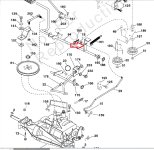

As the pedal is unique, the logic is that at the beginning of the pedal stroke, the clutch is activated/disabled and then the brake.

Separately everything works, but there is a jump when leaving and a certain delay in starting the brake, seeming that the functions are overlapping.

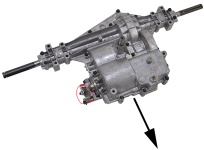

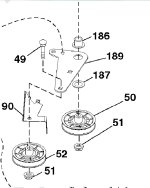

When disassembling, I could see several worn components that I believe are causing the inconvenience.

Parece que esta peça já foi virada um dia...

Some components are not part of the diagram but perform the same function.

The sum of these gaps and others that are difficult to photograph must be the cause.

Am I right in my reasoning or is there something else?

Separately everything works, but there is a jump when leaving and a certain delay in starting the brake, seeming that the functions are overlapping.

When disassembling, I could see several worn components that I believe are causing the inconvenience.

Parece que esta peça já foi virada um dia...

Some components are not part of the diagram but perform the same function.

The sum of these gaps and others that are difficult to photograph must be the cause.

Am I right in my reasoning or is there something else?