You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Kohler 23 hp choke/throttle hookup?

#1

C

Colimotl

C

Colimotl

SITUATION: Replaced 27 hp Kohler engine with a 23 hp Kohler engine.

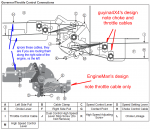

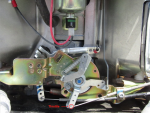

I took my yard tractor to an authorized Kohler dealer for the final electrical and choke/throttle hookups and when I picked it up, it looked as pictured below. However, the choke lever activated the throttle and the throttle lever operated the choke. I took it back and after one month, they called and said that they were unable to figure out the linkage for the choke.

They did switch the cables and the throttle lever now does actually activate the throttle (see red circle). The second cable simply is disconnected. Can anyone tell me how to connect the second cable to the choke?

Thank you.

Double click on image to enlarge.

I took my yard tractor to an authorized Kohler dealer for the final electrical and choke/throttle hookups and when I picked it up, it looked as pictured below. However, the choke lever activated the throttle and the throttle lever operated the choke. I took it back and after one month, they called and said that they were unable to figure out the linkage for the choke.

They did switch the cables and the throttle lever now does actually activate the throttle (see red circle). The second cable simply is disconnected. Can anyone tell me how to connect the second cable to the choke?

Thank you.

Double click on image to enlarge.

#2

EngineMan

EngineMan

I find it hard to believe that a service shop could not work it out...!

The bottom cable that is going to the lever with the blue marks (to the left of photo) is that the governor lever, if so the cable should not be on that. the lever with the red circle should be the choke...! take off the cables and then move the the choke rod to see which lever moves, then fit the choke cable to that lever, do the same with the throttle lever.

By pulling the other lever (throttle) should put tension on the governor springs.

The bottom cable that is going to the lever with the blue marks (to the left of photo) is that the governor lever, if so the cable should not be on that. the lever with the red circle should be the choke...! take off the cables and then move the the choke rod to see which lever moves, then fit the choke cable to that lever, do the same with the throttle lever.

By pulling the other lever (throttle) should put tension on the governor springs.

Attachments

#3

C

Colimotl

C

Colimotl

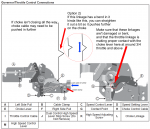

EngineMan, thank you for your prompt response and drawing. I, too, found it difficult to accept that an authorized dealer could not hook up the choke and throttle cables. The whole experience cost me $130 plus, rental for another mower and a lot of wasted time. However, I must say that my new 23 hp Kohler engine runs well and starts easily — once I prime the carburetor with a few drops of gas. But taking the air filter off every time that I start the engine is tiresome. As I stated in my first post, the picture shows exactly how they first attempted to hook up the choke and throttle. I am attaching two additional drawings that I found in my service manual for my 23 hp Kohler engine. Also, I am attaching your drawing with a question mark in red on a part, the shape of which does not appear on my engine. I’ll attempt to follow your instructions. Again, thank you for your help.

Attachments

#4

EngineMan

EngineMan

The lever with the spring(s) on is the throttle lever.... in your photo its on the governor arm (lever) which it shouldn't be, remove both cables and move a lever to see what moves...! the lever that moves the choke linkage ( you will see by looking at the choke opening and closing, that's the one you put on the choke cable on, move the other lever (not the governor arm) that should put tension on the spring(s) from the governor Arm, put your throttle cable on that one.

#6

zman111666

zman111666

I just worked on one like this yesterday, and from what I can see, you need to move the throttle up one hole (on the same lever it is on), and eliminate the choke cable altogether. That looks like the type that turns the choke on by simply moving the throttle forward all the way. In other words, push throttle all the way forward to choke, then pull back the throttle 1/4 of its travel after it starts for full throttle without choke. Your old motor had the throttle and choke on different controls, this one requires only one. The mechanic didn't seem to understand this, and tried to find a place for both cables.

The reason you need to move the throttle up a hole is so that you get more response with less travel of the control lever. It has to reach full throttle by 3/4 of the throw.

To adjust your cable, loosen the clamp, move your throttle control all the way up, and slide the cable forward until the choke butterfly is all the way closed, then tighten the clamp. The issue I had to fix yesterday was that the cable wasn't adjusted right, and the choke wouldn't close enough for the customer to get it started without priming it.

The reason you need to move the throttle up a hole is so that you get more response with less travel of the control lever. It has to reach full throttle by 3/4 of the throw.

To adjust your cable, loosen the clamp, move your throttle control all the way up, and slide the cable forward until the choke butterfly is all the way closed, then tighten the clamp. The issue I had to fix yesterday was that the cable wasn't adjusted right, and the choke wouldn't close enough for the customer to get it started without priming it.

#7

G

guyina4x4

so the fact that mine (cub 2185) is almost identical to his (cub slt1554) should be overlooked?

G

guyina4x4

I just worked on one like this yesterday, and from what I can see, you need to move the throttle up one hole (on the same lever it is on), and eliminate the choke cable altogether. That looks like the type that turns the choke on by simply moving the throttle forward all the way. In other words, push throttle all the way forward to choke, then pull back the throttle 1/4 of its travel after it starts for full throttle without choke. Your old motor had the throttle and choke on different controls, this one requires only one.

The reason you need to move the throttle up a hole is so that you get more response with less travel of the control lever. It has to reach full throttle by 3/4 of the throw.

To adjust your cable, loosen the clamp, move your throttle control all the way up, and slide the cable forward until the choke butterfly is all the way closed, then tighten the clamp. The issue I had to fix yesterday was that the cable wasn't adjusted right, and the choke wouldn't close enough for the customer to get it started without priming it.

so the fact that mine (cub 2185) is almost identical to his (cub slt1554) should be overlooked?

#8

zman111666

Well, I think the biggest difference (and correct me if I'm wrong) is that your picture is a top view, and his is a front view. Your linkages seem to be laying flat, on the top of the engine, and his are down low and vertical in front of the engine, below the carb.

Of course, the quick test would simply to unhook the choke cable, and see if the choke still operates with the throttle cable only. I wish the one I worked on yesterday was still here, so I could show you that it wasn't just close, but exactly like the OPs.

In fact, it looks like you have a horizontal shaft engine, when he has clearly a vertical shaft.

zman111666

View attachment 34501

so the fact that mine (cub 2185) is almost identical to his (cub slt1554) should be overlooked?

Well, I think the biggest difference (and correct me if I'm wrong) is that your picture is a top view, and his is a front view. Your linkages seem to be laying flat, on the top of the engine, and his are down low and vertical in front of the engine, below the carb.

Of course, the quick test would simply to unhook the choke cable, and see if the choke still operates with the throttle cable only. I wish the one I worked on yesterday was still here, so I could show you that it wasn't just close, but exactly like the OPs.

In fact, it looks like you have a horizontal shaft engine, when he has clearly a vertical shaft.

#11

C

Colimotl

C

Colimotl

Thanks to all that have helped me with my cable problem. I apologize for not having replied sooner, but I was painting my house and I was racing against the weather.

zman111666 gave me the correct answer. I did as he suggested and it worked like a charm!

zman111666 gave me the correct answer. I did as he suggested and it worked like a charm!

#12

EngineMan

EngineMan

Nice to know you have it up and running the way it should be...! and thanks for letting us know.

#13

zman111666

zman111666

Yes, thanks for letting us know, and I'm glad I could help.

Now you just have to find a use for the extra choke control knob...... Maybe turbo-boost!! :laughing:

Now you just have to find a use for the extra choke control knob...... Maybe turbo-boost!! :laughing:

#14

P

Patrick0525

Can you post close-up pic of the final working configuration?

P

Patrick0525

Thanks to all that have helped me with my cable problem. I apologize for not having replied sooner, but I was painting my house and I was racing against the weather.

zman111666 gave me the correct answer. I did as he suggested and it worked like a charm!

Can you post close-up pic of the final working configuration?

#16

zman111666

zman111666

Attachments

#17

C

Colimotl

Patrick,

Again, I apologize for the late response. These forums have different interfaces and I received no emails telling me there were additional entries to my thread. Perhaps someone can tell me if, in fact, there is a way to program an instant response.

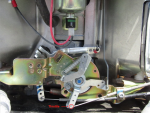

In following zman111666’s instructions, I decided to try one thing at a time. So, I first simply relocated the cable slightly back, as I remember. This meant that when I placed the throttle in the Fast position, the cable was drawn farther back (see the comparison in the attached photo) and this allowed the choke to close enough to start the engine. zman had suggested moving the cable up one hole. However, after all the trouble that I had experienced, when this worked after repeated startings, I decided to go with it. One very important point: In my case the throttle MUST be ALL the way forward. I then back it off. I have a Digital Laser Photo Tachometer and know where the 3,000 RPM AND 3,600 RPM points are.

I have approximately twelve hours on the new engine and have had zero problems with the new adjustment. Since I mowed once a week every week, I never experienced any real tall grass that would activate the governor. So, I can only hope that everything is hooked up okay. Let me know if you have any more questions, and I will try to answer them.

C

Colimotl

Can you post close-up pic of the final working configuration?

Patrick,

Again, I apologize for the late response. These forums have different interfaces and I received no emails telling me there were additional entries to my thread. Perhaps someone can tell me if, in fact, there is a way to program an instant response.

In following zman111666’s instructions, I decided to try one thing at a time. So, I first simply relocated the cable slightly back, as I remember. This meant that when I placed the throttle in the Fast position, the cable was drawn farther back (see the comparison in the attached photo) and this allowed the choke to close enough to start the engine. zman had suggested moving the cable up one hole. However, after all the trouble that I had experienced, when this worked after repeated startings, I decided to go with it. One very important point: In my case the throttle MUST be ALL the way forward. I then back it off. I have a Digital Laser Photo Tachometer and know where the 3,000 RPM AND 3,600 RPM points are.

I have approximately twelve hours on the new engine and have had zero problems with the new adjustment. Since I mowed once a week every week, I never experienced any real tall grass that would activate the governor. So, I can only hope that everything is hooked up okay. Let me know if you have any more questions, and I will try to answer them.

Attachments

#18

P

Patrick0525

P

Patrick0525

Thank you. When you reply to a post there is a green banner in reply "Additional Option" -> subscription-> subscribe to this thread and notify me of change -> check the box for instantly using email.

I will post my choke fix pics after it was adjusted at the dealer.

I will post my choke fix pics after it was adjusted at the dealer.

#20

zman111666

zman111666

I suggested using the middle hole, just in case you weren't getting full range from the far hole. But if that isn't a problem, and you have full range from idle to choke, you are fine the way you have it. I'm just happy I could help.

#21

C

Colimotl

Patrick, thank you for the info. -- Daniel

C

Colimotl

Thank you. When you reply to a post there is a green banner in reply "Additional Option" -> subscription-> subscribe to this thread and notify me of change -> check the box for instantly using email.

I will post my choke fix pics after it was adjusted at the dealer.

Patrick, thank you for the info. -- Daniel

#22

C

Colimotl

Zman, I haven't been on this forum for a couple years, but in reviewing my post I couldn't find where I thanked you. Your response solved my problem. Thanks again. -- Daniel

C

Colimotl

To adjust your cable, loosen the clamp, move your throttle control all the way up, and slide the cable forward until the choke butterfly is all the way closed, then tighten the clamp. The issue I had to fix yesterday was that the cable wasn't adjusted right, and the choke wouldn't close enough for the customer to get it started without priming it.

Zman, I haven't been on this forum for a couple years, but in reviewing my post I couldn't find where I thanked you. Your response solved my problem. Thanks again. -- Daniel

#23

M

MowerPoraiti

M

MowerPoraiti

Great coverage. I have a Kohler 23 HP Courage fitted to a Yardman Series 900 50" riding mower with the CVT system. It has done about 150 hours. From new it was very reluctant to go up a mild slope. My earlier 46" Yardman with its 23HP Briggs breezed up it. I had to pump the accelerator pedal to get the 50" to keep moving. I sent it to the serviceman being new. He made a mild improvement but it was still no where near as good as the older 46". Also the new one was a lot slower on level ground. (I don't think the mower man knew much about the CVT system). I felt that the belt idler rod tensioner was not pulling the dual idler pulleys sufficient to tension the drive belt enough. As a result I considered that the drive belt was not being pulled in sufficiently to increase the ratio at the CVT so that the top driven belt going to the 7.25" pulley on top of the transaxle was being driven slowly and that under load the CVT system was slipping. I screwed the idler rod in as much as possible with hardly any improvement. I removed the idler rod hex lock nut so that I screw it in further. In fact the end of the rod was now reaching the internal end of the ball joint fitting. With the mower still moving at little better than crawling pace I cut about 0.4" off the end of the idler rod so I could screw it in further. By now at least the mower would go up slight slopes without pumping the accelerator pedal. (By the way I also fitted a new OEM drive belt and top belt just in case the originals were the problem). I also bent the idler rod a little to effectively shorten it. By now travel of the idler pulley assembly was being limited by the linkage to the brake assembly. I just put up with a mower that was a poor performer.

I considered other options. I wondered if the motor was not revving sufficiently but not have a suitable rev counter I cannot assess that. I examined the throttle linkage at the motor end and decided to unclamp the throttle cable. I pulled the throttle cable outer casing back by about 0.4" and refastened. The max revs seemed to be higher. It was possible to manually the high speed control lever further and the revs increased markedly but I am concerned about over-revving the motor so I have not tried to move the throttle cable outer casing any more.

This has been a disappointing mower from the start. The motor leaks a lot of oil around the head assembly. The mower was very difficult to start despite me keeping the battery on charge and even fitting a new battery. It churned very slowly. Removal of the stater motor revealed a bent shaft! It was bent above the bearing so went it rotated the stater gear would sometime jump the motor ring gear and other times seemed to lock up and not turn. Removal of the starter motor revealed that the shaft turn eccentrically and was bent by about 0.3" at least. A friendly engineer mounted this in a lathe and was able to gently tap it back into alignment. While this helped the motor to not lock up/jam it still was very very difficult to start and the starter motor turn very slowly. Ultimately it burnt out the starter solenoid - it melted! Obviously there was a very bad contact internally limiting the current - hence hot internal terminals and insufficient current to the starter causing heating in the starter solenoid. However a new non-OEM solenoid fixed that problem immediately and now the mower starts almost every time at first try! However I would still like suggestions as to how I might speed my mower up. As a matter of interest how fast should riding mower such as this Yardman 900 travel over level ground? Am I being unreasonable?

I considered other options. I wondered if the motor was not revving sufficiently but not have a suitable rev counter I cannot assess that. I examined the throttle linkage at the motor end and decided to unclamp the throttle cable. I pulled the throttle cable outer casing back by about 0.4" and refastened. The max revs seemed to be higher. It was possible to manually the high speed control lever further and the revs increased markedly but I am concerned about over-revving the motor so I have not tried to move the throttle cable outer casing any more.

This has been a disappointing mower from the start. The motor leaks a lot of oil around the head assembly. The mower was very difficult to start despite me keeping the battery on charge and even fitting a new battery. It churned very slowly. Removal of the stater motor revealed a bent shaft! It was bent above the bearing so went it rotated the stater gear would sometime jump the motor ring gear and other times seemed to lock up and not turn. Removal of the starter motor revealed that the shaft turn eccentrically and was bent by about 0.3" at least. A friendly engineer mounted this in a lathe and was able to gently tap it back into alignment. While this helped the motor to not lock up/jam it still was very very difficult to start and the starter motor turn very slowly. Ultimately it burnt out the starter solenoid - it melted! Obviously there was a very bad contact internally limiting the current - hence hot internal terminals and insufficient current to the starter causing heating in the starter solenoid. However a new non-OEM solenoid fixed that problem immediately and now the mower starts almost every time at first try! However I would still like suggestions as to how I might speed my mower up. As a matter of interest how fast should riding mower such as this Yardman 900 travel over level ground? Am I being unreasonable?

#24

justcobra

justcobra

CONFIRMED. TORO Z5020 Zero turn mower(model 74399-2009 build with a kohler 23 hp engine) has a single cable throttle controller which does away with a additional choke cable. To start the mower from cold you merely push the the throttle all the way forward to the choke position and wait for the engine to start. As soon as the engine starts retract the throttle lever so it runs at a lower speed. The lower end of the of the throttle cable is attached to midway hole at the base of the carbie. .ps Now you do not have to prime the carbie to start it from cold as I have found out.