You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

B&S 350 Hard to pull start

#1

W

Widget

W

Widget

[EDITED] Sorry, meant B&S 375. not 350.

Hey guys,

I have a B&S 375 mower which is having an issue with starting. Ill pull the cord and it appears really hard or it gets to a point during the pull where it stops/becomes hard to pull (but not impossible)

story:

- Purchased mower

- Got home, looked at mower, started mower, mower ran (poorly), decides to clean mower (carbs particularly)

- Notices rest of mower is filthy, decides to clean more than just carbs

- I remove base/plate from mower (which has blades attached to it)

- Unbolt engine from base and remove (3x bolts)

- I remove Starter/rewind assembly, fuel tank, carb, Armature-Magneto, muffler (already damaged)

- Drain old oil (through oil input hole, I couldn't open drain plug)

- Clean parts thoroughly

- Re-assemble everything

**2x issues**

1. Won't prime. Bulb tries to suck, put wont squirt into intake, I 'think' it could be an issue with the seat-check-valve(?)

- Removed seat-check-valve little rubber seat inlet thing + bearing + spring. Putting my finger over seta check valve hole in carb Im able to fill the bulb, remove finger and can squirt into intake.

2. Pull starter cord, gets to a point then it becomes hard to pull (put pullable)

- Removed/tested starter/rewind assembly, pulls/retracts ok, can't see any issues there

- Turn flywheel by hand, gets to point and tough to turn.

- Removed spark plug, can pull easy.

From what I can tell, it may have something to do with compression?

I jumped online and read something about Hydro-locked, thought this may be it as I did have the engine on the bench and may have tilted it. I tried starting multiple time with spark plug removed, didnt see any excess oil spray out

- put spark plug back in, still tough to pull start

My mind is totally boggled right now.. I have no idea what's happening Any suggestions ?

Any suggestions ?

p.s. I'm probably not the best at explaining things, but if you guys want me to make a video, I can whip out my phone and shoot a few minutes.

Thanks

Hey guys,

I have a B&S 375 mower which is having an issue with starting. Ill pull the cord and it appears really hard or it gets to a point during the pull where it stops/becomes hard to pull (but not impossible)

story:

- Purchased mower

- Got home, looked at mower, started mower, mower ran (poorly), decides to clean mower (carbs particularly)

- Notices rest of mower is filthy, decides to clean more than just carbs

- I remove base/plate from mower (which has blades attached to it)

- Unbolt engine from base and remove (3x bolts)

- I remove Starter/rewind assembly, fuel tank, carb, Armature-Magneto, muffler (already damaged)

- Drain old oil (through oil input hole, I couldn't open drain plug)

- Clean parts thoroughly

- Re-assemble everything

**2x issues**

1. Won't prime. Bulb tries to suck, put wont squirt into intake, I 'think' it could be an issue with the seat-check-valve(?)

- Removed seat-check-valve little rubber seat inlet thing + bearing + spring. Putting my finger over seta check valve hole in carb Im able to fill the bulb, remove finger and can squirt into intake.

2. Pull starter cord, gets to a point then it becomes hard to pull (put pullable)

- Removed/tested starter/rewind assembly, pulls/retracts ok, can't see any issues there

- Turn flywheel by hand, gets to point and tough to turn.

- Removed spark plug, can pull easy.

From what I can tell, it may have something to do with compression?

I jumped online and read something about Hydro-locked, thought this may be it as I did have the engine on the bench and may have tilted it. I tried starting multiple time with spark plug removed, didnt see any excess oil spray out

- put spark plug back in, still tough to pull start

My mind is totally boggled right now.. I have no idea what's happening

p.s. I'm probably not the best at explaining things, but if you guys want me to make a video, I can whip out my phone and shoot a few minutes.

Thanks

#2

Michael72

Michael72

Take a deep breath and have a coffee  ......if i had these issues (pull cord) I would take cover off and make sure brake is disengaging properly, correct distance from flywheel to coil and no keyway damage....when you had plug out was the movement of the piston smooth?....if you had a hydrolock issue you would have oil spitting out of plug and exhaust...just ignore any other problems for the moment...if theres internal damage it wil lbe a waste of time

......if i had these issues (pull cord) I would take cover off and make sure brake is disengaging properly, correct distance from flywheel to coil and no keyway damage....when you had plug out was the movement of the piston smooth?....if you had a hydrolock issue you would have oil spitting out of plug and exhaust...just ignore any other problems for the moment...if theres internal damage it wil lbe a waste of time

Forgot to add...if the vales are sloppy it wouldnt help matters...but check there is no damage to piston or scoring to cylinder.

Forgot to add...if the vales are sloppy it wouldnt help matters...but check there is no damage to piston or scoring to cylinder.

#3

W

Widget

Hey Michael, thanks for the reply

No brake as far as I know. Just put lever to start and pull cord, no handle to squeeze in either.

Distance should be ok. At first I thought maybe Flywheel + Magneto coming in contact, but I separated them both with a business card, tightened the Megneto down then removed card.

What's the "keyway' you speak of? Flywheel key? I googled around and a few people mentioned it being a possibility, might remove flywheel in the morning and have a look.

With the spark plug out and pull starting, it seemed quite smooth, didn't feel much of a resistance, maybe a little, but nothing out of the ordinary I'd think.

With the valve cover off(?) I can see the 2x little valves (with the springs) moving a little back/forth too.

Having the blades/blade base off wouldnt affect starting it in anyway would it ?

Thanks again

W

Widget

Take a deep breath and have a coffee......if i had these issues (pull cord) I would take cover off and make sure brake is disengaging properly, correct distance from flywheel to coil and no keyway damage....when you had plug out was the movement of the piston smooth?....if you had a hydrolock issue you would have oil spitting out of plug and exhaust...just ignore any other problems for the moment...if theres internal damage it wil lbe a waste of time

Hey Michael, thanks for the reply

No brake as far as I know. Just put lever to start and pull cord, no handle to squeeze in either.

Distance should be ok. At first I thought maybe Flywheel + Magneto coming in contact, but I separated them both with a business card, tightened the Megneto down then removed card.

What's the "keyway' you speak of? Flywheel key? I googled around and a few people mentioned it being a possibility, might remove flywheel in the morning and have a look.

With the spark plug out and pull starting, it seemed quite smooth, didn't feel much of a resistance, maybe a little, but nothing out of the ordinary I'd think.

With the valve cover off(?) I can see the 2x little valves (with the springs) moving a little back/forth too.

Having the blades/blade base off wouldnt affect starting it in anyway would it ?

Thanks again

#4

Michael72

Michael72

No it wouldnt effect starting....if you bring the piston to top dead center then turn flywheel an extra 1/4 inch turn clockwise...at this point you will need both valves closed and then check clearance from the valve stems to push rods (just underneath those springs) .. on that model I think clearence should be .005-.007 on intake and exhaust (the smaller valve) .007-.009

#5

Michael72

Michael72

might not be the fix but you might as well have a look since your so far in  ....yes flywheel key I should have said!...I would check also that there is no damage to flywheel itself

....yes flywheel key I should have said!...I would check also that there is no damage to flywheel itself

#6

ILENGINE

The blade acts like a flywheel and while effect turning over of the engine, because you loose the centrifical force. Can cause kickback, loose of cranking momentum.

ILENGINE

Hey Michael, thanks for the reply

No brake as far as I know. Just put lever to start and pull cord, no handle to squeeze in either.

Distance should be ok. At first I thought maybe Flywheel + Magneto coming in contact, but I separated them both with a business card, tightened the Megneto down then removed card.

What's the "keyway' you speak of? Flywheel key? I googled around and a few people mentioned it being a possibility, might remove flywheel in the morning and have a look.

With the spark plug out and pull starting, it seemed quite smooth, didn't feel much of a resistance, maybe a little, but nothing out of the ordinary I'd think.

With the valve cover off(?) I can see the 2x little valves (with the springs) moving a little back/forth too.

Having the blades/blade base off wouldnt affect starting it in anyway would it ?

Thanks again

The blade acts like a flywheel and while effect turning over of the engine, because you loose the centrifical force. Can cause kickback, loose of cranking momentum.

#7

Michael72

Michael72

you learn something new everyday....never had that prob with blade off.. thanks for tip tho

#8

B

bertsmobile1

B

bertsmobile1

On a VIcta, yes.

You cannot start the engine without the blade disc attached.

No blades fine, no disc = no start and this is worse with the 4 blade disc than the 2 blade disc.

Next check the valve lash good chance they have opened up so the automatic decompression is not working.

You can not pull it over full compression.

Bad news on a sprint engine as you adjust the valve lash by either stoning the end of the valve or cutting the seat deeper both of which require you to remove the head.

I charge $ 60 extra for doing the valves + gaskets ( $ 14.00 Aust ) which brings the repair to close to $ 100 so very few bother as they would rather go to Bunnings & buy a piece of Chineese garbage for $ 150.

If you have access to the gear then go ahead & do it, not a hard job just time consuming.

Replace both the head gasket & the valve chest / breather cover gasket .

If the valve lash is ok then put your finger on the inlet valve stem ( carb removed ).

As you turnover the engine you should feel the inlet open, close then just before TDC open just a touch ( decompression ).

IF it does not do this & the valve lash is within specs then you are most likely looking at a new cam, about $ 70 Aust.

Again an uneconomic repair.

AS it is winter down here, consider buying a new cam from the USA ( Jacks Small engines on the sponsors page ) works out about 1/3rd local price if you get it sent USPS. Takes about 4 -6 weeks this time of year.

Before you spend too much time & money check the deck around the left hand handle attachment.

This is the usuall rust out spot and if it is rusted or cracked there then save your money & get a replacement mower.

You cannot start the engine without the blade disc attached.

No blades fine, no disc = no start and this is worse with the 4 blade disc than the 2 blade disc.

Next check the valve lash good chance they have opened up so the automatic decompression is not working.

You can not pull it over full compression.

Bad news on a sprint engine as you adjust the valve lash by either stoning the end of the valve or cutting the seat deeper both of which require you to remove the head.

I charge $ 60 extra for doing the valves + gaskets ( $ 14.00 Aust ) which brings the repair to close to $ 100 so very few bother as they would rather go to Bunnings & buy a piece of Chineese garbage for $ 150.

If you have access to the gear then go ahead & do it, not a hard job just time consuming.

Replace both the head gasket & the valve chest / breather cover gasket .

If the valve lash is ok then put your finger on the inlet valve stem ( carb removed ).

As you turnover the engine you should feel the inlet open, close then just before TDC open just a touch ( decompression ).

IF it does not do this & the valve lash is within specs then you are most likely looking at a new cam, about $ 70 Aust.

Again an uneconomic repair.

AS it is winter down here, consider buying a new cam from the USA ( Jacks Small engines on the sponsors page ) works out about 1/3rd local price if you get it sent USPS. Takes about 4 -6 weeks this time of year.

Before you spend too much time & money check the deck around the left hand handle attachment.

This is the usuall rust out spot and if it is rusted or cracked there then save your money & get a replacement mower.

#9

B

bertsmobile1

B

bertsmobile1

OK, just checked out the photos, forget it that deck is toast unless you are thinking about a welding project as well.

You can put your engine on any Victa Deck if you do repair it but that deck is a waste of time.

You can usually pick up a reasonable non runner on evilbay for under $ 10.00 .

Two stroke or 4 stroke does not matter the decks are the same.

Personnally I don't bother with those under powered B & S engines unless you live down south & have fine grass as the low compression Power torque is 5Hp and the high compression one is 6.5Hp

The Sprint is 3.5.

You can put your engine on any Victa Deck if you do repair it but that deck is a waste of time.

You can usually pick up a reasonable non runner on evilbay for under $ 10.00 .

Two stroke or 4 stroke does not matter the decks are the same.

Personnally I don't bother with those under powered B & S engines unless you live down south & have fine grass as the low compression Power torque is 5Hp and the high compression one is 6.5Hp

The Sprint is 3.5.

#10

W

Widget

W

Widget

Thanks guys,

I'll try take the flywheel off today 1st, see if the key is broken or not.

It's confusing that the issue came up, I didn't really touch anything else, just unbolted a few parts.

if the camshaft was borked, (or other internals) wouldn't you still feel something wrong even with the spark plug out ? (turning flywheel still hard)

Another thing to add, I had the muffler off. As the original muffler was split, I removed it, leaving the opening to the exhaust (where the muffler screw on) exposed. Would that cause any issues? or should the mower still run, even with no muffler attached ?

I originally picked up the mower for $10 (came with a free whipper snipper too). It does have the corner rusted away but the base (and section where rust is) is still sturdy, so not really bothered with a new base. If there is an internal issue, Ill just strip the mower for parts or dump it, though would be nice to figure out what happened with it :/

Thanks again,

I'll try take the flywheel off today 1st, see if the key is broken or not.

It's confusing that the issue came up, I didn't really touch anything else, just unbolted a few parts.

if the camshaft was borked, (or other internals) wouldn't you still feel something wrong even with the spark plug out ? (turning flywheel still hard)

Another thing to add, I had the muffler off. As the original muffler was split, I removed it, leaving the opening to the exhaust (where the muffler screw on) exposed. Would that cause any issues? or should the mower still run, even with no muffler attached ?

I originally picked up the mower for $10 (came with a free whipper snipper too). It does have the corner rusted away but the base (and section where rust is) is still sturdy, so not really bothered with a new base. If there is an internal issue, Ill just strip the mower for parts or dump it, though would be nice to figure out what happened with it :/

Thanks again,

#11

M

mechanic mark

M

mechanic mark

https://www.briggsandstratton.com/us/en/support/manuals/results?NTT=098902-2064* operators manual & parts list, adjust valves per specs. in manual page 9 & replace air filter if needed.

#12

B

bertsmobile1

B

bertsmobile1

Rust in that area will be a problem as that is where the handle bar attaches and gets a lot of forces on it which will cause the other side to crack & fail so the mower will be difficult to use.

Next running for a short time without the muffler will not hurt any thing but prolonged running without muffler will damage the valve.

And no if the cam was cactus you will not feel it as what you are feeling for is not there.

The decompressor is just a slight pimple on the cam.

More mportant is have you done any of the tests/ checks an what was the results ?

Next running for a short time without the muffler will not hurt any thing but prolonged running without muffler will damage the valve.

And no if the cam was cactus you will not feel it as what you are feeling for is not there.

The decompressor is just a slight pimple on the cam.

More mportant is have you done any of the tests/ checks an what was the results ?

#13

W

Widget

W

Widget

Hey guys,

had another look. So far;

Re-attached blade dish, didn't help.

checking valve clearance;

Using my feeler gauge (they only go up in 5's

Intake measured 0.15mm which was a little tight

Exhaust measure - .25mm could slide through with some resistance. .20mm was easier, (.30mm wouldnt get through).

Intake 0.005 0.007 in. (0.13 0.18 mm)

Exhaust 0.007 0.009 in. (0.18 0.23 mm)

I think the exhaust needs a slight adjustment, I'm not sure how to do this. All videos I've come across adjust valves for a different type of engine/mower. I read through the manuals from B&S (linked above), couldn't see anything about adjusting them.

~~ Flywheel key looks ok.

random video clip of be turning flywheel.. dont think its anything special, just shows valves going in and out.

https://youtu.be/M3bim65F4nA

[EDIT/UPDATE]

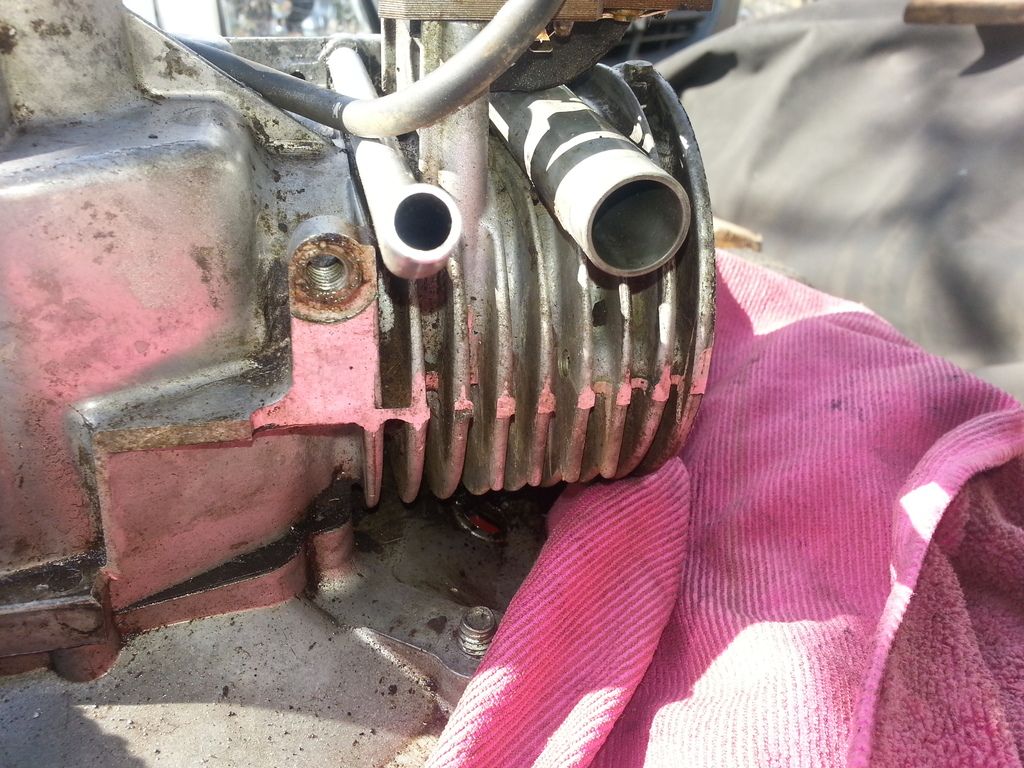

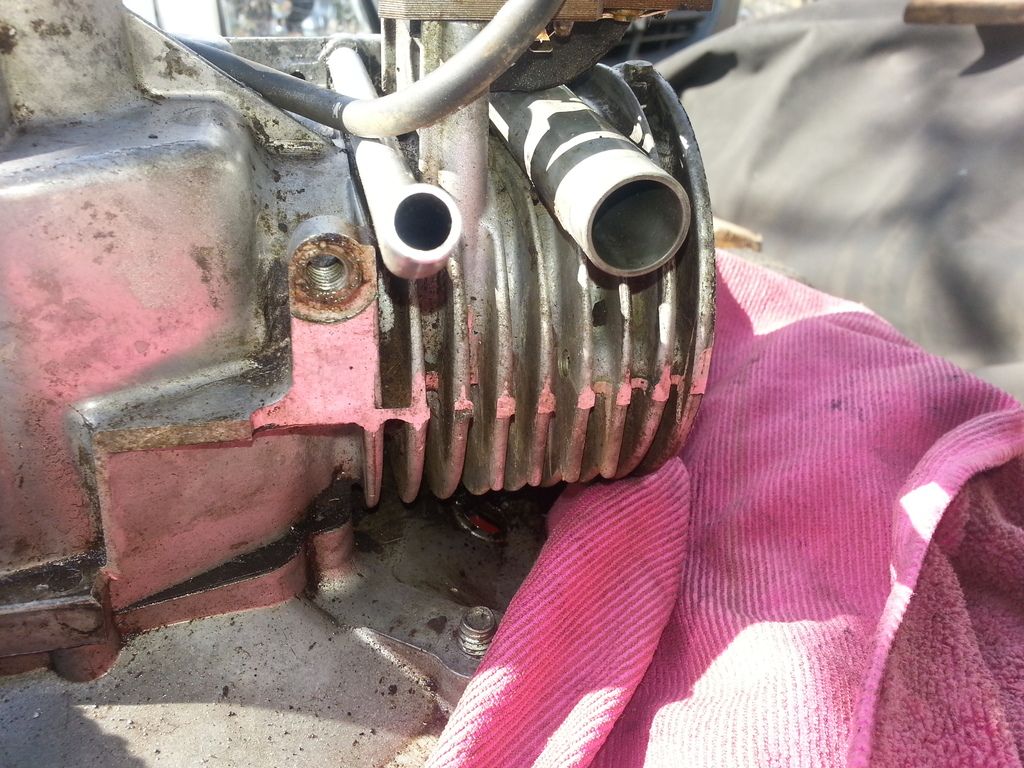

So I decided to just go ahead and take the cylinder head off, exposing the Piston + 2x valves. Came off pretty easily too, gasket still intact. Must say, looks a little dirty...

Cylinder Head

Pistons & Valves

Would it be ok to clean the carbon buildup with a power drill + wire wheel attachment such as,

or should I try and soak the carbon 1st with some cleaner? If so, which cleaner/chemical do you guys prefer??

Video of Piston + Valves moving

https://youtu.be/8AZLxN_0hrc

Thanks again, much appreciated

had another look. So far;

Re-attached blade dish, didn't help.

checking valve clearance;

Using my feeler gauge (they only go up in 5's

Intake measured 0.15mm which was a little tight

Exhaust measure - .25mm could slide through with some resistance. .20mm was easier, (.30mm wouldnt get through).

Intake 0.005 0.007 in. (0.13 0.18 mm)

Exhaust 0.007 0.009 in. (0.18 0.23 mm)

I think the exhaust needs a slight adjustment, I'm not sure how to do this. All videos I've come across adjust valves for a different type of engine/mower. I read through the manuals from B&S (linked above), couldn't see anything about adjusting them.

~~ Flywheel key looks ok.

random video clip of be turning flywheel.. dont think its anything special, just shows valves going in and out.

https://youtu.be/M3bim65F4nA

[EDIT/UPDATE]

So I decided to just go ahead and take the cylinder head off, exposing the Piston + 2x valves. Came off pretty easily too, gasket still intact. Must say, looks a little dirty...

Cylinder Head

Pistons & Valves

Would it be ok to clean the carbon buildup with a power drill + wire wheel attachment such as,

or should I try and soak the carbon 1st with some cleaner? If so, which cleaner/chemical do you guys prefer??

Video of Piston + Valves moving

https://youtu.be/8AZLxN_0hrc

Thanks again, much appreciated

#14

Michael72

Michael72

If gasket is worth saving do so...be gentle....take that brush to the head then....i use grit paper to sort piston out but and i would tilt engine so the the carbon falls outward. you dont want any of that in the cylinder!!..flush out then with a carb cleaner etc... valves look ok lash wise with measurements given but at TDC those valves need to be closed tight ish... ifyou can turn them easily they might need lapping/grinding

#15

B

bertsmobile1

B

bertsmobile1

Going to confuse you now but I never ever use a steel brush to remove a carbon build up.

A brass brush is the go if you are going to use a drill but better will be a shothbrite pad.

Not the ones from Coles, the ones you get from car parts shops.

You still have not told me if you checked the valves to make sure the decompression release is working, remember put your finger on the valve stem?

Now the head is off you can watch the actual valves.

Again you can be spending a lot of time buggerising around for no use if the cam is buggered, the engine will note start regardless of weather the piston & head are clean enough to do open heart surgery on.

And as your valve lashes are within spec ( well close enough not to prevent the engine from running ) I am leaning towards a stuffed cam.

Gaskets are cheap so don't even think of reusing any of them unless you are trying to avoid painting the house by not fixing the mower all winter.

Whole top of engine has way too much carbon on it so either the inlet valve has way too much wear or the rings are well & truly on the way out

Also looks like the mower has been eating rocks, that is a nice ding in the top of the piston.

SO now the lid is open and as you seem good with the camera,how about a shot of the bore, piston at bdc ?

A brass brush is the go if you are going to use a drill but better will be a shothbrite pad.

Not the ones from Coles, the ones you get from car parts shops.

You still have not told me if you checked the valves to make sure the decompression release is working, remember put your finger on the valve stem?

Now the head is off you can watch the actual valves.

Again you can be spending a lot of time buggerising around for no use if the cam is buggered, the engine will note start regardless of weather the piston & head are clean enough to do open heart surgery on.

And as your valve lashes are within spec ( well close enough not to prevent the engine from running ) I am leaning towards a stuffed cam.

Gaskets are cheap so don't even think of reusing any of them unless you are trying to avoid painting the house by not fixing the mower all winter.

Whole top of engine has way too much carbon on it so either the inlet valve has way too much wear or the rings are well & truly on the way out

Also looks like the mower has been eating rocks, that is a nice ding in the top of the piston.

SO now the lid is open and as you seem good with the camera,how about a shot of the bore, piston at bdc ?

#16

W

Widget

W

Widget

Hey Guys,

I cleaned the carbon off (mostly), seems like a lot of it was softer. The remaining small portion I used a brass (at least I think it was brass) wire wheel for the dremel, did an alright job, though there were a few small spots I couldnt removed.

I tried moving the valves, and they don't move, no spinning or wobbles.. they seem pretty sturdy.

Regarding the bore, I ran my fingers around it and it all feels nice and smooth (though the pic looks like it has scratches up/down, it doesn't feel rough)

Sorry about that. I'm still a little confused by what you mean. Is it the manifold-intake that leads from the Carb > plastic tube > hole in top of engine (leads to intake valve)? If so, I put my finger in slightly touching the valve stem, it doesn't move until it's at the intake stroke, then it moves forward, then back into position. That's the only time I feel it moving. What would it feel/look like when it decompresses ?

I had a closer look, though it doesn't look like an ordinary gouge (could be wrong), it sort of looks like it was manufactured into it (looks clean and even)*shrug*

I'm not really going to worry much about it, certainly won't buy replacement parts (especially if it a cam) though I reckon I'll keep going with it and use it as experience, getting a better look at the engine etc..

Regarding the gasket(s), I'll hang onto this one for same, it came off easy and its not split..at least until I see if I can fix the engine or not. But just wondering, do you guys use or know anyone that uses Liquid Silicon gasket (not the quick fix stuff)? I've got another mower that needs gaskets, also a whipper snipper & I thought rather than buying a few gaskets, thought cheap(ish), I thought I might be able use it to seal multiple sections...thoughts ?

is there anything else I should try before cracking it open and looking at its insides ?

Thanks again

I cleaned the carbon off (mostly), seems like a lot of it was softer. The remaining small portion I used a brass (at least I think it was brass) wire wheel for the dremel, did an alright job, though there were a few small spots I couldnt removed.

I tried moving the valves, and they don't move, no spinning or wobbles.. they seem pretty sturdy.

Regarding the bore, I ran my fingers around it and it all feels nice and smooth (though the pic looks like it has scratches up/down, it doesn't feel rough)

You still have not told me if you checked the valves to make sure the decompression release is working, remember put your finger on the valve stem?

Now the head is off you can watch the actual valves.

Sorry about that. I'm still a little confused by what you mean. Is it the manifold-intake that leads from the Carb > plastic tube > hole in top of engine (leads to intake valve)? If so, I put my finger in slightly touching the valve stem, it doesn't move until it's at the intake stroke, then it moves forward, then back into position. That's the only time I feel it moving. What would it feel/look like when it decompresses ?

Also looks like the mower has been eating rocks, that is a nice ding in the top of the piston.

I had a closer look, though it doesn't look like an ordinary gouge (could be wrong), it sort of looks like it was manufactured into it (looks clean and even)*shrug*

I'm not really going to worry much about it, certainly won't buy replacement parts (especially if it a cam) though I reckon I'll keep going with it and use it as experience, getting a better look at the engine etc..

Regarding the gasket(s), I'll hang onto this one for same, it came off easy and its not split..at least until I see if I can fix the engine or not. But just wondering, do you guys use or know anyone that uses Liquid Silicon gasket (not the quick fix stuff)? I've got another mower that needs gaskets, also a whipper snipper & I thought rather than buying a few gaskets, thought cheap(ish), I thought I might be able use it to seal multiple sections...thoughts ?

is there anything else I should try before cracking it open and looking at its insides ?

Thanks again

#17

B

bertsmobile1

B

bertsmobile1

Well now that the head is off you can simply look at the valves going in & out as you rotate the engine.

The inlet should open fully as the piston descends, then close near the bottom of the stroke then just before the piston is back up the top ( compression ) it should open just a tiny bit.

It is a lot easier to feel than to see.

If your inlet valve does not do the little opening then the cam needs to be replaced and most likely the cam followers as well.

These little engines take a beating particularly when mowing hilly yards and the oil level gets a bit low.

This will be the reason why the engine was hard to pull.

The scoring on the barrel gets checked with your fingernail not your skin.

Run your fingernail across it and if you can feel it catch on the scores then the gas will get past and it needs a hone at least.

If you are going to remove the piston & hone the bore then you need to fit new rings and you will need a full gasket kit as the end float on the crank ( the amount it moves up & down ) is controlled by using different thickness of gaskets or multiple gaskets.

You will also need to measure the bore and check for both tapper and ovality.

By the time you have finished you will just about finished the TAFE small engine certificate.

The inlet should open fully as the piston descends, then close near the bottom of the stroke then just before the piston is back up the top ( compression ) it should open just a tiny bit.

It is a lot easier to feel than to see.

If your inlet valve does not do the little opening then the cam needs to be replaced and most likely the cam followers as well.

These little engines take a beating particularly when mowing hilly yards and the oil level gets a bit low.

This will be the reason why the engine was hard to pull.

The scoring on the barrel gets checked with your fingernail not your skin.

Run your fingernail across it and if you can feel it catch on the scores then the gas will get past and it needs a hone at least.

If you are going to remove the piston & hone the bore then you need to fit new rings and you will need a full gasket kit as the end float on the crank ( the amount it moves up & down ) is controlled by using different thickness of gaskets or multiple gaskets.

You will also need to measure the bore and check for both tapper and ovality.

By the time you have finished you will just about finished the TAFE small engine certificate.

#19

B

bertsmobile1

B

bertsmobile1

Hey its winter, although a nice 25 deg C at my place, so plenty of time.

The dreaded Victa blade plate boss is simply pushed onto the shaft so it pulls off the shaft.

And that is the understatement of the century.

It is keyed so you can not turn it so it is lots of penetrant ( not WD40, real penetrant.

I use 50:50 acetone / ATF.

Lots of heat , lots of penetrant, lots of heat.

Victa make a very expensive tool for removing the blade plate boss.

I use a 2 leg puller bearing against a long bolt threaded all the way to the end of the hole.

This is important as otherwise you will strip the thread inside the crankshaft.

Some put a short length of rod down there other use a big ball bearing.

Just be carefull because if you put something soft down there as it can expand and become impossible to remove latter on

A rattle gun on the puller works a lot better.

If it does not come off with your first hit, heat it up to spit boiling point then turn it over and stand the end in a container of penetrant ( this will smoke badly )

Leave it there till it is stone cold. Flip it back over, put your puller back on and heat.

Repeat as necessary. Some have taken better then a week to get off which is why Victa get away with charging $ 200 for the puller.

They only seem to come in two varieties.

Compliant and just about fall off.

Fight you to the death.

The dreaded Victa blade plate boss is simply pushed onto the shaft so it pulls off the shaft.

And that is the understatement of the century.

It is keyed so you can not turn it so it is lots of penetrant ( not WD40, real penetrant.

I use 50:50 acetone / ATF.

Lots of heat , lots of penetrant, lots of heat.

Victa make a very expensive tool for removing the blade plate boss.

I use a 2 leg puller bearing against a long bolt threaded all the way to the end of the hole.

This is important as otherwise you will strip the thread inside the crankshaft.

Some put a short length of rod down there other use a big ball bearing.

Just be carefull because if you put something soft down there as it can expand and become impossible to remove latter on

A rattle gun on the puller works a lot better.

If it does not come off with your first hit, heat it up to spit boiling point then turn it over and stand the end in a container of penetrant ( this will smoke badly )

Leave it there till it is stone cold. Flip it back over, put your puller back on and heat.

Repeat as necessary. Some have taken better then a week to get off which is why Victa get away with charging $ 200 for the puller.

They only seem to come in two varieties.

Compliant and just about fall off.

Fight you to the death.