TiredRetired

Member

- Joined

- Jul 9, 2012

- Threads

- 3

- Messages

- 11

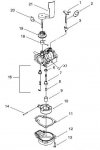

I am the proud owner of a 2003 Lawnboy 10323 mower. Recently I started having an issue with the carb leaking gas into the engine, which as I understand it is a fairly common issue with these plastic carbs. It was bad to the point where when I pulled the starter rope gas would gush out of the muffler.

My short term fix currently was to install a gas shut off so gas would not continue to leak into the carb causing this problem while it sits in the tool shed for 5 days waiting for the next mowing. Other then this issue the mower runs great and starts first pull with to 2/3 pushes of the primer bulb and no choke.

To my question. I need to repair the carb, obviously. Should I buy the complete carb kit 107-4607, which is essentially a completely new carb, in kit form? There are many parts there that I would assume I do not need or should I just go to parts tree and pick up the particular replacement parts that are causing this gas leak blow by problem?

If I did just buy the particular parts, which ones should I get that are causing this issue? Not trying to nickle and dime this issue. I will buy the complete kit it need be, just wondering what others have done here to rectify this issue.

Cheers.

My short term fix currently was to install a gas shut off so gas would not continue to leak into the carb causing this problem while it sits in the tool shed for 5 days waiting for the next mowing. Other then this issue the mower runs great and starts first pull with to 2/3 pushes of the primer bulb and no choke.

To my question. I need to repair the carb, obviously. Should I buy the complete carb kit 107-4607, which is essentially a completely new carb, in kit form? There are many parts there that I would assume I do not need or should I just go to parts tree and pick up the particular replacement parts that are causing this gas leak blow by problem?

If I did just buy the particular parts, which ones should I get that are causing this issue? Not trying to nickle and dime this issue. I will buy the complete kit it need be, just wondering what others have done here to rectify this issue.

Cheers.