Restoring an old 1994 Lawn-Boy Gold-Series Model: 10520 Serial: 4901575 with a 4.5HP motor. Self-propelled model.

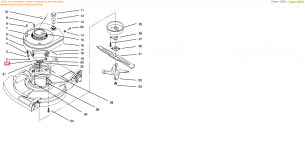

I know there are several threads and videos about how to remove a stuck blade nut by using impact wrench, heat, leverage bars, etc.... That isn't my problem. I did use a leverage bar, but what happened is I thought I broke the nut loose, but it appears the blade has broken loose. With the blade blocked with a piece of wood and clamp, I can use my socket wrench to spin the nut, shaft, and flywheel as one. How can I break the nut loose now? I thought about taking the gas tank and pull starter off and blocking the flywheel but am worried about breaking the fins on the flywheel. Wanted to check here first. Also thought about using a chisel to break the nut off and replace it (which I probably will do anyway). I suspect the muffler cover and/or plate-collar assembly will need replacing and are why the blade has loosened/broken from the shaft.

For those interested in the restore process: (this thing was left outside for 2 years in the upper midwest. Rusted up bad).

I've used a compression gauge with a schrader valve to test the compression to 103.

I've pulled, tested, and cleaned the spark plug. It appeared in good shape. Not too much carbon build-up.

I've pulled and cleaned the carb thoroughly. If it runs rough I may go ahead and buy a rebuild kit for it, but it passes the eye inspection.

I've pulled, cleaned, and flushed the gas tank and let it dry thoroughly. Pulled the shut-off valve and cleaned it also.

Old ignition coil (683080) was bad. No spark. Bought a cheap replacement which tested to provide spark. Will buy a more quality one in the future if I can get this bad boy running.

Cables were all seized up. Used Kreen Oil and WD40 to loosen them up. All seem operation now, but are rusty. Will replace in future as needed.

Deck needs repainting badly. Old paint is peeling off. Will get to that later.

Underside rusted up badly. Need to replace blades and clean the exhaust ports which is where I am and having the blade nut issue.

Help is appreciated.

p.s. I wasn't aware the model 10520 came with a 4.5hp. I thought it only came with a 5hp.

I know there are several threads and videos about how to remove a stuck blade nut by using impact wrench, heat, leverage bars, etc.... That isn't my problem. I did use a leverage bar, but what happened is I thought I broke the nut loose, but it appears the blade has broken loose. With the blade blocked with a piece of wood and clamp, I can use my socket wrench to spin the nut, shaft, and flywheel as one. How can I break the nut loose now? I thought about taking the gas tank and pull starter off and blocking the flywheel but am worried about breaking the fins on the flywheel. Wanted to check here first. Also thought about using a chisel to break the nut off and replace it (which I probably will do anyway). I suspect the muffler cover and/or plate-collar assembly will need replacing and are why the blade has loosened/broken from the shaft.

For those interested in the restore process: (this thing was left outside for 2 years in the upper midwest. Rusted up bad).

I've used a compression gauge with a schrader valve to test the compression to 103.

I've pulled, tested, and cleaned the spark plug. It appeared in good shape. Not too much carbon build-up.

I've pulled and cleaned the carb thoroughly. If it runs rough I may go ahead and buy a rebuild kit for it, but it passes the eye inspection.

I've pulled, cleaned, and flushed the gas tank and let it dry thoroughly. Pulled the shut-off valve and cleaned it also.

Old ignition coil (683080) was bad. No spark. Bought a cheap replacement which tested to provide spark. Will buy a more quality one in the future if I can get this bad boy running.

Cables were all seized up. Used Kreen Oil and WD40 to loosen them up. All seem operation now, but are rusty. Will replace in future as needed.

Deck needs repainting badly. Old paint is peeling off. Will get to that later.

Underside rusted up badly. Need to replace blades and clean the exhaust ports which is where I am and having the blade nut issue.

Help is appreciated.

p.s. I wasn't aware the model 10520 came with a 4.5hp. I thought it only came with a 5hp.