So the first two machines to sell this year are ones that were previously running, but have been sitting in the garage for like 2 years now.

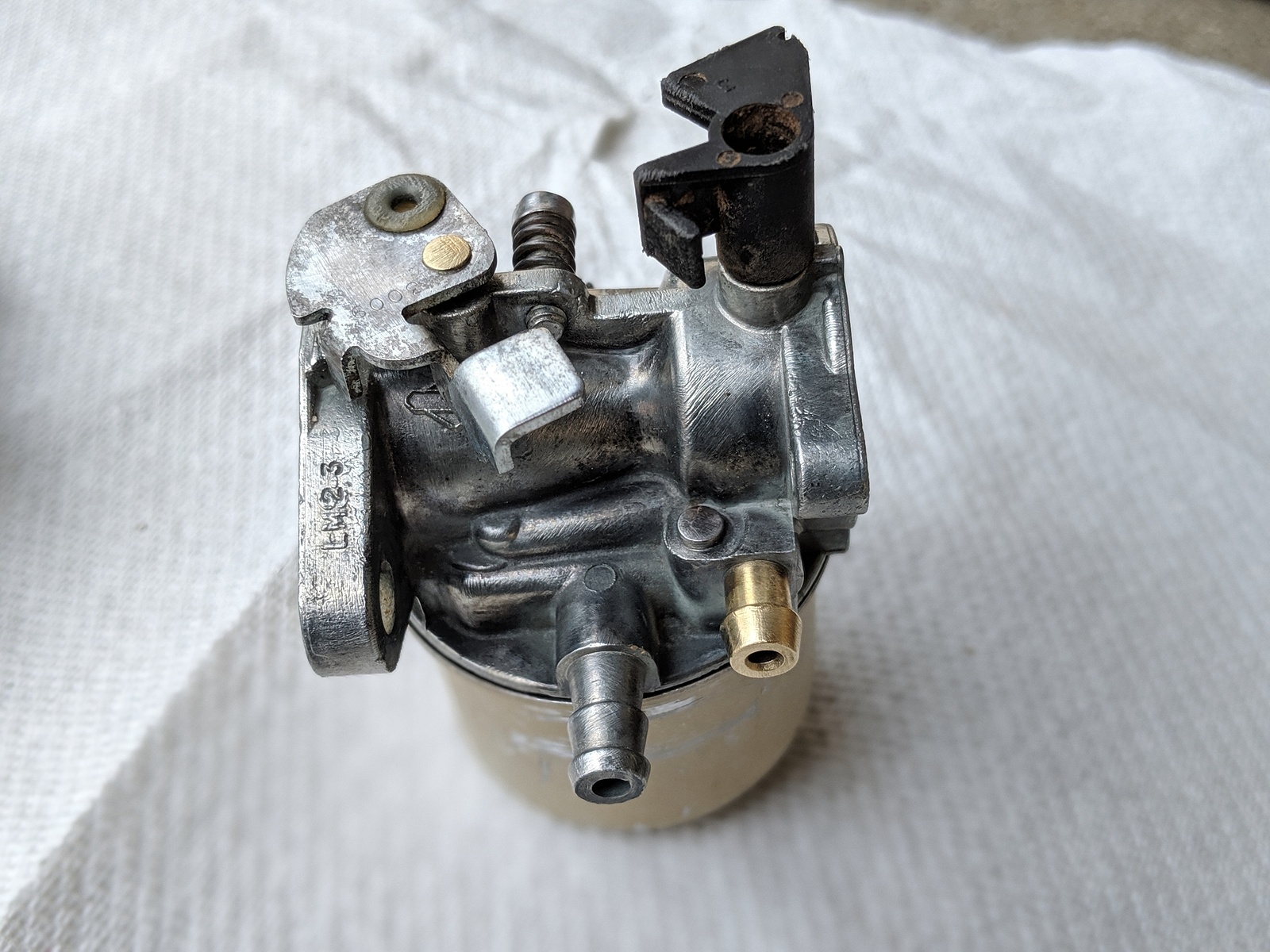

This little Craftsman did run, however, no matter how many times I tried to adjust the carburetor, it would slowly flood and leak gas.

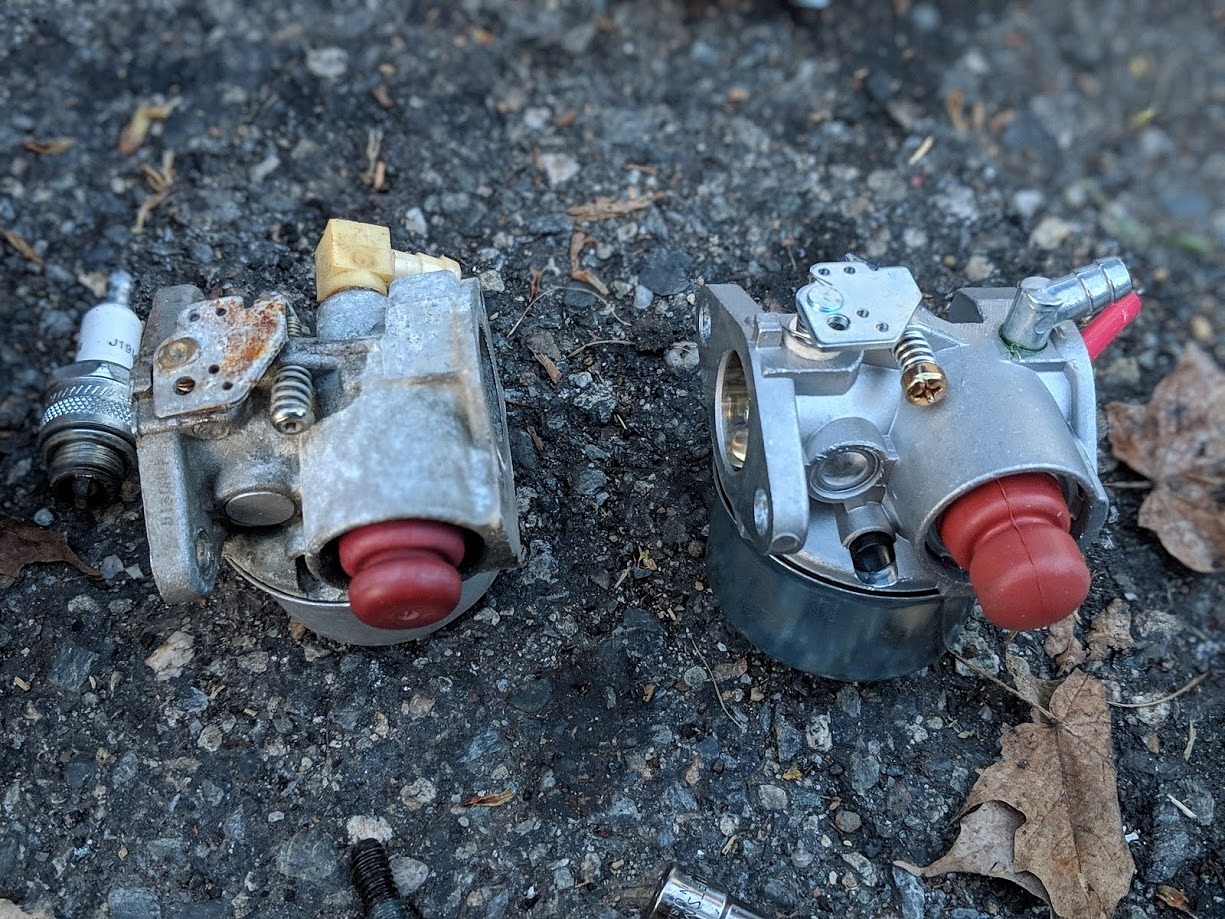

This year I decided I wasn't going to mess with old carburetors and try out brand new ones. Sure, they're Chinese, but they cost only a few dollars more than gasket it for a whole new carburetor! I've bought 2 Tecumseh's and a Briggs carburetor so far and they all work flawlessly.

The Craftsman finally sold today.

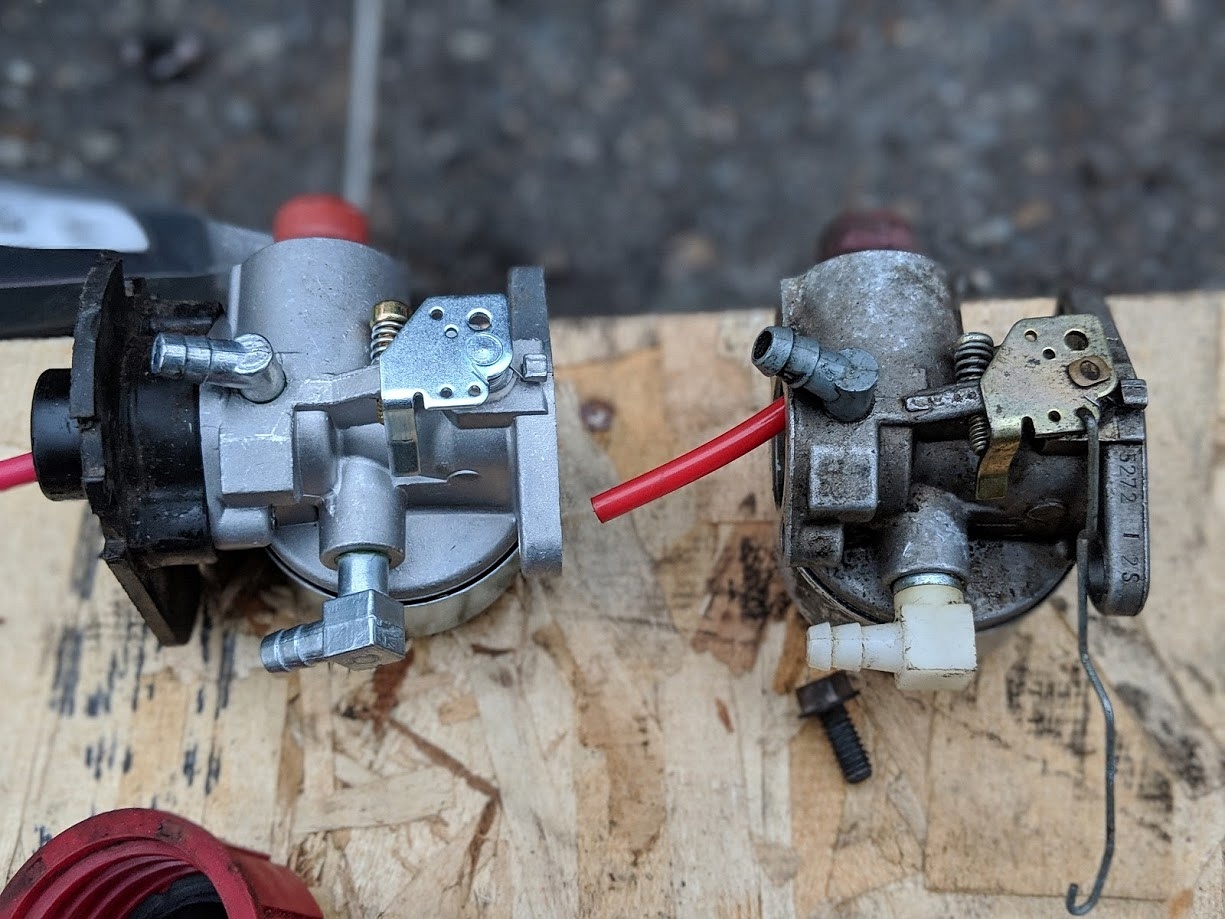

The other one that was completed was this Poulan Pro. Actually works really well. Nice strong engine. I do like the Briggs Quantums.

I was actually a bit hesitant to sell it. I've been using it since I tore apart my Ariens to replace friction disk ring and also repaint the deck, but the lousy weather has kept me from doing the painting. Oh well. I have others!

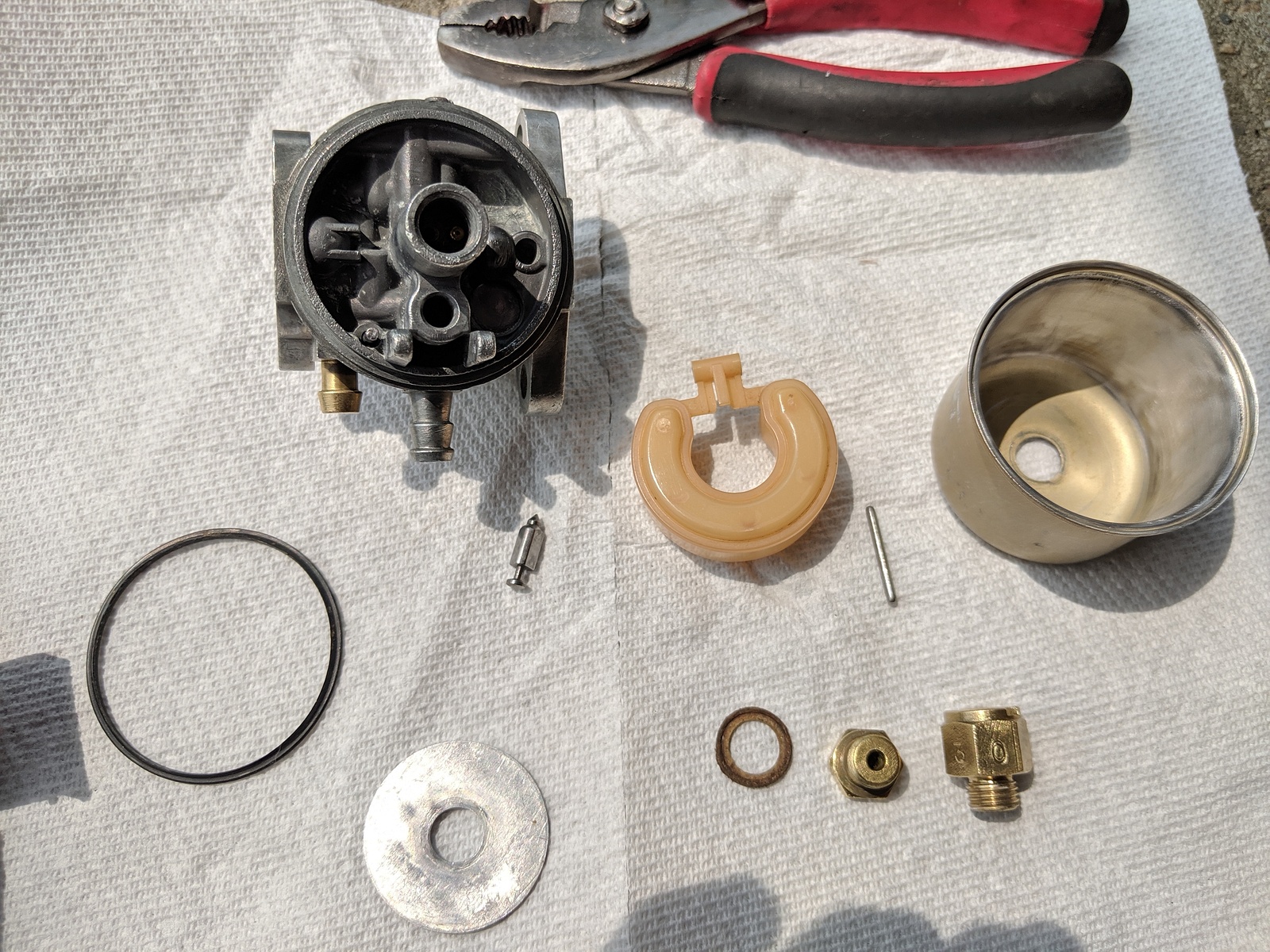

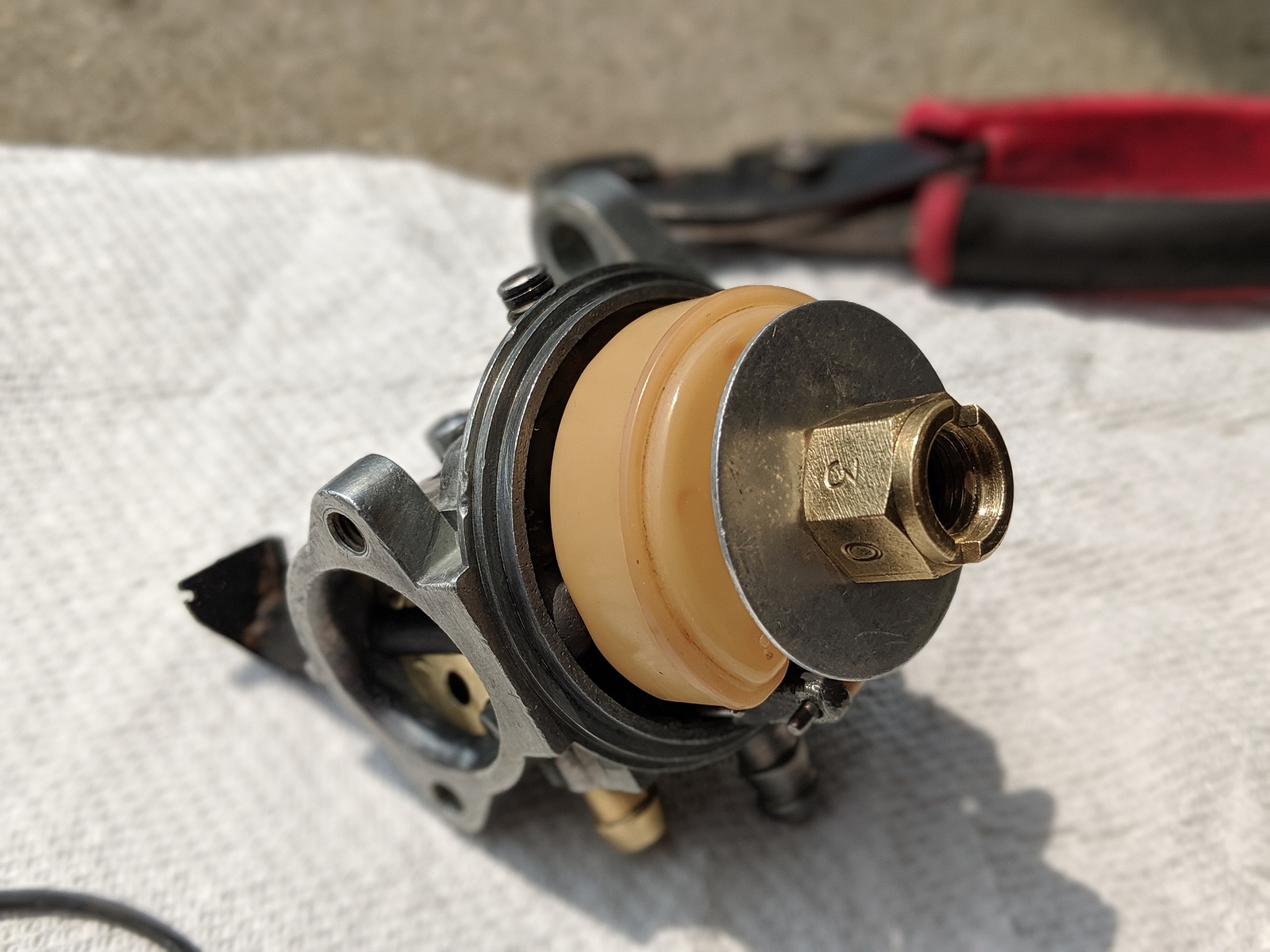

My current headache is this Craftsman.

I had it running before, and while it started, ran, and cut grass, it tended to surge at sometimes.

So this year I put the new carburetor on it to try that. Still seemed to surge some. I was/am getting pretty fed up with it. So I cleaned and it up was planning to sell it with the note that while it ran an d cut grass, it did RPM hunt.

But, I decided to try checking for vacuum leaks before giving up. First I replaced the intake manifold. No change. The next day I decided I was going to check for leaks while it was running...except it wouldn't start. I looked it over and found the replacement manifold was cracked. So I replaced it with another. I also noticed the carburetor mounting bracket was bent and the carburetor wasn't seating quite right. So I replaced that and the o-ring which seemed as bit loose.

Nothing.

Tried replacing the plug (it was wet from priming and probably some shots of starting fluid) after letting the cylinder air out.

Nothing.

It has spark. It ran before. It has compression ( I don't know how much, but it feels the same as before). Flywheel key is straight. It will not start. I'm getting fed up with it. Have to try again when it's not raining...whenever that may be.

The last one to mention for now is this old Toro.

It was given to me way back in 2012. The Tecumseh engine was missing a bunch of parts that I didn't have. Two of the wheels didn't turn. The handlebar was missing hardware. I took the motor off and set it aside (still have it for now), and the deck has sat in my gaarge since. Almost threw it out a few times, but 18" gas mower is a pretty rare breed, so I've held onto it. I contemplated getting rid of it again this year, but realized I had a beat up 21" Recycler that could donate hardware to make this one (almost) whole again, including the sideways fuel tank with the cutout to clear the chute. I also had a spare Quantum that I cleaned up and has been sitting for a while.

The donor was in rough shape. Deck was badly damaged and had a piece of sheet metal over the hole. Surprisingly, it's engine's crankshaft isn't bent, so it may yet live again. And while teh deck is shot, it had a lot of other useful parts I removed both for this little Toro and my other two 21" Recyclers.

It donated handlebar hardware, comparatively huge wheels, and the correct axle bolts to the 18" Toro.

The little deck actually cleans up quite well.

I actually had to use the spare engine and not the one on the bigger Toro because the bigger Toro's crankshaft is considerably longer. Happily, the spare Quantum has a short crankshaft, and using a short MTD blade adapter I had, it's the perfect length.

So here it is put together.

It's precious! So small but with a big heart. I need to get a blade and correct cables to accommodate the Briggs engine, but it's on it's way towards being a runner for the first time in probably years. I also like the big wheels on it.