You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Hydro Gear EZT 2200 Rebuild

#1

N

nccole

N

nccole

I am in the middle of rebuilding a Hydro Gear EZT 2200. Left side, out of a Husqvarna RZ5424. It started going out around 90 hours, but was out of the 3 year warranty by a couple of months. I mow 2 flat acres and knowing what I know now would have bought something with a 2800. The Husqvarna tractor itself is a very nice well built unit, and I opted for the Kawasaki engine. I bought a new one (so it was claimed) and it isn't perfect, but I can get the job done. It overheats after about 10 minutes and I suspect the fluid is contaminated. I read that these are sealed maintenance free, but found a rebuild manual from Hydro Gear. I printed it out, and bought a seals kit and internal filter for it ~$40. I figured if it is shot and if I do nothing with it and at worst I threw away $40, but could save a lot of money, plus it might be fun. I am hoping to find some people who have had these apart at least and who have re-built them possibly.

So far, I think I made a good decision, the gears, shafts, and all critical components look great. The oil doesn't look too bad. The one problem, and a good one I think, is the filter. It seemed to be full of aluminum dust. What I think and hope is that the "center section" that the filter bolts to was just poorly cast and/or poorly machined. It looks rough, and I suspect that in my first 90 hours, the oil moving through the pump has collected and transplanted enough aluminum dust into the filter that now the transmission of power is not possible. I don't have it exactly in my head how this thing works yet, so who knows. Once I started noticing issues with it, it was only about 10 hours later and it now has no power. This is not the issue with good power when its cold either.

So, does this sound reasonable to anyone in the know? What else should I really look at while I have it apart? I don't see any scoring or broken/chipped gears in there, but I haven't cleaned it all up yet either. I haven't read these forum rules yet, but do have pictures I could post if that is possible and would help any.

So far, I think I made a good decision, the gears, shafts, and all critical components look great. The oil doesn't look too bad. The one problem, and a good one I think, is the filter. It seemed to be full of aluminum dust. What I think and hope is that the "center section" that the filter bolts to was just poorly cast and/or poorly machined. It looks rough, and I suspect that in my first 90 hours, the oil moving through the pump has collected and transplanted enough aluminum dust into the filter that now the transmission of power is not possible. I don't have it exactly in my head how this thing works yet, so who knows. Once I started noticing issues with it, it was only about 10 hours later and it now has no power. This is not the issue with good power when its cold either.

So, does this sound reasonable to anyone in the know? What else should I really look at while I have it apart? I don't see any scoring or broken/chipped gears in there, but I haven't cleaned it all up yet either. I haven't read these forum rules yet, but do have pictures I could post if that is possible and would help any.

#2

ILENGINE

ILENGINE

I am a hydrogear authorized service center so I have been inside of that unit. If the center section or the pump or motor surfaces where the unit run against each other have scratches deep enough to catch a fingernail, that part will need to be replaced.

#3

N

nccole

Thank you for the quick reply. I will check out that center section more closely, and I thought replacing it might be a good idea anyway. I haven't found a real p/n for it yet as the manual has a generic parts list 1-159.

Is this common to have what I figure is just a Chinese poor surface finish part that is causing this "failure?" Is this unit worth while to rebuild? Everyone says NO, run away and buy a new one! But for $40 and some labor (free in my case) I can save myself around $800. How does that not make sense especially on a good tractor with 110 hours? This job really isn't that bad, working on my cars is almost always a bigger pain and more frustrating. Also, you know why the left unit is usually the bad one? Sorry for so many questions, just seems these are a mystery but I don't know why, and you are the first person who actually knows more than me about them.

N

nccole

I am a hydrogear authorized service center so I have been inside of that unit. If the center section or the pump or motor surfaces where the unit run against each other have scratches deep enough to catch a fingernail, that part will need to be replaced.

Thank you for the quick reply. I will check out that center section more closely, and I thought replacing it might be a good idea anyway. I haven't found a real p/n for it yet as the manual has a generic parts list 1-159.

Is this common to have what I figure is just a Chinese poor surface finish part that is causing this "failure?" Is this unit worth while to rebuild? Everyone says NO, run away and buy a new one! But for $40 and some labor (free in my case) I can save myself around $800. How does that not make sense especially on a good tractor with 110 hours? This job really isn't that bad, working on my cars is almost always a bigger pain and more frustrating. Also, you know why the left unit is usually the bad one? Sorry for so many questions, just seems these are a mystery but I don't know why, and you are the first person who actually knows more than me about them.

#4

ILENGINE

ILENGINE

The surfaces on the pump, motor, and center section that mate together are glass smooth polished on new units, So if you can catch a fingernail in grooves between the holes, it is damaged and needs to be replaced. I actually live 60 miles from the factory in Illinois, and just went through a factory tour and tear down school back in January.

The outer surface of the center section is rough because it still has the dimples from the lost foam casting. Then all the parts are CNC machined to specification.

The outer surface of the center section is rough because it still has the dimples from the lost foam casting. Then all the parts are CNC machined to specification.

#5

N

nccole

N

nccole

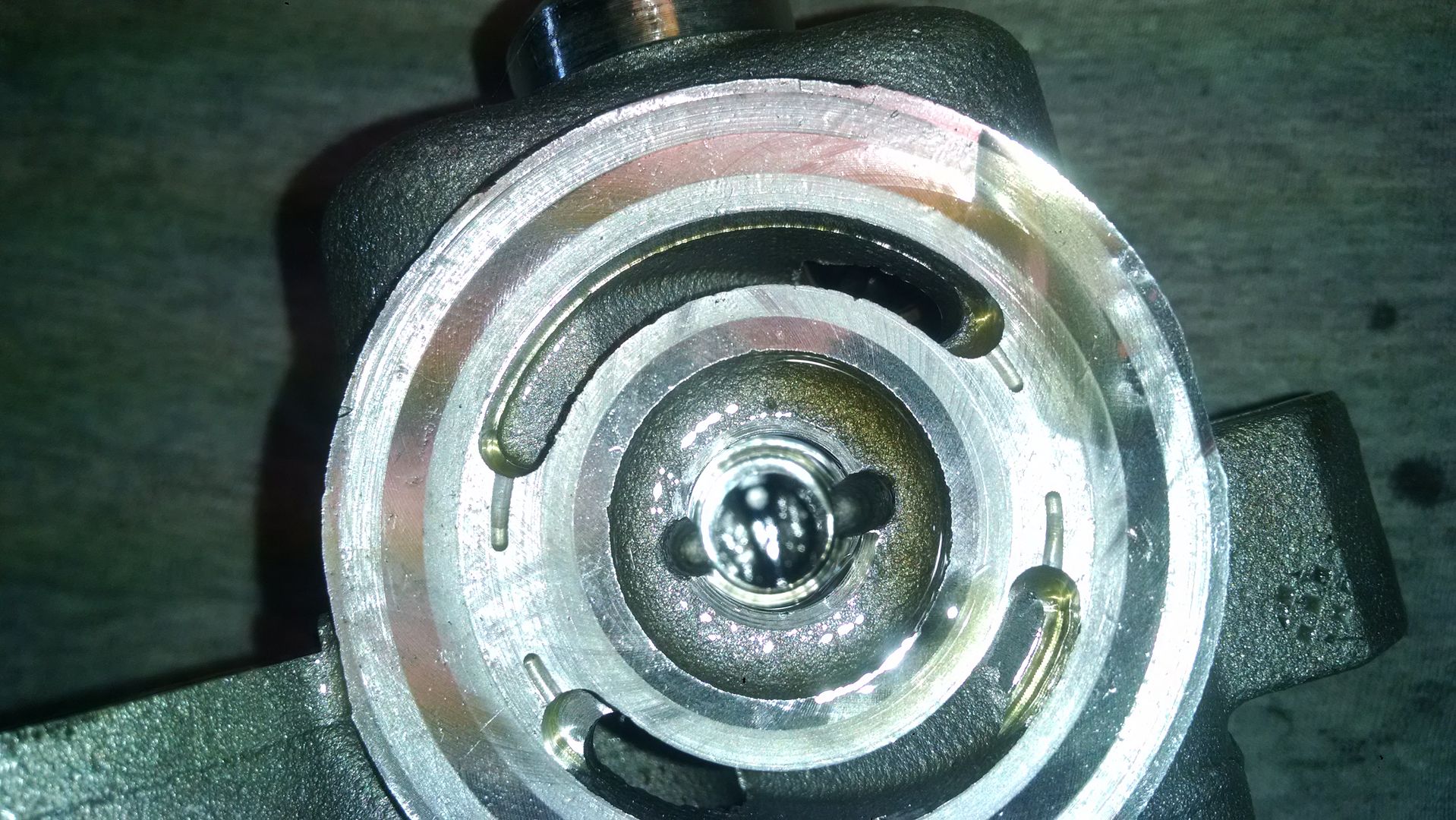

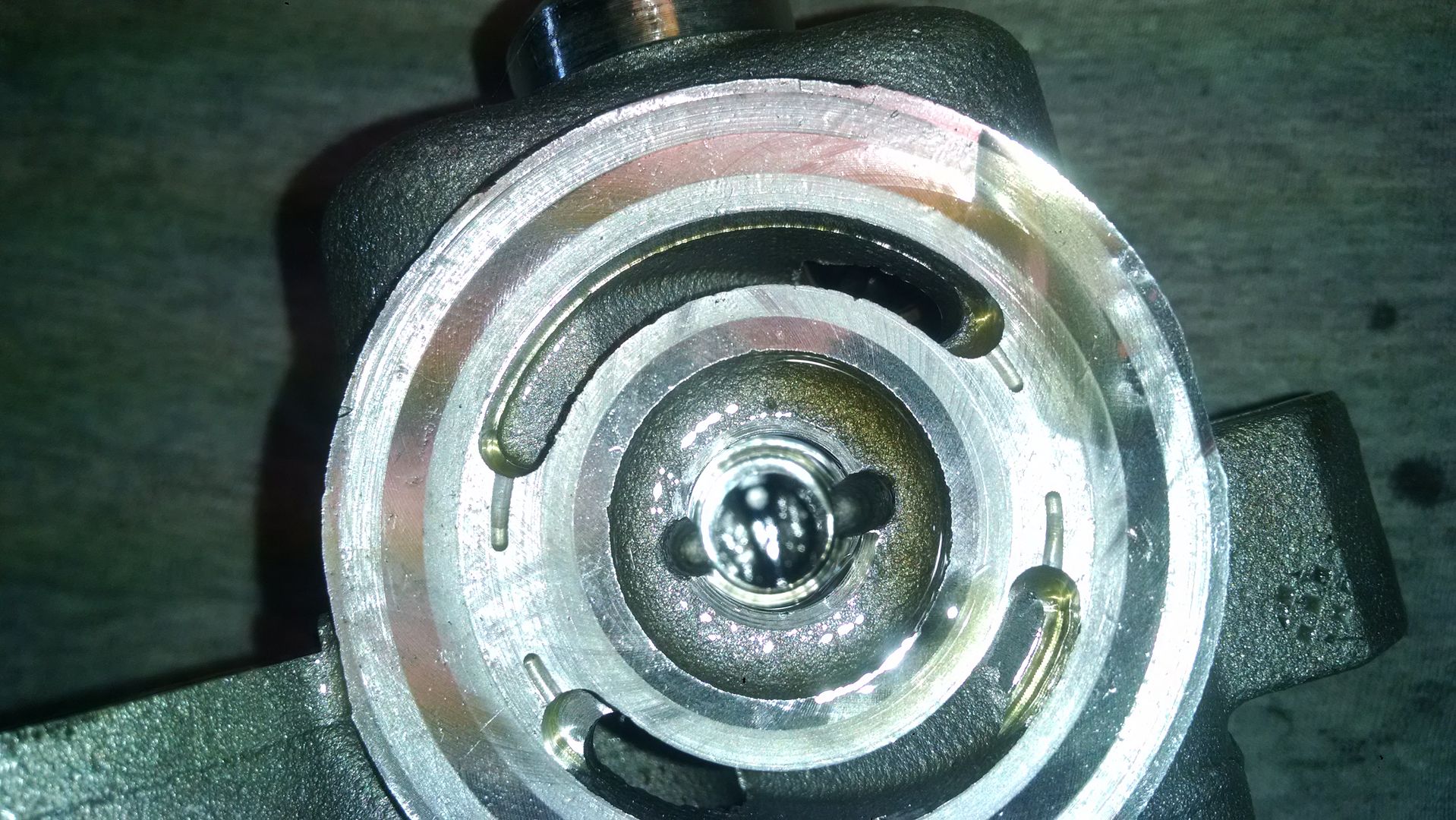

I am going to work on getting a picture uploaded. I have a picture of the mating surface to the pump as I see it. The picture was looking down through the center section because I could see aluminum dust in the filter and I had not yet removed the filter. It does however show one of the mating surfaces. Do they not lap this surface back to smooth?

#6

ILENGINE

ILENGINE

They don't buff or mill them back to smooth because removing any material changes the down tension therefore the output pressure of the pump or motor. Hydrogear doesn't give flatness specs either so there is no way of knowing the tolerances. The reason the left seems to go out before the right is most people turn to the left more often.

the problem with the lower end consumer units is some are not set up with shock valves to relieve the pressure when you attempt to change direction, so if you create too much back pressure within the unit the pressure at the pump will overcome the down force and lift the pump off of the mating surface, which as the pressure is relieved slams down on the center section causing metal to metal contact and damage.

the problem with the lower end consumer units is some are not set up with shock valves to relieve the pressure when you attempt to change direction, so if you create too much back pressure within the unit the pressure at the pump will overcome the down force and lift the pump off of the mating surface, which as the pressure is relieved slams down on the center section causing metal to metal contact and damage.

#7

M

Mike_Goad

M

Mike_Goad

To Illengine, (I hope I spelled that right)...you sir are absolutely correct. I do not see that very often on these forums.

I was a factory trainer who taught dealers how to repair Hydro Gear units.

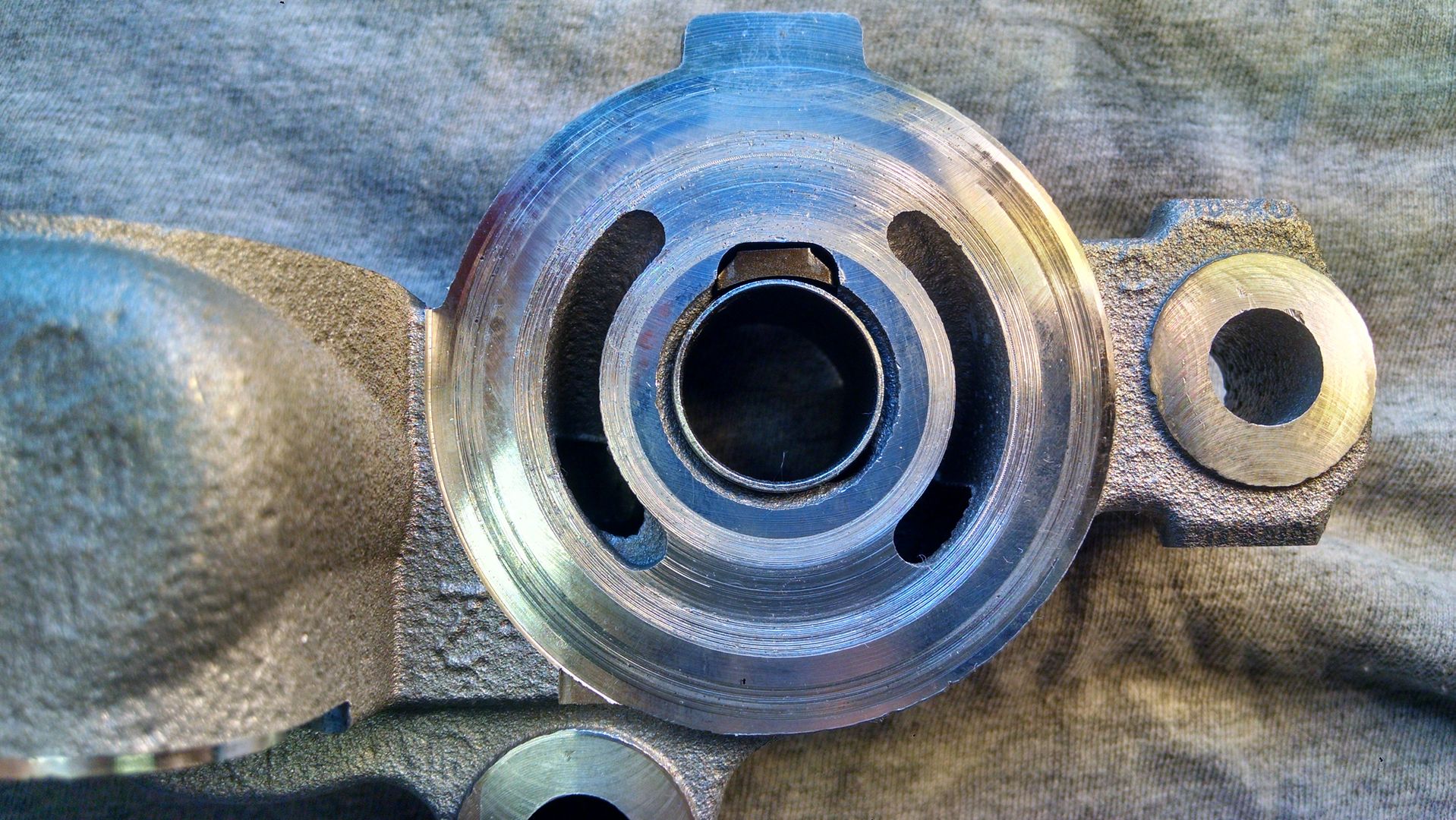

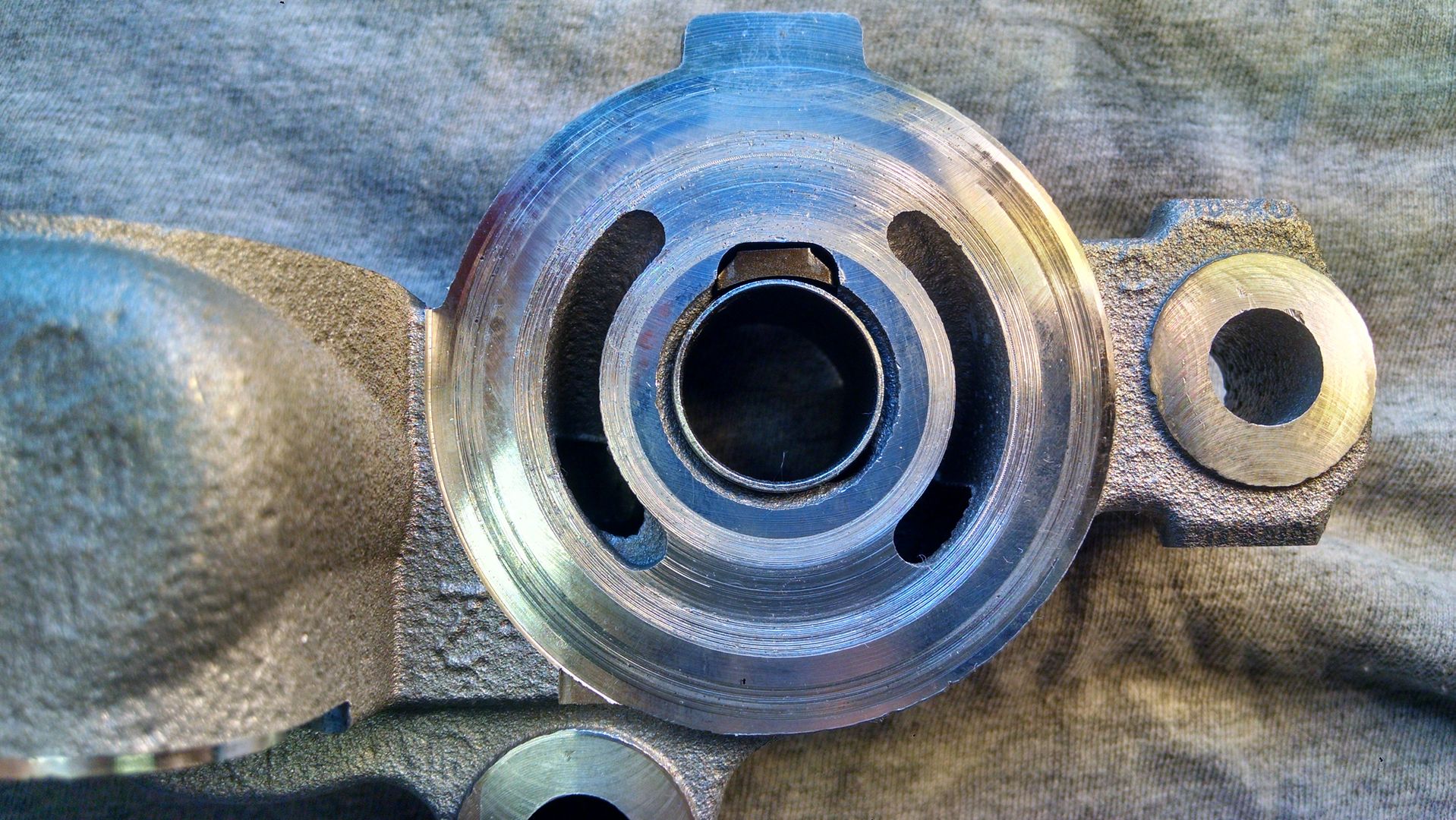

The center section if molded using what is called lost foam molds. if you look at the outside, it looks like Styrofoam. It is then machined flat. Like Ill said, if you run your finger nail across the surface and can catch it on a grove, it is shot.

The aluminum dust is normal. as these unit run, extremely small amounts of aluminum do get worn off. it is not a concern. If you see chunks, however, then be concerned.

If I remember correctly, there is a small wedge looking piece of metal (about a 1/2" sq) that goes in the center section. this is your bypass plate.

there are parts manuals on line. make sure to use OEM parts. just google your entire model number found on a white sticker on the unit.

I was a factory trainer who taught dealers how to repair Hydro Gear units.

The center section if molded using what is called lost foam molds. if you look at the outside, it looks like Styrofoam. It is then machined flat. Like Ill said, if you run your finger nail across the surface and can catch it on a grove, it is shot.

The aluminum dust is normal. as these unit run, extremely small amounts of aluminum do get worn off. it is not a concern. If you see chunks, however, then be concerned.

If I remember correctly, there is a small wedge looking piece of metal (about a 1/2" sq) that goes in the center section. this is your bypass plate.

there are parts manuals on line. make sure to use OEM parts. just google your entire model number found on a white sticker on the unit.

#8

N

nccole

I did not see any chunks (actually, after looking at the picture on the computer, it may not look as good) and the post #5 picture shown is of the pump side of the center section. The bypass plate is on the motor side and I do still have that. After doing a little cleaning, the motor side is worse looking than the pump side shown. I am in contact with Hydro Gear and will be sharing pictures with them. Starting to sound like a new center section is in store. I have a supposedly new second unit currently on the tractor that overheats and quits working after about 10 mins. I may just pull the center section out of it and try that. I have cleaned a lot of the original seal and the original unit is close to being ready to be put back together. I need to mow this weekend though!

I am assuming that in the seal created, the pump/motor is always the "hammer" and the center section is always the "nail" due to material differences. Meaning, the pump/motor will never wear out, but the center section can have the crap beat out of it. Does your history/knowledge backup that assumption? I may still with some input from Hyrdo Gear lap that surface and try it out. If it doesn't cause damage, I am only out some time and tinkering in the garage with a second unit.

Thanks for your informed input as well.

N

nccole

To Illengine, (I hope I spelled that right)...you sir are absolutely correct. I do not see that very often on these forums.

I was a factory trainer who taught dealers how to repair Hydro Gear units.

The center section if molded using what is called lost foam molds. if you look at the outside, it looks like Styrofoam. It is then machined flat. Like Ill said, if you run your finger nail across the surface and can catch it on a grove, it is shot.

The aluminum dust is normal. as these unit run, extremely small amounts of aluminum do get worn off. it is not a concern. If you see chunks, however, then be concerned.

If I remember correctly, there is a small wedge looking piece of metal (about a 1/2" sq) that goes in the center section. this is your bypass plate.

there are parts manuals on line. make sure to use OEM parts. just google your entire model number found on a white sticker on the unit.

I did not see any chunks (actually, after looking at the picture on the computer, it may not look as good) and the post #5 picture shown is of the pump side of the center section. The bypass plate is on the motor side and I do still have that. After doing a little cleaning, the motor side is worse looking than the pump side shown. I am in contact with Hydro Gear and will be sharing pictures with them. Starting to sound like a new center section is in store. I have a supposedly new second unit currently on the tractor that overheats and quits working after about 10 mins. I may just pull the center section out of it and try that. I have cleaned a lot of the original seal and the original unit is close to being ready to be put back together. I need to mow this weekend though!

I am assuming that in the seal created, the pump/motor is always the "hammer" and the center section is always the "nail" due to material differences. Meaning, the pump/motor will never wear out, but the center section can have the crap beat out of it. Does your history/knowledge backup that assumption? I may still with some input from Hyrdo Gear lap that surface and try it out. If it doesn't cause damage, I am only out some time and tinkering in the garage with a second unit.

Thanks for your informed input as well.

#9

ILENGINE

ILENGINE

Center section is toast. If there are not grooves in the pump or motor that you can catch a fingernail in then you can reuse them. If it looks like the center section then they need to be replaced also.

#10

N

nccole

They look pretty good, don't recall feeling any catches. The motor does look a little more rough though.

N

nccole

Center section is toast. If there are not grooves in the pump or motor that you can catch a fingernail in then you can reuse them. If it looks like the center section then they need to be replaced also.

They look pretty good, don't recall feeling any catches. The motor does look a little more rough though.

#11

ILENGINE

ILENGINE

From the pictures it looks like they are grooved deep enough to have fingernail catches in them. I may be wrong. If you go from inside to outside between the holes, and scrap you fingernail across them does it feel rough.

#12

N

nccole

I will have to check later tonight. I am not at home, just posting pictures from my phone. Also waiting to hear back from Hydro Gear. That unit has less than 100 hours on it, but I was two months out of warranty from Husqvarna. I am not sure how their warranty department treats things, maybe they will take care of me.

N

nccole

From the pictures it looks like they are grooved deep enough to have fingernail catches in them. I may be wrong. If you go from inside to outside between the holes, and scrap you fingernail across them does it feel rough.

I will have to check later tonight. I am not at home, just posting pictures from my phone. Also waiting to hear back from Hydro Gear. That unit has less than 100 hours on it, but I was two months out of warranty from Husqvarna. I am not sure how their warranty department treats things, maybe they will take care of me.

#13

N

nccole

N

nccole

The Motor block is shot. The pump block feels smooth, may buy a new one just to have all new critical parts. I have not ordered anything yet, because one of the online stores replaced my 70864L Center Section Kit with a 71529 kit. I didn't notice at first but then read in small print that the 71529 is a direct replacement. I called that company and they weren't much help just reading to me what their computer said. I called Hydro Gear, and he said currently he shows the 70864L as the one to get. I found another site selling parts, and they list the two center sections as available, but they are $34 different. If the 71529 is a replacement and improved version, then I want that one. Not to mention it is cheaper.

#14

ILENGINE

ILENGINE

My hydrogear dealer parts lookup shows the 71529 superceding to 70864L so either one should be usable. my parts distributor shows the 71529 in stock but not the 70864L so who ever you tried to order from probably has the same issues.

#15

N

nccole

Awesome, thanks for the quick response. I will get my order in now.

N

nccole

My hydrogear dealer parts lookup shows the 71529 superceding to 70864L so either one should be usable. my parts distributor shows the 71529 in stock but not the 70864L so who ever you tried to order from probably has the same issues.

Awesome, thanks for the quick response. I will get my order in now.

#16

BlazNT

BlazNT

Found the part# 71529 for $87.39

smallenginesprodealer.com/hydrogear/oem/active/71529-part-71529-hydrogear-original-oem/

smallenginesprodealer.com/hydrogear/oem/active/71529-part-71529-hydrogear-original-oem/

#17

N

nccole

N

nccole

That's where I got all my parts. I got two pump blocks and some other misc things also. I'm new here, but another forum I frequent is funny about posting links to buy things, so I was hesitant to discuss that. Appreciate the tip though.Found the part# 71529 for $87.39

smallenginesprodealer.com/hydrogear/oem/active/71529-part-71529-hydrogear-original-oem/

#18

ILENGINE

Posting links to sites seems to OK here as long as you are not advertising for your own business without being a paying advertiser. I have been on sites that if you post a link to somebody that isn't an advertiser the moderators will delete your post.

ILENGINE

That's where I got all my parts. I got two pump blocks and some other misc things also. I'm new here, but another forum I frequent is funny about posting links to buy things, so I was hesitant to discuss that. Appreciate the tip though.

Posting links to sites seems to OK here as long as you are not advertising for your own business without being a paying advertiser. I have been on sites that if you post a link to somebody that isn't an advertiser the moderators will delete your post.

#19

N

nccole

N

nccole

After having parts back ordered and then more parts back ordered I finally went to another distributor and got my parts. I put it back together and the rebuilt transmission was working but under powered. I was done with it for the night and the next day went through the purge process again and it seemed after running around in the driveway it was getting better as I got fluid moving around. I still couldn't mow that night because a thunderstorm was rolling in. I also had some issue with the engine starting and running full strength so I ordered a Kawasaki air and fuel filter. That did the trick on my engine, but when I went to start mowing to see how if it needed more purging or possibly some mechanical adjustments on the linkage for speed control and how it held up after an hour of mowing, I noticed some oil on the floor after I moved it. It was in fact from the rebuilt transmission. I could identify two places where oil was leaking from. So, off the mower and back on the bench. I took it apart and what I hope and think was that in my attempt to not overdo the application of the sealant, I was too sparse with it and left some aluminum to aluminum contact patches big enough to leak. Now before I put it back together and try again, I had a few questions. Is the sealant I used good? Mine is clear, and I noticed black from the factory. The manual didn't specify that I could see. I dry fit the two halves together and figured out how I would line the pins up, then pulled it apart and applied the sealant to the body and then dropped the side plate into place. I uniformly tightened all the bolts down and let it sit overnight. Then, the next afternoon after about 24 hours, I filled it with oil. To me the sealant does not look good. It seemed a little more brittle than the black factory sealant. Again, maybe I just didn't apply enough. I did do a thorough cleaning of the aluminum sealing surfaces. I had the entire unit broken down and scraped with a plastic razor blade all the old black sealant off and then cleaned with brake cleaner to remove any oil or deposits. Have a look at my pictures and tell me what you think.

#20

M

Mike_Goad

M

Mike_Goad

from the pictures, you did a good job cleaning. however, you will have future issues of leaking. Hydro-Gear uses a black ATV sealant. in fact, they do have their own part number for a caulking tube of sealant. there is enough to do about t-axles per tube. these units run hot and the metal does expand. HG has only endorsed their sealant.

I do know people that simply went to the parts store and bought a black silicon RTV sealer that is heat and oil resistant and it worked fine. that is up to you.

another place people have leaking with is the seals. especially the axle shaft. there are key ways in most of the shafts that are very sharp and have been known to cut the seal. use protection, always practice safe sealing :laughing:

some kind of thin plastic card like an old piece of microfiche works great. at the minimum, use cellophane wrap around the axle shafts.

let me know how it goes.

I do know people that simply went to the parts store and bought a black silicon RTV sealer that is heat and oil resistant and it worked fine. that is up to you.

another place people have leaking with is the seals. especially the axle shaft. there are key ways in most of the shafts that are very sharp and have been known to cut the seal. use protection, always practice safe sealing :laughing:

some kind of thin plastic card like an old piece of microfiche works great. at the minimum, use cellophane wrap around the axle shafts.

let me know how it goes.

#21

N

nccole

Thanks for the information. I will get some good black silicon RTV. Don't want to wait on HG or someone to ship their tube out to me. I would bet a lot of money, it is not a HG proprietary engineered sealant. Just a certain grade re-packaged sealant from a known company. I will also check the axle shaft. I did buy a seals kit, and installed all new seals, so I hope I have no issues there.

N

nccole

from the pictures, you did a good job cleaning. however, you will have future issues of leaking. Hydro-Gear uses a black ATV sealant. in fact, they do have their own part number for a caulking tube of sealant. there is enough to do about t-axles per tube. these units run hot and the metal does expand. HG has only endorsed their sealant.

I do know people that simply went to the parts store and bought a black silicon RTV sealer that is heat and oil resistant and it worked fine. that is up to you.

another place people have leaking with is the seals. especially the axle shaft. there are key ways in most of the shafts that are very sharp and have been known to cut the seal. use protection, always practice safe sealing :laughing:

some kind of thin plastic card like an old piece of microfiche works great. at the minimum, use cellophane wrap around the axle shafts.

let me know how it goes.

Thanks for the information. I will get some good black silicon RTV. Don't want to wait on HG or someone to ship their tube out to me. I would bet a lot of money, it is not a HG proprietary engineered sealant. Just a certain grade re-packaged sealant from a known company. I will also check the axle shaft. I did buy a seals kit, and installed all new seals, so I hope I have no issues there.

#22

N

nccole

N

nccole

I have mowed my yard completely twice since re-re-building using a high temp black RTV. No leaks that I have seen and I am pretty happy with it. I had to do some adjustments to the levers, and have the left (rebuilt) lever fully forward with the right having to be pulled back slightly to go straight. I had the levers tuned pretty good before, but can't seem to get it dialed in. The rebuit one feels more "hydraulic" if that makes sense. It seems to react slower to input vs. the right one. If I had to put a number on it, I would also say that the rebuilt one is about 95% of the right one in terms of power at full speed. It does seem to get a little better as it gets warmed up. I do recall the hydros feeling more "hydraulic" when I first bought the mower, so I am wondering if this feeling will go away after a break in of the new pumps and center section. I did do a purge btw.

Overall, I am satisfied so long as I do not have any red flags pointing to future issues. I can mow my yard in one setting without overheating and needing a cool down every 15 minutes. I am going to at least do another fluid change on the overheating unit and might pull the side cover off to get all that suspected contaminated oil out.

Overall, I am satisfied so long as I do not have any red flags pointing to future issues. I can mow my yard in one setting without overheating and needing a cool down every 15 minutes. I am going to at least do another fluid change on the overheating unit and might pull the side cover off to get all that suspected contaminated oil out.

#23

M

mk1264

M

mk1264

I just took apart my Hydro Gear EZT 2100 transmission on the left side. I ordered a new center block because the motor side was grooved and wore out. i didn't think the motor block was that bad and put it back together but the bearing slipped on the motor side and It jammed inside causing the motor not to turn. Well I tore it back apart and it just scrapped the fixed swash plate a little bit so I cleaned up the surface of the motor block and pump block. Put it back together but it still was weak especially when it got hot! Well pulled it apart and realized I should have went ahead and changed the motor block out because it grooved the brand new center block again. The motor block is a little grooved and this is the new center section looking at the motor side. I have ordered new center and motor block and I believe I should be good to go now! This forum was very helpful thanks!

Attachments

#26

G

garrisond4550

G

garrisond4550

Just joining... I have a 2009 toro z5030. It was driving fine until I pulled the bypass levers to physically push the mower, then moved the bypass back to original position. The next time I went to use the mower only the left side would drive. Then both sides stopped driving. I tapped on the units with a rubber mallet and the right side drove forward only. I have removed the transaxles from the mower. I physically moved the bypass levers with my hand forward and aft and was able to turn the axle in either position as if the bypass is stuck. I drained the oil from both transaxles. One side had 48 oz's and the other had 44 oz's. The oil was dark with no metal in it. Does anyone have any information on this problem? Thank you in advance for your input.