You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Burnish new clutch

- Thread starter Rls8836

- Start date

More options

Export threadmechanic mark

Lawn Pro

- Joined

- Jul 15, 2013

- Threads

- 175

- Messages

- 7,427

StarTech

Lawn Royalty

- Joined

- Feb 19, 2020

- Threads

- 80

- Messages

- 10,320

On tightening the screw [bolt] it depends. On clutch with a double "D" adapter you hold it with a large wrench or in my shop my double "D" holding tool and torque the screw. Note these double "D" are various sizes so need to find the right wrench. Most start at 1-1/2 inches and goes up from there. I had one JD clutch here that took a 46mm.

On other engines you must hold the flywheel. Various ways of doing this, here I use a very large flat blade screw stuck in the ring gear and held up against one the ignition coils posts. Sometimes this requires a helper as my arms are just not long to reach both places at the same time and torque the screw.

AND don't by all means forget to install the anti rotation device on the clutch; otherwise, you will damage your wiring harness. Some these are permanently mounted so can't forget it and other are removable.

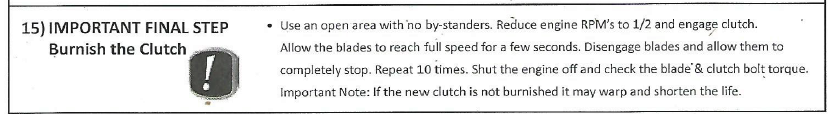

As for burnishing the clutch I use the following procedure from Xtreme. This heat treat the clutch and also removes any anti rust coating used for storage of the clutches before the sale.

On other engines you must hold the flywheel. Various ways of doing this, here I use a very large flat blade screw stuck in the ring gear and held up against one the ignition coils posts. Sometimes this requires a helper as my arms are just not long to reach both places at the same time and torque the screw.

AND don't by all means forget to install the anti rotation device on the clutch; otherwise, you will damage your wiring harness. Some these are permanently mounted so can't forget it and other are removable.

As for burnishing the clutch I use the following procedure from Xtreme. This heat treat the clutch and also removes any anti rust coating used for storage of the clutches before the sale.