You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Echo was working but suddenly no more

#1

J

juntjoo

J

juntjoo

#2

R

Rivets

R

Rivets

I’m seeing one thing you are doing wrong in your pictures. With that much oil on the plug and cylinder you do not have the correct fuel/oil mixture. Echo uses a 50/1 mixture. Second, you have been around this forum since 2017 and have started multiple threads. You should know by now that the techs on this site need model and serial numbers, before we can give you help. Third, in reading other threads you have posted in, you like to make assumptions and jump to conclusions which most times are wrong. AKA, your thread on carbs. Four, turning screws on carbs, especially if you don‘t know their function, can get you in trouble very fast. If it was working fine why would you start playing with any screws? That being said, let’s back up and give us the model and serial numbers, then we can try to figure this out.

#3

J

juntjoo

J

juntjoo

Don't scold me son! What do you mean I'm going to "get in trouble"? And that I shouldn't "assume" anything? If you have a brain you make assumptions. You saying I'm not allowed to as stupid as I am lol? The nerve! Chill with your judgement pops you ain't th e boss of me. And how did you figure out I put too much oil if I didn't give you the essential serial numbers? Did I assume again I was dealing with a general concept here? Oops! You don't need a model number, you need someone to respect you.I’m seeing one thing you are doing wrong in your pictures. With that much oil on the plug and cylinder you do not have the correct fuel/oil mixture. Echo uses a 50/1 mixture. Second, you have been around this forum since 2017 and have started multiple threads. You should know by now that the techs on this site need model and serial numbers, before we can give you help. Third, in reading other threads you have posted in, you like to make assumptions and jump to conclusions which most times are wrong. AKA, your thread on carbs. Four, turning screws on carbs, especially if you don‘t know their function, can get you in trouble very fast. If it was working fine why would you start playing with any screws? That being said, let’s back up and give us the model and serial numbers, then we can try to figure this out.

#4

J

juntjoo

J

juntjoo

And I looked through your threads and see you cheating on your wife. What the...I’m seeing one thing you are doing wrong in your pictures. With that much oil on the plug and cylinder you do not have the correct fuel/oil mixture. Echo uses a 50/1 mixture. Second, you have been around this forum since 2017 and have started multiple threads. You should know by now that the techs on this site need model and serial numbers, before we can give you help. Third, in reading other threads you have posted in, you like to make assumptions and jump to conclusions which most times are wrong. AKA, your thread on carbs. Four, turning screws on carbs, especially if you don‘t know their function, can get you in trouble very fast. If it was working fine why would you start playing with any screws? That being said, let’s back up and give us the model and serial numbers, then we can try to figure this out.

#5

R

Rivets

R

Rivets

Seeing that I’m north of 70, and your son, that would make you 90+. You Made another assumption, that I’m married. I’m going to hit ignore, as you need more help than I or any of the other techs here can give you. From my 50+ years of experience, seeing that much oil on the plug and head, tells me you have an oil leak. Seeing it is a 2-cycle engine, the only possible source is mixture. Good luck in your search Dad, you’re going to need it. If my assumption from your post is wrong, I’m not your son, then you need to grow up.

#6

S

SeniorCitizen

S

SeniorCitizen

From what i'm seeing on the spark plug you may want to consider taking a look at the spark arrestor screen . It could need cleaning .

There's videos on the procedure .

There's videos on the procedure .

#7

M

MParr

M

MParr

It could be several things.

First of all, we don’t even know what Echo model and serial number you have. We don’t even know how old it is.

There is fuel mixture is all over the top of the engine.

There doesn’t look like very much maintenance has been done to it.

The fuel lines, fuel filter, fuel tank grommet, and primer bulb has probably never been changed. The air filter probably needs attention. The spark arrestor has probably never been cleaned. The gaskets on both sides of the intake manifold block could need replacement.

Are you even getting a spark?

First of all, we don’t even know what Echo model and serial number you have. We don’t even know how old it is.

There is fuel mixture is all over the top of the engine.

There doesn’t look like very much maintenance has been done to it.

The fuel lines, fuel filter, fuel tank grommet, and primer bulb has probably never been changed. The air filter probably needs attention. The spark arrestor has probably never been cleaned. The gaskets on both sides of the intake manifold block could need replacement.

Are you even getting a spark?

#8

StarTech

StarTech

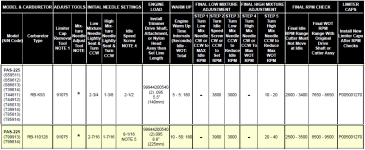

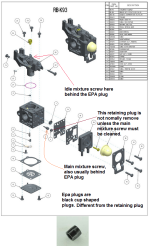

The mixture are EPA plugged for a reason. It is to keep untrained people from adjusting them. Echo does provide the Echo techs with a tune up procedure chart.

But as said first your make the muffler spark arrester is clean. Then you the carb for stiffen metering diaphragm and you tune per the tune up chart using a tach.

Can't even provide the stripped down chart from without the model and serial numbers of the unit you have. But I suspect you have a Zama RB rotary carb and that adjust by the primer is not a mixture screw but also a metering jet too.

But as said first your make the muffler spark arrester is clean. Then you the carb for stiffen metering diaphragm and you tune per the tune up chart using a tach.

Can't even provide the stripped down chart from without the model and serial numbers of the unit you have. But I suspect you have a Zama RB rotary carb and that adjust by the primer is not a mixture screw but also a metering jet too.

#9

R

Rivets

R

Rivets

Jootjun, you need every piece of help you can get, so as a retired instructor, I’m going to provide you with all the info I’d give to my students so they will understand the theory on how a carburetor works. After you read and hopefully understand this material, you will then be in a position to start putting this theory into practice. Until that time you can make assumptions and point out what I do in may spare time, but make sure you can back up your statements. If you can’t back up your statements, you are just the new kid in my class trying to prove what you don’t know. Happy reading. Star, I desperately need that part number.

outdoorpowerinfo.com

outdoorpowerinfo.com

tecumsehcarburetorguide.wordpress.com

tecumsehcarburetorguide.wordpress.com

Small Engine, Lawn Mower, Snowthrower Troubleshooting, Repairs and Safety

Tecumseh Carburetor Guide

Get troubleshooting manual for tecumseh carburetor and detailed information of tecumseh parts.

#10

woodstover

woodstover

Awesome reference reading Rivets! Keeping all those PDF's for future reference. I normally only piddle around with 4 strokes but I always need refresher on the 2 stroke carbs. Thanks!Jootjun, you need every piece of help you can get, so as a retired instructor, I’m going to provide you with all the info I’d give to my students so they will understand the theory on how a carburetor works. After you read and hopefully understand this material, you will then be in a position to start putting this theory into practice. Until that time you can make assumptions and point out what I do in may spare time, but make sure you can back up your statements. If you can’t back up your statements, you are just the new kid in my class trying to prove what you don’t know. Happy reading. Star, I desperately need that part number.

Small Engine, Lawn Mower, Snowthrower Troubleshooting, Repairs and Safety

outdoorpowerinfo.com

Tecumseh Carburetor Guide

Get troubleshooting manual for tecumseh carburetor and detailed information of tecumseh parts.tecumsehcarburetorguide.wordpress.com

#11

J

juntjoo

J

juntjoo

Thanks for all your replies. Even from @Rivets but I'm going to look at yours separately as your a whole other conversation...

Trimmer is old. But I've replaced the carb and associated parts.

I've tried with three plugs and one new, two older.

The "spark arrester screen"? If that's the thing on the muffler I took it off years ago.

The grommet, though new plus fuel lines a month ago or so. I can turn it upside down to replace the string and it won't leak. But I think I've seen some moisture around still. I think ALL the aftermarket carbs grommet don't fit perfect. Idk. It's just not starting. I'd imagine it would start but then struggle if it were related to the grommet tank or lines no?

The bulb works fine and it's new and I've been testing without an air filter.

I see spark of but I've never known how to judge it if it might not be strong enough. But I'm guessing the new plug is good enough.

I've tried squirting carb cleaner in there and even directly into the cylinder through plug hole. Doesn't this inability to start narrow the possible culprits down a lot?

The adjustment screw in the back goes 270 degrees. I've tried both extremes and I just keep it in the middle now as that was where it seemed to be best when it was working.

The diaphragm seems good to me. One vid showed how it becomes brittle when old. Mine seems to float up and down easy. What would it need to do in order just to get the trimmer to start?

Both gaskets seem fine. I'm going to give the whole thing a good cleaning though and keep testing and check where it leaks first.

Is it a no-no to operate these upside down? That's how I do my edging. Is that how I'm getting gas/oil all over it?

@Rivets said echo uses 50:1 mixture. Oops, I think I just followed the instructions on the bottle and did way more like 16:1...so I just flushed carb out with straight 90 gas and put some in the tank JUST to try to get it started then I'll add oil. No luck.

It's a PAS 225. I thought they were all that or otherwise they work basically the same

I don't feel like what info I'm missing currently is dependent on the serial number unless you guys tell me how. Like, what have I not down yet that the serial number would reveal to me? My questions are based on ignorance of general operation mostly until you tell me otherwise.

@StarTech just informed of another adjustment screw on the "zama". Well this is what I got:

Many good reviews. I try to get good quality without breaking the bank

Is it a "timing" issue? Is there a pro tech manual on the dark web somewhere to download?

Okay I'll be back ...

Trimmer is old. But I've replaced the carb and associated parts.

I've tried with three plugs and one new, two older.

The "spark arrester screen"? If that's the thing on the muffler I took it off years ago.

The grommet, though new plus fuel lines a month ago or so. I can turn it upside down to replace the string and it won't leak. But I think I've seen some moisture around still. I think ALL the aftermarket carbs grommet don't fit perfect. Idk. It's just not starting. I'd imagine it would start but then struggle if it were related to the grommet tank or lines no?

The bulb works fine and it's new and I've been testing without an air filter.

I see spark of but I've never known how to judge it if it might not be strong enough. But I'm guessing the new plug is good enough.

I've tried squirting carb cleaner in there and even directly into the cylinder through plug hole. Doesn't this inability to start narrow the possible culprits down a lot?

The adjustment screw in the back goes 270 degrees. I've tried both extremes and I just keep it in the middle now as that was where it seemed to be best when it was working.

The diaphragm seems good to me. One vid showed how it becomes brittle when old. Mine seems to float up and down easy. What would it need to do in order just to get the trimmer to start?

Both gaskets seem fine. I'm going to give the whole thing a good cleaning though and keep testing and check where it leaks first.

Is it a no-no to operate these upside down? That's how I do my edging. Is that how I'm getting gas/oil all over it?

@Rivets said echo uses 50:1 mixture. Oops, I think I just followed the instructions on the bottle and did way more like 16:1...so I just flushed carb out with straight 90 gas and put some in the tank JUST to try to get it started then I'll add oil. No luck.

It's a PAS 225. I thought they were all that or otherwise they work basically the same

I don't feel like what info I'm missing currently is dependent on the serial number unless you guys tell me how. Like, what have I not down yet that the serial number would reveal to me? My questions are based on ignorance of general operation mostly until you tell me otherwise.

@StarTech just informed of another adjustment screw on the "zama". Well this is what I got:

Many good reviews. I try to get good quality without breaking the bank

Is it a "timing" issue? Is there a pro tech manual on the dark web somewhere to download?

Okay I'll be back ...

#12

J

juntjoo

J

juntjoo

Thanks. Yeah, I'm an ASS-umer. And it takes me a while to figure things out and I don't take spoon feeding. So I assume things til I learn for sure if I'm right or not. And yes I do need a lot of help and I'm 48 in a few months so thanks Dad. I WILL BE ABLE ask dumb questions though. I can't study this stuff as as you may have guessed I struggle elsewhere in life where things are a lot more important than the height of my grassJootjun, you need every piece of help you can get, so as a retired instructor, I’m going to provide you with all the info I’d give to my students so they will understand the theory on how a carburetor works. After you read and hopefully understand this material, you will then be in a position to start putting this theory into practice. Until that time you can make assumptions and point out what I do in may spare time, but make sure you can back up your statements. If you can’t back up your statements, you are just the new kid in my class trying to prove what you don’t know. Happy reading. Star, I desperately need that part number.

Small Engine, Lawn Mower, Snowthrower Troubleshooting, Repairs and Safety

outdoorpowerinfo.com

Tecumseh Carburetor Guide

Get troubleshooting manual for tecumseh carburetor and detailed information of tecumseh parts.tecumsehcarburetorguide.wordpress.com

#13

R

Rivets

R

Rivets

Woodstover, I’m glad someone understands that you need to know what you’re working on before they dive in. Not knowing what should be going on, or understanding how things work, is what gets many members in big trouble.

Jootjun, you may not know this, but there are over 100,000 different models of small engines. Echo alone has over 1000 different configurations. That is the reason the techs everywhere ask for model and serial numbers. We need them when trying to help solve problems. Your attitude and unwillingness to help your cause is your biggest problem. We ask questions and point out what we see, because we are miles away and most of our crystal balls have become snow globes. Your replies to my posts show me your immaturity on both the mechanics level and as a person in general. I believe that they are inappropriate to anyone and not a way to get help. If you really want help I suggest you re-examine yourself and the way you deal with answers to your questions. I’ve always told people that if you may not like the answer, don’t ask the question. Finally, people in this industry will tell you that when you are troubleshooting problems, making assumptions is your worst enemy. Sometimes knowing nothing is better than assuming you know a little. Read the instructions I posted, they are very helpful for everyone, even me as I have them because I have to refer to them more often than most people would think.

Jootjun, you may not know this, but there are over 100,000 different models of small engines. Echo alone has over 1000 different configurations. That is the reason the techs everywhere ask for model and serial numbers. We need them when trying to help solve problems. Your attitude and unwillingness to help your cause is your biggest problem. We ask questions and point out what we see, because we are miles away and most of our crystal balls have become snow globes. Your replies to my posts show me your immaturity on both the mechanics level and as a person in general. I believe that they are inappropriate to anyone and not a way to get help. If you really want help I suggest you re-examine yourself and the way you deal with answers to your questions. I’ve always told people that if you may not like the answer, don’t ask the question. Finally, people in this industry will tell you that when you are troubleshooting problems, making assumptions is your worst enemy. Sometimes knowing nothing is better than assuming you know a little. Read the instructions I posted, they are very helpful for everyone, even me as I have them because I have to refer to them more often than most people would think.

#15

J

juntjoo

I learn by using my mind first foremost and last, being stupid and breaking things. Not following the orders of false authorities.

I blew up my first mowers engine and also my truck's. Now I REALLY know how important it is to keep an engine properly lubed. And I'm STILL not afraid to blow something else up by being stupid.

I'm not afraid of "getting in trouble" or of you judging me for it lol.

You're scared of breaking rules. I'm not. I know what I know from experience not blindly following people who claim superiority over me.

When "experts" talk I don't get scared and bow.

You can't homogenize me rivets. I'll never take the jab

And your opinion of my maturity level is as relevant to the post as your ego.

And I like answers to the questions I ASK ..and I even like your irrelevant comments for psychological study

You have mechanical knowledge over me. You can pat yourself on the back for that. As far as the rest let's try to keep on topic

Again I sincerely appreciate the help though and will be taking a look ...

J

juntjoo

I have been and continue to be willing to provide all the necessary information to get help and THEN SOME.Woodstover, I’m glad someone understands that you need to know what you’re working on before they dive in. Not knowing what should be going on, or understanding how things work, is what gets many members in big trouble.

Jootjun, you may not know this, but there are over 100,000 different models of small engines. Echo alone has over 1000 different configurations. That is the reason the techs everywhere ask for model and serial numbers. We need them when trying to help solve problems. Your attitude and unwillingness to help your cause is your biggest problem. We ask questions and point out what we see, because we are miles away and most of our crystal balls have become snow globes. Your replies to my posts show me your immaturity on both the mechanics level and as a person in general. I believe that they are inappropriate to anyone and not a way to get help. If you really want help I suggest you re-examine yourself and the way you deal with answers to your questions. I’ve always told people that if you may not like the answer, don’t ask the question. Finally, people in this industry will tell you that when you are troubleshooting problems, making assumptions is your worst enemy. Sometimes knowing nothing is better than assuming you know a little. Read the instructions I posted, they are very helpful for everyone, even me as I have them because I have to refer to them more often than most people would think.

I learn by using my mind first foremost and last, being stupid and breaking things. Not following the orders of false authorities.

I blew up my first mowers engine and also my truck's. Now I REALLY know how important it is to keep an engine properly lubed. And I'm STILL not afraid to blow something else up by being stupid.

I'm not afraid of "getting in trouble" or of you judging me for it lol.

You're scared of breaking rules. I'm not. I know what I know from experience not blindly following people who claim superiority over me.

When "experts" talk I don't get scared and bow.

You can't homogenize me rivets. I'll never take the jab

And your opinion of my maturity level is as relevant to the post as your ego.

And I like answers to the questions I ASK ..and I even like your irrelevant comments for psychological study

You have mechanical knowledge over me. You can pat yourself on the back for that. As far as the rest let's try to keep on topic

Again I sincerely appreciate the help though and will be taking a look ...

#16

7394

7394

The 1st spark plug pic looks like the porcelain has a hair line crack in it...

Looks like to me.

Looks like to me.

#17

woodstover

woodstover

I have been and continue to be willing to provide all the necessary information to get help and THEN SOME.

I learn by using my mind first foremost and last, being stupid and breaking things. Not following the orders of false authorities.

I blew up my first mowers engine and also my truck's. Now I REALLY know how important it is to keep an engine properly lubed. And I'm STILL not afraid to blow something else up by being stupid.

I'm not afraid of "getting in trouble" or of you judging me for it lol.

You're scared of breaking rules. I'm not. I know what I know from experience not blindly following people who claim superiority over me.

When "experts" talk I don't get scared and bow.

You can't homogenize me rivets. I'll never take the jab

And your opinion of my maturity level is as relevant to the post as your ego.

And I like answers to the questions I ASK ..and I even like your irrelevant comments for psychological study

You have mechanical knowledge over me. You can pat yourself on the back for that. As far as the rest let's try to keep on topic

Again I sincerely appreciate the help though and will be taking a look ...

#18

J

juntjoo

J

juntjoo

Well I tried with a couple plugs, one new. Check the vid above a couple posts. I got fuel/oil coming out of the exhaust. Doesn't that mean there's a major issue with the piston? I've never dealt with oil coming out of the exhaust of a 2 stroke, so not sure what that meansThe 1st spark plug pic looks like the porcelain has a hair line crack in it...

Looks like to me.

#19

woodstover

woodstover

Juntjoo:

I honestly don't know why Rivets is wasting his time with you. Your arrogance and ignorance is deplorable on a site meant to help people. This is not a site to educate you in small engine repair, it's for people that either have some mechanical knowledge or when they find out that it's "out of their league" to either take it to a repair shop for fix'in or toss it and buy a new one. Boasting about your "blow-ups" is not gonna gain you any respect here.

Asking for make, model, serial # and other information that has been requested is to fine tune the responses of the people that reply to you. Why should they waste their time spit balling at an unknown item. Knowing this information is valuable to both you and the people that reply. The benefit of experience can not be over stated and these people have a wealth of information on specific make and model idiosyncrasies that is only gained with years of experience.

But, Mr. Know-it-all, since you feel that you've covered all the troubleshooting bases so far, the next steps would be to vacuum test and pressure test the crank case. I will not lead you through the process or the benefits of these tests. I suggest you research on why it's necessary and get to it.

I honestly don't know why Rivets is wasting his time with you. Your arrogance and ignorance is deplorable on a site meant to help people. This is not a site to educate you in small engine repair, it's for people that either have some mechanical knowledge or when they find out that it's "out of their league" to either take it to a repair shop for fix'in or toss it and buy a new one. Boasting about your "blow-ups" is not gonna gain you any respect here.

Asking for make, model, serial # and other information that has been requested is to fine tune the responses of the people that reply to you. Why should they waste their time spit balling at an unknown item. Knowing this information is valuable to both you and the people that reply. The benefit of experience can not be over stated and these people have a wealth of information on specific make and model idiosyncrasies that is only gained with years of experience.

But, Mr. Know-it-all, since you feel that you've covered all the troubleshooting bases so far, the next steps would be to vacuum test and pressure test the crank case. I will not lead you through the process or the benefits of these tests. I suggest you research on why it's necessary and get to it.

#20

Scrubcadet10

Scrubcadet10

Boys, lets act like men....

Have you taken the muffler off and inspected the cylinder to be sure there is no scoring of the piston or cylinder wall?

Have you taken the muffler off and inspected the cylinder to be sure there is no scoring of the piston or cylinder wall?

#21

StarTech

StarTech

The primer only removes excess from carburetor metering chamber along some surplus fuel. Now when metering diaphragm has stiffen, metering needle valve worn, or the main nozzle check valve is defective then you get flooding but would have to replaced in order to resolve the flooding.

I had offered to provide the carburetor tuning instructions but you have fail to post the equipment model number so I am assuming you want to keep us in the dark so I stepping out of this thread. Beside if the carb still has EPA plugs you would need the 2.5mm extraction tool (3 mm if the plugs are damaged).

And members please stop cocking attitudes. Even I get annoyed at those that asking for help but not willing to provide info needed and those that post unnecessary comments so I usually just bow out without posting nasty comments.

Besides this time of the year for me is the start of the busy season. Right now I got a full work in my shop; already getting backlogged so I will be spending a lot less time on the forum.

I had offered to provide the carburetor tuning instructions but you have fail to post the equipment model number so I am assuming you want to keep us in the dark so I stepping out of this thread. Beside if the carb still has EPA plugs you would need the 2.5mm extraction tool (3 mm if the plugs are damaged).

And members please stop cocking attitudes. Even I get annoyed at those that asking for help but not willing to provide info needed and those that post unnecessary comments so I usually just bow out without posting nasty comments.

Besides this time of the year for me is the start of the busy season. Right now I got a full work in my shop; already getting backlogged so I will be spending a lot less time on the forum.

#22

StarTech

And if the compression is at 100 psi or less then PNC is shot. And engine will not start. Must use compression gauge for small engines to test this. You can't go by feel.

PNC = Piston aNd Cylinder

StarTech

Agree.Boys, lets act like men....

Have you taken the muffler off and inspected the cylinder to be sure there is no scoring of the piston or cylinder wall?

And if the compression is at 100 psi or less then PNC is shot. And engine will not start. Must use compression gauge for small engines to test this. You can't go by feel.

PNC = Piston aNd Cylinder

#23

G

GearHead36

G

GearHead36

Check compression with a tester. Check spark with a tester. Double check your fuel lines to make sure they're not reversed. If it's flooding, try this:

Quickly Unflood A Weedeater Using NO Tools

Quickly Unflood A Weedeater Using NO Tools

#24

woodstover

woodstover

Just love Steve, he knows his stuff!Check compression with a tester. Check spark with a tester. Double check your fuel lines to make sure they're not reversed. If it's flooding, try this:

Quickly Unflood A Weedeater Using NO Tools

#25

J

juntjoo

J

juntjoo

Quick update: started on first pull this morning. Got lucky on this one. So it must have just been water(fuel/oil) logged as this vid suggested

Works like it did recently not perfect but with a liI playing with the adjustment screw can get the job done by will make sure my fuel/oil mix is 50:1 for sure from now on.

@StarTech I did say it was an echo 225. And I still don't understand how tuning it would get it to start after I'd already tried starting it with the adjustment screw in all positions. Could you tell me basically what the tune up procedures are for these if it's any more that playing with that screw?

I'm only in here to learn but my brain doesn't take instruction well, just explanation mostly. And my focus is on basic operation cuz if I don't get what's going on you'll see me again too soon.

Turns out it was just flooded. But I would like to know the tune procedure if there is more to it than just adjusting the screw. Is there something else to adjust?

Works like it did recently not perfect but with a liI playing with the adjustment screw can get the job done by will make sure my fuel/oil mix is 50:1 for sure from now on.

@StarTech I did say it was an echo 225. And I still don't understand how tuning it would get it to start after I'd already tried starting it with the adjustment screw in all positions. Could you tell me basically what the tune up procedures are for these if it's any more that playing with that screw?

I'm only in here to learn but my brain doesn't take instruction well, just explanation mostly. And my focus is on basic operation cuz if I don't get what's going on you'll see me again too soon.

Turns out it was just flooded. But I would like to know the tune procedure if there is more to it than just adjusting the screw. Is there something else to adjust?

#27

J

juntjoo

I got this:

Harbot RB-K93 SRM225 Carburetor for Echo SRM225i SRM225U SRM225SB GT225 GT225i GT225L GT225SF PAS225 PE225 PPF225 SHC225 Trimmer

Is the hi and lo mix the same screw I'm using or have I only found one? If two, you happen to know where is the other? I don't recall seeing anything but my eyes are pretty bad

J

juntjoo

Thanks a lot.So you did in post #11 which is in the middle of the second page.

View attachment 68101

* is 2.5 mm wide flat screwdriver.

I got this:

Harbot RB-K93 SRM225 Carburetor for Echo SRM225i SRM225U SRM225SB GT225 GT225i GT225L GT225SF PAS225 PE225 PPF225 SHC225 Trimmer

Is the hi and lo mix the same screw I'm using or have I only found one? If two, you happen to know where is the other? I don't recall seeing anything but my eyes are pretty bad

#28

J

juntjoo

J

juntjoo

And a echo manual I downloaded doesn't show anything but idle screwSo you did in post #11 which is in the middle of the second page.

View attachment 68101

* is 2.5 mm wide flat screwdriver.

#30

J

juntjoo

J

juntjoo

Thanks a lot! I'll have a deeper look next trim...View attachment 68102

And don't remove the rotary barrel unless you are very careful as there is a tiny roller that is easily lost. Item #2.

#31

J

juntjoo

J

juntjoo

Do you ha e anything for my craftsman? It just says "weed whacker" on itView attachment 68102

And don't remove the rotary barrel unless you are very careful as there is a tiny roller that is easily lost. Item #2.

Attachments

#33

J

juntjoo

J

juntjoo

Do you ha e anything for my craftsman?

Good Luck, don’t ask for model numbers.

Attachments

#37

Etbrown44

Etbrown44

First thing you need to do is clean and regap the plug or try a new one to verify that you have spark that you can see with your eyes. If need be, buy a spark tester.

That oil laden look is what you'll get if you have no spark and you keep pulling the rope.

It's a good idea to reset your mixture adjustment screws to the factory settings. Guys here can tell you what they are.

Worst case, if you have spark, and it still wont run on starting fluid, then buy a $15 carb.

That oil laden look is what you'll get if you have no spark and you keep pulling the rope.

It's a good idea to reset your mixture adjustment screws to the factory settings. Guys here can tell you what they are.

Worst case, if you have spark, and it still wont run on starting fluid, then buy a $15 carb.

#38

MyGrassHasCrabs

MyGrassHasCrabs

ECHO ECHO Pro-Consumer Gas String Trimmers - The Home Depot

Shop our Outdoors Department to customize your ECHO Pro-Consumer Gas String Trimmers today at The Home Depot

www.homedepot.com

#39

J

juntjoo

J

juntjoo

Thanks.I think it was just flooded with fuel/oil as the next day it started upFirst thing you need to do is clean and regap the plug or try a new one to verify that you have spark that you can see with your eyes. If need be, buy a spark tester.

That oil laden look is what you'll get if you have no spark and you keep pulling the rope.

It's a good idea to reset your mixture adjustment screws to the factory settings. Guys here can tell you what they are.

Worst case, if you have spark, and it still wont run on starting fluid, then buy a $15 carb.

#40

oldlawnguy

oldlawnguy

This is great. Can you please post something similar for Walbro carbs? I has all the relevant info including T settings and RPMs. I have both Zama and Walbro carbs and a general chart like this would be great rather than seating H L and then backing out 1/4 turn at a time! I've looked and have not found Walbro or Zama publish along with there docs a generic by carb type of the above. I realize each application may differ settings slightly, however a better staring point would be better on my arm.So you did in post #11 which is in the middle of the second page.

View attachment 68101

* is 2.5 mm wide flat screwdriver.

#41

woodstover

woodstover

If you go back to message #9 you will see that Rivets has posted links to Walbro carb info, can't remember if there was Zama stuff there also.This is great. Can you please post something similar for Walbro carbs? I has all the relevant info including T settings and RPMs. I have both Zama and Walbro carbs and a general chart like this would be great rather than seating H L and then backing out 1/4 turn at a time! I've looked and have not found Walbro or Zama publish along with there docs a generic by carb type of the above. I realize each application may differ settings slightly, however a better staring point would be better on my arm.

#42

oldlawnguy

1. Seat H L and turn out T

2. Turn out L in 1/4 turn until she starts and idles at suggested RPM range turning in T

3. Turn out H to get to 4 stroking and RPM WOT range then turn in slightly (not too rich, rich better than lean)

4. Fine tune with H L and T (you touch one you probably have to tweak the others, rinse and repeat)

As a DYIer the challenge is not having a chart with H L T settings AND idle WOT RPMs. A pro can do in their sleep given they have tuned 1000s of 2 cycle carbs and I've been trial and error on like only 10 2-cycle carbs. The range on H L settings across Walbro and Zama carbs is wide when you take in account pre-EPA and EPA carbs.

oldlawnguy

Yes downloaded all the great info on both Walbro and Zama carbs. However the chart info is not there. With no chart (unless you are a pro) a DYIer usually will :If you go back to message #9 you will see that Rivets has posted links to Walbro carb info, can't remember if there was Zama stuff there also.

1. Seat H L and turn out T

2. Turn out L in 1/4 turn until she starts and idles at suggested RPM range turning in T

3. Turn out H to get to 4 stroking and RPM WOT range then turn in slightly (not too rich, rich better than lean)

4. Fine tune with H L and T (you touch one you probably have to tweak the others, rinse and repeat)

As a DYIer the challenge is not having a chart with H L T settings AND idle WOT RPMs. A pro can do in their sleep given they have tuned 1000s of 2 cycle carbs and I've been trial and error on like only 10 2-cycle carbs. The range on H L settings across Walbro and Zama carbs is wide when you take in account pre-EPA and EPA carbs.

#44

M

mmoffitt

M

mmoffitt

Sir ,Thank you for all those great links PLENTY of good reading there! Be well and Happy Easter!

se greatJootjun, you need every piece of help you can get, so as a retired instructor, I’m going to provide you with all the info I’d give to my students so they will understand the theory on how a carburetor works. After you read and hopefully understand this material, you will then be in a position to start putting this theory into practice. Until that time you can make assumptions and point out what I do in may spare time, but make sure you can back up your statements. If you can’t back up your statements, you are just the new kid in my class trying to prove what you don’t know. Happy reading. Star, I desperately need that part number.

Small Engine, Lawn Mower, Snowthrower Troubleshooting, Repairs and Safety

outdoorpowerinfo.com

Tecumseh Carburetor Guide

Get troubleshooting manual for tecumseh carburetor and detailed information of tecumseh parts.tecumsehcarburetorguide.wordpress.com

#45

Etbrown44

Etbrown44

Two weeks in a row, it seems that some posters asking a question are being abused and berated. It's totally uncalled for even if the poster has said or done something unwise. Can't we give help and advice without criticizing?

First thing I'd try is to clean that plug or try a new one. In a dimly lit room you should see a blue spark with the spark wire attached and the plug removed while pulling the rope.

First thing I'd try is to clean that plug or try a new one. In a dimly lit room you should see a blue spark with the spark wire attached and the plug removed while pulling the rope.

#46

R

Rivets

R

Rivets

This guy won’t learn and he won’t even try to read and learn. If that’s what he does he’ll get grief from me. Plus others will learn what not to do.

#47

StarTech

StarTech

Tuning specs are different base on the model and serial number of each Echo machine and I can't post the whole document as it is a dealer only restricted document. I only got it thru a backdoor access from a fellow Echo dealer that just retired so I am even losing that access to new documents; unless, I find a new source. My last Echo NA carb tuning guide is date Jan 2019 so I need to see Ray has anything newer in his library.This is great. Can you please post something similar for Walbro carbs? I has all the relevant info including T settings and RPMs. I have both Zama and Walbro carbs and a general chart like this would be great rather than seating H L and then backing out 1/4 turn at a time! I've looked and have not found Walbro or Zama publish along with there docs a generic by carb type of the above. I realize each application may differ settings slightly, however a better staring point would be better on my arm.

#48

oldlawnguy

oldlawnguy

Much better to READ what "not to do" than have actually having done it! If you are a DIYer and know it all, then you should expect grief from the pros on this site if you cannot do the 3 L's - learn, listen and list (serial # and model #)This guy won’t learn and he won’t even try to read and learn. If that’s what he does he’ll get grief from me. Plus others will learn what not to do.

#49

oldlawnguy

oldlawnguy

Thanks Star! Understood that dealer restricted info is hard to access for DIYers. Figured I'd ask anyway for a ballpark range by carb type Walbro and Zama.Tuning specs are different base on the model and serial number of each Echo machine and I can't post the whole document as it is a dealer only restricted document. I only got it thru a backdoor access from a fellow Echo dealer that just retired so I am even losing that access to new documents; unless, I find a new source. My last Echo NA carb tuning guide is date Jan 2019 so I need to see Ray has anything newer in his library.

#50

G

Gescha

I don't need a model number to tell you it would easiest just to get a kit and rebuild the carb. Just be careful when turning those adjusting screws because that also changes the amount of lubrication your engine gets. We don't want to harm it.

If you were across the street I'd do it for you. And even though it calls for a 50:1 mix. Go to 40:1 it will last a lot longer getting a bit more oil. May smoke a little more.....but I like things to last as long as possible.

Turn both screws all the way in....not too tight. Open both 1and a half turns. Clean off that plug and make sure you have fire. See if it will start.

Tell me where all of this fuel you speak of is leaking from.

Keep in mind you don't need to adjust much. Just don't screw in those adjusting screws much.....you will starve it of oil.

That other responder must have had a bad night.lol. Remember 1and a half turns out from turned in to touching bottom is a starting point.

And I'm assuming you have the carb with 2 adjusting screws.

G

Gescha

Ok.....lets all calm down......I've been doing this type work for 40+ years.The mixture are EPA plugged for a reason. It is to keep untrained people from adjusting them. Echo does provide the Echo techs with a tune up procedure chart.

But as said first your make the muffler spark arrester is clean. Then you the carb for stiffen metering diaphragm and you tune per the tune up chart using a tach.

Can't even provide the stripped down chart from without the model and serial numbers of the unit you have. But I suspect you have a Zama RB rotary carb and that adjust by the primer is not a mixture screw but also a metering jet too.

I don't need a model number to tell you it would easiest just to get a kit and rebuild the carb. Just be careful when turning those adjusting screws because that also changes the amount of lubrication your engine gets. We don't want to harm it.

If you were across the street I'd do it for you. And even though it calls for a 50:1 mix. Go to 40:1 it will last a lot longer getting a bit more oil. May smoke a little more.....but I like things to last as long as possible.

Turn both screws all the way in....not too tight. Open both 1and a half turns. Clean off that plug and make sure you have fire. See if it will start.

Tell me where all of this fuel you speak of is leaking from.

Keep in mind you don't need to adjust much. Just don't screw in those adjusting screws much.....you will starve it of oil.

That other responder must have had a bad night.lol. Remember 1and a half turns out from turned in to touching bottom is a starting point.

And I'm assuming you have the carb with 2 adjusting screws.

#51

G

Gescha

G

Gescha

I've had my own shop for 40+ years.

Don't need a model or serial number to tell him to have the carb rebuilt.

And if he runs a 40:1 mix instead of the 50:1 it will last a lot longer. Our state workers that cut 8 hours per day 5 days a week know this secret.

Most of you are treating this man wrong. Like he is an idiot imposing on you.

I have decided to delete this site full of arrogant "experts".

Don't need a model or serial number to tell him to have the carb rebuilt.

And if he runs a 40:1 mix instead of the 50:1 it will last a lot longer. Our state workers that cut 8 hours per day 5 days a week know this secret.

Most of you are treating this man wrong. Like he is an idiot imposing on you.

I have decided to delete this site full of arrogant "experts".

#52

StarTech

StarTech

Please be aware the OP said replaced the carburetor so tuning is the next he had to do. They do not not out in any condition other than a will start tuning. Once he gave the model and serial I personally look-up the tuning specs and posted them.

We that are Echo dealers are required to tune to meet EPA requirements. And burning a 40:1 when 50:1 is the requirement is also an EPA violation. Just hope you and your state employees can afford the fine if caught. BTW I use a multi mix synthetic oil that is design for equipment running ratios of 16:1 to 50:1 that is mixed at 50:1

We that are Echo dealers are required to tune to meet EPA requirements. And burning a 40:1 when 50:1 is the requirement is also an EPA violation. Just hope you and your state employees can afford the fine if caught. BTW I use a multi mix synthetic oil that is design for equipment running ratios of 16:1 to 50:1 that is mixed at 50:1

#53

7394

7394

Ditto.....I use a multi mix synthetic oil that is design for equipment running ratios of 16:1 to 50:1 that is mixed at 50:1

#54

B

bertsmobile1

B

bertsmobile1

I am yet to come across a engine wit xcessive wear from too thin a mix bit I do get quite a few scored bores from carbon build up on the exhaust port coming loose & getting stuck on the ring

AS most 2 stroke oil now days is both ashless & synthetic I see no reason to alter the mix ratios.

AS most 2 stroke oil now days is both ashless & synthetic I see no reason to alter the mix ratios.

#55

G

g-man57

G

g-man57

Sorry to interrupt the childish ranting... 'too much (fuel)? seems leaking everywhere'. then you probably have a fuel leak in the carburetor. Something is plugged or stuck.

Now, back to your 'cat fight'.

Now, back to your 'cat fight'.

#56

StarTech

StarTech

Now I did have a commercial customer that was wearing the SRM225 every three years but they were using them up to 10hr/day/6days every week. They also wore out a lot trimmer heads.

#58

RYANS'

RYANS'

Great photos. I wonder if there is a man in your towñ with lots of old equipment. He may have a replacement carburettor for you. In my country we try to recycle these machines. I am teaching my son he is eight.

I've got fuel(too much? seems leaking everywhere) and spark.

Was working decent before after struggling with rear adjustment screw under primer, now suddenly it won't start.

Tried with and without choke, with cover off.

Seems to have compression as always.

Tried with adjustment screw turned fully in both directions.

Not sure if that would matter just starting it.

View attachment 68070Any ideas? Could my fuel mixture be roo rich in oil or off somehow? it's maybe a couple months prepared.

View attachment 68071View attachment 68072

#59

7394

7394

Never too young to start learning, I was wiping wrenches off for my Dad younger than that.I am teaching my son he is eight.

#60

J

juntjoo

I think I already mentioned I got this echo back running. Engine was just flooded I think

J

juntjoo

I wish I'd started young. My grandpa was mechanically inclined shop hobbyist but not my father. Fortunately I ended up with some of my grandpa's interests but it's definitely harder to figure this stuff out later in life especially if you're not doing it every dayNever too young to start learning, I was wiping wrenches off for my Dad younger than that.

I think I already mentioned I got this echo back running. Engine was just flooded I think

#61

G

GearHead36

G

GearHead36

Quickly Unflood A Weedeater Using NO ToolsI think I already mentioned I got this echo back running. Engine was just flooded I think