Harold2689

Member

- Joined

- Sep 17, 2016

- Threads

- 2

- Messages

- 12

I recently came into possession of an old Murry Model 46570X8A lawn tractor. It has a 46" cutting deck, and it has seen better days.

I'm trying to get the old lady back up and working again...

It's old, and appears to have been "rode hard and put away wet.

When I removed the deck, it, and the underside of the tractor looked like this

There was mud, and dried grass everywhere. That bearing was all that was left of the idler pulley that is supposed to be there.

I took the deck completely apart, wire brushed everything, painted & reassembled. Now it looks like this:

It's powered by a Briggs 18.5 hp twin cylinder engine:

It runs great, but there is a starter problem that I can handle.

The remaining problem is the transaxle. I have no experience or knowledge about them at all. I assume it's a

Peerless, but I cannot locate any labels or barcodes anywhere on it. Judging by the dirt and mud under the whole tractor,

it may have fallen off years ago.

This is the only marking I can find on the transaxle.

Here's what I've done so far. I hosed the entire unit with a high pressure nozzle on my garden hose. Nowhere near 3,000psi

from a pressure washer, just 60 psi max, but with a "pressure" nozzle. I got most of the mud and junk removed, and found 1

of the three idler pulleys under the tractor locked up solid. I did not mention that the first time I started this mower up, it did move under its own power,

but very slow, and it whined quite loudly. After replacing the idler pulley it didn't whine quite as loudly, but still way more than i thought it should.

The belt is in very good shape, but I think it was not installed correctly. It is my understanding that on this mower, the steering shaft runs through

main drive belt. I found this one running around the side of the steering shaft. I removed the snap ring, tapped the steering shaft up through the gear,

and reinstalled it after moving the drive belt over. The steering shaft now runs through the drive belt. I also took advantage of the situation to

add a little grease to the bushing at the bottom of the shaft, and the gears. After doing all of this, the mower is still very slow, and still whines when I push

the pedal to go forward. When I take my foot off the brake pedal on the left, it applies tension to the main drive belt, and everything turns fine with no noise.

When I start to move forward, the transaxle whines, and with my handheld GPS, on flat and level ground, I got all the way up to 2.5 mph, with the engine speed

at full throttle, and the pedal literally to the metal. When the pedal is pushed forward from the top, it pushes a rod rearward under the floorboard. There is a clip

and adjustment nut on the end of that rod. I've adjusted the nut to give me maximum rearward movement. It moves both forward and reverse, but I have

2.5 acres to mow, and I need it to move forward a little faster than it is. I tried a test by putting a front wheel against a tree, and pressing the pedal forward. The rear wheels both spun

forward, which tells me that the belt is not slipping, and there is enough torque getting through the transaxle to spin the wheels- just not very fast.

I know absolutely nothing about hydro-static transaxles, so I asked my local lawn tractor repair guy, and he doesn't work on them. He said that most of the manufacturers

don't want you to mess with them, but people do change and add fluid. He thinks that the cause of it whining is that the fluid is low. He recommended replacing the whole transaxle with a used one. But he said that if I wanted to tinker with it, look for a vent cap or rubber plug, and I might be able to add some fluid there. He recommended straight 30W non-detergent motor oil.

When I got home I removed the battery, and looking down, I found 2 rubber plugs:

Is it possible to try to add fluid through either of these 2 rubber plugs? If the transaxle has to be replaced, what's the chances of squeezing a little more life out of this old lady?

It's a 46" cut, so it would really be nice on that 2.5 acres.

What say you guys? If it does need to be replaced, what should I expect to pay for a used one? Is it worth fixing? Would you replace the whole axle?

Thanks in advance for any help you guys may be able to offer...

Harold

I'm trying to get the old lady back up and working again...

It's old, and appears to have been "rode hard and put away wet.

When I removed the deck, it, and the underside of the tractor looked like this

There was mud, and dried grass everywhere. That bearing was all that was left of the idler pulley that is supposed to be there.

I took the deck completely apart, wire brushed everything, painted & reassembled. Now it looks like this:

It's powered by a Briggs 18.5 hp twin cylinder engine:

It runs great, but there is a starter problem that I can handle.

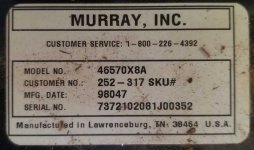

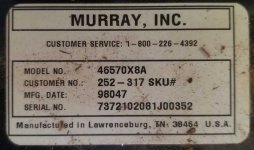

The remaining problem is the transaxle. I have no experience or knowledge about them at all. I assume it's a

Peerless, but I cannot locate any labels or barcodes anywhere on it. Judging by the dirt and mud under the whole tractor,

it may have fallen off years ago.

This is the only marking I can find on the transaxle.

Here's what I've done so far. I hosed the entire unit with a high pressure nozzle on my garden hose. Nowhere near 3,000psi

from a pressure washer, just 60 psi max, but with a "pressure" nozzle. I got most of the mud and junk removed, and found 1

of the three idler pulleys under the tractor locked up solid. I did not mention that the first time I started this mower up, it did move under its own power,

but very slow, and it whined quite loudly. After replacing the idler pulley it didn't whine quite as loudly, but still way more than i thought it should.

The belt is in very good shape, but I think it was not installed correctly. It is my understanding that on this mower, the steering shaft runs through

main drive belt. I found this one running around the side of the steering shaft. I removed the snap ring, tapped the steering shaft up through the gear,

and reinstalled it after moving the drive belt over. The steering shaft now runs through the drive belt. I also took advantage of the situation to

add a little grease to the bushing at the bottom of the shaft, and the gears. After doing all of this, the mower is still very slow, and still whines when I push

the pedal to go forward. When I take my foot off the brake pedal on the left, it applies tension to the main drive belt, and everything turns fine with no noise.

When I start to move forward, the transaxle whines, and with my handheld GPS, on flat and level ground, I got all the way up to 2.5 mph, with the engine speed

at full throttle, and the pedal literally to the metal. When the pedal is pushed forward from the top, it pushes a rod rearward under the floorboard. There is a clip

and adjustment nut on the end of that rod. I've adjusted the nut to give me maximum rearward movement. It moves both forward and reverse, but I have

2.5 acres to mow, and I need it to move forward a little faster than it is. I tried a test by putting a front wheel against a tree, and pressing the pedal forward. The rear wheels both spun

forward, which tells me that the belt is not slipping, and there is enough torque getting through the transaxle to spin the wheels- just not very fast.

I know absolutely nothing about hydro-static transaxles, so I asked my local lawn tractor repair guy, and he doesn't work on them. He said that most of the manufacturers

don't want you to mess with them, but people do change and add fluid. He thinks that the cause of it whining is that the fluid is low. He recommended replacing the whole transaxle with a used one. But he said that if I wanted to tinker with it, look for a vent cap or rubber plug, and I might be able to add some fluid there. He recommended straight 30W non-detergent motor oil.

When I got home I removed the battery, and looking down, I found 2 rubber plugs:

Is it possible to try to add fluid through either of these 2 rubber plugs? If the transaxle has to be replaced, what's the chances of squeezing a little more life out of this old lady?

It's a 46" cut, so it would really be nice on that 2.5 acres.

What say you guys? If it does need to be replaced, what should I expect to pay for a used one? Is it worth fixing? Would you replace the whole axle?

Thanks in advance for any help you guys may be able to offer...

Harold