pappabear

Member

- Joined

- May 27, 2015

- Threads

- 5

- Messages

- 19

Howdy Folks,

My second post on LMF. I have a project Snapper I'm going thru to add to my fleet. It's a Snapper model 38083 Series 3 RER with a Tecumseh TVXL195.

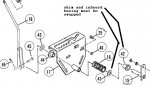

I tore down the shifter and removed the chaincase. The shift inboard bushing was melted and the shift lever broken off. The previous owner was shifting it with visegrips on the lever. So I am after a method to reassemble this mechanism. This thing was a biotch to get off. The shift handle has a thru-hole, with pin and cotter pin outboard. Inboard is a huge spring. I took the bracket off the machine and think the proper way is to partially assemble all the parts, put it in a vice with 2 sockets as bearing points and collapse the spring until the shift rod sticks out enough to install the outboard shim, shift handle, locking pin and cotter pin. Anybody had any experience with getting the monster spring collapsed for reassembly?

Second question regards setting the carburetor cable adjustments on the speed control bracket that mounts on top. This Tecumseh has idle and high speed set screws on the governor arm. Any guides available on for initial set up of the speed control bracket>

My second post on LMF. I have a project Snapper I'm going thru to add to my fleet. It's a Snapper model 38083 Series 3 RER with a Tecumseh TVXL195.

I tore down the shifter and removed the chaincase. The shift inboard bushing was melted and the shift lever broken off. The previous owner was shifting it with visegrips on the lever. So I am after a method to reassemble this mechanism. This thing was a biotch to get off. The shift handle has a thru-hole, with pin and cotter pin outboard. Inboard is a huge spring. I took the bracket off the machine and think the proper way is to partially assemble all the parts, put it in a vice with 2 sockets as bearing points and collapse the spring until the shift rod sticks out enough to install the outboard shim, shift handle, locking pin and cotter pin. Anybody had any experience with getting the monster spring collapsed for reassembly?

Second question regards setting the carburetor cable adjustments on the speed control bracket that mounts on top. This Tecumseh has idle and high speed set screws on the governor arm. Any guides available on for initial set up of the speed control bracket>