You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Tire came off with the axle

#1

S

semimechanicman

S

semimechanicman

Rim was really seized up with the axle so i had to hammer it some. Then it came out with everything and how does it go back in

#2

S

semimechanicman

postimg.cc

postimg.cc

i hope that link works, it shows what came off

S

semimechanicman

Rim was really seized up with the axle so i had to hammer it some. Then it came out with everything and how does it go back in

IMG 3971 — Postimages

i hope that link works, it shows what came off

#3

StarTech

StarTech

It going require pulling the transaxle, disassembling it, finding the broken clip, replacing it, and putting everything back together. A real fun job.

BTW it appears to be a Hydro Gear transaxle.

BTW it appears to be a Hydro Gear transaxle.

#4

S

semimechanicman

S

semimechanicman

damnit, just wanted to change the tire now i don’t think doing all that is worth it nowIt going require pulling the transaxle, disassembling it, finding the broken clip, replacing it, and putting everything back together. A real fun job.

#7

F

Forest#2

F

Forest#2

Experience is what you get when what you got is not what you wanted.

You wil not forget that one anytime soon.

You will feel more like taking it apart after you price a replacement or a replacement mower.

That one sure makes me feel better.

Thanks for the picture.

You wil not forget that one anytime soon.

You will feel more like taking it apart after you price a replacement or a replacement mower.

That one sure makes me feel better.

Thanks for the picture.

#8

F

Freddie21

F

Freddie21

I just went thru the identical same thing. There is a small spring clip that comes off inside the trans. I bought the clip and the axel seal fore under $10, a gallon of 20w50 sys oil and a tube of oil resistant RTV. Under$35 total. Trans came rite out, just shoot pics of the linkage bar connections. No need to remove the fan, belt goes rite over the top. When you open the trans, you'll see gears. One that went one the axel and the two it turns. I found my clip rite under the axel gear.

Now the hardest part, getting the wheel off the axel before you reassemble it. Lots of penitrating oil and time. If you're going to beat on the axel, make sure you don't mushroom either end. I have a hole drilled thru my work bench that I put the axel thru, and using a piece of rerod slightly smaller than the axel, I carefully beat it out. To reassemble, I installed and lube the new seal, slid the lubricated axel thru it, slid on the wnew gear and fought to get the spring clip on. I used needle nose plyers to spread it open and slide it on. Clean the trans case sides very well, apply the RTV and bolt it to torque specs. I refilled the oil while off as getting to the fill plug while in the mower is pretty hard. Install the trans back in, reconnect all linkages and belt and purge the trans.

Mine is running fantastic. Luckily, the other wheel came off easily. I got this mower cheap cuz the guy could not install the inner tube. Well worth the time and experience.

Now the hardest part, getting the wheel off the axel before you reassemble it. Lots of penitrating oil and time. If you're going to beat on the axel, make sure you don't mushroom either end. I have a hole drilled thru my work bench that I put the axel thru, and using a piece of rerod slightly smaller than the axel, I carefully beat it out. To reassemble, I installed and lube the new seal, slid the lubricated axel thru it, slid on the wnew gear and fought to get the spring clip on. I used needle nose plyers to spread it open and slide it on. Clean the trans case sides very well, apply the RTV and bolt it to torque specs. I refilled the oil while off as getting to the fill plug while in the mower is pretty hard. Install the trans back in, reconnect all linkages and belt and purge the trans.

Mine is running fantastic. Luckily, the other wheel came off easily. I got this mower cheap cuz the guy could not install the inner tube. Well worth the time and experience.

#9

S

semimechanicman

S

semimechanicman

yupExperience is what you get when what you got is not what you wanted.

You wil not forget that one anytime soon.

You will feel more like taking it apart after you price a replacement or a replacement mower.

That one sure makes me feel better.

Thanks for the picture.

cirrently got it apart, i have a zero turn and i bought this one for 50 bucks so just having fun with itExperience is what you get when what you got is not what you wanted.

You wil not forget that one anytime soon.

You will feel more like taking it apart after you price a replacement or a replacement mower.

That one sure makes me feel better.

Thanks for the picture.

#10

S

semimechanicman

S

semimechanicman

where do you find the clips? i am only finding the whole transmission for sale and not the clipI just went thru the identical same thing. There is a small spring clip that comes off inside the trans. I bought the clip and the axel seal fore under $10, a gallon of 20w50 sys oil and a tube of oil resistant RTV. Under$35 total. Trans came rite out, just shoot pics of the linkage bar connections. No need to remove the fan, belt goes rite over the top. When you open the trans, you'll see gears. One that went one the axel and the two it turns. I found my clip rite under the axel gear.

Now the hardest part, getting the wheel off the axel before you reassemble it. Lots of penitrating oil and time. If you're going to beat on the axel, make sure you don't mushroom either end. I have a hole drilled thru my work bench that I put the axel thru, and using a piece of rerod slightly smaller than the axel, I carefully beat it out. To reassemble, I installed and lube the new seal, slid the lubricated axel thru it, slid on the wnew gear and fought to get the spring clip on. I used needle nose plyers to spread it open and slide it on. Clean the trans case sides very well, apply the RTV and bolt it to torque specs. I refilled the oil while off as getting to the fill plug while in the mower is pretty hard. Install the trans back in, reconnect all linkages and belt and purge the trans.

Mine is running fantastic. Luckily, the other wheel came off easily. I got this mower cheap cuz the guy could not install the inner tube. Well worth the time and experience.

#11

F

Freddie21

F

Freddie21

Did you find the clip? Here are the parts I used:

Hydro-Gear 53901 Lip Seal Genuine Original Equipment Manufacturer (OEM) Part | eBay

Hydro-Gear 53901 Lip Seal Genuine Original Equipment Manufacturer (OEM) Part

www.ebay.com

NEW GENUINE OEM HYDRO GEAR PART # 44871 SPIRAL RETAINING RING .625E | eBay

PART # 44871. IF YOU ARE UNSURE THIS PART FITS YOUR MODEL. Briggs & Stratton Diamond Dealer. Kohler Expert Dealer and a.

www.ebay.com

#12

S

semimechanicman

my model is t2 abbc 5x1a 1xx1

S

semimechanicman

would it fit the transmission i have? i can ask the people selling to make sure but just in caseDid you find the clip? Here are the parts I used:

Hydro-Gear 53901 Lip Seal Genuine Original Equipment Manufacturer (OEM) Part | eBay

Hydro-Gear 53901 Lip Seal Genuine Original Equipment Manufacturer (OEM) Partwww.ebay.com

NEW GENUINE OEM HYDRO GEAR PART # 44871 SPIRAL RETAINING RING .625E | eBay

PART # 44871. IF YOU ARE UNSURE THIS PART FITS YOUR MODEL. Briggs & Stratton Diamond Dealer. Kohler Expert Dealer and a.www.ebay.com

my model is t2 abbc 5x1a 1xx1

#13

F

Freddie21

F

Freddie21

These parts seem to be for many Hydro-Gear models. Someone on this forum was nice enough to give me the part numbers. My trans is a T2-AABC-1X1A-1GXX. I found that in the parts diagram of my Craftsman model.

#14

StarTech

StarTech

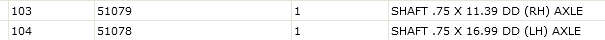

Yes the HG 44871 is for the T2-ABBC-5X1A 1XX1 transaxle per the dealer portal.

Also the axle seal 53901 is also the correct part number.

Also the axle seal 53901 is also the correct part number.

#15

B

bertsmobile1

B

bertsmobile1

I use an air hammer / air chisel to remove rusted on wheels .

So on the other side soak the axel with your favourite penetrant .

If the key is close to the E-clip tap it in 1/4 to 1/2" this will break the rust seal around the key & slot

Move slot to the top & apply more penetrant

Place a pair of scissor jacks between the wheel & the frame then do them up WITH YOUR FINGERS to take up the slack

Then hit the axel with the air hammer till the jacks come loose

Tighten them again and repeat

Some times I wire brush the axel behind the wheel as it moves, then the hole in the wheel lube & tap back on to get the penetrant in .

Patience is what is needed

Heat will help

You can heat the wheel to red heat if you like but that means repainting the wheel and risks damage to the tyre

When you refit the wheel polish off the rust on both the wheel & the hole ( rifle brushes work well for the wheel )

Apply plenty of grease and fill the key slot with grease ( copper anti seize is better )

Replace the wheel then tap the key in flush with the end of the rim

This fills the key slot with grease & prevents water getting in thus a repeat performance.

The axels should be greased every 2 to 6 years depending upon your climate

I do them every second service

Check the slot the clip in the gearbox sits in

Some times the edges break off or crack and of course that little chunk of alloy will wait for the least oppertune moment to get jambed between the teeth .

For the side that is out

polish the inside of the axel

place the axel on some hardwood

put a socket or pipe on the rim tube and hammer the rim further onto the axel

Helps if you can tap the key out with a long pin punch first

As the axel comes out of the front of the wheel, polish it then tap back in using a drift so you do not damage the end of the axel

Once it is a bout 1/4 to 1/3 the way out usually it will tap in then right through with sufficent lubricant

So on the other side soak the axel with your favourite penetrant .

If the key is close to the E-clip tap it in 1/4 to 1/2" this will break the rust seal around the key & slot

Move slot to the top & apply more penetrant

Place a pair of scissor jacks between the wheel & the frame then do them up WITH YOUR FINGERS to take up the slack

Then hit the axel with the air hammer till the jacks come loose

Tighten them again and repeat

Some times I wire brush the axel behind the wheel as it moves, then the hole in the wheel lube & tap back on to get the penetrant in .

Patience is what is needed

Heat will help

You can heat the wheel to red heat if you like but that means repainting the wheel and risks damage to the tyre

When you refit the wheel polish off the rust on both the wheel & the hole ( rifle brushes work well for the wheel )

Apply plenty of grease and fill the key slot with grease ( copper anti seize is better )

Replace the wheel then tap the key in flush with the end of the rim

This fills the key slot with grease & prevents water getting in thus a repeat performance.

The axels should be greased every 2 to 6 years depending upon your climate

I do them every second service

Check the slot the clip in the gearbox sits in

Some times the edges break off or crack and of course that little chunk of alloy will wait for the least oppertune moment to get jambed between the teeth .

For the side that is out

polish the inside of the axel

place the axel on some hardwood

put a socket or pipe on the rim tube and hammer the rim further onto the axel

Helps if you can tap the key out with a long pin punch first

As the axel comes out of the front of the wheel, polish it then tap back in using a drift so you do not damage the end of the axel

Once it is a bout 1/4 to 1/3 the way out usually it will tap in then right through with sufficent lubricant

#16

StarTech

StarTech

You can't tap an axle when there is not one. This transaxle uses the double D axles.

From Hydro Gear Dealer IPL lookup

If rim will move a little I have found soaking with 2 cycle fuel mix works better than the penetration fluids like WD-40. Still take time and applications along constant attempts at loosening as this work out the rust and dirt. Completely froze out rims are different story. A royal pita to get off.

Also can't just use a punch on the end of the axle because it has a threaded hole for the retaining screw. Now a punch that fit inside the hole and bottoms out can work. Either way the rim must be block to where it is held out and it can't move so the axle takes the impacts and not the whole assembly. Even then axle will only move slightly will require re-shimming the rim after each movement. Now does assumes that axle is still in the transaxle. If out then it is different.

From Hydro Gear Dealer IPL lookup

If rim will move a little I have found soaking with 2 cycle fuel mix works better than the penetration fluids like WD-40. Still take time and applications along constant attempts at loosening as this work out the rust and dirt. Completely froze out rims are different story. A royal pita to get off.

Also can't just use a punch on the end of the axle because it has a threaded hole for the retaining screw. Now a punch that fit inside the hole and bottoms out can work. Either way the rim must be block to where it is held out and it can't move so the axle takes the impacts and not the whole assembly. Even then axle will only move slightly will require re-shimming the rim after each movement. Now does assumes that axle is still in the transaxle. If out then it is different.

#17

B

bertsmobile1

support the rim then hit the end with the air hammer

I use an off set jaw vice for this but the hole in a bench would work just fine

B

bertsmobile1

In which case, ignore my last paragraph for your mower .You can't tap an axle when there is not one. This transaxle uses the double D axles.

From Hydro Gear Dealer IPL lookup

View attachment 66960

If rim will move a little I have found soaking with 2 cycle fuel mix works better than the penetration fluids like WD-40. Still take time and applications along constant attempts at loosening as this work out the rust and dirt. Completely froze out rims are different story. A royal pita to get off.

Also can't just use a punch on the end of the axle because it has a threaded hole for the retaining screw. Now a punch that fit inside the hole and bottoms out can work. Either way the rim must be block to where it is held out and it can't move so the axle takes the impacts and not the whole assembly. Even then axle will only move slightly will require re-shimming the rim after each movement. Now does assumes that axle is still in the transaxle. If out then it is different.

support the rim then hit the end with the air hammer

I use an off set jaw vice for this but the hole in a bench would work just fine

#18

S

semimechanicman

S

semimechanicman

i got everything else done but i just need the gasket for the transaxle now, can’t seem to find it yetThese parts seem to be for many Hydro-Gear models. Someone on this forum was nice enough to give me the part numbers. My trans is a T2-AABC-1X1A-1GXX. I found that in the parts diagram of my Craftsman model.

#20

F

Freddie21

F

Freddie21

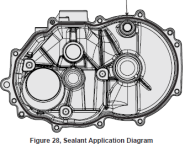

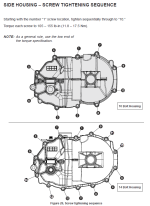

There is no gasket. Clean all the old RTV off and use a oil resistant RTV to seal it. Only put a 1\6-1\8" bead around the casting and around the bolt holes. Mate the parts while still wet. Torque to 1\2 spec in proper sequence, then to spec. I have attached the torque and sequence pages from the svc manual. I let it sit overnight to allow the RTV to cure then filled with 20w50 full synthetic oil to 1\2" below the fill hole. There is a fill plug on the top of the trans, use an Allen to remove. Then reinstall and purge. Procedure attached.

Attachments

#22

StarTech

StarTech

That okay. I am in the middle of full virus scan that has already taken 5 hours and it still scanning hopefully thru before 8 pm.

#23

H

hlw49

H

hlw49

Anyone ever try Superzilla had a wheel to get off, was all rusted on. Sprayed with Supperzilla let it set for a little while and it cam off pretty easy. This stuff works. Had a pulley to get off a hydro and could get to the top through the frame. Took a pry bar and hammer and tried to drive it off no luck. Sprayed with Superzillz put a longer bolt and washer in the hydro shaft so pulley would not fall off and get bent when it hit the floor, it came off easy.