You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

HELP !!!!! This snapper ZT is driving to the looney bin.

#1

M

Mutt

M

Mutt

Would love to hear from anyone with a Snapper 52" Zero Turn like this one. I have been fighting it for hours and hours. The drive belt keeps jumping off. This mower has 3 belts. One that drives the deck from the clutch, one that drives the deck itself and one that drives the hydro pumps. The deck and pump belts work fine. I bought a new drive belt. Jumps right off as soon as ya start cutting, bought a new 1" shorter than stock belt. Jumps right off. Checked the tensioner spring. Its fine, clutch is fine. motor to front deck drive pulley bearings are good, no slop in the pulley. Who's got some ideas, because I know I'm not the only one that has had this experience. Ya'll give me some ideas please. It's insane I looked for hours on end just for the stinkin' drive belt lay out. Only found them for single belt models

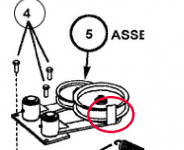

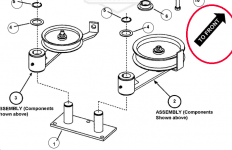

the 2 red arrows point to the drive belt pulley and it's idler pulley. The belt goes from the clutch on the crank shaft straight across to these 2 pulleys. I even straightened up the guide for that belt (it looked bent out a bit, which seemed to help, but not a lot. it still jumps off

the 2 red arrows point to the drive belt pulley and it's idler pulley. The belt goes from the clutch on the crank shaft straight across to these 2 pulleys. I even straightened up the guide for that belt (it looked bent out a bit, which seemed to help, but not a lot. it still jumps off

#3

StarTech

StarTech

oh well my crystal ball shattered and my Ouija Board had JB Weld spilled on it. Now just a bunch of shattered crystal and gooey mess so neither is working.

#4

M

Mutt

M

Mutt

#6

M

MParr

M

MParr

Now we are getting somewhere. Your mower originally came with two belts. Who knows why there are three on there?

#7

M

Mutt

M

Mutt

yeah, it's on there. Is it supposed to pivot, cause when I went to straighten it, I noticed it turns. It was bent down like 20º or more from vertical.Power Portal partially down but is some info. Tag is a little misleading as the part no is the model number.

View attachment 57565

One thing I don't see is the belt retainer.

View attachment 57566

#8

M

Mutt

M

Mutt

yeah, it's on there. Is it supposed to pivot, cause when I went to straighten it, I noticed it turns. It was bent down like 20º or more.

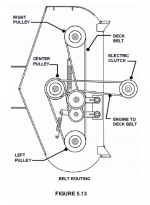

There are actually 4. one goes from the crank to each hydraulic pump for steering, one from the crank to the deck and one on the deck itselfNow we are getting somewhere. Your mower originally came with two belts. Who knows why there are three on there?

#9

M

MParr

M

MParr

Evidently it’s a 2006 model. I’ve copied a link for the operators manual. It shows two hydro belts in addition to the deck belts.

#10

M

MParr

M

MParr

Y

Two hydro belts and two deck belts.There are actually 4. one goes from the crank to each hydraulic pump for steering, one from the crank to the deck and one on the deck itself

#11

M

Mutt

M

Mutt

is the main drive belt supposed to be a smooth V belt or the v belt with teeth?Y

Two hydro belts and two deck belts.

#13

StarTech

StarTech

#15

M

Mutt

M

Mutt

The guide is right now on the left side of the mower. is it supposed to be on the right side of the mower?

#16

M

Mutt

M

Mutt

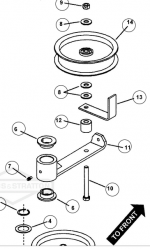

I will go check those 4 bushings right nowAnd this should give you an idea as where it needs to positioned.

View attachment 57570

Also make sure item 6 (two of them) are not worn out ie allowing the idler to floppy around.

Ok, mine is the smooth beltIf you mean the engine PTO to deck then it is the following.

View attachment 57568

Which appears to be a cloth covered belt and not a cog belt.

#17

StarTech

StarTech

#19

M

MParr

www.stens.com

www.stens.com

M

MParr

Stens replacement is:If you mean the engine PTO to deck then it is the following.

View attachment 57568

Which appears to be a cloth covered belt and not a cog belt.

265-270 OEM Replacement Belt

#21

M

Mutt

M

Mutt

Ok, Thanks y'all. I moved the guide to the right side of the deck. This made a vast improvement, but the belt still pops off if you try to cut at more than about 1/8 mph and also every time you do a zero turn

#22

StarTech

StarTech

Then it sounds something else moving out place too.

I know it a pain but sometimes takes a lot things to get one working right. First you got to narrow to where coming off at. I seen things like this to have multiple all at once and got to get each fixed. Just remember don't pull your hair out as that wouldn't help. I have at times just scream at the top my lungs with frustration, walk away, and few days try again to only find problem was just staring me in the face all along. Pateince is key to solving problems like this.

I know it a pain but sometimes takes a lot things to get one working right. First you got to narrow to where coming off at. I seen things like this to have multiple all at once and got to get each fixed. Just remember don't pull your hair out as that wouldn't help. I have at times just scream at the top my lungs with frustration, walk away, and few days try again to only find problem was just staring me in the face all along. Pateince is key to solving problems like this.

#23

bkeller500

bkeller500

Can you retry to engage the blades with the deck at a higher setting and again at a low setting to see if it makes any difference? Wondering if the lift support is attached to the deck improperly. Had a Simplicity Courier zero turn ( very similar model) you might search under that model and see if there is a similar post.Ok, Thanks y'all. I moved the guide to the right side of the deck. This made a vast improvement, but the belt still pops off if you try to cut at more than about 1/8 mph and also every time you do a zero turn

#24

M

Mutt

M

Mutt

I moved the guide to the right side. Tremendous improvement , but the belt still pops off if ya mow at 1/8 mph or do a zero turn

#25

M

Mutt

M

Mutt

I am happy to do any thing any one suggests. I just got to get it mowing. My friends Kubota literally can mow circles around this oneThen it sounds something else moving out place too.

I know it a pain but sometimes takes a lot things to get one working right. First you got to narrow to where coming off at. I seen things like this to have multiple all at once and got to get each fixed. Just remember don't pull your hair out as that wouldn't help. I have at times just scream at the top my lungs with frustration, walk away, and few days try again to only find problem was just staring me in the face all along. Pateince is key to solving problems like this.

#26

M

Mutt

M

Mutt

I'll try that next and see what happensCan you retry to engage the blades with the deck at a higher setting and again at a low setting to see if it makes any difference? Wondering if the lift support is attached to the deck improperly. Had a Simplicity Courier zero turn ( very similar model) you might search under that model and see if there is a similar post.

#27

M

MParr

When engaging the blades, make sure that you have the deck set to the height that you are going to mow. In other words, don’t engage the blades and then lower the deck.

M

MParr

Spring tension on the pulleys or the pulleys themselves are likely causing the continuing problems. The part with the two pulleys that pivot on the two shafts shouldn’t have any slop in them. Check them and grease them.I am happy to do any thing any one suggests. I just got to get it mowing. My friends Kubota literally can mow circles around this one

When engaging the blades, make sure that you have the deck set to the height that you are going to mow. In other words, don’t engage the blades and then lower the deck.

#28

M

Mutt

M

Mutt

got it. I never move the deck. I'll check those 2 pulleys for slop.Spring tension on the pulleys or the pulleys themselves are likely causing the continuing problems. The part with the two pulleys that pivot on the two shafts shouldn’t have any slop in them. Check them and grease them.

When engaging the blades, make sure that you have the deck set to the height that you are going to mow. In other words, don’t engage the blades and then lower the deck.

#29

M

MParr

M

MParr

Also check to make sure your PTO clutch is torqued down properly to the engines to drive shaft.got it. I never move the deck. I'll check those 2 pulleys for slop.

#30

M

Mutt

M

Mutt

I seem to spend more time looking for the parts diagrams for this mower and working on it. Does anyone have a link to a parts book for this particular model? There are 2 arms, that run from the back side of the deck to the rear end. Stabilizer bars? Im just wondering if the round ends of these 2 bars are supposed to have bushings in them. As it sits right now, the bar's have like a 1 1/8 or so bores and the attaching bolts are 1/2" diameter. Seems extremely sloppy to me. I've looked til I am blue in the face for a picture of this stuff with part #'s and I cant find it any where. Only the deck itself and the spindles,etc. No sway bars or it's parts in any diagram I have seen. Also, it it just because the mower is 15 years old that the spindles cost $250-$325 EACH. I see other types that you can get 3 spindles,belts, pulleys,blades all in a kit for $200 delivered.I removed the deck this morning. The blade end of the drive spindle is loose as a goose. Pretty sure that's the reason for the belt popping off all the time.

#31

S

slomo

I'll put mine up against a Kubota any day. Mine has a real bagger system that will suck spare change off your garage floor. Mulches like no other and side slings like a champ. Also if you need to (every 15 years), the entire mower can be positioned vertically. Great for blade swapping and cleaning the deck. Rubber drive ring costs like 8 bucks to replace. Try that with your 0-turn hydros LOL. Fluid alone is way more than that.

slomo

S

slomo

These 0-turns were terrible mowers. Get an older Snapper rear engine rider if you want a reliable mower.I seem to spend more time looking for the parts diagrams for this mower and working on it.

I'll put mine up against a Kubota any day. Mine has a real bagger system that will suck spare change off your garage floor. Mulches like no other and side slings like a champ. Also if you need to (every 15 years), the entire mower can be positioned vertically. Great for blade swapping and cleaning the deck. Rubber drive ring costs like 8 bucks to replace. Try that with your 0-turn hydros LOL. Fluid alone is way more than that.

slomo

#32

M

Mutt

M

Mutt

Has any one ever removed the double pulley from the spindle on this model? I removed the blade. To my amazement, the blade is only held on the spindle with one long bolt and nut, no key, no teeth, etc.so I need to remove the 6 spindle housing bolts /nuts and the spindle and pulley will come off the deck as a unit. How do I remove the pulley? It doesnt appear to be keyed on

#33

M

MParr

M

MParr

It looks like a long bolt goes all the way through the spindle and pulley and is all held together with a nut on top of the pulley. See Page 47. Page 58 shows the spindle assemblies breakdown.

https://bsintek.basco.com/BriggsDocumentDisplay/default.aspx?filename=ahnmzJvLlSZk

https://bsintek.basco.com/BriggsDocumentDisplay/default.aspx?filename=ahnmzJvLlSZk

#34

M

Mutt

M

Mutt

Thanks a MILLION. That's what I need. On page 48 part #17 suspension bushing. Should be 8 of there. There are zero on here right now. Page 58 shows the spindle with 2 pulleys. I pulled the bolt,blade spacers, but still cant figure out what is holding the 2 pulleys to the rest of the spindleIt looks like a long bolt goes all the way through the spindle and pulley and is all held together with a nut on top of the pulley. See Page 47. Page 58 shows the spindle assemblies breakdown.

https://bsintek.basco.com/BriggsDocumentDisplay/default.aspx?filename=ahnmzJvLlSZk

#35

StarTech

StarTech

Whoa...Wait a minute or so. Let me ask this what is the reason you need to remove the spindle housing? I just did a month the drill out and retap on Toro six bolt spindle where all six broken off during removal and I had to 18 holes on 3 spindles that only need the bearing replaced.

#36

M

Mutt

M

Mutt

the bearings in the drive spindle, especially the bearing on the blade end, is shot. I have one of the 6 nuts off. I'll be extra careful removing the nuts. That spindle is anywhere from $200 to $325 plus shipping,How does the 2 pulleys come off the top of the spindle?Whoa...Wait a minute or so. Let me ask this what is the reason you need to remove the spindle housing? I just did a month the drill out and retap on Toro six bolt spindle where all six broken off during removal and I had to 18 holes on 3 spindles that only need the bearing replaced.

#37

M

Mutt

M

Mutt

Ok, so a bunch of old hard grease was holding the 2 pulleys on. Got both off, now to rebuild the spindle.........

#38

M

MParr

M

MParr

Part #9 is the spindle shaft. There are splines on part #9. The pulleys should have matching splines. The big nut has to come off of the long blade bolt. Those pulleys have probably never been off. You are going to need a puller and a good soaking of liquid wrench to pull those pulleys.

#39

M

MParr

M

MParr

Yay!Ok, so a bunch of old hard grease was holding the 2 pulleys on. Got both off, now to rebuild the spindle.........

#40

M

Mutt

M

Mutt

Ok, so instead of ordering the suspension bushings, I'm just machining them myself. Got the first 2 of the 8 machined and installed and back on the deck. no more slop now. Also the 4 bushings on the 2 idler pulleys are also sloppy, so I'll machine 4 of them also and eliminate the ridiculous amount of slop in them.

#41

M

MParr

M

MParr

Sounds like you are on the right path now. Once you get those spindles rebuilt, you should have a good performing machine.

#42

M

Mutt

M

Mutt

Yeah, It runs and drives really nice. I take it that the last guy rebuilt the outer spindles as there is no slop in either one of them.Sounds like you are on the right path now. Once you get those spindles rebuilt, you should have a good performing machine.

#43

M

Mutt

M

Mutt

Ok, so I rebuilt the 2 outside spindles. zero slop,shake or up and down play. The bottom of the drive center spindle was beyond repair, so I replaced it with a brand new OEM spindle. Mowed probably 100 square feet and the belt came off again. I am spending more time putting the belt back on than I am mowing. I can mow faster with my Toro 6.5 hp push mower!!! Surely Snapper couldn't have put out such a poor product ??? So I know all the spindles are in perfect working order (as new), all the pulleys appear to be good, tensioner springs work, pto pulley is good. 3 new blades. Belt on deck that drives right and left belts never comes off or has any issues. I replaces all the suspension bushings. What else is possibly left to fix. It's already started eating up the second drive belt and you have to drive slower than a push mower or the belt comes off. Does anyone have one of these ZTR mowers that is in working order ? Maybe you can post of pic of the drive belt routing along with where the little L piece is located. I installed the belt as per the drawing posted early in the thread. When I got the mower, the belt retainer was on the left of the drive tensioner pulley. Someone here suggested that it went on the right side, so I moved it to the right side. Would the 2 shoulder bushings on the drive tensioner arm being worn and sloppy be an issue with the belt jumping off? That's all that is left to replace. I'll machine some new bushings for it so it doesn't have any up/down slop. If that doesn't fix the problem, there is nothing left to replace and I'll have to take it that Snapper just sells cheap junk and start looking for a zero turn that doesn't have this belt issue. A friend has a Kubota and uses it commercially. The belt never comes off and they mow at a very fast pace. They even moweed where I was mowing and they had teh whole area done in 20 minutes/ I spent more than 20 minutes this morning just putting the belt back on numerous times and you can barely tell I have mowed anything at all........

#44

M

Mutt

M

Mutt

Ok, so I pulled the deck off again and removed the tensioner plate. Turns out there is nothing wrong with the tensioner pin bushings. They measure about 1.003" just enough clearance for a 1.000" pin. It's the pins that are bad, real bad. The plate has (2) 1" holes , the pins are set in place and welded on the back side. Turns out that instead of hardening the pins and letting the easily replaceable bushings take the wear, the awesome company engineers, used soft pins and hardened the bushings. So instead of just replacing for 4 bushings for $25, you get to replace the weldment at the insane cost of $113 plus shipping to $191 (depending on what vendor you choose) for this " weldment ". I can see guaranteed money for Snapper for their parts vendors on replacement parts this way. I'd happily manufacturer this weldment for $50 a pop , all day long.

As you can see, the tops and bottoms of these pins are WAYYYYY undersized. After looking at the cost of this weldment, I figure I could just machine the 2 new pins and replace them myself in about 1½ worth of time and 6" of bar stock.. So I ground the welds off the original pins and knocked them out, machined a couple of new pins, and welded them back in place. No slop now, so the whole deck has now been rebuilt. Every bearing is new or as new, all pulleys are in great shape, one is new, deck belt is brand new and as soon as I get the new drive belt in the mail Tuesday. I'm gonna cross my fingers and hope for the best. Everything has been either rebuilt or replaced with new parts. There is nothing else to replace to make this belt stay in place.

As you can see, the tops and bottoms of these pins are WAYYYYY undersized. After looking at the cost of this weldment, I figure I could just machine the 2 new pins and replace them myself in about 1½ worth of time and 6" of bar stock.. So I ground the welds off the original pins and knocked them out, machined a couple of new pins, and welded them back in place. No slop now, so the whole deck has now been rebuilt. Every bearing is new or as new, all pulleys are in great shape, one is new, deck belt is brand new and as soon as I get the new drive belt in the mail Tuesday. I'm gonna cross my fingers and hope for the best. Everything has been either rebuilt or replaced with new parts. There is nothing else to replace to make this belt stay in place.

Attachments

#45

M

MParr

M

MParr

I had a suspicion that was the problem. Aren’t there grease fittings in those bushings?Ok, so I pulled the deck off again and removed the tensioner plate. Turns out there is nothing wrong with the tensioner pin bushings. They measure about 1.003" just enough clearance for a 1.000" pin. It's the pins that are bad, real bad. The plate has (2) 1" holes , the pins are set in place and welded on the back side. Turns out that instead of hardening the pins and letting the easily replaceable bushings take the wear, the awesome company engineers, used soft pins and hardened the bushings. So instead of just replacing for 4 bushings for $25, you get to replace the weldment at the insane cost of $113 plus shipping to $191 (depending on what vendor you choose) for this " weldment ". I can see guaranteed money for Snapper for their parts vendors on replacement parts this way. I'd happily manufacturer this weldment for $50 a pop , all day long.

As you can see, the tops and bottoms of these pins are WAYYYYY undersized. After looking at the cost of this weldment, I figure I could just machine the 2 new pins and replace them myself in about 1½ worth of time and 6" of bar stock.. So I ground the welds off the original pins and knocked them out, machined a couple of new pins, and welded them back in place. No slop now, so the whole deck has now been rebuilt. Every bearing is new or as new, all pulleys are in great shape, one is new, deck belt is brand new and as soon as I get the new drive belt in the mail Tuesday. I'm gonna cross my fingers and hope for the best. Everything has been either rebuilt or replaced with new parts. There is nothing else to replace to make this belt stay in place.

#46

M

Mutt

M

Mutt

yes, but doesnt look like they were ever greasedI had a suspicion that was the problem. Aren’t there grease fittings in those bushings?

#47

M

MParr

M

MParr

That’s what I figured. Maybe this will be the end of your problems.yes, but doesnt look like they were ever greased