro'. I called 3 different shops. None of them would touch the electrical system. The mower isn't in an unsafe position. The seat switch still kills the engine. The only difference is that the PTO runs in reverse, which it didn't before. No biggie.

If I experienced the attitude you display now as a potential customer, I wouldn't have used your shop anyway. Yeah, I'm sure you've seen a lot of stupid stuff. But it doesn't mean you show it. Thanks again for the schematic and the small assistance you provided. Have a nice day.

As for PTO operating in reverse without making someone isn't behind (and it does happen) as being no biggie tell that to numerous toddlers that have been injured or killed because of in attention of an operator mowing in reverse.

The main reason the other shops turned down the job they don't have the knowledge either. I deal with John Deere that can't even find a bad wire connection that is staring them in the face. Or to have them tell a customer that their engine doesn't have an oil pump and to ignore the oil pressure light when right in front of them is an oil filter. I even had one warranty case with the local Stihl dealer where they couldn't even find a bad spark plug. Sometimes I think the local JD dealer's techs couldn't find their way out of a wet paper bag with both ends open.

As for my attitude I do think people that are unwilling to admit they are in over their head are fools. I have been doing this work for over 40 yrs now. I have learn to admit my limits and to ask for plus pay for help. We all know some things but none of us will never know everything as we are humans not Gods. Most people like you are just wanting us to give you our knowledge for free but we do have families too that needs feeding and have other expenses too like the shop to be available for them to come to.

Plus employees usually draws a hourly wage. Do you work for free?

As for giving local advice I don't help others to cut my throat. I am not here to lose money; although, I am a near non profit business as it is. Ever seen the cost of a well written service manual? Or the cost of a lawyer to defend you against a claim by customer that you sold parts to that had bypassed things and had an accident?

What I know is hard earned and what you know was probably hard earn too. Natural ability to do some things are a talent just like being able to play a musical instrument which I am have no ability to do, just can't do it no matter how much a try with teachers.

Have you seen the Briggs prices lately? Some are going through the roof like the fuel kit that was under $30 that is now over $110.Wouldn’t it have been easier to purchase a Briggs and Stratton ignition switch, wiring harness and solenoid to make it work correctly?

All he needed was a starter solenoid, a few wire terminals, some jumper wire (various colors), a terminal housing or two and maybe a new fuse. These things I have on hand as I took the time to figure which one the OEMs used and found a resource that have them. The only things that were need was a pair of wire cutter, a wire stripper, and an open barrel terminal crimper; of course, normal hands are also required. Unlike other shops that sell complete harnesses I repair them most times as a savings for the customer and a profit for my shop.

As a shop it was worth it to invest $70 in the crimpers so I do professional factory style crimps. I actually brought a second one to have it modify for my needs. Those crimpers sold places like Walmart are just junk. Also needed is the extractor tools. The hardware is brought in 50-100 piece units except for the housing which I reason amount as I use most of the present ones. Most of terminals and housings are Molex Standard .084 in (MLX) and/or AMP versions. Actually the pins were only 0.10 ea the last time I brought them.

I did take the time to do a write up with part numbers and pictures of the commonly used terminals and housing for the PPETEN forum group. Those documents were posted in their download forum under the Briggs service info section but I recently removed them from the public forum when the Briggs crankshaft specs section. I still have the three documents available on my drive. I start writing up one for the weather pack terminals and connectors but that is a work in progress as get time and feel like working on it. Lots different ones so it is harder to figure out what the mower OEMs are using without actually seeing them.

#31

C

cmrho

Nobody wants hard-earned experience from others for free. At least nobody that understands the give and take of this world. You provided some insight initially as a gift and I appreciated that. Somehow you moved to condescension in your later posts. I'm not sure why anyone would be a part of a forum like this unless they were trying to help. Being a 'tightwad' isn't what my engine replacement was about. It's about doing something I haven't done before to grow my education, was supposed to be straight-forward, and turned out not to be. Yeah, you know quite a bit in this area. But I'm certain you've been where I was at before, maybe a long time ago. Sure, you probably fix a lot of people's mistakes in your shop now. And you can shake your head all you want. But keep doing that, and customers notice. I know, because I have 2 businesses. If I did that, I wouldn't have many left anymore. It doesn't matter if what they did was stupid or idiotic and I've seen it for the umpteenth time. If I think it, it comes across in my tone and attitude. They know the situation. And they don't need me to remind them of it.

C

cmrho

As for the PTO in reverse, there are no toddlers on my property. I actually look at where I'm driving when I back up. I'm good with that.It wasn't assumed; you admitted that you couldn't read schematics.

As for PTO operating in reverse without making someone isn't behind (and it does happen) as being no biggie tell that to numerous toddlers that have been injured or killed because of in attention of an operator mowing in reverse.

The main reason the other shops turned down the job they don't have the knowledge either. I deal with John Deere that can't even find a bad wire connection that is staring them in the face. Or to have them tell a customer that their engine doesn't have an oil pump and to ignore the oil pressure light when right in front of them is an oil filter. I even had one warranty case with the local Stihl dealer where they couldn't even find a bad spark plug. Sometimes I think the local JD dealer's techs couldn't find their way out of a wet paper bag with both ends open.

As for my attitude I do think people that are unwilling to admit they are in over their head are fools. I have been doing this work for over 40 yrs now. I have learn to admit my limits and to ask for plus pay for help. We all know some things but none of us will never know everything as we are humans not Gods. Most people like you are just wanting us to give you our knowledge for free but we do have families too that needs feeding and have other expenses too like the shop to be available for them to come to.

Plus employees usually draws a hourly wage. Do you work for free?

As for giving local advice I don't help others to cut my throat. I am not here to lose money; although, I am a near non profit business as it is. Ever seen the cost of a well written service manual? Or the cost of a lawyer to defend you against a claim by customer that you sold parts to that had bypassed things and had an accident?

What I know is hard earned and what you know was probably hard earn too. Natural ability to do some things are a talent just like being able to play a musical instrument which I am have no ability to do, just can't do it no matter how much a try with teachers.

Have you seen the Briggs prices lately? Some are going through the roof like the fuel kit that was under $30 that is now over $110.

All he needed was a starter solenoid, a few wire terminals, some jumper wire (various colors), a terminal housing or two and maybe a new fuse. These things I have on hand as I took the time to figure which one the OEMs used and found a resource that have them. The only things that were need was a pair of wire cutter, a wire stripper, and an open barrel terminal crimper; of course, normal hands are also required. Unlike other shops that sell complete harnesses I repair them most times as a savings for the customer and a profit for my shop.

As a shop it was worth it to invest $70 in the crimpers so I do professional factory style crimps. I actually brought a second one to have it modify for my needs. Those crimpers sold places like Walmart are just junk. Also needed is the extractor tools. The hardware is brought in 50-100 piece units except for the housing which I reason amount as I use most of the present ones. Most of terminals and housings are Molex Standard .084 in (MLX) and/or AMP versions. Actually the pins were only 0.10 ea the last time I brought them.

I did take the time to do a write up with part numbers and pictures of the commonly used terminals and housing for the PPETEN forum group. Those documents were posted in their download forum under the Briggs service info section but I recently removed them from the public forum when the Briggs crankshaft specs section. I still have the three documents available on my drive. I start writing up one for the weather pack terminals and connectors but that is a work in progress as get time and feel like working on it. Lots different ones so it is harder to figure out what the mower OEMs are using without actually seeing them.

Nobody wants hard-earned experience from others for free. At least nobody that understands the give and take of this world. You provided some insight initially as a gift and I appreciated that. Somehow you moved to condescension in your later posts. I'm not sure why anyone would be a part of a forum like this unless they were trying to help. Being a 'tightwad' isn't what my engine replacement was about. It's about doing something I haven't done before to grow my education, was supposed to be straight-forward, and turned out not to be. Yeah, you know quite a bit in this area. But I'm certain you've been where I was at before, maybe a long time ago. Sure, you probably fix a lot of people's mistakes in your shop now. And you can shake your head all you want. But keep doing that, and customers notice. I know, because I have 2 businesses. If I did that, I wouldn't have many left anymore. It doesn't matter if what they did was stupid or idiotic and I've seen it for the umpteenth time. If I think it, it comes across in my tone and attitude. They know the situation. And they don't need me to remind them of it.

#32

C

cmrho

I wouldn't have changed anything, looking back. Yeah I had a lot of headaches. But I learned a lot from the experience. While it would've been easy to just buy a new one, I think as a society we are moving toward a 'trash and replace', rather than trying to fix things. I don't blame anyone. The cost of repairing these days is often much closer to the cost of a brand new one. It didn't used to be that way. But as long as there's something new for me to learn, I'll always want to DIY it. It's in my blood.

Thanks again!

C

cmrho

Yeah, I'm sure the B&S harness would've worked just fine. But I probably would've have to do just as much work as I did, I think. Tracing the wires back to the terminals, figuring out which ones go to which on the ignition switch, etc. Because the sight of the large bundle of wires was originally a little overwhelming, I was going in circles. Once I realized that I just needed the magento, alternator, and carb solenoid wires to match up, and use the old connector, I was halfway there. I knew I'd need a new start solenoid wire from the get-go. I just wasn't expecting the PTO clutch to not work. I'm sure someone with experience could figure it out by looking at the schematics, but while I can trace basic pathways, it just wasn't worth even more time to figure out why. I'm sure a pro would've done that; it's the right way to do it. But that's why I just installed a separate switch. And, yeah, I would tell anyone doing this to just replace it with the same engine, lol. But at a cost of $1900 for a brand new Kohler V-twin 26hp, I would've just bought a new mower instead. I can afford it, no problem. But that's not why I did what I did.The B&S #591393 wiring harness should have plugged right up. You would likely have to change your starter switch to match the wiring harness.

Like you said, it is what it is. And, a direct Kohler switch would have save a lot of time and headache. ?

I wouldn't have changed anything, looking back. Yeah I had a lot of headaches. But I learned a lot from the experience. While it would've been easy to just buy a new one, I think as a society we are moving toward a 'trash and replace', rather than trying to fix things. I don't blame anyone. The cost of repairing these days is often much closer to the cost of a brand new one. It didn't used to be that way. But as long as there's something new for me to learn, I'll always want to DIY it. It's in my blood.

Thanks again!

#33

StarTech

StarTech

As with everything you must build on your previous knowledge pool. When EFI first came out there was a very learning curve for all of us. It just not a simple as most no tech think it is. It also two cylces; although, are simple engines a lot of thing can and do go wrong. Unlike 4 cycles that limp along with a failing system on 2 cycles are more problematic.

As for costs yes when we buy an engine for a repower it is often fairly expensive. It is because engine OEM gives the equipment OEM huge discounts due to volume deals then they tried make up for that by sticking to us that buy in small quantities. Year ago I use to see walk behind selling less than the cost of engine otherwise purchased. And this is not unique to small engines either. I used to service office equipment. We sold a $99 calculator where the replacement printer was over $300 for the unit. As a dealer we just simply brought multiple units and parted them out for the parts. Of course Victor didn't like that as part purchases when down.

I got a Bob Cat EFI ZTR schedule to come in shortly. Although, I have worked EFI vehicles this is still new area to learn but at least I have a basic understanding of EFI systems. With that in mind lawn mower EFI are different. If it is Kawasaki engine I will need to buy the interface module (a painful $400+ unit) for the software I have. The Briggs interface is already here. Now the Kohler EFI equipment is something I also need to get. It customer already knows that I taking it in base on my limited knownledge but I am willing to see what is wrong. Most likely I will need to find a service for it.

As for costs yes when we buy an engine for a repower it is often fairly expensive. It is because engine OEM gives the equipment OEM huge discounts due to volume deals then they tried make up for that by sticking to us that buy in small quantities. Year ago I use to see walk behind selling less than the cost of engine otherwise purchased. And this is not unique to small engines either. I used to service office equipment. We sold a $99 calculator where the replacement printer was over $300 for the unit. As a dealer we just simply brought multiple units and parted them out for the parts. Of course Victor didn't like that as part purchases when down.

I got a Bob Cat EFI ZTR schedule to come in shortly. Although, I have worked EFI vehicles this is still new area to learn but at least I have a basic understanding of EFI systems. With that in mind lawn mower EFI are different. If it is Kawasaki engine I will need to buy the interface module (a painful $400+ unit) for the software I have. The Briggs interface is already here. Now the Kohler EFI equipment is something I also need to get. It customer already knows that I taking it in base on my limited knownledge but I am willing to see what is wrong. Most likely I will need to find a service for it.