You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

How far can I push/modify a 12hp on stock internals?

#1

R

reddman

R

reddman

I got a racing mower for cheap, and I'm trying to squeeze as much as I can out of her with minimal investment. I want to keep stock internals, as I'm on a very limited window of time. I'm doing the standard eyebrow shave, intake/exhaust porting, milling the head down, and advancing the timing, but I'm guessing on some of this. I need some input from people who know more about this stuff.

I am a machinist and off-road race car fabricator, so some of the stuff I'm making is kinda fancy. 1-1/2" titanium exhaust, 2" aluminum intake, but these are just materials I had sitting around, so really I'm still at zero dollars invested in upgrades. I am trying to stay close to that number.

The carb was mutilated by the previous owner, so it's gotta be replaced, and I think I should be shopping for a bigger unit to accomidate the higher flow. I don't know about interchangeability though, and am hoping someone can guide my in the right direction there. I also don't know what is a safe limit on compression. By my math, the stock compression is about 8:1, and if I shave .05" off that should put me about 9:1. I'd like to go even higher, and I have access to 115 octane leaded race gas, so I want to take it as high as I can without blowing the motor up.

Here is the beginning of the titanium exhaust, and the mower as it sits now while I beef up the front end. We are doing our next race on a rockcrawling course, and I think keeping the wheels on is going to be more important than power on this one. I still need that HP though!

I am a machinist and off-road race car fabricator, so some of the stuff I'm making is kinda fancy. 1-1/2" titanium exhaust, 2" aluminum intake, but these are just materials I had sitting around, so really I'm still at zero dollars invested in upgrades. I am trying to stay close to that number.

The carb was mutilated by the previous owner, so it's gotta be replaced, and I think I should be shopping for a bigger unit to accomidate the higher flow. I don't know about interchangeability though, and am hoping someone can guide my in the right direction there. I also don't know what is a safe limit on compression. By my math, the stock compression is about 8:1, and if I shave .05" off that should put me about 9:1. I'd like to go even higher, and I have access to 115 octane leaded race gas, so I want to take it as high as I can without blowing the motor up.

Here is the beginning of the titanium exhaust, and the mower as it sits now while I beef up the front end. We are doing our next race on a rockcrawling course, and I think keeping the wheels on is going to be more important than power on this one. I still need that HP though!

#2

R

reddman

R

reddman

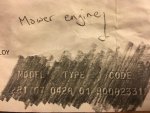

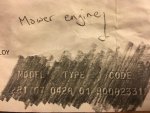

I should add, this is a 28000 series motor. No idea on age. The cylinder is in good shape.

Model: 281707

Type: 0428-01

Code: 90082331

Oh, and any thoughts on improved cooling? I'm thinking of hanging a 10" electric fan above the motor to help shove air into the cooling blower. Think that's overthinking things or???

Edit | Delete

Model: 281707

Type: 0428-01

Code: 90082331

Oh, and any thoughts on improved cooling? I'm thinking of hanging a 10" electric fan above the motor to help shove air into the cooling blower. Think that's overthinking things or???

Edit | Delete

#3

B

bertsmobile1

B

bertsmobile1

The rev killer is the counterweight.

Run that engine much over 4000 rpm with it one and it will exit through the crankcase.

You do not need it in a racing engine to damp out engine vibrations.

However once removed you will need to replace the the engine mounting self tapping bolt with through bolts.

Depending upon which chassis the mower has you might also need to put a stiffener plate under the engine.

Pay close attention to the ends of the steering links, they are normally buggered and putting extra load on them will cause them to part company and the mower to flip.

Pull the plastic bushes out of the front cross member and replace them with either full length nylon or gunmetal.

If you are going to leave the cross member loose then remove the support plates & check the flare that becomes the bush, generally they are rusted / worn through.

Glue some nylon/ teflon sheet on the cross member or support plates to take the twist out of the cross member when you turn.

Some bolt it solid, however that makes the mower more likely flip on corners.

On the subject of bushes , check the one in the steering shaft, some are plastic, some are brass and all of them are buggered.

With a bit of work you can also double the fan gear.

Flip the worm bear on the end of the steering shaft over so you are using full depth gears or the first hard corner will be the last for that day.

And don't forget to have fun.

Run that engine much over 4000 rpm with it one and it will exit through the crankcase.

You do not need it in a racing engine to damp out engine vibrations.

However once removed you will need to replace the the engine mounting self tapping bolt with through bolts.

Depending upon which chassis the mower has you might also need to put a stiffener plate under the engine.

Pay close attention to the ends of the steering links, they are normally buggered and putting extra load on them will cause them to part company and the mower to flip.

Pull the plastic bushes out of the front cross member and replace them with either full length nylon or gunmetal.

If you are going to leave the cross member loose then remove the support plates & check the flare that becomes the bush, generally they are rusted / worn through.

Glue some nylon/ teflon sheet on the cross member or support plates to take the twist out of the cross member when you turn.

Some bolt it solid, however that makes the mower more likely flip on corners.

On the subject of bushes , check the one in the steering shaft, some are plastic, some are brass and all of them are buggered.

With a bit of work you can also double the fan gear.

Flip the worm bear on the end of the steering shaft over so you are using full depth gears or the first hard corner will be the last for that day.

And don't forget to have fun.

#4

R

reddman

Thanks for all the info!

I will have to look up what's involved in the counterweight removal. I'm hoping to avoid getting any deeper into the motor at this time. I pretty much only have this week to finish everything. Because I haven't touched the governor yet, am I safe to assume that the RPMs will stay in the safe range?

I've got some interesting plans for beefing up the front end, but I hadn't paid much attention to the steering joints on the push/pull link. I am making bronze bushings for everything up front tonight, and hoping to make some more progress on the exhaust.

What cross member are you referring to? The entire mowing deck and all related brackets are gone, and I can't think of a cross member anywhere on the chassis. I'm at work right now, so I can't go climb under it.

The steering gears seem tight. It's a rack and radial pinion setup, no worm gear here.

Thanks again!

R

reddman

The rev killer is the counterweight.

Run that engine much over 4000 rpm with it one and it will exit through the crankcase.

You do not need it in a racing engine to damp out engine vibrations.

However once removed you will need to replace the the engine mounting self tapping bolt with through bolts.

Depending upon which chassis the mower has you might also need to put a stiffener plate under the engine.

Pay close attention to the ends of the steering links, they are normally buggered and putting extra load on them will cause them to part company and the mower to flip.

Pull the plastic bushes out of the front cross member and replace them with either full length nylon or gunmetal.

If you are going to leave the cross member loose then remove the support plates & check the flare that becomes the bush, generally they are rusted / worn through.

Glue some nylon/ teflon sheet on the cross member or support plates to take the twist out of the cross member when you turn.

Some bolt it solid, however that makes the mower more likely flip on corners.

On the subject of bushes , check the one in the steering shaft, some are plastic, some are brass and all of them are buggered.

With a bit of work you can also double the fan gear.

Flip the worm bear on the end of the steering shaft over so you are using full depth gears or the first hard corner will be the last for that day.

And don't forget to have fun.

Thanks for all the info!

I will have to look up what's involved in the counterweight removal. I'm hoping to avoid getting any deeper into the motor at this time. I pretty much only have this week to finish everything. Because I haven't touched the governor yet, am I safe to assume that the RPMs will stay in the safe range?

I've got some interesting plans for beefing up the front end, but I hadn't paid much attention to the steering joints on the push/pull link. I am making bronze bushings for everything up front tonight, and hoping to make some more progress on the exhaust.

What cross member are you referring to? The entire mowing deck and all related brackets are gone, and I can't think of a cross member anywhere on the chassis. I'm at work right now, so I can't go climb under it.

The steering gears seem tight. It's a rack and radial pinion setup, no worm gear here.

Thanks again!

#5

B

bertsmobile1

B

bertsmobile1

The one the front wheels fit into.

The gear ( pinion ) that turns the fan gear ( rack ) is cut very helical sorry if Aust has caused confusion.

Without the counterweight the engine will accelerate a lot quicker.

The governor will tend to over correct so if you are leaving it in stretch the long spring the throttle rod passes through and bend new hooks on each end.

Down here they usually toss the governor and screw in the high speed throttle stop to limit the amount of throttle opening but you will need to check the local rules.

The gear ( pinion ) that turns the fan gear ( rack ) is cut very helical sorry if Aust has caused confusion.

Without the counterweight the engine will accelerate a lot quicker.

The governor will tend to over correct so if you are leaving it in stretch the long spring the throttle rod passes through and bend new hooks on each end.

Down here they usually toss the governor and screw in the high speed throttle stop to limit the amount of throttle opening but you will need to check the local rules.

#6

R

reddman

R

reddman

Gotcha. Yeah that thing is pretty chintzy. It flexes a huge amount with the push/pull of the steering, I can't believe they went into production with that design. I've got all kinds of beefiness that is going to address the front end.

I'll have to look at the pinion if I ever leave work, but I want to say mine is straight cut teeth. Sounds like you know a thing or two about these though, so I may well be mistaken.

The previous owner attached a cable to the gov, and with a little tug it can be overridden. I may just tweak the spring like you suggest though. I did something similar on the Honda mower I actually use for my yard, and while she screams like a banshee, she just keeps on going. The racing I'm doing is pretty unofficial. The rules are what we make them. :laughing: Maybe I will pull the counterweight as you suggest. I don't know if I'll have time for that kind of surgery before this next event though.

What are your thoughts on compression? I am hoping to mill the head tomorrow night, but I don't know how high I dare go. I will be milling out pockets for valve clearance as needed, and will be helicoiling the threads for the plug so I can add a copper washer to it to keep the valves from hitting it as well.

I'll have to look at the pinion if I ever leave work, but I want to say mine is straight cut teeth. Sounds like you know a thing or two about these though, so I may well be mistaken.

The previous owner attached a cable to the gov, and with a little tug it can be overridden. I may just tweak the spring like you suggest though. I did something similar on the Honda mower I actually use for my yard, and while she screams like a banshee, she just keeps on going. The racing I'm doing is pretty unofficial. The rules are what we make them. :laughing: Maybe I will pull the counterweight as you suggest. I don't know if I'll have time for that kind of surgery before this next event though.

What are your thoughts on compression? I am hoping to mill the head tomorrow night, but I don't know how high I dare go. I will be milling out pockets for valve clearance as needed, and will be helicoiling the threads for the plug so I can add a copper washer to it to keep the valves from hitting it as well.

#7

sgkent

sgkent

In general it is torque when down low, and the RPM at the top that moves things. Since you are giving up a higher RPM I don't know how much the work you are doing is going to make that much more torque. You really can't flow that much more air thru it at a lower RPM and the things you are doing cater to higher RPM's. I would have looked to bore it to the largest piston the class would allow too.

Maybe you might want to also post in a go cart forum to get ideas.

Maybe you might want to also post in a go cart forum to get ideas.

#8

R

reddman

Why do you say I'm giving up the top end of the RPM range? I am shooting for a more hp oriented motor over torque. I think it'll spend the majority of it's time near the upper limit of its RPM range, which is why I'm trying to get air through the motor with less restriction. I am trying to do this on a shoestring budget, so I know I won't be getting the maximum performance attainable. This is more for racing with buddies than sanctioned events, so the rules are very basic. All my cash goes to my skiing addiction and desert racing, this is more of an experiment to play with something that I can blow up and not lose a lot of sleep over. That said, I would like the motor to keep its guts on the inside. :laughing:

I looked at several karting forums, but they are so specific with their built-for-racing 206 and Animal motors, and those that I did find which had a forum for more general B&S threads see so little traffic that I may not get a response this year. I tried on the busiest appropriate karting forum I could find, and it has 5 views in 24 hours, zero responses. The kart guys just don't seem to do anything with this family of motors.

R

reddman

In general it is torque when down low, and the RPM at the top that moves things. Since you are giving up a higher RPM I don't know how much the work you are doing is going to make that much more torque. You really can't flow that much more air thru it at a lower RPM and the things you are doing cater to higher RPM's. I would have looked to bore it to the largest piston the class would allow too.

Maybe you might want to also post in a go cart forum to get ideas.

Why do you say I'm giving up the top end of the RPM range? I am shooting for a more hp oriented motor over torque. I think it'll spend the majority of it's time near the upper limit of its RPM range, which is why I'm trying to get air through the motor with less restriction. I am trying to do this on a shoestring budget, so I know I won't be getting the maximum performance attainable. This is more for racing with buddies than sanctioned events, so the rules are very basic. All my cash goes to my skiing addiction and desert racing, this is more of an experiment to play with something that I can blow up and not lose a lot of sleep over. That said, I would like the motor to keep its guts on the inside. :laughing:

I looked at several karting forums, but they are so specific with their built-for-racing 206 and Animal motors, and those that I did find which had a forum for more general B&S threads see so little traffic that I may not get a response this year. I tried on the busiest appropriate karting forum I could find, and it has 5 views in 24 hours, zero responses. The kart guys just don't seem to do anything with this family of motors.

#9

B

bertsmobile1

B

bertsmobile1

You sure you got those numbers right

280707-0428-01 is a side banger so pushing up the compression ratio is not going to make all that much difference

A long intake tract and resonant exhaust will make a big difference but SV's breathe so badly pushing up the CR by itself is of little value and oft leads to detonation of the incoming charge by the outgoing exhaust.

Building up the head as per the KR Harley can make them flow a lot better but the angles of the inlet & exhaust tracts are critical.

A solid copper head gasket is worthwhile

One of the programmable electronic ignitions is also very worthwhile as the modules fitted as standard are so close to fixed ignition it is not funny

280707-0428-01 is a side banger so pushing up the compression ratio is not going to make all that much difference

A long intake tract and resonant exhaust will make a big difference but SV's breathe so badly pushing up the CR by itself is of little value and oft leads to detonation of the incoming charge by the outgoing exhaust.

Building up the head as per the KR Harley can make them flow a lot better but the angles of the inlet & exhaust tracts are critical.

A solid copper head gasket is worthwhile

One of the programmable electronic ignitions is also very worthwhile as the modules fitted as standard are so close to fixed ignition it is not funny

#10

R

reddman

Yeah those #s are correct. I will be blending a very high octane fuel. I'll start with premium and cut it with 115 leaded as I dial in the timing to keep preignition/detonation in check to figure out my target octane. I may be up in the night, but I think I can control the problem with that approach. The flow through the intake and exhaust tracts looks like a joke on this motor, so while it doesn't sound like she's the best candidate for high HP, I have to assume that with my experience in aerodynamics I can at least create more laminar flow, without making them too big, and squeeze what is possible out of this thing. Because I can't find any solid info on compression ratio, I am just going to shoot for 9-9.5:1, that seems reasonable in my mind. If anyone disagrees on any of this, I would love to hear from someone with more B&S experience than myself. I'm not too proud to accept input from anyone, rather I would much appreciate it.

R

reddman

You sure you got those numbers right

280707-0428-01 is a side banger so pushing up the compression ratio is not going to make all that much difference

A long intake tract and resonant exhaust will make a big difference but SV's breathe so badly pushing up the CR by itself is of little value and oft leads to detonation of the incoming charge by the outgoing exhaust.

Building up the head as per the KR Harley can make them flow a lot better but the angles of the inlet & exhaust tracts are critical.

A solid copper head gasket is worthwhile

One of the programmable electronic ignitions is also very worthwhile as the modules fitted as standard are so close to fixed ignition it is not funny

Yeah those #s are correct. I will be blending a very high octane fuel. I'll start with premium and cut it with 115 leaded as I dial in the timing to keep preignition/detonation in check to figure out my target octane. I may be up in the night, but I think I can control the problem with that approach. The flow through the intake and exhaust tracts looks like a joke on this motor, so while it doesn't sound like she's the best candidate for high HP, I have to assume that with my experience in aerodynamics I can at least create more laminar flow, without making them too big, and squeeze what is possible out of this thing. Because I can't find any solid info on compression ratio, I am just going to shoot for 9-9.5:1, that seems reasonable in my mind. If anyone disagrees on any of this, I would love to hear from someone with more B&S experience than myself. I'm not too proud to accept input from anyone, rather I would much appreciate it.

#11

sgkent

Does working as a automotive engine machinist for a shop that built winning racers and engines for Al Unser Jr qualify for experience understanding racing motors? Winning many SCCA events and a championship in FP qualify?

"I have to assume that with my experience in aerodynamics I can at least create more laminar flow" - I am puzzled. One does not want a laminar flow because that denies you use of the rest of the manifold cross section. Be sure to keep the inside of the manifolds sand paper rough because the turbulence will pull the laminar flows back to use the whole manifold cross section.

3500 RPM is 3500 RPM. 3500 RPM x the gearbox (belt hubs, wheels etc) is X number of MPH whether in a Ferrari or on a mower. A mower doing 30 mph and a Ferrari traveling 30 mph are neck in neck and remain that way indefinitely. In order for the Ferrari to pass the mower it has to move faster which requires the engine run a higher RPM. The way you beat someone is you (1) get your engine to a higher RPM so your top HP is greater given the same gear ratios (2) lighten your vehicle so that there is less mass to push to that top speed, you'll get there first (3) increase torque so your vehicle goes faster between RPM's. By back cutting the valves, improving the intake and exhaust you can increase the amount of air (to combine with fuel) available. To use it the engine has to either be a larger displacement or be able to reach a higher RPM quicker. What you are doing will help the engine speed up faster but not so much I would bank that is a winning strategy. Personally I'd start by lowering the weight of the vehicle combined with what you are doing, and the largest displacement that can be used with that connecting rod, crank, hub and keys. I will add this - if you are able to raise the power band with what you are doing, play with the drive hub sizes to see if you can get to speed faster. Anything that lets you get to your max speed faster will give you time gains over your competition. I am guessing those mowers don't do anything but compression brake so raising the compression should assist in braking if the course has slower sections on it. Be sure to take your practice laps.

sgkent

Yeah those #s are correct. I will be blending a very high octane fuel. I'll start with premium and cut it with 115 leaded as I dial in the timing to keep preignition/detonation in check to figure out my target octane. I may be up in the night, but I think I can control the problem with that approach. The flow through the intake and exhaust tracts looks like a joke on this motor, so while it doesn't sound like she's the best candidate for high HP, I have to assume that with my experience in aerodynamics I can at least create more laminar flow, without making them too big, and squeeze what is possible out of this thing. Because I can't find any solid info on compression ratio, I am just going to shoot for 9-9.5:1, that seems reasonable in my mind. If anyone disagrees on any of this, I would love to hear from someone with more B&S experience than myself. I'm not too proud to accept input from anyone, rather I would much appreciate it.

View attachment 40665View attachment 40666

Does working as a automotive engine machinist for a shop that built winning racers and engines for Al Unser Jr qualify for experience understanding racing motors? Winning many SCCA events and a championship in FP qualify?

"I have to assume that with my experience in aerodynamics I can at least create more laminar flow" - I am puzzled. One does not want a laminar flow because that denies you use of the rest of the manifold cross section. Be sure to keep the inside of the manifolds sand paper rough because the turbulence will pull the laminar flows back to use the whole manifold cross section.

3500 RPM is 3500 RPM. 3500 RPM x the gearbox (belt hubs, wheels etc) is X number of MPH whether in a Ferrari or on a mower. A mower doing 30 mph and a Ferrari traveling 30 mph are neck in neck and remain that way indefinitely. In order for the Ferrari to pass the mower it has to move faster which requires the engine run a higher RPM. The way you beat someone is you (1) get your engine to a higher RPM so your top HP is greater given the same gear ratios (2) lighten your vehicle so that there is less mass to push to that top speed, you'll get there first (3) increase torque so your vehicle goes faster between RPM's. By back cutting the valves, improving the intake and exhaust you can increase the amount of air (to combine with fuel) available. To use it the engine has to either be a larger displacement or be able to reach a higher RPM quicker. What you are doing will help the engine speed up faster but not so much I would bank that is a winning strategy. Personally I'd start by lowering the weight of the vehicle combined with what you are doing, and the largest displacement that can be used with that connecting rod, crank, hub and keys. I will add this - if you are able to raise the power band with what you are doing, play with the drive hub sizes to see if you can get to speed faster. Anything that lets you get to your max speed faster will give you time gains over your competition. I am guessing those mowers don't do anything but compression brake so raising the compression should assist in braking if the course has slower sections on it. Be sure to take your practice laps.

#12

R

reddman

You seem a little irritated that I have said "I think this ____, but would love to hear from people who know more about this than I". I didn't question or dismiss what you said, I tried discussing my understanding of it so I can further my knowledge. I'm not trying to debate. If you believe I'm mistaken about something, I'm happy to listen, but I hope that you will wholly understand my situation and my goals.

Since I cannot regear for a higher top speed per our rules, I expect to be generally running in top gear at max RPM and pulling the governor as needed to raise the RPM ceiling. I have lower gears I can use where torque multiplication is the ticket for a section. My specialties are more chassis, suspension, etc. design. We have a motor builder build our naturally aspirated 900 hp V8s, I don't get into them. I would tap them for info, but their knowledge of 9000 rpm V8 engines really is an entire different world than a flathead single cylinder pushing a fraction of the power/cylinder that I'm trying to learn about. That's where I'd love to tap brains like yours for details.

Like I've mentioned several times, I am not participating in sanctioned events, merely budget racing with buddies for fun and I'm trying to gain some advantage. The rules are lax, but gearing changes and piston/crank changes are on the list of the prohibitions. There is no additional weight I could remove. Deck is gone. Brackets are gone. Wiring has been removed and only the bare minimum to make it run remains. Like the old racers say, "If it doesn't make your car go faster or stop faster, get it off your car!" The improved compression braking will be appreciated, because as I mentioned earlier, we are racing on a rockcrawling trail, and there will certainly be steep technical downhill sections. This mower has no mechanical brakes, unless perhaps something automatic is built into the gearbox.

I understand about the surface texture on the intake tract, but where I was trying to go with that is that the razor sharp 90 degree turns the air is expected to must cause some reduction in performance. I didn't say port and polish, just smoothing the general shape of the tracts, hopefully with minimal increase in volume so I can maintain some torque too. Similar to the dimples on a golf ball, a rough surface will cause tiny vortices along the surface boundary, and allow the bulk of the flow to essentially "roll" along those vortices, reducing overall drag. I imagine the laws of fluid dynamics apply whether it's inside or outside of a car. I'd appreciate your help in pointing out where I may be mistaken though. As a non-motor-builder, there is some of this that doesn't yet make sense to me yet, like what you mean by "pull the laminar flows back to use the whole manifold cross section." I am looking to hear from people like you who know about small motors. But I can't help but look at it through the lens of my current understanding of these concepts. I'm open and hoping to learn some new concepts here though.

R

reddman

Does working as a automotive engine machinist for a shop that built winning racers and engines for Al Unser Jr qualify for experience understanding racing motors? Winning many SCCA events and a championship in FP qualify?

"I have to assume that with my experience in aerodynamics I can at least create more laminar flow" - I am puzzled. One does not want a laminar flow because that denies you use of the rest of the manifold cross section. Be sure to keep the inside of the manifolds sand paper rough because the turbulence will pull the laminar flows back to use the whole manifold cross section.

3500 RPM is 3500 RPM. 3500 RPM x the gearbox (belt hubs, wheels etc) is X number of MPH whether in a Ferrari or on a mower. A mower doing 30 mph and a Ferrari traveling 30 mph are neck in neck and remain that way indefinitely. In order for the Ferrari to pass the mower it has to move faster which requires the engine run a higher RPM. The way you beat someone is you (1) get your engine to a higher RPM so your top HP is greater given the same gear ratios (2) lighten your vehicle so that there is less mass to push to that top speed, you'll get there first (3) increase torque so your vehicle goes faster between RPM's. By back cutting the valves, improving the intake and exhaust you can increase the amount of air (to combine with fuel) available. To use it the engine has to either be a larger displacement or be able to reach a higher RPM quicker. What you are doing will help the engine speed up faster but not so much I would bank that is a winning strategy. Personally I'd start by lowering the weight of the vehicle combined with what you are doing, and the largest displacement that can be used with that connecting rod, crank, hub and keys. I will add this - if you are able to raise the power band with what you are doing, play with the drive hub sizes to see if you can get to speed faster. Anything that lets you get to your max speed faster will give you time gains over your competition. I am guessing those mowers don't do anything but compression brake so raising the compression should assist in braking if the course has slower sections on it. Be sure to take your practice laps.

You seem a little irritated that I have said "I think this ____, but would love to hear from people who know more about this than I". I didn't question or dismiss what you said, I tried discussing my understanding of it so I can further my knowledge. I'm not trying to debate. If you believe I'm mistaken about something, I'm happy to listen, but I hope that you will wholly understand my situation and my goals.

Since I cannot regear for a higher top speed per our rules, I expect to be generally running in top gear at max RPM and pulling the governor as needed to raise the RPM ceiling. I have lower gears I can use where torque multiplication is the ticket for a section. My specialties are more chassis, suspension, etc. design. We have a motor builder build our naturally aspirated 900 hp V8s, I don't get into them. I would tap them for info, but their knowledge of 9000 rpm V8 engines really is an entire different world than a flathead single cylinder pushing a fraction of the power/cylinder that I'm trying to learn about. That's where I'd love to tap brains like yours for details.

Like I've mentioned several times, I am not participating in sanctioned events, merely budget racing with buddies for fun and I'm trying to gain some advantage. The rules are lax, but gearing changes and piston/crank changes are on the list of the prohibitions. There is no additional weight I could remove. Deck is gone. Brackets are gone. Wiring has been removed and only the bare minimum to make it run remains. Like the old racers say, "If it doesn't make your car go faster or stop faster, get it off your car!" The improved compression braking will be appreciated, because as I mentioned earlier, we are racing on a rockcrawling trail, and there will certainly be steep technical downhill sections. This mower has no mechanical brakes, unless perhaps something automatic is built into the gearbox.

I understand about the surface texture on the intake tract, but where I was trying to go with that is that the razor sharp 90 degree turns the air is expected to must cause some reduction in performance. I didn't say port and polish, just smoothing the general shape of the tracts, hopefully with minimal increase in volume so I can maintain some torque too. Similar to the dimples on a golf ball, a rough surface will cause tiny vortices along the surface boundary, and allow the bulk of the flow to essentially "roll" along those vortices, reducing overall drag. I imagine the laws of fluid dynamics apply whether it's inside or outside of a car. I'd appreciate your help in pointing out where I may be mistaken though. As a non-motor-builder, there is some of this that doesn't yet make sense to me yet, like what you mean by "pull the laminar flows back to use the whole manifold cross section." I am looking to hear from people like you who know about small motors. But I can't help but look at it through the lens of my current understanding of these concepts. I'm open and hoping to learn some new concepts here though.

#13

sgkent

sgkent

just to clarify - wasn't saying you wouldn't benefit from what you are doing - just thinking where the most gain would be. I went over to the Briggs racing forum and read some articles written by Briggs racing. They even recommend special oils so one does not froth the oil on a splash dipping rod. Lots of tips over there.

Once a laminar flow separates from the walls it is like a wind coming over a fence - it takes a while to come back. Doing so creates eddies and back currents, dead areas. Like a river it leaves a dead area on the inside of the bend. The roughness helps keep that from happening. You want to give the air the cleanest path possible both in the intake and exhaust. I used to know the formulas for tuning the exhausts but I no longer do - but there should be calculators out there on the web. On the back of the valves make sure there is no lip where the valve face begins. You can put the stem in solvent with the solvent stream or a small water stream flowing down the stem. If the surface is right the fluis (including air) will adhere to the valve and wrap around it like it wasn't there. If a lip is there it will splay out and create a large dead area in the cylinder behind the valve. More important on the intake that the exhaust because of the direction the flow is moving. Make sure any obstructions in the intake manifold etc like gaskets are clean with the surface to reduce any drag in the intake area. I used to taper any area that flow happened so that air moved across it easier - thin the edges of the butterfly etc streamlining how air moved by the obstacles in the path. Sometimes when a carb is cast there can be a small lip inside it where different parts of the mold came together - I'd sand those all out so the air had the most streamlined path into the chamber. Every molecule of air you can stuff in there is that little bit more fuel you can make. These are probably cast crankshafts and rods - if you know anyone with an x-ray machine who owes you a favor make sure there are no big flaws in them. Machine an air horn for the carb. That helps get air into the engine a little. Make sure that the clips holding the wrist pin will handle any RPM increases. When jetting remember that it is an air cooled engine so it may be using a little fuel to cool it. We have that issue with our late VW bus engines. Getting more power can be easier than cooling an air cooled engine to get rid of the heat it generates. Saw you were looking at a fan. Ask yourself what could your buddies do to theirs to beat you. Add a small turbo? Make it a hybrid when they need a little boost accelerating? Good luck

Once a laminar flow separates from the walls it is like a wind coming over a fence - it takes a while to come back. Doing so creates eddies and back currents, dead areas. Like a river it leaves a dead area on the inside of the bend. The roughness helps keep that from happening. You want to give the air the cleanest path possible both in the intake and exhaust. I used to know the formulas for tuning the exhausts but I no longer do - but there should be calculators out there on the web. On the back of the valves make sure there is no lip where the valve face begins. You can put the stem in solvent with the solvent stream or a small water stream flowing down the stem. If the surface is right the fluis (including air) will adhere to the valve and wrap around it like it wasn't there. If a lip is there it will splay out and create a large dead area in the cylinder behind the valve. More important on the intake that the exhaust because of the direction the flow is moving. Make sure any obstructions in the intake manifold etc like gaskets are clean with the surface to reduce any drag in the intake area. I used to taper any area that flow happened so that air moved across it easier - thin the edges of the butterfly etc streamlining how air moved by the obstacles in the path. Sometimes when a carb is cast there can be a small lip inside it where different parts of the mold came together - I'd sand those all out so the air had the most streamlined path into the chamber. Every molecule of air you can stuff in there is that little bit more fuel you can make. These are probably cast crankshafts and rods - if you know anyone with an x-ray machine who owes you a favor make sure there are no big flaws in them. Machine an air horn for the carb. That helps get air into the engine a little. Make sure that the clips holding the wrist pin will handle any RPM increases. When jetting remember that it is an air cooled engine so it may be using a little fuel to cool it. We have that issue with our late VW bus engines. Getting more power can be easier than cooling an air cooled engine to get rid of the heat it generates. Saw you were looking at a fan. Ask yourself what could your buddies do to theirs to beat you. Add a small turbo? Make it a hybrid when they need a little boost accelerating? Good luck

#14

B

bertsmobile1

B

bertsmobile1

Because of the internal air flow, you really can not get SV engines to rev high.

The faster they spin the less exhaust gets out the engine runs lean looses power overheats and seizes.

On SV intake air velocity is king.

Long induction tubes and delayed inlet opening will get more fuel into the engine.

Forget about 9:1 all that will do is blow head gaskets.

By design SV engines are slow reving high torque engines.

So your aim is to bring the Max torque down to lower revs and to make the torque cure as flat as possible.

It is torque that gives you the intitial acceleration so you get off the line faster than your opposition and holding the torque for longer means you get to go further before you need to change a gear.

Don't know how they organize the racing over there but here it is 1, 1.5 or 2 miles on a trotting ( turf or cinders ) track,

This means most run a single gearing ratio and clutch slip for the start.

Usually the diffs get locked up cause they gobble up power and the drivers use speedway slides to corner.

Most of what you would do to make a cross flow head OHV engine perform is of little to no use on a SV.

This is why there is a market for special cams , Cranks , flywheels, con rods & pistons for making B&S racing engines.

About the only thing original in them is crankcase.

Side bangers will work much better if you weld a V inside the head to make proper passages for the intake & exhaust.

Generally it is made to give the exhaust a wide funnel into the exhaust valve and the inlet is fairly strait to protect it from the exhaust.

Separating the inlet & exhaust ports will make a massive difference to the breathing but shaving the head actually chokes the engine.

The shape of the head is critical it neds to be designed to keep inlet gasses flowing quickly .

So if you have access to a mill that is where time spent will be most rewarding.

Again I will tell you to search SV Harley engine performance information.

That is where your head needs to be.

The faster they spin the less exhaust gets out the engine runs lean looses power overheats and seizes.

On SV intake air velocity is king.

Long induction tubes and delayed inlet opening will get more fuel into the engine.

Forget about 9:1 all that will do is blow head gaskets.

By design SV engines are slow reving high torque engines.

So your aim is to bring the Max torque down to lower revs and to make the torque cure as flat as possible.

It is torque that gives you the intitial acceleration so you get off the line faster than your opposition and holding the torque for longer means you get to go further before you need to change a gear.

Don't know how they organize the racing over there but here it is 1, 1.5 or 2 miles on a trotting ( turf or cinders ) track,

This means most run a single gearing ratio and clutch slip for the start.

Usually the diffs get locked up cause they gobble up power and the drivers use speedway slides to corner.

Most of what you would do to make a cross flow head OHV engine perform is of little to no use on a SV.

This is why there is a market for special cams , Cranks , flywheels, con rods & pistons for making B&S racing engines.

About the only thing original in them is crankcase.

Side bangers will work much better if you weld a V inside the head to make proper passages for the intake & exhaust.

Generally it is made to give the exhaust a wide funnel into the exhaust valve and the inlet is fairly strait to protect it from the exhaust.

Separating the inlet & exhaust ports will make a massive difference to the breathing but shaving the head actually chokes the engine.

The shape of the head is critical it neds to be designed to keep inlet gasses flowing quickly .

So if you have access to a mill that is where time spent will be most rewarding.

Again I will tell you to search SV Harley engine performance information.

That is where your head needs to be.

#15

R

reddman

R

reddman

Thanks for the guidance gents. Here is the latest on this hunk of junk:

I built a new front end and suspension. It's a very simple design, a layout similar to ancient torque-tube designs, with a panhard rod to control lateral forces. I have kept on top of my zero dollar goal here, and was able to piece this together purely with old bent rod ends, leftover bushings, tabs, and scraps of tube sitting around. It rides on some heavy duty valve springs out of a LS7 racing motor, working out to about 1" (2.5cm) of ride travel, and nearly 4" (10cm) of articulation travel at the wheels. I also increased the length of the steering arm on the knuckle, which will give me a little more leverage on the steering, at the expense of the last 15 degrees or so of steering, which I really don't need on a racer. That will also make the steering racks life a little easier.

I ported the intake and exhaust to make for much more linear flow, and (you may call me crazy, but this project is an expiriment, so don't crucify me for it) I filled the large void on the outside turn of the tracts with high temp epoxy so that port diameter remains constant, with the goal of keeping air velocity up. I also worked the valves a bit for better flow. Also lapped the valve seats and reset the valve clearances.

I decided not to mill the head down, but to lap the block and head dead flat, and run a special sealant like Permatex Super 300. If it's good enough to seal diesel heads, then I'll give it a shot in this little toy. I tossed the gasket when I removed it, but it looked to be something like .03-.04" (1mm) thick, which will put me in the neighborhood of 8.5:1 or maybe a hair higher. If it starts leaking, well, I'm 6 bolts and a head gasket away from going back to the proven stock setup.

I am going to change up to a BX belt, which is about 1/8" (3-4mm) wider, which will effectively ride on the motor pulley as if it was larger, but because of the design of the rear drive pulley, it won't act any larger. This will get me around the "no pulley swap" rule.

Our next race is on a rockcrawling trail, and I've attached a pic of one of the smoother portions of the trail. It's going to be a bloodbath. I think it will mostly be a race of attrition, with a couple smooth sections where some speed will pay off.

I built a new front end and suspension. It's a very simple design, a layout similar to ancient torque-tube designs, with a panhard rod to control lateral forces. I have kept on top of my zero dollar goal here, and was able to piece this together purely with old bent rod ends, leftover bushings, tabs, and scraps of tube sitting around. It rides on some heavy duty valve springs out of a LS7 racing motor, working out to about 1" (2.5cm) of ride travel, and nearly 4" (10cm) of articulation travel at the wheels. I also increased the length of the steering arm on the knuckle, which will give me a little more leverage on the steering, at the expense of the last 15 degrees or so of steering, which I really don't need on a racer. That will also make the steering racks life a little easier.

I ported the intake and exhaust to make for much more linear flow, and (you may call me crazy, but this project is an expiriment, so don't crucify me for it) I filled the large void on the outside turn of the tracts with high temp epoxy so that port diameter remains constant, with the goal of keeping air velocity up. I also worked the valves a bit for better flow. Also lapped the valve seats and reset the valve clearances.

I decided not to mill the head down, but to lap the block and head dead flat, and run a special sealant like Permatex Super 300. If it's good enough to seal diesel heads, then I'll give it a shot in this little toy. I tossed the gasket when I removed it, but it looked to be something like .03-.04" (1mm) thick, which will put me in the neighborhood of 8.5:1 or maybe a hair higher. If it starts leaking, well, I'm 6 bolts and a head gasket away from going back to the proven stock setup.

I am going to change up to a BX belt, which is about 1/8" (3-4mm) wider, which will effectively ride on the motor pulley as if it was larger, but because of the design of the rear drive pulley, it won't act any larger. This will get me around the "no pulley swap" rule.

Our next race is on a rockcrawling trail, and I've attached a pic of one of the smoother portions of the trail. It's going to be a bloodbath. I think it will mostly be a race of attrition, with a couple smooth sections where some speed will pay off.

#16

S

SidecarFlip

S

SidecarFlip

You want to use Detroit Diesel anerobic sealant, not Permatex. It's become my 'go to' sealant, gasket maker for just about everything now.

#17

R

reddman

Thanks for the info! Loctite has a red anaerobic sealant that I love for sealing things with nice and flat surfaces, and that was my initial thought. A bit of googling brought me no examples of folks using it for any application similar, and I did keep seeing references to the 300 stuff for use on lapped heads. I like how the anaerobic practically glues the mating parts together in a way that silicone and others could never dream of, but I worried that any difference in thermal expansion between the block and head might shear it. It sounds like the 300 stuff never fully hardens, but can handle the pressures, so it made sense as I thought about it. The block and head both seem to be aluminum, so thermal expansion is likely going to be similar enough that a hard sealant will work. I already have the loctite/permatex anaerobic in my fluids cabinet, so I may just go that route. Gotta keep up with my cheap AF goal on this project. I think the only dollars spent specifically on things for this will be about $40 for a new carb, however much for a conical air filter, $10 for fresh oil, and maybe $20 on rattle cans for a sweet paint job. I'm going with a paint scheme similar to the Gulf racing Porsches.

R

reddman

You want to use Detroit Diesel anerobic sealant, not Permatex. It's become my 'go to' sealant, gasket maker for just about everything now.

Thanks for the info! Loctite has a red anaerobic sealant that I love for sealing things with nice and flat surfaces, and that was my initial thought. A bit of googling brought me no examples of folks using it for any application similar, and I did keep seeing references to the 300 stuff for use on lapped heads. I like how the anaerobic practically glues the mating parts together in a way that silicone and others could never dream of, but I worried that any difference in thermal expansion between the block and head might shear it. It sounds like the 300 stuff never fully hardens, but can handle the pressures, so it made sense as I thought about it. The block and head both seem to be aluminum, so thermal expansion is likely going to be similar enough that a hard sealant will work. I already have the loctite/permatex anaerobic in my fluids cabinet, so I may just go that route. Gotta keep up with my cheap AF goal on this project. I think the only dollars spent specifically on things for this will be about $40 for a new carb, however much for a conical air filter, $10 for fresh oil, and maybe $20 on rattle cans for a sweet paint job. I'm going with a paint scheme similar to the Gulf racing Porsches.

#18

Boudreaux In Eunice La.

Boudreaux In Eunice La.

reddman your engine is a 1990 year model... How high are you gonna be for RPM's ?? I saw you mentioned opening the gov in short bursts when you needed it....

I don't know if it has been mentioned yet, but a way higher RPM for a long period might cause valve floating.

I am sure you thought about that already ..........

Plus Tard Mon Ami ~!~!

I don't know if it has been mentioned yet, but a way higher RPM for a long period might cause valve floating.

I am sure you thought about that already ..........

Plus Tard Mon Ami ~!~!

#19

R

reddman

Going with the el-cheapo theme here, I am machining some bronze washers to sit under the valve springs. I know that won't increase their spring rate, but it will increase the amount of force seen during valve closing. I hope to stay off the gov override as much as possible. I have always been intimidated by motors for some reason, so this is a nice way to dip my toes into that pool without risking going broke. Funny, because I won't hesitate to rebuild a manual or auto tranny, setup ring and pinions, chop up and totally redo someones half million dollar race car, etc. but this is my first time dabbling with a motor. Maybe this winter when I have some time I'll get into the block and pull the counterweight, machine a billet con-rod, etc. If I do, I'll likely buck up for some bigger springs and do that part right.

R

reddman

reddman your engine is a 1990 year model... How high are you gonna be for RPM's ?? I saw you mentioned opening the gov in short bursts when you needed it....

I don't know if it has been mentioned yet, but a way higher RPM for a long period might cause valve floating.

I am sure you thought about that already ..........

Plus Tard Mon Ami ~!~!

Going with the el-cheapo theme here, I am machining some bronze washers to sit under the valve springs. I know that won't increase their spring rate, but it will increase the amount of force seen during valve closing. I hope to stay off the gov override as much as possible. I have always been intimidated by motors for some reason, so this is a nice way to dip my toes into that pool without risking going broke. Funny, because I won't hesitate to rebuild a manual or auto tranny, setup ring and pinions, chop up and totally redo someones half million dollar race car, etc. but this is my first time dabbling with a motor. Maybe this winter when I have some time I'll get into the block and pull the counterweight, machine a billet con-rod, etc. If I do, I'll likely buck up for some bigger springs and do that part right.

#20

B

bertsmobile1

Anything over 5000 rpm for any length of time and valve float will get eclipsed by piston low earth orbit.

B

bertsmobile1

reddman your engine is a 1990 year model... How high are you gonna be for RPM's ?? I saw you mentioned opening the gov in short bursts when you needed it....

I don't know if it has been mentioned yet, but a way higher RPM for a long period might cause valve floating.

I am sure you thought about that already ..........

Plus Tard Mon Ami ~!~!

Anything over 5000 rpm for any length of time and valve float will get eclipsed by piston low earth orbit.

#21

Boudreaux In Eunice La.

Too funny Bert LOL... I don't know about his club rules on stock engines and about the washers he's adding for more spring strength but, when I was into Sprint Kart racing stock was stock and if you got challenged your engine was tore down by race tech's and checked......... If you were caught you lost the race.... Happened to us a few times.........

Never got caught we were in spec....

Plus Tard Mon Ami ~!~!

Boudreaux In Eunice La.

Anything over 5000 rpm for any length of time and valve float will get eclipsed by piston low earth orbit.

Too funny Bert LOL... I don't know about his club rules on stock engines and about the washers he's adding for more spring strength but, when I was into Sprint Kart racing stock was stock and if you got challenged your engine was tore down by race tech's and checked......... If you were caught you lost the race.... Happened to us a few times.........

Never got caught we were in spec....

Plus Tard Mon Ami ~!~!

#22

B

bertsmobile1

B

bertsmobile1

The local club kicked off a few years back and way too many thought you could just remove the governor and make the engine run faster.

We all know what happened next.

Sold a lot of old crankcases that year.

I am not the worlds best tuner but I am the cheapest supply of parts so I get all the sob stories.

We have done a few engines and without going for a forged steel cap rod you have a bomb sitting in front of you.

Modifing the head made a massive difference, but as soon as you win a few race you go up a class and that means an OHV engine.

We all know what happened next.

Sold a lot of old crankcases that year.

I am not the worlds best tuner but I am the cheapest supply of parts so I get all the sob stories.

We have done a few engines and without going for a forged steel cap rod you have a bomb sitting in front of you.

Modifing the head made a massive difference, but as soon as you win a few race you go up a class and that means an OHV engine.

#23

R

reddman

I honestly have no clue what RPM these things spin at. I'm not getting inside the motor at all at this point, and I don't plan on yanking the gov override often, maybe to help with a pass here or there. What kind of RPM do you think these guys run at governed, and do you know how much higher they may go when the gov is overrode? I really don't want to blow her up. This winter I might be able to get inside and see what I can do to up my redline safely, but for today the goal is to finish the race. Can't win if you don't survive to the finish, and this course will certainly eat a few mowers.

I should also mention that this mower is unlikely to ever join sanctioned races. These are informal races put together by friends, so the rule book is only a dozen lines long. No pulley changes, until we have a modified class no piston/crank/cam changes, fire extinguisher, DOT helmet, and whoever picks up the most trash on the trail (this is in an OHV area of the desert) wins a bottle of whiskey. Not much more rules than that. As with all forms of racing, the rules define the lines not to cross, and the racers walk as close to that line as they can get away with. We are all friends, so I don't think we'll have any cheats.

R

reddman

Anything over 5000 rpm for any length of time and valve float will get eclipsed by piston low earth orbit.

I honestly have no clue what RPM these things spin at. I'm not getting inside the motor at all at this point, and I don't plan on yanking the gov override often, maybe to help with a pass here or there. What kind of RPM do you think these guys run at governed, and do you know how much higher they may go when the gov is overrode? I really don't want to blow her up. This winter I might be able to get inside and see what I can do to up my redline safely, but for today the goal is to finish the race. Can't win if you don't survive to the finish, and this course will certainly eat a few mowers.

I should also mention that this mower is unlikely to ever join sanctioned races. These are informal races put together by friends, so the rule book is only a dozen lines long. No pulley changes, until we have a modified class no piston/crank/cam changes, fire extinguisher, DOT helmet, and whoever picks up the most trash on the trail (this is in an OHV area of the desert) wins a bottle of whiskey. Not much more rules than that. As with all forms of racing, the rules define the lines not to cross, and the racers walk as close to that line as they can get away with. We are all friends, so I don't think we'll have any cheats.

#24

sgkent

sgkent

good job. I smiled because there were a couple formula races we were involved in where the rule book was quite clear that you can't weld metal onto an intake manifold to improve the flow - bu it said nothing about using non-metallic epoxy.

#25

Boudreaux In Eunice La.

I had to leave before I could reply earlier... I had to go do my regular Thursday evening radio show On KBON 101.1 FM...

Get a tach and see what you are turning....... Those are usually turning at 3400 to 3600...... Bert did say anything over 4000 for a long period the counter balance will come out of place.........

Plus Tard Mon Ami ~!~!

Boudreaux In Eunice La.

I honestly have no clue what RPM these things spin at. I'm not getting inside the motor at all at this point, and I don't plan on yanking the gov override often, maybe to help with a pass here or there. What kind of RPM do you think these guys run at governed, and do you know how much higher they may go when the gov is overrode? I really don't want to blow her up. This winter I might be able to get inside and see what I can do to up my redline safely, but for today the goal is to finish the race. Can't win if you don't survive to the finish, and this course will certainly eat a few mowers.

I should also mention that this mower is unlikely to ever join sanctioned races. These are informal races put together by friends, so the rule book is only a dozen lines long. No pulley changes, until we have a modified class no piston/crank/cam changes, fire extinguisher, DOT helmet, and whoever picks up the most trash on the trail (this is in an OHV area of the desert) wins a bottle of whiskey. Not much more rules than that. As with all forms of racing, the rules define the lines not to cross, and the racers walk as close to that line as they can get away with. We are all friends, so I don't think we'll have any cheats.

I had to leave before I could reply earlier... I had to go do my regular Thursday evening radio show On KBON 101.1 FM...

Get a tach and see what you are turning....... Those are usually turning at 3400 to 3600...... Bert did say anything over 4000 for a long period the counter balance will come out of place.........

Plus Tard Mon Ami ~!~!