Scraperman

Forum Newbie

- Joined

- Oct 26, 2019

- Threads

- 3

- Messages

- 8

Newbie here from the U.K. so hope someone may be able to help. I've been using a Scag Turf Runner with a vee-twin petrol (gasoline) Kohler for 20 years. Engine details attached.

Yesterday I started it and was just about to put the deck into gear and she suddenly stopped. She wouldn't start so back in the workshop. Took both plugs out and put one back in the HT lead and earthed it and cranked the engine. Unfortunately I was looking closely for a spark and I was literally showered in petrol. Long story short, I checked the dipstick and petrol was very nearly up to the top, way past the full mark. Today I pulled the sump plug and got over a gallon of mainly petrol mixed with the engine oil out of the engine. Somehow petrol has been getting into the sump - lots of it !

It appears that this engine has a pulse style fuel pump (not come across these before) Apparently it sucks fuel out of the fuel tank on the downward stroke of a piston and then pushes it into the carburettor on an upward stroke of a piston. Presumably there are some valves in the pump which aren't working as they should and herefore allowing a lot of petrol into the sump.

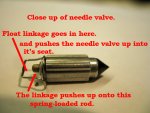

Or is it possibly nothing to do with the pump and instead it's a damaged needle valve or a stuck or damaged float in the carburettor ?

It's all I can come up with - does anyone else have any other ideas please ? TIA for any help.

Yesterday I started it and was just about to put the deck into gear and she suddenly stopped. She wouldn't start so back in the workshop. Took both plugs out and put one back in the HT lead and earthed it and cranked the engine. Unfortunately I was looking closely for a spark and I was literally showered in petrol. Long story short, I checked the dipstick and petrol was very nearly up to the top, way past the full mark. Today I pulled the sump plug and got over a gallon of mainly petrol mixed with the engine oil out of the engine. Somehow petrol has been getting into the sump - lots of it !

It appears that this engine has a pulse style fuel pump (not come across these before) Apparently it sucks fuel out of the fuel tank on the downward stroke of a piston and then pushes it into the carburettor on an upward stroke of a piston. Presumably there are some valves in the pump which aren't working as they should and herefore allowing a lot of petrol into the sump.

Or is it possibly nothing to do with the pump and instead it's a damaged needle valve or a stuck or damaged float in the carburettor ?

It's all I can come up with - does anyone else have any other ideas please ? TIA for any help.