You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Mower Blades

#1

D

djg618

D

djg618

My zero turn is a 60" Howard Price 360Z. Manufactured in St. Louis years ago but has closed since. There may be someone there (60 mi away) that sells parts but they've been hard to get a hold of in the past.

I need new mower blades (3).

20-1/2" x 2-1/2" wide x 3/16" thick. Only hole is in the center and is 1" dia. The numbers on it are 20 750 and 23726.

A logo I can't read and made in USA stamped on it also.

The part number in the manual is 09-256-A.

Any help?

I need new mower blades (3).

20-1/2" x 2-1/2" wide x 3/16" thick. Only hole is in the center and is 1" dia. The numbers on it are 20 750 and 23726.

A logo I can't read and made in USA stamped on it also.

The part number in the manual is 09-256-A.

Any help?

#3

M

MParr

M

MParr

The only one that I found was the Snapper blade that @StarTech linked to.

Another option is to use a step drill bit to enlarge an existing hole in a commercial mower blade. A vice and drill press would work nicely.

Another option is to use a step drill bit to enlarge an existing hole in a commercial mower blade. A vice and drill press would work nicely.

#5

B

bertsmobile1

B

bertsmobile1

The place I usually go is the Stens " chart - blades " which you will find in the resources section on their web page, along with a lot of other very useful stuff.

So you need to download the pdf file then look at the blades that are 20.5" long or slightly longer because you can cut a long blade a little shorter.

The 1" hole will be a problem so as MParr mentioned you might need to go for a 15/16" and either get your spindles machined down or enlarge the holes .

A word to the wise on the latter as mower blades work harden so you will need a 1" carbide drill and that hole needs to be very accurate size & position wise

If it was my mower I would go with machining down the spindles to one of the sizes on the chart as it can be easily machined very accurately where as enlarging the hole accurately is quite difficult .

The other option is to have a spacer 1" ø to 1.125" ø made to space out you spindle to fit the 1.125"ø blades

If you go with the spacer it must be hardened and shrunk fitted on

Alternatively you can get the shaft hard faced & ground back to 1.125"ø

This should keep you scratching your head for a while

Check each blade option in the catalogue and then check the prices before you decide which way to go .

Oregon might have a blade that will fit but I have never been able to find a downloadable blade size chart so you would have to ring or email .

Stens have a "find a dealer" on their web page but most mower shops will have a stens account

So you need to download the pdf file then look at the blades that are 20.5" long or slightly longer because you can cut a long blade a little shorter.

The 1" hole will be a problem so as MParr mentioned you might need to go for a 15/16" and either get your spindles machined down or enlarge the holes .

A word to the wise on the latter as mower blades work harden so you will need a 1" carbide drill and that hole needs to be very accurate size & position wise

If it was my mower I would go with machining down the spindles to one of the sizes on the chart as it can be easily machined very accurately where as enlarging the hole accurately is quite difficult .

The other option is to have a spacer 1" ø to 1.125" ø made to space out you spindle to fit the 1.125"ø blades

If you go with the spacer it must be hardened and shrunk fitted on

Alternatively you can get the shaft hard faced & ground back to 1.125"ø

This should keep you scratching your head for a while

Check each blade option in the catalogue and then check the prices before you decide which way to go .

Oregon might have a blade that will fit but I have never been able to find a downloadable blade size chart so you would have to ring or email .

Stens have a "find a dealer" on their web page but most mower shops will have a stens account

#6

D

djg618

D

djg618

Just to be clear, since it's not in the photo, my spindles are threaded and a nut screws onto them.

#7

B

bertsmobile1

B

bertsmobile1

Well that knocks out altering the spindles so you are left with enlarging the blades or getting an enlarging bush made upJust to be clear, since it's not in the photo, my spindles are threaded and a nut screws onto them.

#10

D

djg618

I remeasured all three blades in case I was measuring a damaged one and all three are 20-1/2" long. Actually 1/16" shy (wear?). They are 2-1/2" wide and 1/4" thick. The hole AND the spindle measure 0.982" with a micrometer.

I'm considering buying a 0.204" thick blade in that length with a 15/16" (0.938") hole. I could open up the hole on each blade by running a conical stone in a drill from each side of the blade until it fits the arbor.

Is blade thickness that imortant? Should I stick with 1/4"?

D

djg618

No I didn't. Maybe that's where the 20-3/4" comes from.Did you measure the blade length diagonally?

I remeasured all three blades in case I was measuring a damaged one and all three are 20-1/2" long. Actually 1/16" shy (wear?). They are 2-1/2" wide and 1/4" thick. The hole AND the spindle measure 0.982" with a micrometer.

I'm considering buying a 0.204" thick blade in that length with a 15/16" (0.938") hole. I could open up the hole on each blade by running a conical stone in a drill from each side of the blade until it fits the arbor.

Is blade thickness that imortant? Should I stick with 1/4"?

#12

D

djg618

D

djg618

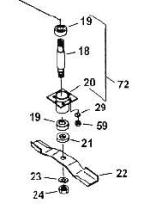

Good point. I didn't catch that. Is the notches in my blade important? Just as long as I get ones with the tips bent up (high lift)? I've measured all three and the center hole is 0.982" Is that considered 15/16" (0.934") or 1"?Your image showed straight but IPL image of the spindle is showing dropped blade and that is also important to not as it changes the cutting height.

View attachment 65476

#14

M

MParr

M

MParr

How to measure lawn mower blades

usamowerblades.com

usamowerblades.com

How to Measure a Lawn Mower Blade - USA Mower Blades

#15

sgkent

sgkent

see my post above for the link and number you might call to get blades or an answer. We were posting at the same time.

#16

StarTech

StarTech

Also if these are drop blades then the Land Pride 890-375C blades would possibly work but they are 0.320 thick.

Also the XHTZ B1LP1002 is a possible but are 20-7/8" so they might need trimming. They are 0.203 thick.

Also the XHTZ B1LP1002 is a possible but are 20-7/8" so they might need trimming. They are 0.203 thick.

#17

D

djg618

D

djg618

That's the original manufacturer that went out of business. I did buy parts from them about 5 years ago, but I don't know if they are still selling them. I'll try again tomorrow. I did call the Atlas Lawn care number but could not get through.see my post above for the link and number you might call to get blades or an answer. We were posting at the same time.

#18

B

bertsmobile1

Blade thickness is not important for fit

Thicker blades have a lot more momentum so will not die as quick in long tough grasses and of course will take more punishment before it bends .

Thicker blades also require more sharpening to do a good cut and reduce load on the engine . I explain this in terms of line trimmer thickness as almost every one has run line that was too thick through their trimmer at lease once .

Blade width is important as a blades that are too wide will hit each other .

Because blade length is measured diagonally a 20 x 3" blade is actually shorter than a 20 x 2.5" blade so the narrower blades may strike the sides of the deck just the same as blades that are too long will

The notch where the flute starts is there to prevent cracking & allow the flutes to be bent easily it has no functional difference in use

Unless the blade is centred in a 4 jaw chuck and you use a pedestal grinder you will not be able to open out the holes by hand.

The tinest bit off centre left right or front back will have the blade out of balance

The height between the cutting edge & the underside of the deck is CRITICAL ( yes I am shouting in the hope you will listen ) .

Too close and the deck will get overwhelmed with clippings so will clog which can quite easily cause the belt to break

Too far away and the clippings will not discharge properly and the deck will also clog all the time when cutting long grass

In both cases you will end up with blobs of cuttings all over the lawn ( we call them grass turds ) .

Pressed decks are less fussy about this but with fabricated decks with a flat steel plate on the top it is critical

If you find that you can not get original blades then buy a set of all that look like they fit.

Blades are not all that expensive particulaly when compared to buying a replacement mower .

A lot of my customers use different blades at different times in the season and in any case having a spare set ( or 2 ) of sharp blades encourages people to change them when they start to go dull

You get a much better cut & can cut a lot faster with sharp blades

B

bertsmobile1

If you bothered to check that chart then you would have seen 15/16" is a std blade hole sizeNo I didn't. Maybe that's where the 20-3/4" comes from.

I remeasured all three blades in case I was measuring a damaged one and all three are 20-1/2" long. Actually 1/16" shy (wear?). They are 2-1/2" wide and 1/4" thick. The hole AND the spindle measure 0.982" with a micrometer.

I'm considering buying a 0.204" thick blade in that length with a 15/16" (0.938") hole. I could open up the hole on each blade by running a conical stone in a drill from each side of the blade until it fits the arbor.

Is blade thickness that imortant? Should I stick with 1/4"?

Blade thickness is not important for fit

Thicker blades have a lot more momentum so will not die as quick in long tough grasses and of course will take more punishment before it bends .

Thicker blades also require more sharpening to do a good cut and reduce load on the engine . I explain this in terms of line trimmer thickness as almost every one has run line that was too thick through their trimmer at lease once .

Blade width is important as a blades that are too wide will hit each other .

Because blade length is measured diagonally a 20 x 3" blade is actually shorter than a 20 x 2.5" blade so the narrower blades may strike the sides of the deck just the same as blades that are too long will

The notch where the flute starts is there to prevent cracking & allow the flutes to be bent easily it has no functional difference in use

Unless the blade is centred in a 4 jaw chuck and you use a pedestal grinder you will not be able to open out the holes by hand.

The tinest bit off centre left right or front back will have the blade out of balance

The height between the cutting edge & the underside of the deck is CRITICAL ( yes I am shouting in the hope you will listen ) .

Too close and the deck will get overwhelmed with clippings so will clog which can quite easily cause the belt to break

Too far away and the clippings will not discharge properly and the deck will also clog all the time when cutting long grass

In both cases you will end up with blobs of cuttings all over the lawn ( we call them grass turds ) .

Pressed decks are less fussy about this but with fabricated decks with a flat steel plate on the top it is critical

If you find that you can not get original blades then buy a set of all that look like they fit.

Blades are not all that expensive particulaly when compared to buying a replacement mower .

A lot of my customers use different blades at different times in the season and in any case having a spare set ( or 2 ) of sharp blades encourages people to change them when they start to go dull

You get a much better cut & can cut a lot faster with sharp blades

#20

D

djg618

Went to the local farm store and took my deck with me. Tried installing a 15/16" CH over the threaded spindle. Did not go on. I definitely have a 1" CH.

D

djg618

It measures 0.982 also. Turns out my cheap micrometer is off a little.What does the spindle shaft mike to?

Went to the local farm store and took my deck with me. Tried installing a 15/16" CH over the threaded spindle. Did not go on. I definitely have a 1" CH.

#21

D

djg618

D

djg618

Alot of good information here. Thanks. I'm currently looking for a 20.75" drop blade 2.5" wide (not 3") and a thickness of no more than 0.25" and a center hole of 1-1/8". Someone pointed out 1" to 1-1/8" reducing bushings are available that I could cut the flange off and grind to the thickness of the new blades. These are friction fit blades.If you bothered to check that chart then you would have seen 15/16" is a std blade hole size

Blade thickness is not important for fit

Thicker blades have a lot more momentum so will not die as quick in long tough grasses and of course will take more punishment before it bends .

Thicker blades also require more sharpening to do a good cut and reduce load on the engine . I explain this in terms of line trimmer thickness as almost every one has run line that was too thick through their trimmer at lease once .

Blade width is important as a blades that are too wide will hit each other .

Because blade length is measured diagonally a 20 x 3" blade is actually shorter than a 20 x 2.5" blade so the narrower blades may strike the sides of the deck just the same as blades that are too long will

The notch where the flute starts is there to prevent cracking & allow the flutes to be bent easily it has no functional difference in use

Unless the blade is centred in a 4 jaw chuck and you use a pedestal grinder you will not be able to open out the holes by hand.

The tinest bit off centre left right or front back will have the blade out of balance

The height between the cutting edge & the underside of the deck is CRITICAL ( yes I am shouting in the hope you will listen ) .

Too close and the deck will get overwhelmed with clippings so will clog which can quite easily cause the belt to break

Too far away and the clippings will not discharge properly and the deck will also clog all the time when cutting long grass

In both cases you will end up with blobs of cuttings all over the lawn ( we call them grass turds ) .

Pressed decks are less fussy about this but with fabricated decks with a flat steel plate on the top it is critical

If you find that you can not get original blades then buy a set of all that look like they fit.

Blades are not all that expensive particulaly when compared to buying a replacement mower .

A lot of my customers use different blades at different times in the season and in any case having a spare set ( or 2 ) of sharp blades encourages people to change them when they start to go dull

You get a much better cut & can cut a lot faster with sharp blades

#22

D

djg618

Oh, and the deck is a fabricated deck. Very heavy. Took two people to git int my truck.

D

djg618

I see that was you.Alot of good information here. Thanks. I'm currently looking for a 20.75" drop blade 2.5" wide (not 3") and a thickness of no more than 0.25" and a center hole of 1-1/8". Someone pointed out 1" to 1-1/8" reducing bushings are available that I could cut the flange off and grind to the thickness of the new blades. These are friction fit blades.

Oh, and the deck is a fabricated deck. Very heavy. Took two people to git int my truck.

#23

B

bertsmobile1

B

bertsmobile1

Search "Steel reducing bushes" you should come up with a dozen supplier in the USA .

I assume this mower has a 60" deck

If you flip the deck over and measure the distance spindle centre to spindle centre this is basically the right length for your blades

I usually measure inside to inside then outside to outside , add them up & divide by 2 because that tends to be more accurate than trying to guess the middle of the spindle

Probably worth doing both sides , left to middle then right to middle .

Not all that long ago there used to be a good 1/2" of blade cutting circle overlap but as decks get shorter front to back the amount of overlap is reducing

Husqvarna now uses 2 x 21" blades to do a supposedly 42" cut and you are lucky to get a season out of them before they start to leave rooster tails between the blades .

I assume this mower has a 60" deck

If you flip the deck over and measure the distance spindle centre to spindle centre this is basically the right length for your blades

I usually measure inside to inside then outside to outside , add them up & divide by 2 because that tends to be more accurate than trying to guess the middle of the spindle

Probably worth doing both sides , left to middle then right to middle .

Not all that long ago there used to be a good 1/2" of blade cutting circle overlap but as decks get shorter front to back the amount of overlap is reducing

Husqvarna now uses 2 x 21" blades to do a supposedly 42" cut and you are lucky to get a season out of them before they start to leave rooster tails between the blades .

#24

D

djg618

Only 20-1/2" long. Not sure how the manufacturer measures theirs. Would these leave the rooster tails? Thought the middle blade overlapped the outer two. Yes 60" deck. Don't know what the drop is. They don't say.

D

djg618

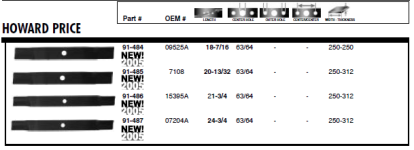

I'm looking at these:Search "Steel reducing bushes" you should come up with a dozen supplier in the USA .

I assume this mower has a 60" deck

If you flip the deck over and measure the distance spindle centre to spindle centre this is basically the right length for your blades

I usually measure inside to inside then outside to outside , add them up & divide by 2 because that tends to be more accurate than trying to guess the middle of the spindle

Probably worth doing both sides , left to middle then right to middle .

Not all that long ago there used to be a good 1/2" of blade cutting circle overlap but as decks get shorter front to back the amount of overlap is reducing

Husqvarna now uses 2 x 21" blades to do a supposedly 42" cut and you are lucky to get a season out of them before they start to leave rooster tails between the blades .

Only 20-1/2" long. Not sure how the manufacturer measures theirs. Would these leave the rooster tails? Thought the middle blade overlapped the outer two. Yes 60" deck. Don't know what the drop is. They don't say.

#25

M

MParr

It would be nice if you could replace your spindles with Exmark spindles.

M

MParr

They could leave uncut strips. @bertsmobile1 had some good advice earlier about measuring the distance between the outside spindles and center spindle.I'm looking at these:

Only 20-1/2" long. Not sure how the manufacturer measures theirs. Would these leave the rooster tails? Thought the middle blade overlapped the outer two. Yes 60" deck. Don't know what the drop is. They don't say.

It would be nice if you could replace your spindles with Exmark spindles.

#27

D

djg618

I have emails out to three US manufacurers and If I don't hear back from them, I've got a slightly longer, 20-15/16" blade, picked out.

D

djg618

Yes I do, but thanks. As I said before, I believe they are closed. Production stopped 20 years ago but parts remained available from them a couple years ago. I've called both numbers several times last week and no answer. I'll keep trying.

I have emails out to three US manufacurers and If I don't hear back from them, I've got a slightly longer, 20-15/16" blade, picked out.

#29

D

djg618

I did put the old blades back on and measured the minimum distance between blades and all the way around and it was 3/8". So now I'd be down to 1/4" which would be doable. If I have trouble locating those, I'll get back to you....Thanks.

D

djg618

I must have thought they were flat the first time or I didn't notice that. My apologies. I do need the "offset" and "air lift" as pictured. I'm learning a lot about blades as I go (lol). I'll have to measure mine. I butch my grass so I would hate loosing height by using a blade without an offset.This is why I suggested the Land Pride blades in an aftermarket version (B1LP1002). They are 20-7/8" long which only an 1/8" longer instead of 3/16" and have a 1" hole. That will bring the blade tips a 1/4" closer at they meeting point instead of 3/8" so might need to trim them.

View attachment 65733

I did put the old blades back on and measured the minimum distance between blades and all the way around and it was 3/8". So now I'd be down to 1/4" which would be doable. If I have trouble locating those, I'll get back to you....Thanks.

#30

D

djg618

D

djg618

Update:

This is what I ended up with. 20-15/16" blades just missed each other on a trial fit. So for comfort, I ground off 1/16" each end and made sure the blades were balanced. Mowed the grass twice until the belt broke. Got another one and will install tomorrow. Don't think it's added pressure on the belt since the blades are the same thickness design. Belts just break. and I had the same problem a couple of years ago. Went through two belts back to back. Found out the belt retainer post was dragging. Moved it out of way and re-tighten. Worked fine. I think I may have bumped it when removing the deck.

Thanks everyone!

This is what I ended up with. 20-15/16" blades just missed each other on a trial fit. So for comfort, I ground off 1/16" each end and made sure the blades were balanced. Mowed the grass twice until the belt broke. Got another one and will install tomorrow. Don't think it's added pressure on the belt since the blades are the same thickness design. Belts just break. and I had the same problem a couple of years ago. Went through two belts back to back. Found out the belt retainer post was dragging. Moved it out of way and re-tighten. Worked fine. I think I may have bumped it when removing the deck.

Thanks everyone!