OK

Assuming you are stuck with this deck I would be inclined to get a much longer bolt for the pivot bolt on the tensioning arm and move the rear pulley forward so it becomes a fixed idler pulley and the belt routing becomes the usual T shape.

If there is enough depth on the engine pulley for a 5/8" belt then fit one.

Tensioning should always be on the slack side of a belt or chain for that matter so the only tensioning arm should be on the out side of the engine pulley.

By the look of the shape of the curved tab which resembles a belt keeper it looks like the original design had a fixed idler in this position.

At this point in time you have very little to loose and as it is coming to the end of the season you will have some mucking around time.

You might need to go to a grade 8 or 9 bolt and put a stiffening plate under the deck to stop it leaning.

When you have finished moving the pulley get some 5/8 rope and run it around all of the pulleys.

Stretch it till the tension arm is at 1/2 to 1/3 of its movement and that amount of rope is the belt you need , rounded off to the nearest whole inch.

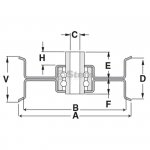

Idler pulleys are specified by these dimensions which was pinched of the Stens on line catalogue.

The image is not true and double row bearings have not been used for decades.

Also the centre is a stepped bush pushed into a standard deep groove bearing, not an inner race extending out of the bearing.

Armed with this information you can measure the distance from the bolt hole to what looks like a belt keeper then look for a idler that will fit.