I have installed a new Kohler EZT740-3022, 25 hp fuel injected engine in a Deere LX173. The original engine was a Kohler CV15. Mechanically everything has been modified and the new engine is installed in the tractor, including the ability to close the modified hood.

I have run into the challenge of how to wire the Deere’s 4 pin “W2 Engine Wiring Harness” connector to mate with the new Kohler’s 6 pin connector.

I purchased a matching male connector to the Kohler 6 pin connector to replace the original Deere 4 pin “Engine Wiring Harness” connector. I thought I understood the wiring diagram; I had the Deere white Ignition Module wire pin opposite the Kohler white wire, engine wouldn't start and I realized the Kohler white wire was going to Diagonistic Connector. It seems that 3 of the Deere wires are a simple match to 3 of the Kohler pins to mate together. The big challenge seems to be what to do with the Deere #940 white wire that went to the original single cylinder ignition module.

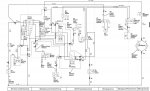

The Kohler has the following 6 pin wire connector from the engine: [Information from page 36 EFI System in the Service Manual]

#1 pin empty

#2 pin-white wire leads to diagnostic connector

#3 pin- black wire leads to Malfunction Indicator Lamp, MIL (installed MIL in dash on Deere)

#4 pin- red/white wire leads to ignition switch

#5 pin- green wire leads to oil pressure sentry sensor, this engine does not have an oil sentry on it.

#6 pin- dark blue wire leads to starter

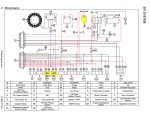

The Deere has the following wires: (numbers are from Deere Service Manual wiring layout; the first 4 wires were in the original Deere 4 wire “W2 Engine Wiring Harness” connector that mated to the original Kohler CV15 engine)

1) #205- red wire, key switch

2) #416- yellow/black wire, fuel shut-off for carb solenoid

3) #620- tan wire, engine oil sentry

4) #940- white wire, ignition module

#721- purple/while wire, starter motor (this wire had a separate connector to the original Kohler CV15 engine starter)

It seems that the following 4 wires mate together, the wires have pinned to correspond to the new Kohler engine connector:

Deere # 205, key switch would mate to the Kohler #4 pin to the ignition switch

Deere # 620, engine oil sentry would mate to the Kohler #5 pin to the oil sentry (may add the oil sentry later)

Deere #721, starter motor wire would mate to the Kohler #6 pin to the starter

New wire to mate with from Kohler #3 pin to the MIL, Malfunction Indicator Lamp installed on dash

The question is where should the Deere #940 white wire for the ignition module connect to? I tried the white wires but had no success, that is when I realized the Kohler white wire fed directly to the Diagnostic Connection. Is the Deere #416 fuel shut-off solenoid wire necessary to connect to the new EFI engine or is this now to be clipped and abandoned?

We live on an off-grid remote ranch in S.E. Oregon the closest town that might have a technician that possibly could help is over two hours away, and realistically more than likely almost 4 hours away. If possible, I need to resolve this issue here on the ranch. I greatly appreciate any advice anyone can give me.

I have run into the challenge of how to wire the Deere’s 4 pin “W2 Engine Wiring Harness” connector to mate with the new Kohler’s 6 pin connector.

I purchased a matching male connector to the Kohler 6 pin connector to replace the original Deere 4 pin “Engine Wiring Harness” connector. I thought I understood the wiring diagram; I had the Deere white Ignition Module wire pin opposite the Kohler white wire, engine wouldn't start and I realized the Kohler white wire was going to Diagonistic Connector. It seems that 3 of the Deere wires are a simple match to 3 of the Kohler pins to mate together. The big challenge seems to be what to do with the Deere #940 white wire that went to the original single cylinder ignition module.

The Kohler has the following 6 pin wire connector from the engine: [Information from page 36 EFI System in the Service Manual]

#1 pin empty

#2 pin-white wire leads to diagnostic connector

#3 pin- black wire leads to Malfunction Indicator Lamp, MIL (installed MIL in dash on Deere)

#4 pin- red/white wire leads to ignition switch

#5 pin- green wire leads to oil pressure sentry sensor, this engine does not have an oil sentry on it.

#6 pin- dark blue wire leads to starter

The Deere has the following wires: (numbers are from Deere Service Manual wiring layout; the first 4 wires were in the original Deere 4 wire “W2 Engine Wiring Harness” connector that mated to the original Kohler CV15 engine)

1) #205- red wire, key switch

2) #416- yellow/black wire, fuel shut-off for carb solenoid

3) #620- tan wire, engine oil sentry

4) #940- white wire, ignition module

#721- purple/while wire, starter motor (this wire had a separate connector to the original Kohler CV15 engine starter)

It seems that the following 4 wires mate together, the wires have pinned to correspond to the new Kohler engine connector:

Deere # 205, key switch would mate to the Kohler #4 pin to the ignition switch

Deere # 620, engine oil sentry would mate to the Kohler #5 pin to the oil sentry (may add the oil sentry later)

Deere #721, starter motor wire would mate to the Kohler #6 pin to the starter

New wire to mate with from Kohler #3 pin to the MIL, Malfunction Indicator Lamp installed on dash

The question is where should the Deere #940 white wire for the ignition module connect to? I tried the white wires but had no success, that is when I realized the Kohler white wire fed directly to the Diagnostic Connection. Is the Deere #416 fuel shut-off solenoid wire necessary to connect to the new EFI engine or is this now to be clipped and abandoned?

We live on an off-grid remote ranch in S.E. Oregon the closest town that might have a technician that possibly could help is over two hours away, and realistically more than likely almost 4 hours away. If possible, I need to resolve this issue here on the ranch. I greatly appreciate any advice anyone can give me.