You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

John Deere D120 21hp Briggs OHV very hard cranking, breaking metal pinion starter gears.

#1

C

cyberslick18

C

cyberslick18

Hey everyone, like many of you I figured I could restore a clapped out John Deere I got for a song and a dance and it keeps finding new and exciting ways to not run when I need it to.

So, I bought it from the original owner with 400 hours on it, says the starter was stuck up and he was done with it. Didn't bother to tell me he had obliterated the mowing deck somehow, but thats another story, and my fault for not inspecting.

I replace the starter, and with a jump pack I was able to start and use the mower fine for a week or two.

Last week, it broke a pinion gear when trying to start. Just exploded into 2 or 3 pieces. It was a metal pinion gear with a plastic inner piece to ride on the plastic threaded spindle from the starter motor. I replaced it with the old original pinion and it started hard, but would still start up and run fine.

Then it ran for maybe 10 minutes, and stalled out. It would start back up but then die out. I checked all of the fuel supply and ultimately decided the fuel pump was weak, maybe perforated. I replaced that and it ran like a champ for one day. The next day I start it, and the pinion gear exploded again. At $15 a pop for cheap ones and more for OEM, this is getting old.

The engine is extremely hard to turn over by hand on the compression stroke, and I can hear it burping out of the air intake box (with the air filter off) when I get over the stroke. I adjusted the valves two times: One time as the B&S manual says, by finding TDC and then continuing 1/4 down (I believe to better match the ignition to the camshaft decompression function, which I know very little about), and also by simply alternating the valves closing and opening and setting the gap there as well, .004 for each as is spec for my model. Neither have helped the engine turn over via the starter. With the spark plug out it turns by hand considerably easier.

What are some other things I can check? I'm going to double check with a different fresh battery.

So, I bought it from the original owner with 400 hours on it, says the starter was stuck up and he was done with it. Didn't bother to tell me he had obliterated the mowing deck somehow, but thats another story, and my fault for not inspecting.

I replace the starter, and with a jump pack I was able to start and use the mower fine for a week or two.

Last week, it broke a pinion gear when trying to start. Just exploded into 2 or 3 pieces. It was a metal pinion gear with a plastic inner piece to ride on the plastic threaded spindle from the starter motor. I replaced it with the old original pinion and it started hard, but would still start up and run fine.

Then it ran for maybe 10 minutes, and stalled out. It would start back up but then die out. I checked all of the fuel supply and ultimately decided the fuel pump was weak, maybe perforated. I replaced that and it ran like a champ for one day. The next day I start it, and the pinion gear exploded again. At $15 a pop for cheap ones and more for OEM, this is getting old.

The engine is extremely hard to turn over by hand on the compression stroke, and I can hear it burping out of the air intake box (with the air filter off) when I get over the stroke. I adjusted the valves two times: One time as the B&S manual says, by finding TDC and then continuing 1/4 down (I believe to better match the ignition to the camshaft decompression function, which I know very little about), and also by simply alternating the valves closing and opening and setting the gap there as well, .004 for each as is spec for my model. Neither have helped the engine turn over via the starter. With the spark plug out it turns by hand considerably easier.

What are some other things I can check? I'm going to double check with a different fresh battery.

#2

StarTech

StarTech

First have verified the ACR is actually working? Looks to be a 330000 series Briggs which have the 793880 camshaft the ACR is bad about breaking due to poor design. Also note it sometime damages the governor too.

#3

C

cyberslick18

How do I test it?

C

cyberslick18

What is the ACR? The camshaft decompress feature?First have verified the ACR is actually working? Looks to be a 330000 series Briggs which have the 793880 camshaft the ACR is bad about breaking due to poor design. Also note it sometime damages the governor too.

How do I test it?

#4

ILENGINE

ILENGINE

Remove the valve cover adjust the valves to proper clearance-.004-.006 and then roll the engine over a few times by hand both to double check the clearance and also to make sure the intake valve which in this case is the bottom valve in the head bumps off seat slightly before TDC compression stroke. No bump then compression release is broke on the camshaft and pieces are laying in the oil sump. Also be aware that the OEM camshaft has been on nationwide backorder for several months with no ETA, and the aftermarket camshafts can be hit and miss for quality.

#5

StarTech

To check if it working. You rotate the crankshaft two complete turns. As piston approaches TDC compression stroke the intake (lower valve) rocker will bump open if the ACR is working. If not present then the ACR has broken off the camshaft. Note: Normally the valve clearances has to be set correctly but you have already done this.

There current after market version of the 793880 camshaft but are not made very well. Several I tried would even fit in the camshaft journals as just were .001" oversized nor would the oil pump shafts as they also were .001" oversized.

Now the OEM (Briggs) has superseded the camshaft with PN 84005207.

BUT as IL noted they are on back order with no ETA. Just another Briggs screw-up.

StarTech

Yes it is an Automatic Compression Release feature of the camshaft.What is the ACR? The camshaft decompress feature?

How do I test it?

To check if it working. You rotate the crankshaft two complete turns. As piston approaches TDC compression stroke the intake (lower valve) rocker will bump open if the ACR is working. If not present then the ACR has broken off the camshaft. Note: Normally the valve clearances has to be set correctly but you have already done this.

There current after market version of the 793880 camshaft but are not made very well. Several I tried would even fit in the camshaft journals as just were .001" oversized nor would the oil pump shafts as they also were .001" oversized.

Now the OEM (Briggs) has superseded the camshaft with PN 84005207.

BUT as IL noted they are on back order with no ETA. Just another Briggs screw-up.

#6

C

cyberslick18

C

cyberslick18

I will check this when I get home. Just from memory though and based on how it's behaving I sounds like the ACR is not functioning.

Is there a work around to modifying the existing camshaft itself or some other modification to the engine to achieve a similar function?

When I can get the thing to actually turn over and fire up it runs well enough for my purposes.

edit: Thanks for the quick responses really appreciate it

Is there a work around to modifying the existing camshaft itself or some other modification to the engine to achieve a similar function?

When I can get the thing to actually turn over and fire up it runs well enough for my purposes.

edit: Thanks for the quick responses really appreciate it

#7

C

cyberslick18

C

cyberslick18

Quick thought, probably dumb:

The nut on the top of the flywheel assembly is a 15/16.

Any reason I can't just put an impact driver on it and spin it to fire up? Is it a reverse thread that'll spin off if I try to send it clockwise or anything? I assume the magneto is what provides and times the spark, so if the key is on and I can overcome the compression stroke fast enough it should fire?

The nut on the top of the flywheel assembly is a 15/16.

Any reason I can't just put an impact driver on it and spin it to fire up? Is it a reverse thread that'll spin off if I try to send it clockwise or anything? I assume the magneto is what provides and times the spark, so if the key is on and I can overcome the compression stroke fast enough it should fire?

#8

Scrubcadet10

Scrubcadet10

Depends... it's possible to cause some damage to the crankshaft and threads if you use an IMPACT big enough to spin it over fast enough... but i think if the starter is having trouble spinning, a corded or cordless drill will have just as much trouble.

#9

StarTech

StarTech

Not to mention over tightening the flywheel causing damage to it.

Besides an impact is just like a hammer drill hammering things. A good 1/2 hp drill probably will work but it cost is near what the camshaft is.

You could the mower graveyards for a blown engine that may have a good camshaft still.

Besides an impact is just like a hammer drill hammering things. A good 1/2 hp drill probably will work but it cost is near what the camshaft is.

You could the mower graveyards for a blown engine that may have a good camshaft still.

#10

R

rdedrick

R

rdedrick

Using a drill you may get you hurt. When the engine fires up it may be spinning possibly at a higher RPM's than the drill. You may not be able to release the socket which has a 1/2 drill attached. So there's that.

#11

Scrubcadet10

Scrubcadet10

OEM cam is available at parts tree

www.partstree.com

www.partstree.com

PartsTree - Home of OEM Parts for Outdoor Power Equipment

We are committed to providing you with the largest selection of OEM parts from the best brands, the best diagrams and part search tools anywhere.

www.partstree.com

www.partstree.com

#12

C

cyberslick18

C

cyberslick18

As a tool and die maker I could machine something to mount to the flywheel stud without tightening the existing bolt, and could create a simple clutch / safer mechanism to separate the drill from the flywheel once fired up, but I try not to spend all my free time machining if I can help it. Ive come up with some stupidly elaborate solutions to very simple problems.

I'm not going to lie, I'm very tempted to try and aftermarket cam at almost a quarter of the price of that OEM one. There are a few on amazon with okay reviews.

I'm not going to lie, I'm very tempted to try and aftermarket cam at almost a quarter of the price of that OEM one. There are a few on amazon with okay reviews.

#13

Scrubcadet10

Scrubcadet10

reading through reviews on different CCP Cams, of those that fail it appears most failures of those happen within a few minutes, to hours of run time.

And the OEM cam lasted 400 hours...depending on how much you mow, that could be over 12 years.

And the OEM cam lasted 400 hours...depending on how much you mow, that could be over 12 years.

#14

StarTech

StarTech

Well of the 5 after market camshafts that I brought off Amazon myself two had to the journals worked down by .001" just to fit in the engines camshaft bearings. The other have poorly finish camshaft lobes. And neither of the five oil pump shafts will fit. Plus on the last three the ACR was quite loose. On top of that I would have return the last three the company selling closed up shop soon after I got the camshaft in stock. No way to return so I am stuck with those garbage camshafts.

So personally I am not buying any more after market camshafts. Not worth it to save just $25 over my Briggs distributor price of $58.96. Once Brigg has them back in stock I'll at 5 of them for stock plus whatever I for repairs.

As for how OEM last it is the luck of the draw there too as I had one customer broken one last Summer and then again this Spring and he cuts only about 2.5 acres weekly. Then others have yet to break one like me that cuts up to 6 acres bi-monthly. I still on the first camshaft and the mower is a 2005 model.

So personally I am not buying any more after market camshafts. Not worth it to save just $25 over my Briggs distributor price of $58.96. Once Brigg has them back in stock I'll at 5 of them for stock plus whatever I for repairs.

As for how OEM last it is the luck of the draw there too as I had one customer broken one last Summer and then again this Spring and he cuts only about 2.5 acres weekly. Then others have yet to break one like me that cuts up to 6 acres bi-monthly. I still on the first camshaft and the mower is a 2005 model.

#15

C

cyberslick18

That's kind of my dilemma. Everyone saying the design is the flaw regardless, and you get lucky or unlucky, so its a hard to pill to swallow for the OEM cam being $110+ shipping and 2-4 week delivery versus $35 and two day delivery if its going to be a crap shoot anyway. If it's a thou or two off I'll just turn it down quick, I'm not worried about the fit so much as I am the price. If I wait a month for the OEM and it just grenades immediately anyway I'm probably going to give this mower a viking funeral.

C

cyberslick18

Well of the 5 after market camshafts that I brought off Amazon myself two had to the journals worked down by .001" just to fit in the engines camshaft bearings. The other have poorly finish camshaft lobes. And neither of the five oil pump shafts will fit. Plus on the last three the ACR was quite loose. On top of that I would have return the last three the company selling closed up shop soon after I got the camshaft in stock. No way to return so I am stuck with those garbage camshafts.

So personally I am not buying any more after market camshafts. Not worth it to save just $25 over my Briggs distributor price of $58.96. Once Brigg has them back in stock I'll at 5 of them for stock plus whatever I for repairs.

As for how OEM last it is the luck of the draw there too as I had one customer broken one last Summer and then again this Spring and he cuts only about 2.5 acres weekly. Then others have yet to break one like me that cuts up to 6 acres bi-monthly. I still on the first camshaft and the mower is a 2005 model.

That's kind of my dilemma. Everyone saying the design is the flaw regardless, and you get lucky or unlucky, so its a hard to pill to swallow for the OEM cam being $110+ shipping and 2-4 week delivery versus $35 and two day delivery if its going to be a crap shoot anyway. If it's a thou or two off I'll just turn it down quick, I'm not worried about the fit so much as I am the price. If I wait a month for the OEM and it just grenades immediately anyway I'm probably going to give this mower a viking funeral.

#17

C

cyberslick18

www.briggsandstratton.com

I'm at work so I don't have the actual B&S technicians manual, but the procedure is the same. If you google for the B&S tech manual a pdf should pop up.

www.briggsandstratton.com

I'm at work so I don't have the actual B&S technicians manual, but the procedure is the same. If you google for the B&S tech manual a pdf should pop up.

The method they teach their service techs, to the best of my knowledge anyway, is to use a straight tool of some kind (screwdriver, socket extension etc) as a reference in the spark plug hole, find TDC and then continue the stroke so the piston is, measuring your straight tool as reference, .250 down the bore, and then set your clearances at this point.

I saw some debate on other forums and videos as to whether this is worth the trouble or not, so I tried it this way, and also by just alternating the valves open and close and setting clearances there, and neither provided any meaningful decompression improvement.

C

cyberslick18

"by finding TDC and then continuing 1/4 down"

Elaborate on this a little.

Engine Valve Maintenance & Repair | Briggs & Stratton

Looking for valve maintenance and repair tips for your small engines? Follow our step-by-step guide to remove and clean your valves for better engine performance!

The method they teach their service techs, to the best of my knowledge anyway, is to use a straight tool of some kind (screwdriver, socket extension etc) as a reference in the spark plug hole, find TDC and then continue the stroke so the piston is, measuring your straight tool as reference, .250 down the bore, and then set your clearances at this point.

I saw some debate on other forums and videos as to whether this is worth the trouble or not, so I tried it this way, and also by just alternating the valves open and close and setting clearances there, and neither provided any meaningful decompression improvement.

#18

StarTech

StarTech

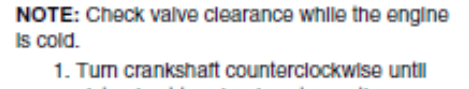

TDC Compression is where piston at the top of the stroke with both valves close. The following from the Briggs Single Cylinder OHV service manual. The reason for 1/4" pass TDC is to make the ACR is in the way. Personally I just use the old way where one valve is fully closed and adjust the opposite valve."by finding TDC and then continuing 1/4 down"

Elaborate on this a little.

#19

Fish

Fish

I am aware of the procedure, was just wanting to find out if you meant 1/4" of the piston travel, or 1/4 of a revolution of the flywheel.I'm at work so I don't have the actual B&S technicians manual, but the procedure is the same. If you google for the B&S tech manual a pdf should pop up.Engine Valve Maintenance & Repair | Briggs & Stratton

Looking for valve maintenance and repair tips for your small engines? Follow our step-by-step guide to remove and clean your valves for better engine performance!www.briggsandstratton.com

The method they teach their service techs, to the best of my knowledge anyway, is to use a straight tool of some kind (screwdriver, socket extension etc) as a reference in the spark plug hole, find TDC and then continue the stroke so the piston is, measuring your straight tool as reference, .250 down the bore, and then set your clearances at this point.

I saw some debate on other forums and videos as to whether this is worth the trouble or not, so I tried it this way, and also by just alternating the valves open and close and setting clearances there, and neither provided any meaningful decompression improvement.

#20

J

Joed756

J

Joed756

Have you checked the crankshaft key to make sure the key isn't broken or bent, the keyway isn't degraded and the key is correct size?

#21

C

catman606

C

catman606

Do what I did three years ago to my old Craftsman, go to FB Marketplace and find you a $50 Flathead.

#23

StarTech

StarTech

Not if you are turning from the PTO which is lot easier when the shroud is in place. They assuming that the shroud is in place and you are using a wrench or pull bar to turn the engine via the PTO end.That Briggs manual says turn crank CCW. Is that correct? Thought it was CW looking down at the flywheel? Typo?

View attachment 57585