You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Good fix for wheels?

- Thread starter H20loo

- Start date

More options

Export threadtom3

Lawn Addict

- Joined

- Apr 9, 2018

- Threads

- 25

- Messages

- 1,579

Have taken a strip of aluminum flashing material and made a bushing for the inside of the all plastic wheel. Roll it around the bolt to get it to size. Might need to ream out the bore a little bit, need lube every so often. A strip of brass might do it better if you have it.

Hello,

A better fix might be to use a sintered bronze bushing if the plastic wheel has enough meat to do so. I think better hardware store sell these bushings in various sizes.

Drill out the wheel and press in the bronze bushing.

Regards

Jeff

A better fix might be to use a sintered bronze bushing if the plastic wheel has enough meat to do so. I think better hardware store sell these bushings in various sizes.

Drill out the wheel and press in the bronze bushing.

Regards

Jeff

2smoked

Well-Known Member

- Joined

- Aug 1, 2014

- Threads

- 13

- Messages

- 238

Hello,

A better fix might be to use a sintered bronze bushing if the plastic wheel has enough meat to do so. I think better hardware store sell these bushings in various sizes.

Drill out the wheel and press in the bronze bushing.

Regards

Jeff

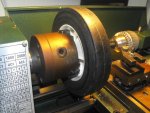

Here are some photos of this method I submitted in a post from 8/17. The wheel hole was drilled out with a 5/8 inch bit.

Attachments

7394

Lawn Addict

- Joined

- Sep 5, 2014

- Threads

- 84

- Messages

- 4,718

I bored out the wheels on my old 22" MTD, & pressed in some sleeves I had laying around.

The sleeves are made outta bronze. Still working good, I do pop off the wheels at service time & grease the axle bolts. It ain't rocket science..

The sleeves are made outta bronze. Still working good, I do pop off the wheels at service time & grease the axle bolts. It ain't rocket science..

Lawn-Boy Rocky

Member

- Joined

- May 22, 2019

- Threads

- 7

- Messages

- 40

7394

Lawn Addict

- Joined

- Sep 5, 2014

- Threads

- 84

- Messages

- 4,718

Folks,

My brother did a nice job of drilling out my four wheels to 5/8" (as mentioned above) and pressing in bronze bushings from True-Value. Nice and "true".

Rocky

Rocky- Better than store bought new wheels for sure.. :thumbsup:

Mow'N Weeds

Active Member

- Joined

- Jul 4, 2018

- Threads

- 8

- Messages

- 57

I'm assuming the felt-type spacers for these wheels are nothing available anymore?

Would a copper sleeve suffice vs bronze? I ask because I have various small pcs laying about that could be used as such.

I have one 19-in with these style wheels and they are in fact, wobbly and it bugs me. I had planned on looking into a cause and fix for the issue.

Would a copper sleeve suffice vs bronze? I ask because I have various small pcs laying about that could be used as such.

I have one 19-in with these style wheels and they are in fact, wobbly and it bugs me. I had planned on looking into a cause and fix for the issue.