Hey Guys,

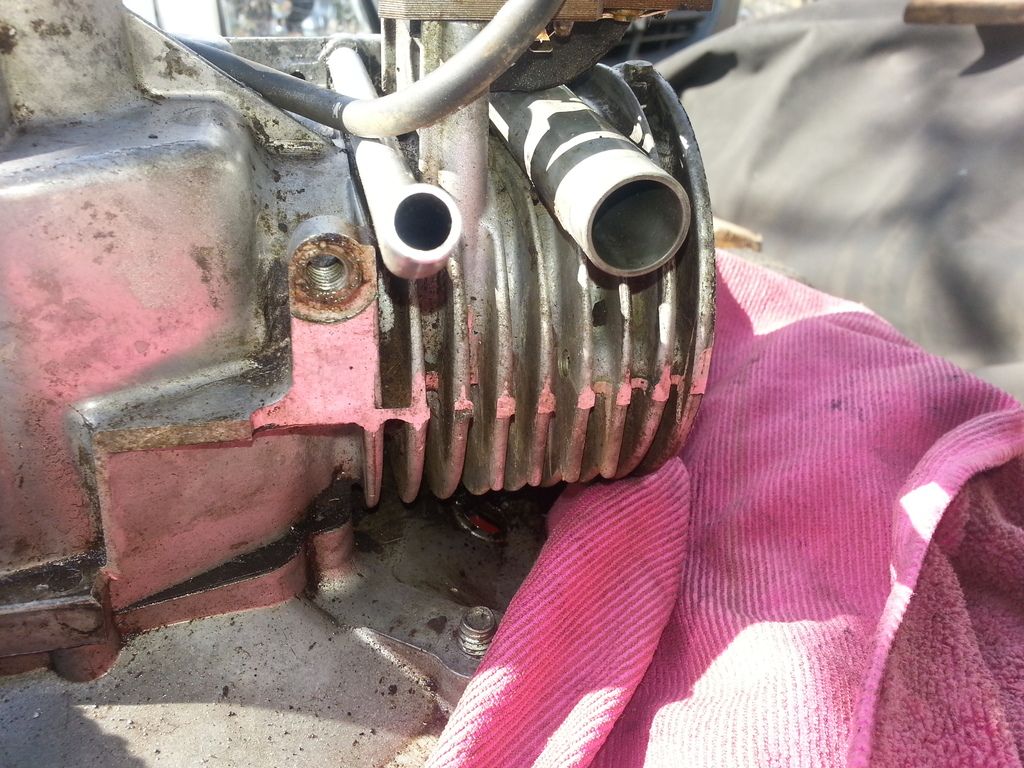

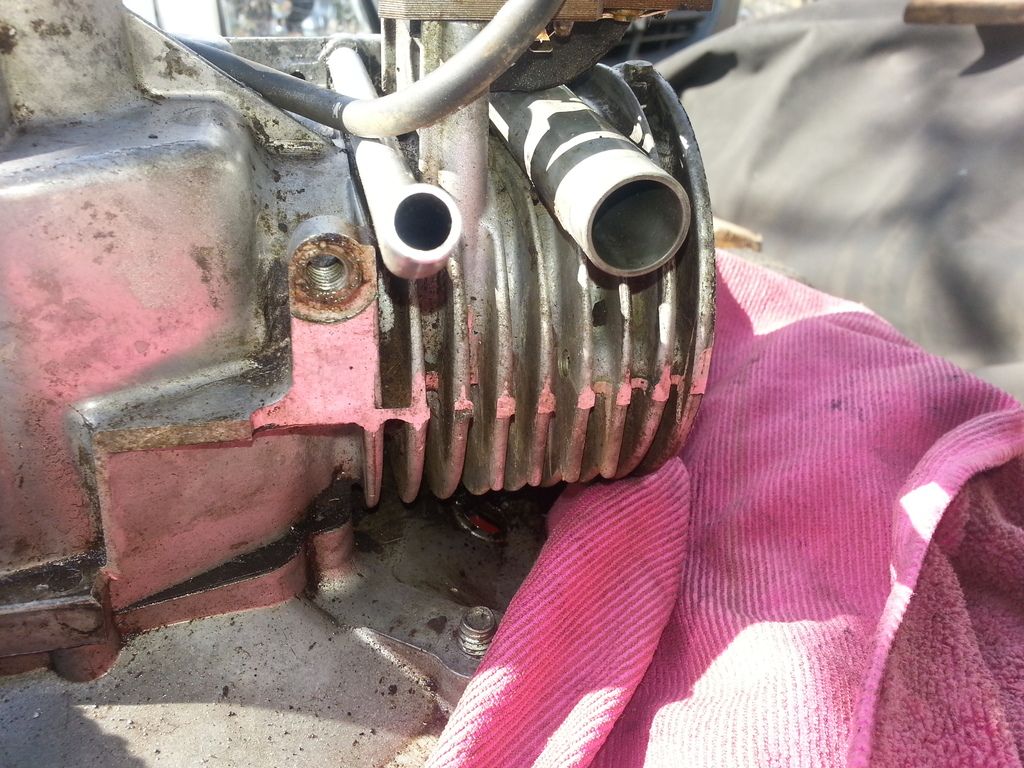

I cleaned the carbon off (mostly), seems like a lot of it was softer. The remaining small portion I used a brass (at least I think it was brass) wire wheel for the dremel, did an alright job, though there were a few small spots I couldnt removed.

I tried moving the valves, and they don't move, no spinning or wobbles.. they seem pretty sturdy.

Regarding the bore, I ran my fingers around it and it all feels nice and smooth (though the pic looks like it has scratches up/down, it doesn't feel rough)

You still have not told me if you checked the valves to make sure the decompression release is working, remember put your finger on the valve stem?

Now the head is off you can watch the actual valves.

Sorry about that. I'm still a little confused by what you mean. Is it the manifold-intake that leads from the Carb > plastic tube > hole in top of engine (leads to intake valve)? If so, I put my finger in slightly touching the valve stem, it doesn't move until it's at the intake stroke, then it moves forward, then back into position. That's the only time I feel it moving. What would it feel/look like when it decompresses ?

Also looks like the mower has been eating rocks, that is a nice ding in the top of the piston.

I had a closer look, though it doesn't look like an ordinary gouge (could be wrong), it sort of looks like it was manufactured into it (looks clean and even)*shrug*

I'm not really going to worry much about it, certainly won't buy replacement parts (especially if it a cam) though I reckon I'll keep going with it and use it as experience, getting a better look at the engine etc..

Regarding the gasket(s), I'll hang onto this one for same, it came off easy and its not split..at least until I see if I can fix the engine or not. But just wondering, do you guys use or know anyone that uses Liquid Silicon gasket (not the quick fix stuff)? I've got another mower that needs gaskets, also a whipper snipper & I thought rather than buying a few gaskets, thought cheap(ish), I thought I might be able use it to seal multiple sections...thoughts ?

is there anything else I should try before cracking it open and looking at its insides ?

Thanks again