You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

H3011H only runs when starter is engaged

#1

F

fordperf

F

fordperf

I have a H3011H that only fires when the starter is engaged. It fires but only runs as fast as the starter will allow. As soon as I let go of the starter, it dies. It feels like it gets spark while the starter is engaged, but no spark when letting off the starter. This had me thinking it was something positional, or some kind of sensor that may be actively killing the spark while in run position.

Potentially related, months ago I had issues with it not recognizing the parking brake was off, and when I released the parking brake and put it into drive the alarm would sound. I disconnected the grey connector that controls that under the seat, and was able to drive normally and mow. However I noticed just with this recent start/run problem that even with the parking brake off and the mower off, the mower does not roll--the back wheels seem locked. I had to drag it around in the shed it would not roll at all.

I dont know if 1) the brake is somehow broken and permanently stuck on; or 2) there is a sensor that is reading this 'brake on' situation as a reason to kill the ignition during run (I cant think of a logical reason for this).

I know the 3011 has a bunch of sensors that could go bad--I'm open to any ideas!

Potentially related, months ago I had issues with it not recognizing the parking brake was off, and when I released the parking brake and put it into drive the alarm would sound. I disconnected the grey connector that controls that under the seat, and was able to drive normally and mow. However I noticed just with this recent start/run problem that even with the parking brake off and the mower off, the mower does not roll--the back wheels seem locked. I had to drag it around in the shed it would not roll at all.

I dont know if 1) the brake is somehow broken and permanently stuck on; or 2) there is a sensor that is reading this 'brake on' situation as a reason to kill the ignition during run (I cant think of a logical reason for this).

I know the 3011 has a bunch of sensors that could go bad--I'm open to any ideas!

#2

F

fordperf

F

fordperf

Forget the parking brake issue, I stupidly forgot to disengage the transmission release lever which I actually knew was there because I had released it years ago for something else. Me 0, mower 1.

I also ordered a new ignition key switch off ebay and working on getting a new combination relay from somewhere. The combo relay seems to be the root cause of many 'will not start' issues on the 3011, I am especially concerned with the ignition relay inside not working to run the ignition coil OR possibly I have burned out my ignition coil. Tho since the engine seems to fire when the start is engaged I took a gamble that the ignition coil is working but the ignition relay isnt engaging long enough.

I also ordered a new ignition key switch off ebay and working on getting a new combination relay from somewhere. The combo relay seems to be the root cause of many 'will not start' issues on the 3011, I am especially concerned with the ignition relay inside not working to run the ignition coil OR possibly I have burned out my ignition coil. Tho since the engine seems to fire when the start is engaged I took a gamble that the ignition coil is working but the ignition relay isnt engaging long enough.

#3

B

bertsmobile1

B

bertsmobile1

Don't beat yourself up about it.

Have any Idea how many times I get called out to fix a

"I ran out of fuel & now it won't start " job only to find the PTO is still engaged.

I used to waste time asking questions but found from a PR point of view best to drop by sort it out as a freebie ( for existing customers ) then choof off.

Have any Idea how many times I get called out to fix a

"I ran out of fuel & now it won't start " job only to find the PTO is still engaged.

I used to waste time asking questions but found from a PR point of view best to drop by sort it out as a freebie ( for existing customers ) then choof off.

#4

F

fordperf

F

fordperf

Thanks man. The mower is at a cabin in the middle of nowhere several hours from me, so when I make a trip out there to mow the grass it's like a one day committment at least. And when stuff doesnt work, it just shoots the whole trip plan to crap.

My folks bought the H3011H in 1990 for I believe $1700 used. It's a 30 year old mower! It's gone through a few belts and we put tubes in the tires, but it has run faithfully and we try to keep it maintained. But things invariably break over time. The sensors, the combo relay, etc. In the attached pics you can see less than half of the area to be mowed. Right now I didnt mow it for a year, the grass grew to 10 inches, flopped over and kept growing heh. Some of the pricker weeds are 5 feet tall. It's a lot for this mower to handle, it's only a 11hp motor on it.

If I cant get it running reliably it may just be time to upgrade. Looking at a Cub Cadet XT2 LX46, but I am not rushing to spend $2500 lol

My folks bought the H3011H in 1990 for I believe $1700 used. It's a 30 year old mower! It's gone through a few belts and we put tubes in the tires, but it has run faithfully and we try to keep it maintained. But things invariably break over time. The sensors, the combo relay, etc. In the attached pics you can see less than half of the area to be mowed. Right now I didnt mow it for a year, the grass grew to 10 inches, flopped over and kept growing heh. Some of the pricker weeds are 5 feet tall. It's a lot for this mower to handle, it's only a 11hp motor on it.

If I cant get it running reliably it may just be time to upgrade. Looking at a Cub Cadet XT2 LX46, but I am not rushing to spend $2500 lol

#5

B

bertsmobile1

B

bertsmobile1

Ok to start from the top.

Your engine has a magneto ignition which is self energizing.

The key switch grounds out the coil to turn the engine off and goes open circuit to allow the engine to start & run

A relay is just a switch that is controlled by another switch ( or series of switches )

I do not have a circuit diagram for your mower.

However all mowers have 3 circuits

1) cranking circuit

2) ignition circuit

3) charging circuit

When you split them into these 3 fixing it becomes a lot lot easier.

The cranking circuit will go from the battery ( generally a take off from the battery cable to the starting solenoid to save wire ) througn the key switch, through the PTO switch throuhg the brake switch and if you ae a mechanical gearbox, through the Neutral switch then to the trigger wire on the starting solenoid.

This is a daisy chain so if any one of these switches remains open the mower will not crank.

The ignition circuit

This is a series of parallel circuits that will ground the magneto and kill the engine

usually

PTO + seat switch ( So you can not chop your own hand of foot off by clearing the deck chute with the blades spinning )

Seat Switch + Brake switch ( so you can not run over yourself if you fall off )

During cranking the set switch is out of the circuit but once you let the key return to run, it is in circuit so if the seeat switch thinks you are not there and the brake seat thinks the brake is not on then the magneto gets grounded & the mower turns off.

If the carburettor has a fuel shut off solenoid then you can remove the kill wire from the magneto and use the furl shut off to kill the engine.

However this is not a safe mannar to run the mower in but it might get you out of trouble.

On lesser mowers the seat switch & brake switch have 2 sets of contacts so the start & crank can be separate circuits for the brake and the seat can have 2 separate circuits, one to the PTO & the other to the parking brake.

On this model these switches are single pole switches and the cleaver stuff is done in the very expensive relay housing.

Yours sounds like it has seen better days'\

Usually they are just a few individual relays and some diodes and can be fixed if you can follow smoke trails.

Otherways it is new relay box or rewire the mower.

Both of which are worth doing as this is a very good mower.

Wat wat better than anything you will pay less than $ 5,000 for now days.

The caveat will be condition of the rest of the mower in particular how much rust there is.

Your engine has a magneto ignition which is self energizing.

The key switch grounds out the coil to turn the engine off and goes open circuit to allow the engine to start & run

A relay is just a switch that is controlled by another switch ( or series of switches )

I do not have a circuit diagram for your mower.

However all mowers have 3 circuits

1) cranking circuit

2) ignition circuit

3) charging circuit

When you split them into these 3 fixing it becomes a lot lot easier.

The cranking circuit will go from the battery ( generally a take off from the battery cable to the starting solenoid to save wire ) througn the key switch, through the PTO switch throuhg the brake switch and if you ae a mechanical gearbox, through the Neutral switch then to the trigger wire on the starting solenoid.

This is a daisy chain so if any one of these switches remains open the mower will not crank.

The ignition circuit

This is a series of parallel circuits that will ground the magneto and kill the engine

usually

PTO + seat switch ( So you can not chop your own hand of foot off by clearing the deck chute with the blades spinning )

Seat Switch + Brake switch ( so you can not run over yourself if you fall off )

During cranking the set switch is out of the circuit but once you let the key return to run, it is in circuit so if the seeat switch thinks you are not there and the brake seat thinks the brake is not on then the magneto gets grounded & the mower turns off.

If the carburettor has a fuel shut off solenoid then you can remove the kill wire from the magneto and use the furl shut off to kill the engine.

However this is not a safe mannar to run the mower in but it might get you out of trouble.

On lesser mowers the seat switch & brake switch have 2 sets of contacts so the start & crank can be separate circuits for the brake and the seat can have 2 separate circuits, one to the PTO & the other to the parking brake.

On this model these switches are single pole switches and the cleaver stuff is done in the very expensive relay housing.

Yours sounds like it has seen better days'\

Usually they are just a few individual relays and some diodes and can be fixed if you can follow smoke trails.

Otherways it is new relay box or rewire the mower.

Both of which are worth doing as this is a very good mower.

Wat wat better than anything you will pay less than $ 5,000 for now days.

The caveat will be condition of the rest of the mower in particular how much rust there is.

#6

F

fordperf

Regarding the cranking circuit: since my motor does in fact crank over, is it safe to assume that all the safety switches are in fact properly closed? Could they be damaged-closed?

I didnt think the starter would turn over if the PTO switch was open (engaged) so I assume because the starter engages that the PTO was properly disengaged. The mower has a seat switch which worked last I knew; again it would not engage the starter if that seat switch was broken, so I assume that works too for the same reason as the PTO. Same with the brake switch. So because the starter cranks, I assume the PTO, seat, key, and brake switches are all closed. One might be broken, but it broke closed instead of open (if that's possible).

I do not know if it has a fuel cutoff solenoid. It has a manual fuel cutoff lever on the carb.

I bit the bullet and ordered a new combination relay for $130 as well as a new rectifier and key switch. I plan on immediately replacing the combo relay and rectifier, but since the key switch seems to be functioning I will hold off on that.

I will also check the fuse first, because like a dummy I forgot to look last time. I also picked up a new plug.

I appreciate all your help!

F

fordperf

The mower is in great shape as are the accessories (mulch kit, bagger). The only reason I am spending this much time on travel and diags is because the mower is a champ when it works. I wish I had pics of the mower to share, I have pics of every other damn thing lol.Ok to start from the top.

Your engine has a magneto ignition which is self energizing.

The key switch grounds out the coil to turn the engine off and goes open circuit to allow the engine to start & run

A relay is just a switch that is controlled by another switch ( or series of switches )

I do not have a circuit diagram for your mower.

However all mowers have 3 circuits

1) cranking circuit

2) ignition circuit

3) charging circuit

When you split them into these 3 fixing it becomes a lot lot easier.

The cranking circuit will go from the battery ( generally a take off from the battery cable to the starting solenoid to save wire ) througn the key switch, through the PTO switch throuhg the brake switch and if you ae a mechanical gearbox, through the Neutral switch then to the trigger wire on the starting solenoid.

This is a daisy chain so if any one of these switches remains open the mower will not crank.

The ignition circuit

This is a series of parallel circuits that will ground the magneto and kill the engine

usually

PTO + seat switch ( So you can not chop your own hand of foot off by clearing the deck chute with the blades spinning )

Seat Switch + Brake switch ( so you can not run over yourself if you fall off )

During cranking the set switch is out of the circuit but once you let the key return to run, it is in circuit so if the seeat switch thinks you are not there and the brake seat thinks the brake is not on then the magneto gets grounded & the mower turns off.

If the carburettor has a fuel shut off solenoid then you can remove the kill wire from the magneto and use the furl shut off to kill the engine.

However this is not a safe mannar to run the mower in but it might get you out of trouble.

On lesser mowers the seat switch & brake switch have 2 sets of contacts so the start & crank can be separate circuits for the brake and the seat can have 2 separate circuits, one to the PTO & the other to the parking brake.

On this model these switches are single pole switches and the cleaver stuff is done in the very expensive relay housing.

Yours sounds like it has seen better days'\

Usually they are just a few individual relays and some diodes and can be fixed if you can follow smoke trails.

Otherways it is new relay box or rewire the mower.

Both of which are worth doing as this is a very good mower.

Wat wat better than anything you will pay less than $ 5,000 for now days.

The caveat will be condition of the rest of the mower in particular how much rust there is.

Regarding the cranking circuit: since my motor does in fact crank over, is it safe to assume that all the safety switches are in fact properly closed? Could they be damaged-closed?

I didnt think the starter would turn over if the PTO switch was open (engaged) so I assume because the starter engages that the PTO was properly disengaged. The mower has a seat switch which worked last I knew; again it would not engage the starter if that seat switch was broken, so I assume that works too for the same reason as the PTO. Same with the brake switch. So because the starter cranks, I assume the PTO, seat, key, and brake switches are all closed. One might be broken, but it broke closed instead of open (if that's possible).

I do not know if it has a fuel cutoff solenoid. It has a manual fuel cutoff lever on the carb.

I bit the bullet and ordered a new combination relay for $130 as well as a new rectifier and key switch. I plan on immediately replacing the combo relay and rectifier, but since the key switch seems to be functioning I will hold off on that.

I will also check the fuse first, because like a dummy I forgot to look last time. I also picked up a new plug.

I appreciate all your help!

#7

F

fordperf

F

fordperf

I watched some videos on bypassing the combo relay using an external switch, but I know that also bypasses the safety features. The terrain is rocky and hilly and frankly falling out of the seat is an actual possibility, I would rather not be run over by my own mower. If replacing the combo relay and rectifier do not solve my problem I may consider the bypass but I would rather not. People other than myself use the mower and I cant risk not having the safety features.

#8

AVB

AVB

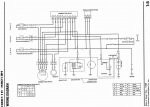

If I am reading the schematic coorectly ( very blurry on the copy I got) you should check to see if 12v is present Black/Yellow wire at the ignition switch when it is in the run and start positions. If not present in the run position it would indicate a bad ignition switch.

#9

B

bertsmobile1

B

bertsmobile1

Number 1 rule

Check everything assume nothing.

All of the switches appear to have only one pair of contacts.

If that is the case they will be simple on off switches so you can connect a meter to the terminals then work the switch plunger.

Every time you depress the plunger the meter should change.

Check the seat switch by getting on ^ off the seat , check the brake by turning it on & off, same thing with the PTO switch.

Do it a couple of dozen times, If it fails to work on any single occasion then the switch is worn out,

If all f the switches are working properly then all that leaves is a broken wire or a broken relay or ignition switch.

I can not be any more specific than this because we did not get that mower down here so I can not get a wiring diagram for it.

Usually the switches are a ground circuit but when a master relay module is used then can be either a power or a ground circuit.

Check everything assume nothing.

All of the switches appear to have only one pair of contacts.

If that is the case they will be simple on off switches so you can connect a meter to the terminals then work the switch plunger.

Every time you depress the plunger the meter should change.

Check the seat switch by getting on ^ off the seat , check the brake by turning it on & off, same thing with the PTO switch.

Do it a couple of dozen times, If it fails to work on any single occasion then the switch is worn out,

If all f the switches are working properly then all that leaves is a broken wire or a broken relay or ignition switch.

I can not be any more specific than this because we did not get that mower down here so I can not get a wiring diagram for it.

Usually the switches are a ground circuit but when a master relay module is used then can be either a power or a ground circuit.

#12

F

fordperf

F

fordperf

Agreed, I will test as many of the switches as I can. My Fluke has a tone for continuity thankfullyNumber 1 rule

Check everything assume nothing.

All of the switches appear to have only one pair of contacts.

If that is the case they will be simple on off switches so you can connect a meter to the terminals then work the switch plunger.

Every time you depress the plunger the meter should change.

Check the seat switch by getting on ^ off the seat , check the brake by turning it on & off, same thing with the PTO switch.

Do it a couple of dozen times, If it fails to work on any single occasion then the switch is worn out,

If all f the switches are working properly then all that leaves is a broken wire or a broken relay or ignition switch.

I can not be any more specific than this because we did not get that mower down here so I can not get a wiring diagram for it.

Usually the switches are a ground circuit but when a master relay module is used then can be either a power or a ground circuit.

#13

B

bertsmobile1

B

bertsmobile1

OK,

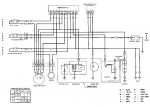

Now we have a wiring schematic we can do some thing

All of the safety switched are ground switches.

So in the run position seat occupied, brake on , PTO off , in Neutral ,you should see these measurements at the Relay plug

G/R = Ground

W / Bl = Ground

G / Bu = open

Bl / R = open

Bl / Y = battery voltage

Bl / W = open ( should show battery voltage when the key is in Start position )

G / Y = Ground

G / Bl = Ground

Bl / Bu = open ( should show battery voltage when the key is in Start position )

BL = Ground

If not make some jumpers and jump the seat PTO & neutral switches

If you don't get the right reading with the switches jumped then you have a wiring fault, most likely a chaffed wire making a ground contact or the relay is broken

Put your meter between the Bl / R wire and ground.

IT should read ground when the key is off

IT should read open in the start & run position ( jumped as per above. )

Now we have a wiring schematic we can do some thing

All of the safety switched are ground switches.

So in the run position seat occupied, brake on , PTO off , in Neutral ,you should see these measurements at the Relay plug

G/R = Ground

W / Bl = Ground

G / Bu = open

Bl / R = open

Bl / Y = battery voltage

Bl / W = open ( should show battery voltage when the key is in Start position )

G / Y = Ground

G / Bl = Ground

Bl / Bu = open ( should show battery voltage when the key is in Start position )

BL = Ground

If not make some jumpers and jump the seat PTO & neutral switches

If you don't get the right reading with the switches jumped then you have a wiring fault, most likely a chaffed wire making a ground contact or the relay is broken

Put your meter between the Bl / R wire and ground.

IT should read ground when the key is off

IT should read open in the start & run position ( jumped as per above. )

#15

AVB

AVB

That is your main starter power cable. It should be 6 ga wire; although, some oem uses a 8 ga wire.

#16

F

fordperf

F

fordperf

Ok I assume starting the motor takes more than 5 amps which would blow the fuse, but then why have a 5 amp fuse at all off the battery? What else is the battery doing besides starting the engine and there is a bypass around the fuse, so then why have a fuse..That is your main starter power cable. It should be 6 ga wire; although, some oem uses a 8 ga wire.

#17

AVB

AVB

First it is power for the relay(s) and PTO clutch when the engine is not running (the run and start position). Second it is the alternator (here called the charge coil) voltage regulator positiive return path to recharge the battery.

There is no bypass of the fuse.

There is no bypass of the fuse.

#18

AVB

AVB

Also the starter solenoid is also considered a relay or contactor. Just depends which field of electricity terms you are accustom too.

#19

F

fordperf

F

fordperf

This just hit me as I was walking back to my office, it provides limited 12v power for the buzzer and continuity circuits and to move the relays. I did not know about the return path thank you.First it is power for the relay(s) and PTO clutch when the engine is not running (the run and start position). Second it is the alternator (here called the charge coil) voltage regulator positiive return path to recharge the battery.

There is no bypass of the fuse.

#20

F

fordperf

F

fordperf

So the magneto spinning on the motor creates an ac current, which the rectifier converts back to dc to be used to run things like the buzzer and circuit continuity and charge the battery back in through the 5a fuse once the engine is running

#21

AVB

AVB

When come small engine the term magneto usually refers to ignition coil. What is call an alternator is the stator coil and the flywheel internal magnets. Si if you are to the spinning flywheel then it creates an AC voltage and current which is converted by diodes into DC then feed through a voltage regulator then to rest of the circuit.

#22

B

bertsmobile1

I did say "At the relay"

You should be able to poke the probes from your Fluke meter in the back of the plug block to get those readings.

I just ran left to right from the wiring diagram.

B

bertsmobile1

The Bl wire in my post is th e last wire on the plug to the relay.Can you tell me what is Bl here? It looks like a wire that completely bypasses the fuse from the battery to the starter..

View attachment 50596

I did say "At the relay"

You should be able to poke the probes from your Fluke meter in the back of the plug block to get those readings.

I just ran left to right from the wiring diagram.

#23

AVB

Here I have work on equipment where every wire is the same color; although they are numbered. In this case there are several wires that are black without numbering. Personally I wound have not used for 12v lines but the manufacture is thinking along AC wiring with black being the non ground lead. The Standard Register 2500 forms burster is one; 100 white wires. Another company that use numbered wires is John Deere but they have multiple colored wires used in different circuits.

AVB

Bert, You need to read the whole post and look the snipped image and compare to the whole wiring diagram before responding. He was asking about the starter main lead.The Bl wire in my post is th e last wire on the plug to the relay.

I did say "At the relay"

You should be able to poke the probes from your Fluke meter in the back of the plug block to get those readings.

I just ran left to right from the wiring diagram.

Here I have work on equipment where every wire is the same color; although they are numbered. In this case there are several wires that are black without numbering. Personally I wound have not used for 12v lines but the manufacture is thinking along AC wiring with black being the non ground lead. The Standard Register 2500 forms burster is one; 100 white wires. Another company that use numbered wires is John Deere but they have multiple colored wires used in different circuits.

#24

F

fordperf

F

fordperf

Havent forgotten about ya'll, I just picked up the mower and brought it back to my garage to start repairs. I plan on:

- replacing the combo relay

- replacing the rectifier

- replacing the key switch

- replacing the fuel filter

- installing an SAE charge/jump port on the body, so I can leave the battery inside and charge/jump as necessary

- replacing the blade

- installing the short discharge chute

#26

F

fordperf

F

fordperf

Couldnt get the blade off (needed a breaker bar which I didnt have with me). Next step is replace the fuel filter (not sure where that is, it isnt listed in the shop manual at all) and mount the SAE charge/jump port. Possibly an oil change.

EDIT: didnt replace the key switch since the old one still works. I lost the discharge cute (not the bagging chute) so another one is ordered. 2 blades are on order should be in next week. Maybe clean out the spark arrestor. Other than that, she purrs like a cat, transmission is smooth and strong.

EDIT: didnt replace the key switch since the old one still works. I lost the discharge cute (not the bagging chute) so another one is ordered. 2 blades are on order should be in next week. Maybe clean out the spark arrestor. Other than that, she purrs like a cat, transmission is smooth and strong.

#27

StarTech

StarTech

That is why I brought an AirCat 1150 impact. I got tired of having to use pull bar with a 5 ft extension pipe to break free some the blade bolts that run into here by row boating them.

#28

F

fordperf

F

fordperf

Laying on a cold garage floor trying to whack a 3/8" socket wrench with a small sledge gets old real fast!That is why I brought an AirCat 1150 impact. I got tired of having to use pull bar with a 5 ft extension pipe to break free some the blade bolts that run into here by row boating them.

#29

Hammermechanicman

Hammermechanicman

You betcha, i dropped the bucks on a IR Titamium 2135. That and 140psi with 3/8 hose and high flow connectors makes short work of any blade bolt. About a year ago i needed to onsite work on some commercial mowers. Picked up the HF Earthquake 1/2" impact. I must say i am very impress by it. Kinda heavy but it has taken off all blades and whell lugs with little rffort.That is why I brought an AirCat 1150 impact. I got tired of having to use pull bar with a 5 ft extension pipe to break free some the blade bolts that run into here by row boating them.

#30

StarTech

StarTech

Beside you tear up a perfectly good socket wrench, not mention yourself. I try my best to use the correct tools for the job. Probably why I got some 40+ yrs old tools that I still use weekly.

I went with the AirCat due its torque and how quite it is. Definitely needed the hi-flow fitting though. Many of the el cheapo M style fitting are not even the standard size CFM wise.

I went with the AirCat due its torque and how quite it is. Definitely needed the hi-flow fitting though. Many of the el cheapo M style fitting are not even the standard size CFM wise.

#31

Hammermechanicman

Hammermechanicman

Maybe we should start a AirCat vs Titanium thread like Ford vs Chevy or Mac vs PC. LOL.?

#32

StarTech

StarTech

All I know for sure is that I will never buy another Campbell Hausfeld impact from Tram law (Walmart). It couldn't even remove my truck's lug nuts but boy it sounded like it wss ripping things apart. I just gave it away once I got a good impact.

#33

Hammermechanicman

Hammermechanicman

All the lower end Campbell Hausfeld is a zombie branded low end crap now. I have a 20gal CH compressor I bought 30 years ago. Used the heck out of it till i got the 60gal 5 hp Quincy. Still runs like new. The new stuff is asian junk on par with Harbor freight. Same for the air tools.

#34

B

bertsmobile1

B

bertsmobile1

Way way back I got a hydrovne compressor from a petrol station that was closing down.

One of the best items I have ever bought.

Must have had it for at least 30 years.

Very quiet very efficient.

When I started doing mowers I finally hooked it up to the 200 gallon receiving tank.

Now all that is left to do is to plumb the 12 outlets around & outside the workshop so I don't have to keep on hooking 3 hoses together .

I think it runs for about 10 minutes a week and it is so good when I have to run the 3/4" impact on overtightened blade bolts.

One of the best items I have ever bought.

Must have had it for at least 30 years.

Very quiet very efficient.

When I started doing mowers I finally hooked it up to the 200 gallon receiving tank.

Now all that is left to do is to plumb the 12 outlets around & outside the workshop so I don't have to keep on hooking 3 hoses together .

I think it runs for about 10 minutes a week and it is so good when I have to run the 3/4" impact on overtightened blade bolts.

#35

F

fordperf

F

fordperf

After some PB Blaster on the rust I was able to get the blade off the mower, and then the blade holder off the blade. New blades got delivered, was sharp but not sharp enough, and naturally I couldnt find my grind stone for the drill, so that'll get handled tomorrow. The old blade is imbalanced and I'm just going to chuck it.

Last is wiring the jump/charge port, and I discovered my Weller iron is broken, because of course it is. Weller turned to crap as a brand lately. Need to find a better replacement (260W+)

Last is wiring the jump/charge port, and I discovered my Weller iron is broken, because of course it is. Weller turned to crap as a brand lately. Need to find a better replacement (260W+)

#37

F

fordperf

F

fordperf

I still havent returned with the mower to the lawn that needs cutting, the covids got in the way. Hopefully soon! Be Safe1