You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

belt size question

#1

C

corvairbob

C

corvairbob

i have the poulan pro snowblower model pr271 and the impeller belt finally gave up. the book calls it a 581 83 24-01 it turns out to be 35.4" long. so has anyone figured out the normal size of this belt so i may get on at the autoparts store or maybe lowes? the drive bel they crossed in the book to be a 4lx38.2 belt along with there numbers but not the impeller belt. i did get one from ebay but that is a week out. so maybe the next time i can just use a normal number.

mine measures to be the correct size and the width is 3/8" just a tad narrower than the .4 i found it should be. but in order to get it to work i have had to adjust the cable ot now to the max and that is still a bit short. i guess when the new belt gets here i may wind up having to figure out that adjustment if it turns out to be still to long. but for now lets see if a new belt cures this issue of getting tossed off.

thanks bp.

mine measures to be the correct size and the width is 3/8" just a tad narrower than the .4 i found it should be. but in order to get it to work i have had to adjust the cable ot now to the max and that is still a bit short. i guess when the new belt gets here i may wind up having to figure out that adjustment if it turns out to be still to long. but for now lets see if a new belt cures this issue of getting tossed off.

thanks bp.

#2

StarTech

StarTech

SKU number look-up here say it is a 4L x 35.4 so it 1/2 (Kevlar recommended) x 35.4. No local auto parts store will have this size. So that 3/8 width belt is the wrong width.

- (3/8") 3L Section Kevlar V-Belts

- (1/2") A Section Kevlar V-Belts

- (1/2") 4L Section Kevlar V-Belts

- (5/8") B Section Kevlar V-Belts

- (5/8") 5L Section Kevlar V-Belts

#3

C

corvairbob

C

corvairbob

thanks they are 2 different widths according to the poulan pro website. the drive belt is the 4L x 38.2 the impeller belt is 3/8" x 35.4 long and yes you can get kevlar belts at the auto parts store i have got lots of them over the years but they may not have the 35.2" belt but they do have 3/8" wide belts. or at least the parts store i use has those sizes some of the older alt belts were 3/8" wide and they had the notches in them due to the smaller pulleys on them. but normally cars use the 1/2 width sizes. anyway thanks. i have on in the mail but was hoping to see if anyone has the regula numbers and now just the part number form the book. thanks bp.

#6

StarTech

StarTech

What is the model number from the serial number tag as something amiss here. Include rev level if stated.

#7

C

corvairbob

C

corvairbob

the model is pr271 (96192007301) according to my owners manual t different size belt. like i said i got the 4L x 38.2 belt one time from the parts store, one time form lowes and one time from poulan website and they all are for the drive belt i tried the poulan one on the impeller and i could not get close to the available cable adjustment.

and from what you show it looks like your saying it may be the 1/2 x 35.25 belt. my belt is a bit worn but not so much that the original fabric is gone. but i agree the belt may have been installed and called out wrong. it sure looks like it should have been a 1/2" wide belt originally as this one sets way deep in the drive sheave and some in the driven sheave.

i appreciate the help a lot and if you do happen to fine a normal number that will be a big help for the next time. thanks a lot bp.

and from what you show it looks like your saying it may be the 1/2 x 35.25 belt. my belt is a bit worn but not so much that the original fabric is gone. but i agree the belt may have been installed and called out wrong. it sure looks like it should have been a 1/2" wide belt originally as this one sets way deep in the drive sheave and some in the driven sheave.

i appreciate the help a lot and if you do happen to fine a normal number that will be a big help for the next time. thanks a lot bp.

#9

C

corvairbob

C

corvairbob

ok but i'm saying they are 2 different sizes. i have 3 of the drive belts now and when i compare them the difference i like 2" when holding them in your hands and i tried using one on the impeller and it was loose as a goose. so if you ever had to do one and get that belt i'm betting your going to have the same issue. but hey thanks for the help.

i got one from ebay and the number is the same 581 83 2401 and when it gets here i will see if ti is the same as the drive belt or if it is smaller and works. when it gets here and is what i need i will update to let you know either way. if it is to big i will just take it to the parts store and have them get me one as close to this as they can but a bit shorter.

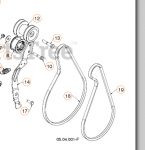

ok i went out and installed the 4l x 38.2" belt and here is a photo and here is one of both belts side by side for comparison

again thanks

i got one from ebay and the number is the same 581 83 2401 and when it gets here i will see if ti is the same as the drive belt or if it is smaller and works. when it gets here and is what i need i will update to let you know either way. if it is to big i will just take it to the parts store and have them get me one as close to this as they can but a bit shorter.

ok i went out and installed the 4l x 38.2" belt and here is a photo and here is one of both belts side by side for comparison

again thanks

Attachments

#10

C

corvairbob

C

corvairbob

ok i got the belt size it is a 1/2x35 1/4" belt for those that need to find one local in a hurry. i sent out a bunch of questions to online v-belt sites and most came back to me with that size. the husqvarna dealer told me they have an error and some place send out the same size as the drive belt. i mentioned to them that if the belt was the same size they would not have 2 numbers or items listed. anyway they also have an updated original part number this is the husqvarna site info

Husqvarna OEM Auger & Drive Belt Set 581832401-584216102 Fits ST224, 224P, 227P

they gave me 589793501 for the updated belt, but a 1/2 x 35 1/4" belt is the same thing and you can get them local to you. thanks for the help

Husqvarna OEM Auger & Drive Belt Set 581832401-584216102 Fits ST224, 224P, 227P

they gave me 589793501 for the updated belt, but a 1/2 x 35 1/4" belt is the same thing and you can get them local to you. thanks for the help

#12

C

corvairbob

C

corvairbob

may have been as these are not the same size belts the drive belts is 1/2 x 38.2" and the impeller belts it 1/2 x 34.4" just an fyi i have 3 of the 3501 belts and they fit the drive and are lose as a goose on th impeller see that photo i posted. i ordered on from poulan one form husqvarna and one from sears direct and all have different number per their store listings but all showed up the same size. i had to go into my stash 2 years ago to get one close enough to work and then forgot to order one last summer when it would have good time to get one and make sure it was correct. now i have knee deep snow and no blower to move it. let's hope the one i ordered this time is correct. this is form a v-belt dealer crossing out the poulan numbers

A36K Commercial Kevlar Belt / 584216101

Dimensions: 1/2" Top Width X 38" Outside Circ.

Regular Price: $10.95

Special Price $7.11

this is for the drive

OEM Replacement Belt (1/2X35 1/4) Compatible With 581832401

A33K Commercial Kevlar Belt

Dimensions: 1/2" Top Width X 35" Outside Circ.

Regular Price: $10.02

Special Price $6.51

this is the impeller belt

A36K Commercial Kevlar Belt / 584216101

Dimensions: 1/2" Top Width X 38" Outside Circ.

Regular Price: $10.95

Special Price $7.11

this is for the drive

OEM Replacement Belt (1/2X35 1/4) Compatible With 581832401

A33K Commercial Kevlar Belt

Dimensions: 1/2" Top Width X 35" Outside Circ.

Regular Price: $10.02

Special Price $6.51

this is the impeller belt

#13

B

bertsmobile1

B

bertsmobile1

There is more o the belt than the length & profile.

Serpentine belts need the reinforcing cords to be deeper in the belt to prevent the back falling off in use.

High shock load belts use fewer thicker cords

So different part numbers.

Serpentine belts need the reinforcing cords to be deeper in the belt to prevent the back falling off in use.

High shock load belts use fewer thicker cords

So different part numbers.

#14

StarTech

StarTech

Hopefully they are actually the size stated. Many are not the size stated. This is the reason I had to buy a $200 v-belt measuring tool. I was receiving belt up to 2 inches shorter than the stated sizes when I was purchasing after market belts.

#15

C

corvairbob

C

corvairbob

i know about how belts work this is from the husqvarna. some belts need to be cogged also to be able to take a sharper bend. and this is not a serpentine belt it only uses the back side for getting the tension for grabbing the drive sheave. belts have done that way before serpentine belts came along but thanks for that. and now i have the length form the mfg. and now you do to. click the link here it take you to the site. thanks bp.

#16

C

corvairbob

C

corvairbob

we will see tomorrow. if it turns out to be the wrong length i will stop back and let you all know. and then i will go the the auto parts store and get one. i could not before as i did not have the length. thanks bpHopefully they are actually the size stated. Many are not the size stated. This is the reason I had to buy a $200 v-belt measuring tool. I was receiving belt up to 2 inches shorter than the stated sizes when I was purchasing after market belts.

#17

StarTech

StarTech

I was referring to the two after market belts that where listed in post #12.

I just had a lot of bad luck with after market belts. My main distributor of after market parts got to where every belt that were 1/2 (A) was at least one inch short and every 5/8 (B) belt was at least 2 inches short. I ended up throwing out over a $1000 (cost not counting shipping) in belts as they were purchased over a two year period for stock. Then it was recommended to purchase Stens belts. The very first ten belts were wrong sizes too with most being at least 1/2 inch short and even got a couple that were one longer than the labeled specs. I have gone back to the OEM belts and in the last two years haven't had a belt length problem. But with my experiences I still measure every belt when it comes in before an attempted installation.

A&I even asked me to trust them again after two years saying they had resolved the problem. Guess what the first two belts I order were over an inch short yet again. I flat will not order belts from them again.

Just to note with the belt being under 40" a 1/4" is a lot of difference to work with. Sometimes there is enough pulley wear to where the belt will work and sometimes not.

Now V-belt Supply has been tried here but the length time in shipping and high cost of SHC I just cant justify them besides I can get Husqvarna and MTD OEM belts in usually one day with reasonable costs.

Maybe it is just my luck here. Either way though it was an expensive lesson.

I just had a lot of bad luck with after market belts. My main distributor of after market parts got to where every belt that were 1/2 (A) was at least one inch short and every 5/8 (B) belt was at least 2 inches short. I ended up throwing out over a $1000 (cost not counting shipping) in belts as they were purchased over a two year period for stock. Then it was recommended to purchase Stens belts. The very first ten belts were wrong sizes too with most being at least 1/2 inch short and even got a couple that were one longer than the labeled specs. I have gone back to the OEM belts and in the last two years haven't had a belt length problem. But with my experiences I still measure every belt when it comes in before an attempted installation.

A&I even asked me to trust them again after two years saying they had resolved the problem. Guess what the first two belts I order were over an inch short yet again. I flat will not order belts from them again.

Just to note with the belt being under 40" a 1/4" is a lot of difference to work with. Sometimes there is enough pulley wear to where the belt will work and sometimes not.

Now V-belt Supply has been tried here but the length time in shipping and high cost of SHC I just cant justify them besides I can get Husqvarna and MTD OEM belts in usually one day with reasonable costs.

Maybe it is just my luck here. Either way though it was an expensive lesson.

#18

C

corvairbob

C

corvairbob

i guess it depends on how you actually measure them. in my 40 years as a machine repairman and in on stint i worked in the shops apint line and i had to maintain maybe 4 sets of belted machines, all fans a few for the chain drive. and in my time on that job i measured then the same way i measured these on the snowblower. by the back of the belt. i laid a tape on a flat surface marked the belt around and ran it own the tape. worked every time. and i do not know about your setup but i have never had a setup that did not have some amount of takeup do to the variances in the mfg. of the belt.

in fact when you have to roder belts in multiple those show be all mace from the same core so that theya re all the same length. if you were to just order lets say 3 belts for a multiple setup one at a time your going to see them at different lengths, and in that situation you can't just take up one as the complete frive gets adjusted all at once. and even then if you were to notice you may even see one that is a bit loose. happens all the time. that is one reason mfg. put at least 3 belts on a multiple drive setup just for that, the engineer knows one belt is going to be a bit loose

what i'm talking about here is that i did order the impeller belt from huskvarna,poulan and sears, under the part number in the book and they all showed up for the drive section. that is why i asked. if anyone happen to order or have one on hand that fits and what the number were or if they new the size. i could not use mine as it was a old spare form some other intem that i had laying around. could have been from a car, a machine, a lawn mower or whatever!

in all my research i did finally find a company that was able to cross the number and gave me the one size i had at 38.2 for the drive and 36.4 for the impeller. so i passed that on here for other that happen to need to source one form a local part store, as most online are out, hey it is winter.

so you really do not need the so called belt measuring tool if you just lay them flat on a surface and run them along a tape from the ene of the tape to the mark you placed on the belt as you started. that actually is how they are intended to be measured. thanks bp

in fact when you have to roder belts in multiple those show be all mace from the same core so that theya re all the same length. if you were to just order lets say 3 belts for a multiple setup one at a time your going to see them at different lengths, and in that situation you can't just take up one as the complete frive gets adjusted all at once. and even then if you were to notice you may even see one that is a bit loose. happens all the time. that is one reason mfg. put at least 3 belts on a multiple drive setup just for that, the engineer knows one belt is going to be a bit loose

what i'm talking about here is that i did order the impeller belt from huskvarna,poulan and sears, under the part number in the book and they all showed up for the drive section. that is why i asked. if anyone happen to order or have one on hand that fits and what the number were or if they new the size. i could not use mine as it was a old spare form some other intem that i had laying around. could have been from a car, a machine, a lawn mower or whatever!

in all my research i did finally find a company that was able to cross the number and gave me the one size i had at 38.2 for the drive and 36.4 for the impeller. so i passed that on here for other that happen to need to source one form a local part store, as most online are out, hey it is winter.

so you really do not need the so called belt measuring tool if you just lay them flat on a surface and run them along a tape from the ene of the tape to the mark you placed on the belt as you started. that actually is how they are intended to be measured. thanks bp

#19

StarTech

StarTech

That works for shorter belt but when you start working with 180" belts finding a 16 foot board or straight run is hard in my shop. On top of that every vendor would find excuses as to I was measuring the belts wrong. Stens even tried claiming the measuring tool I got and was using is no good at measuring the belts even they sold the same tool for that purpose. Now don't that take the cake.

Using the rolling method along a surface does work as long as the belt or tape measure don't slip.

As for multiple belt setups I try to get a matched set whenever I can.

And yes manufactures suppliers do screw up sometimes but at least a distributor will usually make things right. As you stated at first the belt was 3/8 which was the wrong width.

And yes adjustments are built in most times but some equipment are very picky about the belt sizes especially the MTD CVT drive system. I also had a couple Husqvarna 625/675 HWT trimmer that spec'd a 3/8 belt that a 1/4 over a standard length that when using the even size would not work without modifying the belt drive system. The belt would not slip when in neutral there the trimmer head would spin all the time.

This was just another instance of Husqvarna sending out the wrong size belts as they were over an inch short.

Considering the number machines I see each year I am surprised that this don't happen more often.

Using the rolling method along a surface does work as long as the belt or tape measure don't slip.

As for multiple belt setups I try to get a matched set whenever I can.

And yes manufactures suppliers do screw up sometimes but at least a distributor will usually make things right. As you stated at first the belt was 3/8 which was the wrong width.

And yes adjustments are built in most times but some equipment are very picky about the belt sizes especially the MTD CVT drive system. I also had a couple Husqvarna 625/675 HWT trimmer that spec'd a 3/8 belt that a 1/4 over a standard length that when using the even size would not work without modifying the belt drive system. The belt would not slip when in neutral there the trimmer head would spin all the time.

This was just another instance of Husqvarna sending out the wrong size belts as they were over an inch short.

Considering the number machines I see each year I am surprised that this don't happen more often.

#20

C

corvairbob

C

corvairbob

well i just do not know how to advise you on that. like i said i was a machine repairman for 40 years and i use the shop floor to measure long belts. and for long belts if i needed hep i found help to hold them. for long belts i would just lay them sideways and run them along the wall. but then i never had to do belts much over 12' about wht your doing. and you get a percentage of length variance in any belt

conveyor belts are different. i would make them as needed. hard to find a conveyor belt the correct size.

but again this thread is for the poulan snowblower. and yes for some reason husqvarna must have had a miss print in there specs for these machines. that is why i asked if anyone found one local and what was that size. no one stepped up but for factory numbers that were wrong to begin with. i have 3 on the bench like that. so i did the work and passe the number on so other will not have to get 3 before they fine one that fits. with a belt that small a 1/4" will make a big difference. thanks bp.

conveyor belts are different. i would make them as needed. hard to find a conveyor belt the correct size.

but again this thread is for the poulan snowblower. and yes for some reason husqvarna must have had a miss print in there specs for these machines. that is why i asked if anyone found one local and what was that size. no one stepped up but for factory numbers that were wrong to begin with. i have 3 on the bench like that. so i did the work and passe the number on so other will not have to get 3 before they fine one that fits. with a belt that small a 1/4" will make a big difference. thanks bp.

#21

StarTech

StarTech

Since I work out of a 24 x 24 that is full of tools and parts, plus got one room of home full of parts now just make some room a new 44" tool box system; space is at a premium. Most of my work is now outdoors.

As for the numbers that's why I showed you the supersedes on post #11. This the latest price file update from Husqvarna which contains the latest supersedes that they provide my distributor which provides me the same file. Even this don't help when they put the right SKU number on the wrong belt. This why I measure every belt now as it has happen too many times here. All they got to do is to load the machine with the wrong part then a 1000 or so units gets printed wrong. IT happens but should have caught by quality control but it even pas them when they are on a coffee break.

As for belt variances it is understood but many OEM usually spec the shortest in the first place. I just did a JD recently that spec'd a mule drive v-belt and theirs came in a 1/4" shorter than spec and would not even fit over the spring loaded pulley with the assembly hitting its stop. Ended up having to unmount the pulley just to get the belt on. Definitely wasn't done by the service manual instructions.

As for the numbers that's why I showed you the supersedes on post #11. This the latest price file update from Husqvarna which contains the latest supersedes that they provide my distributor which provides me the same file. Even this don't help when they put the right SKU number on the wrong belt. This why I measure every belt now as it has happen too many times here. All they got to do is to load the machine with the wrong part then a 1000 or so units gets printed wrong. IT happens but should have caught by quality control but it even pas them when they are on a coffee break.

As for belt variances it is understood but many OEM usually spec the shortest in the first place. I just did a JD recently that spec'd a mule drive v-belt and theirs came in a 1/4" shorter than spec and would not even fit over the spring loaded pulley with the assembly hitting its stop. Ended up having to unmount the pulley just to get the belt on. Definitely wasn't done by the service manual instructions.

#22

C

corvairbob

C

corvairbob

if you just cut the belt it will still be the same length it it is worn that will not change the length if it is broke cut off the jagged [arts off and measure with a tape you can to the in a bathroom

thanks

thanks

#23

B

bertsmobile1

B

bertsmobile1

Belt measurers are handy, particularly if you get an order of 50 belts that need to be checked, priced & stowed away.

FWIW , my go to for belt lengths is Gates.

Mos of the interchange sites have just been copied of a copy of some one elses that was copied off some one elses that was copied of some one elses so there are a lot of transcription errors like L sections being listed as std M-A-B-C for starters.

Even from the manufacturers you get errors.

I just put a new belt on a 2000 series Cub 42" deck.

The customer supplied it, it was a brand I did not recognise but he got it from the Cub Store on line.

It was too loose

SO I went back to the shop & get a Stens belt, it was too long

Now both of these belts came from the same maker and had the makers part number tape on them 3606

There was 2.5" difference between the two belts, neither fitted and both came from sleeves that had the correct Cub number on them.

So the "fix" was to get a slightly smaller from the stock pile .

I try to measure all belts when delivered .

Over the 8 years I have been operating I have had melts in the wrong sleeves and occasionally a belt that was labeled wrong ( vendors number on the belt ) but I have never before come across a belt that was labeled wrong ay the belt factory but this proved to me it does happen .

What most home users do not realize is belts come from the factory in bales, usually with a makers number on them .

That is the number you see a couple of inches away from the Vendors brand and part number .

These then go to a third party to have the afore mentioned branding tape adhered to the belts then be put in sleeves ready for sale.

Some vendors will sell belts in scanes ( bundles to some ) usually tied together with another belt and no sleeve for a considerably lower price .

So there are a lot of places where mis lableing can happen .

When you first posted , I ran your numbers through Gates and they came up as per your post so at that time there was no reason for me to chime in.

However the dialogue has progressed ( as they tend to do ) so I feel the above was prudent at this point in time .

Finally FWIW I keep several broken belts in the back of the van, marked at 6" intervals with a white Sharpie so when I come across a broken belt on site I can get a rough idea of the right size belt which can save me hours trolling through catalogues & IPL's trying to work out what is the right belt and there are dozens of mowers running around here wearing a Bert's Guestimate belt and working fine.

FWIW , my go to for belt lengths is Gates.

Mos of the interchange sites have just been copied of a copy of some one elses that was copied off some one elses that was copied of some one elses so there are a lot of transcription errors like L sections being listed as std M-A-B-C for starters.

Even from the manufacturers you get errors.

I just put a new belt on a 2000 series Cub 42" deck.

The customer supplied it, it was a brand I did not recognise but he got it from the Cub Store on line.

It was too loose

SO I went back to the shop & get a Stens belt, it was too long

Now both of these belts came from the same maker and had the makers part number tape on them 3606

There was 2.5" difference between the two belts, neither fitted and both came from sleeves that had the correct Cub number on them.

So the "fix" was to get a slightly smaller from the stock pile .

I try to measure all belts when delivered .

Over the 8 years I have been operating I have had melts in the wrong sleeves and occasionally a belt that was labeled wrong ( vendors number on the belt ) but I have never before come across a belt that was labeled wrong ay the belt factory but this proved to me it does happen .

What most home users do not realize is belts come from the factory in bales, usually with a makers number on them .

That is the number you see a couple of inches away from the Vendors brand and part number .

These then go to a third party to have the afore mentioned branding tape adhered to the belts then be put in sleeves ready for sale.

Some vendors will sell belts in scanes ( bundles to some ) usually tied together with another belt and no sleeve for a considerably lower price .

So there are a lot of places where mis lableing can happen .

When you first posted , I ran your numbers through Gates and they came up as per your post so at that time there was no reason for me to chime in.

However the dialogue has progressed ( as they tend to do ) so I feel the above was prudent at this point in time .

Finally FWIW I keep several broken belts in the back of the van, marked at 6" intervals with a white Sharpie so when I come across a broken belt on site I can get a rough idea of the right size belt which can save me hours trolling through catalogues & IPL's trying to work out what is the right belt and there are dozens of mowers running around here wearing a Bert's Guestimate belt and working fine.

#24

StarTech

StarTech

Sounds like you learn like me the only one to trust to make sure the belt are right is yourself. To me it very aggravating to pull a belt out of stock to only find it is wrong when go to install it. So far with Gates when it comes to their inch size belts I only had one case of an A86 being 86" and every local shop had the same problem. Finally had to order one to get an A86 that was 88".

BTW Bert I have been at this for 12 yrs now myself. I however try to avoid field repairs whenever I can since inventory and tools are here in the shop. Even then there are days that I got to order a new tool like today where I got to order 46mm (1-13/16) socket for a new project. None of the local tool stores carries this large of a socket in stock especially in 6 point deep well impact. Never thought I would be needing sockets this large.

BTW Bert I have been at this for 12 yrs now myself. I however try to avoid field repairs whenever I can since inventory and tools are here in the shop. Even then there are days that I got to order a new tool like today where I got to order 46mm (1-13/16) socket for a new project. None of the local tool stores carries this large of a socket in stock especially in 6 point deep well impact. Never thought I would be needing sockets this large.

#25

B

bertsmobile1

B

bertsmobile1

Well it is

" Berts Mobile Mower Repairs"

Hand helds and most walk behinds need to come to me

Ride ons I come to them

If I can fix it in situ then that is what happens otherwise it gets loaded onto the trailer.

The work shop is on a farm so it can legally not be a workshop as that would contravine zoning laws.

" Berts Mobile Mower Repairs"

Hand helds and most walk behinds need to come to me

Ride ons I come to them

If I can fix it in situ then that is what happens otherwise it gets loaded onto the trailer.

The work shop is on a farm so it can legally not be a workshop as that would contravine zoning laws.

#26

StarTech

StarTech

I tried mobile repairs here but I had problems with the customers. They wanted the work done and then didn't want to pay for the repairs. Here they can legally order you off their property and not pay. Besides most customer don't even have decent hard surface to work on. Now it is bring it to me or I pick it up for repairs and I get paid before leaving the equipment.

I just had one of my better charge account customers to stick me with a repair bill. Boy do they got a surprise on the next repair call as I am not going. I was lucky it was only a belt and engine mounting screws parts wise. If I got it in the shop I can hold it until the bill is paid. Since I move to where I am now I had to go to small claims once to recover a repair bill. Most times I just sell or part out the equipment after 3 months of completion. Going to small claims court is a pain I would rather avoid most times.

As for what mobile repairs I do make I charge extra on the labor for the service which gives the customer the incentive to bring the equipment in.

And yes zoning laws are a pain for small shops. We don't make enough to rent a building many times. I am lucky that I am in the countryside and in farm country too. But the tax mob still taxes everything they can here even labor.

I just had one of my better charge account customers to stick me with a repair bill. Boy do they got a surprise on the next repair call as I am not going. I was lucky it was only a belt and engine mounting screws parts wise. If I got it in the shop I can hold it until the bill is paid. Since I move to where I am now I had to go to small claims once to recover a repair bill. Most times I just sell or part out the equipment after 3 months of completion. Going to small claims court is a pain I would rather avoid most times.

As for what mobile repairs I do make I charge extra on the labor for the service which gives the customer the incentive to bring the equipment in.

And yes zoning laws are a pain for small shops. We don't make enough to rent a building many times. I am lucky that I am in the countryside and in farm country too. But the tax mob still taxes everything they can here even labor.

#27

Hammermechanicman

Hammermechanicman

I feel for the you. Where i live i can't have a retail business on my property so i can't put out sign but the dog grooming business can and a couple others. I have business license and a tax ID and liability insurance and am a LLC. Like star said can't afford to rent a storefront unless i was a whole lot bigger operation and i don't need the headache of that.Well it is

" Berts Mobile Mower Repairs"

Hand helds and most walk behinds need to come to me

Ride ons I come to them

If I can fix it in situ then that is what happens otherwise it gets loaded onto the trailer.

The work shop is on a farm so it can legally not be a workshop as that would contravine zoning laws.

#28

StarTech

Some customers think we as business owners have it easy. They ought to try putting in up 16-18 hrs a day at times; although, I try to limit my time to only 12 hrs a day. Got to rest and let the headache pills work. Since I have manage a service office for nearly 16 yrs before going out on my own I knew what I was in for somewhat but the hours are a lot longer than I expected since I now got to do everything myself. At least my boss now is easy to work for.

I had to slow down some since my near strokes back Oct 2019. I simply wasn't watching my health and the blood pressure got out of control. Whole left side was shutting down. I still fighting the bp problem but I think I have hit on the right mix. Anyway I had to quit the last pills the doctor prescribed as I started seeing things that weren't there after 2 weeks. So I am just experimenting with second pill he prescribed and things seems to working right now. At lest the hacking cough is gone that the first pill he prescribed gave me. Now if can just get the right shoulder to stop hurting.

StarTech

What? You just want to go back to that 8 hr a day job with little to no headaches?I feel for the you. Where i live i can't have a retail business on my property so i can't put out sign but the dog grooming business can and a couple others. I have business license and a tax ID and liability insurance and am a LLC. Like star said can't afford to rent a storefront unless i was a whole lot bigger operation and i don't need the headache of that.

Some customers think we as business owners have it easy. They ought to try putting in up 16-18 hrs a day at times; although, I try to limit my time to only 12 hrs a day. Got to rest and let the headache pills work. Since I have manage a service office for nearly 16 yrs before going out on my own I knew what I was in for somewhat but the hours are a lot longer than I expected since I now got to do everything myself. At least my boss now is easy to work for.

I had to slow down some since my near strokes back Oct 2019. I simply wasn't watching my health and the blood pressure got out of control. Whole left side was shutting down. I still fighting the bp problem but I think I have hit on the right mix. Anyway I had to quit the last pills the doctor prescribed as I started seeing things that weren't there after 2 weeks. So I am just experimenting with second pill he prescribed and things seems to working right now. At lest the hacking cough is gone that the first pill he prescribed gave me. Now if can just get the right shoulder to stop hurting.

#29

Hammermechanicman

Hammermechanicman

What? You just want to go back to that 8 hr a day job with little to no headaches?

I wish. At age 61 i walked away from a $30/hr job. I was working 50-60 hours a week plus being on call 24/7 every few weeks plus running 2 side businesses. I got tired of getting called out at night and driving a hundred miles each way for a service call and then being back at it at 8:00 AM. That and telling pissed off customers their million dollar machine is down for a $5 part since the company slashed parts inventories to the bone. I will take the stress of running a mower shop and my other business. I am busy but at least i am in control.

I wish. At age 61 i walked away from a $30/hr job. I was working 50-60 hours a week plus being on call 24/7 every few weeks plus running 2 side businesses. I got tired of getting called out at night and driving a hundred miles each way for a service call and then being back at it at 8:00 AM. That and telling pissed off customers their million dollar machine is down for a $5 part since the company slashed parts inventories to the bone. I will take the stress of running a mower shop and my other business. I am busy but at least i am in control.

#30

StarTech

StarTech

Boy you did learn that $30/hr and then some. Here I was only $15 and had service area of 30+ counties but limited to 40hrs per no matter what as they would not pay overtime; unless, the customer was willing to $180-$240 per hour. which included travel time even if I did not have the parts. No customer was ever willing to pay that. I spent more time behind the windshield than on actual repairs.

#31

C

corvairbob

C

corvairbob

ok update i got the belts it is working this one came from husqvarna at one time and i got it from ebay original part number on the cover is 581-832401 like the book says. so maybe when the part was picked the incorrect belts were in the wrong bins. even after 3 tries. anyway like i said if you need an american number it is 1/2 x 35 1/4" belt. and now i'm going to get another one so i will not be caught again with my pants down. i had on the old sleve get a new one asap and i dropped that ball. oldtimers i guess. so now you know. thanks bp.

#32

C

corvairbob

C

corvairbob

ok final update the belt i just got 34.4" 90cm long by 1/2" wide works like a champ. i went out yearterday and blowed out the back drive section about as big as a 40 x 80 barn 12" deep compressed for a week and it blew the snow liek a champ. so for those looking for a belt the 1/2" x 35 1/4" belt shoud be just fine. ihave also order another one this tiem i got the cogged belt as they will bend easier around the drive pulley so if i need to use that one we will see then what one did work better! but ihave used that type before on other machines with great success.

so if you find you need a belt for this type of a machine and because poulan did not enter the normal belt size this is one that works as it should.

1/2 x 35 1/4" fit good installs fast oh! one thing i did do but most may not be able is i cut slots at the bottom of the impeller house where the lower belt guide is and took off the belt guide and slotted that so i could also get it closer to help prevent any future failures if and when this belt get worn. the made that guid so it sets about 3/4 of the thickness of the belt width so when it wears it can jump off the lower pulley. but that may be more then most can do.

so if you find you need a belt for this type of a machine and because poulan did not enter the normal belt size this is one that works as it should.

1/2 x 35 1/4" fit good installs fast oh! one thing i did do but most may not be able is i cut slots at the bottom of the impeller house where the lower belt guide is and took off the belt guide and slotted that so i could also get it closer to help prevent any future failures if and when this belt get worn. the made that guid so it sets about 3/4 of the thickness of the belt width so when it wears it can jump off the lower pulley. but that may be more then most can do.