You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Husqvarna RZ5424 with Kohler SV725-3026

#1

A

Andi

A

Andi

Hello all! I have a bit of a conundrum...help?

I have a question. My son (he's learning) went to replace the starter solenoid and did not make note of how the wiring connected. I replaced the entire harness because he connected the single black wire to the positive, and well...Anyhow,

My RZ5424 does not have lights. My unit came with 2 battery pos (one to the solenoid and from there to starter) and the battery neg connected to the other solenoid stud. On the harness, (together in one offshoot) there is the yellow wire to the solenoid tang, the red lead to battery + lead...and then there is a single black wire. it reads 12.34v when the battery is connected, but it sure does not go to the solenoid or the engine ground. The Husqvarna schematic was not updated when the harness was. Does anyone know where that black wire is supposed to go?

Before he fried the harness, I taped off the black wire and it started.

I have also replaced all switches (except the steering interlocks) plugs and both coils. BUT something must be open...somewhere. I get no click, nothing whatsoever. When I replaced the coils this morning, I cleaned the pick-up and made sure the coils were the correct spacing, and I can turn the engine by hand. I have been doing electrical work for 20 years (we have a 73 MCI bus that is a home on wheels) but I am stumped on this.

I have a question. My son (he's learning) went to replace the starter solenoid and did not make note of how the wiring connected. I replaced the entire harness because he connected the single black wire to the positive, and well...Anyhow,

My RZ5424 does not have lights. My unit came with 2 battery pos (one to the solenoid and from there to starter) and the battery neg connected to the other solenoid stud. On the harness, (together in one offshoot) there is the yellow wire to the solenoid tang, the red lead to battery + lead...and then there is a single black wire. it reads 12.34v when the battery is connected, but it sure does not go to the solenoid or the engine ground. The Husqvarna schematic was not updated when the harness was. Does anyone know where that black wire is supposed to go?

Before he fried the harness, I taped off the black wire and it started.

I have also replaced all switches (except the steering interlocks) plugs and both coils. BUT something must be open...somewhere. I get no click, nothing whatsoever. When I replaced the coils this morning, I cleaned the pick-up and made sure the coils were the correct spacing, and I can turn the engine by hand. I have been doing electrical work for 20 years (we have a 73 MCI bus that is a home on wheels) but I am stumped on this.

#2

B

bertsmobile1

B

bertsmobile1

Should not have needed to replace the entire harness, just the wires between the solenoid & the battery,

Have you replaced the fuses ?

usually a backwards connected battery just blows the fuse.

Plain black wires are always ground so if you have battery voltage on it you have a wire in the wrong place.

With the exception of the cranking circuit all the other wires are ground wires and all switching is done via ground wires.

Very important

The magneto coils have a timing chip in them.

If this ever see battery voltage it will get fried.

So start by pulling the kill wires off the coils to prevent them accidentially getting voltage

From there, start at the battery side of the solenoid and check for battery voltage.

Do the same with the thin wire that goes from the solenoid battery cable to the B terminal on the ignition switch via a fuse.

This wire is usually red or red / black.

It connects to the yellow wire that passes through to PTO switch, both lap bars then the Brake Switch & finally the yellow trigger wire to the solenoid.

Have you replaced the fuses ?

usually a backwards connected battery just blows the fuse.

Plain black wires are always ground so if you have battery voltage on it you have a wire in the wrong place.

With the exception of the cranking circuit all the other wires are ground wires and all switching is done via ground wires.

Very important

The magneto coils have a timing chip in them.

If this ever see battery voltage it will get fried.

So start by pulling the kill wires off the coils to prevent them accidentially getting voltage

From there, start at the battery side of the solenoid and check for battery voltage.

Do the same with the thin wire that goes from the solenoid battery cable to the B terminal on the ignition switch via a fuse.

This wire is usually red or red / black.

It connects to the yellow wire that passes through to PTO switch, both lap bars then the Brake Switch & finally the yellow trigger wire to the solenoid.

#3

Hammermechanicman

Hammermechanicman

Are you saying when you turn the key the engine does not crank?

Dows the starter solenoid have 3 or 4 terminals?

When you say harness was it the engine or mower wiring or both?

Dows the starter solenoid have 3 or 4 terminals?

When you say harness was it the engine or mower wiring or both?

#4

A

Andi

A

Andi

The engine does not crank...the solenoid does not click

Fuses are both good.

OEM was 3 wire solenoid. I have a few spares...3 and 4 terminal, but now there is a 3 wire solenoid on it.

I replaced the mower harness because there were wires melted under the conduit, and it was easier than fixing every inch of wire. The engine harness is okay.

The schematic shows...and the wiring matches...red/blk wire goes to "B" (with a red/blk jumper to "A2"), then to 20A fuse, then to battery connect (via the small connector on the + cable) then to ground. It shows a separate ground than the switch that is grounded at the engine bolt. But when I ground the black wire,...nothing happens.

What the schematic does not show is the battery to solenoid cable connections... and the harness was revised on 7/26/12 per manufacturer. It shows a yellow tang wire on the solenoid (that goes to the brake switch) and then to ground.

It also shows 2 accessory outlets (lights that I do not have), I only have one acc outlet with 2 blk and a yellow/blk, and three engine grounds, I only have 2.

I have 12.32 volts at every connection point that should have voltage. That little black wire also has 12.32 volts, hence my frustration because the harness is otherwise simple plug and go. Everything matched up to the original.

And the switch is grounded to the engine frame, with the PTO. So my problem must be the red/blk circuit or the solenoid...but the red/blk should be grounded by the switch, no?

I sincerely appreciate your help. I have 214 circuits that each run 40' on the bus. The only difference is the bus is 24V- (and to reverse the polarity is to kill them all) and the mower is 12V- and I can't figure this mower out.

Fuses are both good.

OEM was 3 wire solenoid. I have a few spares...3 and 4 terminal, but now there is a 3 wire solenoid on it.

I replaced the mower harness because there were wires melted under the conduit, and it was easier than fixing every inch of wire. The engine harness is okay.

The schematic shows...and the wiring matches...red/blk wire goes to "B" (with a red/blk jumper to "A2"), then to 20A fuse, then to battery connect (via the small connector on the + cable) then to ground. It shows a separate ground than the switch that is grounded at the engine bolt. But when I ground the black wire,...nothing happens.

What the schematic does not show is the battery to solenoid cable connections... and the harness was revised on 7/26/12 per manufacturer. It shows a yellow tang wire on the solenoid (that goes to the brake switch) and then to ground.

It also shows 2 accessory outlets (lights that I do not have), I only have one acc outlet with 2 blk and a yellow/blk, and three engine grounds, I only have 2.

I have 12.32 volts at every connection point that should have voltage. That little black wire also has 12.32 volts, hence my frustration because the harness is otherwise simple plug and go. Everything matched up to the original.

And the switch is grounded to the engine frame, with the PTO. So my problem must be the red/blk circuit or the solenoid...but the red/blk should be grounded by the switch, no?

I sincerely appreciate your help. I have 214 circuits that each run 40' on the bus. The only difference is the bus is 24V- (and to reverse the polarity is to kill them all) and the mower is 12V- and I can't figure this mower out.

#5

A

Andi

A

Andi

UPDATE

Just to be redundant, I did pull the kill wires off my new coils

I went out and re-checked the small red wire on the battery + terminal...12.32V

BUT...that small black wire no longer has voltage. So, where does it go to ground it?

There was no key in the ignition...should that red/blk wire "B" have voltage with no key?...oh, yes it should as it connects to the battery via the small red connector on the cable. Sorry.

Just to be redundant, I did pull the kill wires off my new coils

I went out and re-checked the small red wire on the battery + terminal...12.32V

BUT...that small black wire no longer has voltage. So, where does it go to ground it?

There was no key in the ignition...should that red/blk wire "B" have voltage with no key?...oh, yes it should as it connects to the battery via the small red connector on the cable. Sorry.

#6

AVB

AVB

What puzzling me why there was voltage on the ground circuit especially you the wires off the ignition coils. This may fried the ignition coils as they no protection from voltage being applied to kill terminal which is grounded to kill the ignition.

Trace and check the starter circuit. Yellow wire. You could fire one of the switches and voltage is no getting to the starter solenoid trigger terminal. First have the ignition that output 12v when in the start position on the "S" terminal. From the wiring goes to the PTO (must have continuity across the two yellow wire terminals with the switch in the off position. From there the wiring to both of the control/motion arms, again continuity across each yellow terminal in park/neutral position. Next stop would be the brake switch. here you looking for continuity across the two yellow wire terminal with the brake set. Last check would the starter solenoid terminal. Here you simply check for voltage if the all the other connections and switches are okay by engaging the ignition switch start position. Note with the mower having a three solenoid you have two large posts and one small one with solenoid metal mounting being the return ground for the solenoid.

Hopefully this makes sense of the wiring. But you may also need someone that familiar with mower wiring to help out on site. I have been doing electrical for quiet a few years but I still need a hands approach on some wiring problems.

Trace and check the starter circuit. Yellow wire. You could fire one of the switches and voltage is no getting to the starter solenoid trigger terminal. First have the ignition that output 12v when in the start position on the "S" terminal. From the wiring goes to the PTO (must have continuity across the two yellow wire terminals with the switch in the off position. From there the wiring to both of the control/motion arms, again continuity across each yellow terminal in park/neutral position. Next stop would be the brake switch. here you looking for continuity across the two yellow wire terminal with the brake set. Last check would the starter solenoid terminal. Here you simply check for voltage if the all the other connections and switches are okay by engaging the ignition switch start position. Note with the mower having a three solenoid you have two large posts and one small one with solenoid metal mounting being the return ground for the solenoid.

Hopefully this makes sense of the wiring. But you may also need someone that familiar with mower wiring to help out on site. I have been doing electrical for quiet a few years but I still need a hands approach on some wiring problems.

#7

A

Andi

Also of note...the ignition switch does not want to seat all the way...3 of them all OEM Husqvarna, BUT the connectors are contacting the switch.

A

Andi

There is no voltage on that black wire as of now. All that is disconnected at this point, is the starter and the white coil kill wires.What puzzling me why there was voltage on the ground circuit especially you the wires off the ignition coils. This may fried the ignition coils as they no protection from voltage being applied to kill terminal which is grounded to kill the ignition.

Trace and check the starter circuit. Yellow wire. You could fire one of the switches and voltage is no getting to the starter solenoid trigger terminal. First have the ignition that output 12v when in the start position on the "S" terminal. From the wiring goes to the PTO (must have continuity across the two yellow wire terminals with the switch in the off position. From there the wiring to both of the control/motion arms, again continuity across each yellow terminal in park/neutral position. Next stop would be the brake switch. here you looking for continuity across the two yellow wire terminal with the brake set. Last check would the starter solenoid terminal. Here you simply check for voltage if the all the other connections and switches are okay by engaging the ignition switch start position. Note with the mower having a three solenoid you have two large posts and one small one with solenoid metal mounting being the return ground for the solenoid.

Hopefully this makes sense of the wiring. But you may also need someone that familiar with mower wiring to help out on site. I have been doing electrical for quiet a few years but I still need a hands approach on some wiring problems.

Also of note...the ignition switch does not want to seat all the way...3 of them all OEM Husqvarna, BUT the connectors are contacting the switch.

#8

B

bertsmobile1

B

bertsmobile1

When faced with problems like yours on ZTR's I use a pile of short jumper leads to bypass each switch one at a time.

I will guess that one of the double switches ( or switch plugs ) that has both a power circuit ( cranking circuit = yellow wires ) and a safety circuit has shorted so the power is being connected to the ground.

So pull the key switch and jump from the B to the S terminal then go look for power where there should not be any.

I will guess that one of the double switches ( or switch plugs ) that has both a power circuit ( cranking circuit = yellow wires ) and a safety circuit has shorted so the power is being connected to the ground.

So pull the key switch and jump from the B to the S terminal then go look for power where there should not be any.

#9

A

Andi

A

Andi

Okay...BEFORE I jumped B to S...I took the batt - off the solenoid (Attached it to frame) and put the starter wire on that post. I also connected the little black "mystery" wire to the frame. The starter had 0 voltage but the batt + and the yellow tag had 12.32 volts. Is solenoid not powering from one side to the other? But when the battery - is there, the starter has voltage. Anyhoo...

I jumped B to S. Had voltage on the yellow lines, including at solenoid, no voltage on white wires at the brake, PTO or either lap switch.

I jumped B to S. Had voltage on the yellow lines, including at solenoid, no voltage on white wires at the brake, PTO or either lap switch.

#10

A

Andi

A

Andi

By the way, the engine manual makes the following suggestion...that I have NOT tried yet:

"Locate connectors where wiring harnesses from engine and equipment are joined. Separate connectors and

remove white kill lead from engine connector. Rejoin connectors and position or insulate kill lead terminal so it

cannot touch ground. Try to start engine to verify whether reported problem is still present"

"Locate connectors where wiring harnesses from engine and equipment are joined. Separate connectors and

remove white kill lead from engine connector. Rejoin connectors and position or insulate kill lead terminal so it

cannot touch ground. Try to start engine to verify whether reported problem is still present"

#11

B

bertsmobile1

B

bertsmobile1

[QUOTE="Andi, post: 350360, member: 100681"

I jumped B to S. Had voltage on the yellow lines, including at solenoid, no voltage on white wires at the brake, PTO or either lap switch.

[/QUOTE]

I am having some troubles following what you are doing but the above is exactly what should be happening.

The starter should also crank if the yellow wire is hooked up to the solenoid.

You should only have power to one heavy lead on the solenoid till that yellow wire goes +.

The solenoid is just a switch like any other realy except it can handle 200 Amps.

Now to clarify things, does your mower have a remote solenoid or one that is piggy back on the starter which most Kohlers have ?

I jumped B to S. Had voltage on the yellow lines, including at solenoid, no voltage on white wires at the brake, PTO or either lap switch.

[/QUOTE]

I am having some troubles following what you are doing but the above is exactly what should be happening.

The starter should also crank if the yellow wire is hooked up to the solenoid.

You should only have power to one heavy lead on the solenoid till that yellow wire goes +.

The solenoid is just a switch like any other realy except it can handle 200 Amps.

Now to clarify things, does your mower have a remote solenoid or one that is piggy back on the starter which most Kohlers have ?

#12

AVB

AVB

According to Kohler Plus the SV725-3026 would using a starter with a remote starter solenoid (relay). If the solenoid connected correctly then it clicks or not. If not it is bad but even it clicks it still can bad because burned contacts on the main internal contacts. To test for bad contacts you simple use a junk screwdriver and jump the two main terminals if the starter than cranks it is the solenoid; otherwise, it is the starter that is bad or a bad engine ground.

Maybe this will help...

Maybe this will help...

#13

A

Andi

A

Andi

Yep. That is the schematic, and as soon as the ice stops, I'm going to replace the solenoid...it won't even click. I have a three-position and a four-position that both bench tested good.

BUT...

What initially messed me up on the schematic was the 2 hour meters and 2 accessory outlets. I only have one of each. I believe that black wire would go to the other light socket if I had lights. There is only one wire from "L"..

The solenoid and "S" circuit show grounds separate from the others, but the solenoid is grounded by attaching it to the frame.

Although this is very different from the bus, should I put the negative cable back on the solenoid? (It came from the dealer with batt - on one side, batt + on the other with + to the starter and one tang for the yellow wire. It has 42.6 hours on it and has otherwise been a wonderful machine.

BUT...

What initially messed me up on the schematic was the 2 hour meters and 2 accessory outlets. I only have one of each. I believe that black wire would go to the other light socket if I had lights. There is only one wire from "L"..

The solenoid and "S" circuit show grounds separate from the others, but the solenoid is grounded by attaching it to the frame.

Although this is very different from the bus, should I put the negative cable back on the solenoid? (It came from the dealer with batt - on one side, batt + on the other with + to the starter and one tang for the yellow wire. It has 42.6 hours on it and has otherwise been a wonderful machine.

#14

AVB

AVB

Those are options as I have work on a couple that didn't even either of them. All grounds are frame ground even the one that says engine ground is a frame point.

I think you might be mistaken as to if solenoid large terminals were setup as what you describe(with battery positive on one and the battery negative on the other) if I reading it correctly is a dead short once the solenoid engages. Normally the three terminal solenoids is connected as follows. Large posts> one connect to the battery positive terminal and the other connect to starter post via a cable. Then starter is ground return path is through the engine.frame ground back to the battery negative terminal. Small terminal is the solenoid switching terminal and solenoid trigger return path is the grounding of it to frame (mounting to metal frame). Now the post model of the solenoid would need a return to the battery negative side or just grounded to frame.Although this is very different from the bus, should I put the negative cable back on the solenoid? (It came from the dealer with batt - on one side, batt + on the other with + to the starter and one tang for the yellow wire. It has 42.6 hours on it and has otherwise been a wonderful machine.

#15

A

Andi

A

Andi

I thought it was odd, but both battery cables were indeed connected to the solenoid. On the positive side, there was also the cable that went to the starter. I pulled the battery out due to low temps and I am going to make new cables. If it does not start when I put it back (I'll put batt - to frame), I'll try jumping the starter with the car battery.

#16

AVB

AVB

I am beening to think that your son may have wired it this way which is possible per the following comment. As the starter would never started without the battery being grounded to frame. Even then it would cranked all the time; unless, contrary to the engine's IPL it has a solenoid shift starter which would solenoid trigger to connect to trigger terminal on the starter's mounted solenoid. Please review the image as to determine which starter you have.

I have a question. My son (he's learning) went to replace the starter solenoid and did not make note of how the wiring connected. I replaced the entire harness because he connected the single black wire to the positive, and well...Anyhow,

#17

AVB

AVB

Also if you are removing the cable from the starter please use two wrenches as using just one can break the cable mounting area on many starters.

#18

A

Andi

A

Andi

It's the inertia drive starter. One bolt on the bottom where the batt + attaches. And yes, I always use two wrenches for items such as this.

#19

A

Andi

A

Andi

Okay... PLEASE forgive the crude example. The only thing I am sure of...the batt - was on the left the batt + and the starter wire was on the right, and the small wire (purple in pic only...yellow on tractor) was on the tang

It came from the dealer that way.

What I didn't know...there is a small black wire that I believe goes to nothing (unless I install lights) and I wanted to ask. If this were on the bus, it would make more sense to me, so I appreciate your help...more than I can express.

It came from the dealer that way.

What I didn't know...there is a small black wire that I believe goes to nothing (unless I install lights) and I wanted to ask. If this were on the bus, it would make more sense to me, so I appreciate your help...more than I can express.

Attachments

#20

AVB

AVB

Now the following is the typical three post wiring setup. Just this image is from a Cub Cadet but the wiring is the same except the battery small black on yours is green in this image. It is connect to the bolt that mounts the solenoid. The small red in the image is connected to the same post that goes to battery. Also note that the main battery negative cable is ground to the frame/engine crankcase

#21

B

bertsmobile1

B

bertsmobile1

All the solenoid does is connect the 2 heavy terminals on the top.

So one of them has the power from the battery and the other has the power cable to the starter.

It is turned on & off by the small terminal at the base being given 12V ( VIA THE CRANKING CIRCUIT ) .

The other half of the trigger is the bolt holding the solenoid down that makes the ground half of the trigger circuit.

If the solenoid is bolted onto something that is plastic then there will be a ground strap to one of the bolts.

On the same post as the wire from the battery should be power feed to the mower, usually a red wire with a fuse in it that connects to the B on the battery,

No wire should have an aligator clip on it so that wire might be a power take off to run an accessory .

You need to follow it back through the loom and see where it goes to

So one of them has the power from the battery and the other has the power cable to the starter.

It is turned on & off by the small terminal at the base being given 12V ( VIA THE CRANKING CIRCUIT ) .

The other half of the trigger is the bolt holding the solenoid down that makes the ground half of the trigger circuit.

If the solenoid is bolted onto something that is plastic then there will be a ground strap to one of the bolts.

On the same post as the wire from the battery should be power feed to the mower, usually a red wire with a fuse in it that connects to the B on the battery,

No wire should have an aligator clip on it so that wire might be a power take off to run an accessory .

You need to follow it back through the loom and see where it goes to

#22

A

Andi

A

Andi

I should have clarified. My picture was a very crude example of how the battery cables were connected. The alligator clip was only an example of the negative cable, the red wires were positive and the green was showing where the yellow start wire was. They are not the actual cables and wires.

I will connect it and find a place to put the battery negative to chassis, with a known good solenoid.

I will connect it and find a place to put the battery negative to chassis, with a known good solenoid.

#23

AVB

AVB

That part I understood and that gave the example of how it should be connected; though, not exactly as I would not be crossing over the tow main leads even though they are heavily insulated.I should have clarified. My picture was a very crude example of how the battery cables were connected. The alligator clip was only an example of the negative cable, the red wires were positive and the green was showing where the yellow start wire was. They are not the actual cables and wires.

I will connect it and find a place to put the battery negative to chassis, with a known good solenoid.

#24

A

Andi

A

Andi

Okay...

I hooked everything up as I should...nothing. I have 12.33 volts at the starter and the yellow wire and both sides of the solenoid but the starter won't engage...thinking I need to replace it. But I was also wondering about the ignition switch (they do not seat all the way) If I make a three-way jumper between A1-S-B (all else being equal) it should start...according to the schematic key position 4. IF that works, I can direct wire the switch. Thoughts?

BUT I connected the little black wire to the solenoid body bolt and I had 12.33 volts at the solenoid mounting screw on that side, so I called Husqvarna. It doesn't go anywhere. If I ever put lights in the tractor, it is the jumper between the lights.

I hooked everything up as I should...nothing. I have 12.33 volts at the starter and the yellow wire and both sides of the solenoid but the starter won't engage...thinking I need to replace it. But I was also wondering about the ignition switch (they do not seat all the way) If I make a three-way jumper between A1-S-B (all else being equal) it should start...according to the schematic key position 4. IF that works, I can direct wire the switch. Thoughts?

BUT I connected the little black wire to the solenoid body bolt and I had 12.33 volts at the solenoid mounting screw on that side, so I called Husqvarna. It doesn't go anywhere. If I ever put lights in the tractor, it is the jumper between the lights.

#25

AVB

AVB

I am beginning to think you have grounding issue here as if the solenoid is mounted to the metal frame that black wire would have burned or severely overheated with it having 12V on it.. Please check the battery negative post to frame ground cable. The engine should also be grounded to the frame. Without a negative return path nothing going to work.

I just repaired an IH Farmall Super M tractor this week where the cable end was not making contact with the 2 gauge ground wire even though it was bolted to the cable. Found to be corroded clean it up and everything is working again. To bad the owner had put a new starter on it as it is not returnable.

I just repaired an IH Farmall Super M tractor this week where the cable end was not making contact with the 2 gauge ground wire even though it was bolted to the cable. Found to be corroded clean it up and everything is working again. To bad the owner had put a new starter on it as it is not returnable.

#26

A

Andi

A

Andi

I think you're right...I have 12.34 volts everywhere there is supposed to be voltage. the battery negative bolted to the frame solid connections on both ends. the cable looks good, but I could make a new one with 0 or 00 cable?

That black wire still has 12.34 V with key on.

One thing I didn't mention (because I am a bus gal and don't know crap about lawn tractors) Before all this started, when the only electrical problem was the solenoid, the tractor went to the shop and got a new middle spindle, blade and belt. Could the shop have unplugged anything down there that I don't see? Could the paint on the frame be causing the batt - issue?

That black wire still has 12.34 V with key on.

One thing I didn't mention (because I am a bus gal and don't know crap about lawn tractors) Before all this started, when the only electrical problem was the solenoid, the tractor went to the shop and got a new middle spindle, blade and belt. Could the shop have unplugged anything down there that I don't see? Could the paint on the frame be causing the batt - issue?

#27

A

Andi

A

Andi

I found this post...same tractor, different wire problem...BUT if you look at the third picture the little black wire is sitting below the guy's finger. I believe he got the wrong harness but his black wire didn't go anywhere either?

www.lawnmowerforum.com

www.lawnmowerforum.com

Husqvarna RZ5424 Wire Harness Replacement. Strange Solenoid Connector.

I'm installing a new wire harness on my RZ5424. I've been making my way through with no issues until I got to the solenoid. The old red wire ring terminal connection that stacks on the hot battery connection is non existent on the new harness. Instead, there is a white plastic barrel type...

#28

AVB

AVB

First the cable doesn't any larger than 6 ga,

As far paint normally the screw have star washers and make good contact via the threads provided they are tight.

There is no reason to unplug anything under the mower body when replacing the deck belt, spindle, or blade. Replacing the drive is a different story as they have remove the electric PTO clutch and hopefully they plugged it back in and have the anti-rotation device installed correctly.One thing I didn't mention (because I am a bus gal and don't know crap about lawn tractors) Before all this started, when the only electrical problem was the solenoid, the tractor went to the shop and got a new middle spindle, blade and belt. Could the shop have unplugged anything down there that I don't see? Could the paint on the frame be causing the batt - issue?

As far paint normally the screw have star washers and make good contact via the threads provided they are tight.

#29

A

Andi

A

Andi

I did exactly that and I had 12.32 V on the mounting screw. under the seat? I'll upload a few pics

#30

A

Andi

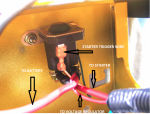

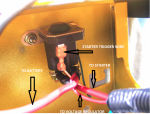

ABOVE: Little black wire in harness with acc. outlet, red batt connector wire and yellow starter solenoid wire

BELOW: I have 3 ignition switches...all OEM, This is how they seat. The copper flares out, so they do not sit flush but they DO make contact

My new Coils...white wire off so as not to burn the little chip inside.

A

Andi

ABOVE: Little black wire in harness with acc. outlet, red batt connector wire and yellow starter solenoid wire

BELOW: I have 3 ignition switches...all OEM, This is how they seat. The copper flares out, so they do not sit flush but they DO make contact

My new Coils...white wire off so as not to burn the little chip inside.

#31

Hammermechanicman

Hammermechanicman

There is something wrong with that ignition switch and connector.

Pull them apart and post pics of both switch and connector.

Pull them apart and post pics of both switch and connector.

#32

A

Andi

A

Andi

I have three switches...all the same. There is a bit of dielectric grease more so on the switch. The harness is brand new, and I carefully compared every connection before I installed it.

I thought about direct wiring the switch, but when the key is on, I have the proper voltage, so???

I thought about direct wiring the switch, but when the key is on, I have the proper voltage, so???

Attachments

#33

AVB

AVB

The connector and switch is fine as far as mating. I have same switch and connectors here. The Plastic stand offs is makes it to look like isn't going on completely.

Now there might be damage on the G terminal area of the 7 slot connector or it could just be dielectric grease.

Now there might be damage on the G terminal area of the 7 slot connector or it could just be dielectric grease.

#34

A

Andi

A

Andi

It's grease...I have checked all of the connectors.

In a perfect world...where should the battery negative cable be bolted? It is to a frame hole now, but I do not know where it came from. The engine grounds off the harness are connected to the engine on the right side...they are perfect. Why does that darn black wire go...and why does it have 12.34 volts???

I REALLY appreciate all of yalls help. I have been doing 24VDC work for 20 years...and I can not figure this out.

In a perfect world...where should the battery negative cable be bolted? It is to a frame hole now, but I do not know where it came from. The engine grounds off the harness are connected to the engine on the right side...they are perfect. Why does that darn black wire go...and why does it have 12.34 volts???

I REALLY appreciate all of yalls help. I have been doing 24VDC work for 20 years...and I can not figure this out.

#35

A

Andi

A

Andi

Theoretically, if I made a jumper from "A1" to "S" to "B" with (or without) a ground strap...if I plug it into the ignition switch, shouldn't that work?

Even though all but one has been replaced, how do I by-pass the interlock switches and the seat switch and brake switch safety circuits?

Even though all but one has been replaced, how do I by-pass the interlock switches and the seat switch and brake switch safety circuits?

#36

AVB

AVB

The only difference between 24 VDC and 12VDC circuit is the voltages that you working. To find the bad area when tracing an issue like is to do the voltage drop tests between points. With mower wiring where black in DC in normally ground it can either way because some manufactures tend to AC wiring color codes where black is live and white is the neutral or ground. It can be confusing at times without the wire schematics.

But as far if it interconnect problem since you have 12V on the yellow wire at the solenoid they are all good in reference to the starter circuit so no need to do bypassing there. As far test jump at the switch all you need to jump is the B to S for the starter relay to operate provide the ground return path is intact and that B has 12v on it. Now the engine may run as it probably has a fuel solenoid but what you right now is to get the starter operate.

But as far if it interconnect problem since you have 12V on the yellow wire at the solenoid they are all good in reference to the starter circuit so no need to do bypassing there. As far test jump at the switch all you need to jump is the B to S for the starter relay to operate provide the ground return path is intact and that B has 12v on it. Now the engine may run as it probably has a fuel solenoid but what you right now is to get the starter operate.

#37

A

Andi

A

Andi

I am going to change the relay and make a new negative battery cable. I'll report back tomorrow AM at latest...as soon as I read voltages again...thanks again