You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

L110 Will Not Start

#1

D

Dirtbmw20

D

Dirtbmw20

I have a L110 that when you turn the key, the mower does absolutely NOTHING. The lights DO come on, and the hour meter DOES work, but other than that there is nothing. No "trying" to start, no clicking, absolutely NOTHING !!! I have owned this mower for probably about 10 years and never had this problem before. I HAVE had the problem of the starter solenoid going out, but I have replaced the starter solenoid and that does not fix it.

Is there a switch of some kind on the brake pedal ??? Since that pedal MUST be pushed in before the mower will start......

SOMETIMES (maybe 1 out of 10 times) I can keep the pedal pushed in, and rock the mower back and forth while having the key turned, and WHALLA..... it will start. BUT like I said, that is only 1 out of every 10 times. Couldn't get it cranked at all yesterday

If I jump the terminals on the starter solenoid with a screwdriver, it will start up. But I have THREE different starter solenoids, one being BRAND NEW, and another "confirmed" good one, but even if I replace the solenoid, it does NOT fix my problem.

WHAT GIVES ?????????

Is there a switch of some kind on the brake pedal ??? Since that pedal MUST be pushed in before the mower will start......

SOMETIMES (maybe 1 out of 10 times) I can keep the pedal pushed in, and rock the mower back and forth while having the key turned, and WHALLA..... it will start. BUT like I said, that is only 1 out of every 10 times. Couldn't get it cranked at all yesterday

If I jump the terminals on the starter solenoid with a screwdriver, it will start up. But I have THREE different starter solenoids, one being BRAND NEW, and another "confirmed" good one, but even if I replace the solenoid, it does NOT fix my problem.

WHAT GIVES ?????????

#3

D

Dirtbmw20

My first thought was one on the brake pedal, but yesterday at home I couldn't find the damn thing located on the mower. NOW that I got to work and can get on a real computer (no PC at the house, only phones), I have found where the brake switch is located so I will check that.

If ANY of those switches are bad, would the mower still start when I jump the terminals on the starter solenoid ??? Because as I mentioned, I can jump the terminals with a screwdriver and it will start and run just fine.

D

Dirtbmw20

Safety switches on the seat, brake and mower engage, check them all.

My first thought was one on the brake pedal, but yesterday at home I couldn't find the damn thing located on the mower. NOW that I got to work and can get on a real computer (no PC at the house, only phones), I have found where the brake switch is located so I will check that.

If ANY of those switches are bad, would the mower still start when I jump the terminals on the starter solenoid ??? Because as I mentioned, I can jump the terminals with a screwdriver and it will start and run just fine.

#4

Boobala

My neighbor had the same problem last year... HIS was solved when he ran an EXTRA ground wire

from the ENGINE to the SOLENOID FRAME ... he said screws holding the solenoid didn't provide enough

metal to metal contact ... course his solenoid...grounds through its frame...not from a terminal as on 4

terminal solenoids .

Boobala

My first thought was one on the brake pedal, but yesterday at home I couldn't find the damn thing located on the mower. NOW that I got to work and can get on a real computer (no PC at the house, only phones), I have found where the brake switch is located so I will check that.

If ANY of those switches are bad, would the mower still start when I jump the terminals on the starter solenoid ??? Because as I mentioned, I can jump the terminals with a screwdriver and it will start and run just fine.

My neighbor had the same problem last year... HIS was solved when he ran an EXTRA ground wire

from the ENGINE to the SOLENOID FRAME ... he said screws holding the solenoid didn't provide enough

metal to metal contact ... course his solenoid...grounds through its frame...not from a terminal as on 4

terminal solenoids .

#5

B

bertsmobile1

The Seat switch has absolutely nothing to do with the starting circuit, Leave it alone.

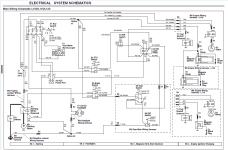

The power to energise the starter solenoid goes from the ignition switch to the PTO switch then to the brake switch then to the starter solenoid.

This is a daisy chain so if any one is bad it wont crank.

The switches are simple plunger switches so they should be in starting mode when the plunger is all the way in.

They are cheap I simply replace them as that is a 10 minute job as compared to a 60 minute job running bypasses to check each switch individually.

Both have 2 circuits.

One is a power ( +12V ) and closes plunger in to start the mower

The other a ground circuit and goes closed to shut the mower down, plunger fully out.

B

bertsmobile1

My first thought was one on the brake pedal, but yesterday at home I couldn't find the damn thing located on the mower. NOW that I got to work and can get on a real computer (no PC at the house, only phones), I have found where the brake switch is located so I will check that.

If ANY of those switches are bad, would the mower still start when I jump the terminals on the starter solenoid ??? Because as I mentioned, I can jump the terminals with a screwdriver and it will start and run just fine.

The Seat switch has absolutely nothing to do with the starting circuit, Leave it alone.

The power to energise the starter solenoid goes from the ignition switch to the PTO switch then to the brake switch then to the starter solenoid.

This is a daisy chain so if any one is bad it wont crank.

The switches are simple plunger switches so they should be in starting mode when the plunger is all the way in.

They are cheap I simply replace them as that is a 10 minute job as compared to a 60 minute job running bypasses to check each switch individually.

Both have 2 circuits.

One is a power ( +12V ) and closes plunger in to start the mower

The other a ground circuit and goes closed to shut the mower down, plunger fully out.

#6

M

mjb8fj

bert is right on the money, the seat switch has nothing to do with it turning over. If you have tried what he has said so far, and the other suggestions, and its not working, use a DVM (volt meter) and look at the solenoid- one of the big positive cables should have 12v the other 0v, try to start one should have close to 12v (if it does turn over its under a load and voltage will go down) and the other side should have close to the same voltage. So 12v on one side and 12v on the other when starting. If you don't, the solenoid has gone out, no biggie the go out all the time, if you got 12v going in, and 12v going out, your now looking at the starter not working. I think I read that you already replaced two or more previously over the years, well they do go bad. If your jumping the solenoid with a screwdriver, is it because the solenoid crapped out, or cause the brake safety isn't working? Key switch? There is only a few things to try, and its hard to help you out online or thru a forum but theres a lot of help here for ya. I have one of the 110's as well, not a bad machine at all.

M

mjb8fj

The Seat switch has absolutely nothing to do with the starting circuit, Leave it alone.

The power to energise the starter solenoid goes from the ignition switch to the PTO switch then to the brake switch then to the starter solenoid.

This is a daisy chain so if any one is bad it wont crank.

The switches are simple plunger switches so they should be in starting mode when the plunger is all the way in.

They are cheap I simply replace them as that is a 10 minute job as compared to a 60 minute job running bypasses to check each switch individually.

Both have 2 circuits.

One is a power ( +12V ) and closes plunger in to start the mower

The other a ground circuit and goes closed to shut the mower down, plunger fully out.

bert is right on the money, the seat switch has nothing to do with it turning over. If you have tried what he has said so far, and the other suggestions, and its not working, use a DVM (volt meter) and look at the solenoid- one of the big positive cables should have 12v the other 0v, try to start one should have close to 12v (if it does turn over its under a load and voltage will go down) and the other side should have close to the same voltage. So 12v on one side and 12v on the other when starting. If you don't, the solenoid has gone out, no biggie the go out all the time, if you got 12v going in, and 12v going out, your now looking at the starter not working. I think I read that you already replaced two or more previously over the years, well they do go bad. If your jumping the solenoid with a screwdriver, is it because the solenoid crapped out, or cause the brake safety isn't working? Key switch? There is only a few things to try, and its hard to help you out online or thru a forum but theres a lot of help here for ya. I have one of the 110's as well, not a bad machine at all.

#7

T

Telesis

T

Telesis

Let me apologize for this great american novel. My purpose is to help you understand how the components work.

Think of the solenoid as a simple but heavy duty relay. The two spade terminals are the coil connections. The two studded connections are the contacts. When 12v is connected to the coil(via the purple and black wires connected to the spade terminals), the internal heavy contacts close connecting one of the studded terminals to the other, in turn connecting the heavy battery red wire to the heavy starter motor wire and the engine turns over. The purple wire provides the +12V to the solenoid coil(when you go to start it) and the black wire is connected to ground.

Another simple way of checking the solenoid is to remove the purple and black wires from the spade terminals. Connect a jumper wire from one of the spade terminals to the positive batt terminal and another jumper wire from the other spade terminal to the negative batt terminal. If this causes the starter to turn the engine over, both the solenoid and the starter are good. If the starter does not turn over, the solenoid is bad. By doing this test, you are bypassing all the wiring/switches, etc that provide the power to the solenoid coil.

If the solenoid is good, then you need to work back. Reconnect the black wire to the solenoid spade terminal. Touch the jumper wire from the other to the positive battery terminal again. This tests if the solenoid coil is grounded good. If it turns over, the grounded side of the solenoid coil is fine. This is likely the case. If it does not turn over, you have a problem with the black ground wire.

At this point you've determined you have a good solenoid and starter and that the solenoid is grounded properly. The problem is, as explained by others, the daisy chain of the safety switch, pto switch and ign switch. Those are all in series. When working properly, +12 volts starts at one end, and passes through each of those, and ends up at the purple solenoid wire(when you are trying to start it). My recommendation from experience is, as bert indicated, just go ahead and replace the safety switch.

If you are so inclined and want to spend the time, you can use a voltmeter set on DC volts and a range to measure 12 volts. Connect the black meter lead to the negative batt terminal and with the purple wire disconnected from the solenoid, touch the red meter lead to the purple wire. Do whatever you need to do to start it(pto off, ign on, brake engaged etc) and see if you measure 12V. If you've done everything up till now, then you will NOT see 12 volts, meaning one of the switches is NOT working. Trace the purple wire back to each device and see where the 12v appears.

Having said all that, my guess is the pto switch is OK, and the ign switch is OK and the likely culprit is the safety switch. That's why we are saying to just go ahead and replace it. It's not a costly part.

Good luck!

Think of the solenoid as a simple but heavy duty relay. The two spade terminals are the coil connections. The two studded connections are the contacts. When 12v is connected to the coil(via the purple and black wires connected to the spade terminals), the internal heavy contacts close connecting one of the studded terminals to the other, in turn connecting the heavy battery red wire to the heavy starter motor wire and the engine turns over. The purple wire provides the +12V to the solenoid coil(when you go to start it) and the black wire is connected to ground.

Another simple way of checking the solenoid is to remove the purple and black wires from the spade terminals. Connect a jumper wire from one of the spade terminals to the positive batt terminal and another jumper wire from the other spade terminal to the negative batt terminal. If this causes the starter to turn the engine over, both the solenoid and the starter are good. If the starter does not turn over, the solenoid is bad. By doing this test, you are bypassing all the wiring/switches, etc that provide the power to the solenoid coil.

If the solenoid is good, then you need to work back. Reconnect the black wire to the solenoid spade terminal. Touch the jumper wire from the other to the positive battery terminal again. This tests if the solenoid coil is grounded good. If it turns over, the grounded side of the solenoid coil is fine. This is likely the case. If it does not turn over, you have a problem with the black ground wire.

At this point you've determined you have a good solenoid and starter and that the solenoid is grounded properly. The problem is, as explained by others, the daisy chain of the safety switch, pto switch and ign switch. Those are all in series. When working properly, +12 volts starts at one end, and passes through each of those, and ends up at the purple solenoid wire(when you are trying to start it). My recommendation from experience is, as bert indicated, just go ahead and replace the safety switch.

If you are so inclined and want to spend the time, you can use a voltmeter set on DC volts and a range to measure 12 volts. Connect the black meter lead to the negative batt terminal and with the purple wire disconnected from the solenoid, touch the red meter lead to the purple wire. Do whatever you need to do to start it(pto off, ign on, brake engaged etc) and see if you measure 12V. If you've done everything up till now, then you will NOT see 12 volts, meaning one of the switches is NOT working. Trace the purple wire back to each device and see where the 12v appears.

Having said all that, my guess is the pto switch is OK, and the ign switch is OK and the likely culprit is the safety switch. That's why we are saying to just go ahead and replace it. It's not a costly part.

Good luck!

#8

A

alitterit

A

alitterit

Dirt, Yes the mower will start because by jumping the starter you are bypassing that whole safety circuit and is not recommended for obvious reasons. Bert hit the nail on the head with his post though, easy and cheap to replace the switch and get you back starting/ running again as it should be.

#9

D

Dirtbmw20

D

Dirtbmw20

Thanks everyone very much for the replies back. Sorry for the delay in returning back to the forum, but with no computer at home (only phones) and 2 kids running around, I JUST got time to mess with this on Monday. Had to put a new battery in it anyways, so I went ahead and replaced the safety switch at the brake pedal while replacing the battery.

Still not EXACTLY sure of the problem, but I'm pretty sure I figured it out, won't know until I can re-wire the switch. When I unplugged the connector from the brake switch, one of the metal terminals fell out of the connector cavity, so I "think" that is my problem, and why it has been intermittent. It's only connecting on 3 of the 4 terminals on the switch.

NOW..... here's the damn bummer. JD only sells the connector CAVITY, not the connector with leads. So I either have to build another terminal block with a bare cavity I got from JD, or just straight wire each individual wire. Has anybody ever come across this before ?? I am a parts guy by trade, have been in the auto parts business for 40 years of my life, and so far General Motors is the only company I have come across that doesn't sell connectors with leads, until now. JD dealer says only way to get the wiring is to buy the whole harness. Same jackass engineer must design for GM and JD too.......

Still not EXACTLY sure of the problem, but I'm pretty sure I figured it out, won't know until I can re-wire the switch. When I unplugged the connector from the brake switch, one of the metal terminals fell out of the connector cavity, so I "think" that is my problem, and why it has been intermittent. It's only connecting on 3 of the 4 terminals on the switch.

NOW..... here's the damn bummer. JD only sells the connector CAVITY, not the connector with leads. So I either have to build another terminal block with a bare cavity I got from JD, or just straight wire each individual wire. Has anybody ever come across this before ?? I am a parts guy by trade, have been in the auto parts business for 40 years of my life, and so far General Motors is the only company I have come across that doesn't sell connectors with leads, until now. JD dealer says only way to get the wiring is to buy the whole harness. Same jackass engineer must design for GM and JD too.......

#10

Boobala

Check out this video ... might prove helpful ...

https://www.youtube.com/watch?v=Yiimgl-Rdmw

I use these connectors all the time ... best part is you can take the splice apart at any time with cutting the wire great for a situation like yours ( I M O )

you can get them here ... https://www.posi-products.com/

I have bought some at ADVANCE Auto Parts also..

Boobala

Thanks everyone very much for the replies back. Sorry for the delay in returning back to the forum, but with no computer at home (only phones) and 2 kids running around, I JUST got time to mess with this on Monday. Had to put a new battery in it anyways, so I went ahead and replaced the safety switch at the brake pedal while replacing the battery.

Still not EXACTLY sure of the problem, but I'm pretty sure I figured it out, won't know until I can re-wire the switch. When I unplugged the connector from the brake switch, one of the metal terminals fell out of the connector cavity, so I "think" that is my problem, and why it has been intermittent. It's only connecting on 3 of the 4 terminals on the switch.

NOW..... here's the damn bummer. JD only sells the connector CAVITY, not the connector with leads. So I either have to build another terminal block with a bare cavity I got from JD, or just straight wire each individual wire. Has anybody ever come across this before ?? I am a parts guy by trade, have been in the auto parts business for 40 years of my life, and so far General Motors is the only company I have come across that doesn't sell connectors with leads, until now. JD dealer says only way to get the wiring is to buy the whole harness. Same jackass engineer must design for GM and JD too.......

Check out this video ... might prove helpful ...

https://www.youtube.com/watch?v=Yiimgl-Rdmw

I use these connectors all the time ... best part is you can take the splice apart at any time with cutting the wire great for a situation like yours ( I M O )

you can get them here ... https://www.posi-products.com/

I have bought some at ADVANCE Auto Parts also..

#11

D

Dirtbmw20

Those would work great if I was splicing two wires together, but in no way could I use those for my problem/issue. I just simply (not so simple) need the metal terminals that go into the connector body so I can build another connector with leads.

D

Dirtbmw20

Check out this video ... might prove helpful ...

https://www.youtube.com/watch?v=Yiimgl-Rdmw

I use these connectors all the time ... best part is you can take the splice apart at any time with cutting the wire great for a situation like yours ( I M O )

you can get them here ... https://www.posi-products.com/

I have bought some at ADVANCE Auto Parts also..

Those would work great if I was splicing two wires together, but in no way could I use those for my problem/issue. I just simply (not so simple) need the metal terminals that go into the connector body so I can build another connector with leads.

#12

Boobala

Boobala

It sounds to me as though you want to have an "ORIGINAL" type connection with a "molen" typeconnector

I'm not sure this will help but I have built complete wiring harness's using similar products while doing Aircraft Overhaul work ...

http://www.painlessperformance.com/webcatalog/copi

https://www.google.com/search?q=mal...I3OFXchHPmQ1VbE30uCoSCWZPNE7UZKFfEVoFDpwpqFrO

https://www.google.com/search?q=mal...I3OFXchHPmQ1VbE30uCoSCWZPNE7UZKFfEVoFDpwpqFrO

I hope this helps in your quest of information ...

I'm not sure this will help but I have built complete wiring harness's using similar products while doing Aircraft Overhaul work ...

http://www.painlessperformance.com/webcatalog/copi

https://www.google.com/search?q=mal...I3OFXchHPmQ1VbE30uCoSCWZPNE7UZKFfEVoFDpwpqFrO

https://www.google.com/search?q=mal...I3OFXchHPmQ1VbE30uCoSCWZPNE7UZKFfEVoFDpwpqFrO

I hope this helps in your quest of information ...

#13

T

Telesis

T

Telesis

I don't know the exact switch on the L110. I googled it and it seems like part no GY20094 is it. I'll assume for the moment it is. This switch has 1/4" male spade terminals. Instead of trying to find the complete mating connector, can you just cut it off, and terminate each of the 4 wires with an individual insulated female spade terminal? You can find those online, or at home center or hardware stores. This is what I'm referring to:

http://www.homedepot.com/p/Tyco-Ele...-Insulated-Nylon-CPGI-3-350820-2-10/202204295

You just need to get the right wire on the right terminal of the switch...

Is this a possibility?

http://www.homedepot.com/p/Tyco-Ele...-Insulated-Nylon-CPGI-3-350820-2-10/202204295

You just need to get the right wire on the right terminal of the switch...

Is this a possibility?

#14

D

Dirtbmw20

Boobala, Yes, that is exactly what I want is the ORIGINAL connector with leads. What you gave links to is exactly what I already have from JD, JUST the cavity or body of the connector. IF someone could tell me the correct metal terminal to go into it, where it would snap in like it's suppose to, I would have no problem building my own connector, but nobody at JD can tell me which terminals go into the body.

D

Dirtbmw20

It sounds to me as though you want to have an "ORIGINAL" type connection with a "molen" typeconnector

I'm not sure this will help but I have built complete wiring harness's using similar products while doing Aircraft Overhaul work ...

http://www.painlessperformance.com/webcatalog/copi

https://www.google.com/search?q=mal...I3OFXchHPmQ1VbE30uCoSCWZPNE7UZKFfEVoFDpwpqFrO

https://www.google.com/search?q=mal...I3OFXchHPmQ1VbE30uCoSCWZPNE7UZKFfEVoFDpwpqFrO

I hope this helps in your quest of information ...

Boobala, Yes, that is exactly what I want is the ORIGINAL connector with leads. What you gave links to is exactly what I already have from JD, JUST the cavity or body of the connector. IF someone could tell me the correct metal terminal to go into it, where it would snap in like it's suppose to, I would have no problem building my own connector, but nobody at JD can tell me which terminals go into the body.

#15

D

Dirtbmw20

YES, of course this is a possibility and seems to be my only option at this moment. If you go back to post #9, I mentioned that if I can't find the connector with leads already on it, I'll just have to straight wire each one individually.

D

Dirtbmw20

I don't know the exact switch on the L110. I googled it and it seems like part no GY20094 is it. I'll assume for the moment it is. This switch has 1/4" male spade terminals. Instead of trying to find the complete mating connector, can you just cut it off, and terminate each of the 4 wires with an individual insulated female spade terminal? You can find those online, or at home center or hardware stores. This is what I'm referring to:

http://www.homedepot.com/p/Tyco-Ele...-Insulated-Nylon-CPGI-3-350820-2-10/202204295

You just need to get the right wire on the right terminal of the switch...

Is this a possibility?

YES, of course this is a possibility and seems to be my only option at this moment. If you go back to post #9, I mentioned that if I can't find the connector with leads already on it, I'll just have to straight wire each one individually.

#16

D

Dirtbmw20

D

Dirtbmw20

IF anyone else is interested........... The part number for the metal terminals that go inside the cavity are U46662, thanks VERY MUCH to forum member JoeM for the part number.

#17

T

Telesis

T

Telesis

I'm sorry, I missed your comment about direct wire. Can you please confirm with a pic or a part no of the switch or the cavity what you are dealing with? Is it the one I mentioned using the spade terminals or is it something that uses the round pins and sockets as Boobala indicated. He mentioned 'molen'. That's a typo. He's referring to a 'Molex' type connector. That's a manufacturer name and they have been around forever and you can buy individual pins and sockets at electronics suppliers like Mouser, Digikey, Newark, etc. They are very common. The question is whether the 'standard' molex pins are used in the JD cavity. If I can just see a pic of exactly what you are looking for I can probably give you more help.

So, for this next comment I'll assume I was wrong about the spade terminal connector and instead it's a molex connector. I've assembled a boatload of molex connectors over the years and it's not uncommon for a male or female insert to pop out of the cavity. If you look closely at the insert, there are two "nibs", one on each side of the insert. When it is pushed into the cavity, those 'snap' in to retain it. If those are bent in, they won't grab. You can take an Xacto knife and gently bend them back out and push the insert back in and get it to grab. I mention this as you may not need to replace and can repair instead.

Sorry to belabor the issue, but my confusion is what type of connection you are dealing with in the first place. If you could provide a pic of the connector and of the pin that fell out, that would be helpful and I can point you to specific part numbers. If in fact it's molex pins you are looking for(and they are the standard ones), there's a good chance I have what you need in my shop and I can just send them to you! [I've been designing, building, and repairing electronics for the better part of 50 years and I've worked with all kinds of connectors, including molex. That's why I'm asking to see it!]

So, for this next comment I'll assume I was wrong about the spade terminal connector and instead it's a molex connector. I've assembled a boatload of molex connectors over the years and it's not uncommon for a male or female insert to pop out of the cavity. If you look closely at the insert, there are two "nibs", one on each side of the insert. When it is pushed into the cavity, those 'snap' in to retain it. If those are bent in, they won't grab. You can take an Xacto knife and gently bend them back out and push the insert back in and get it to grab. I mention this as you may not need to replace and can repair instead.

Sorry to belabor the issue, but my confusion is what type of connection you are dealing with in the first place. If you could provide a pic of the connector and of the pin that fell out, that would be helpful and I can point you to specific part numbers. If in fact it's molex pins you are looking for(and they are the standard ones), there's a good chance I have what you need in my shop and I can just send them to you! [I've been designing, building, and repairing electronics for the better part of 50 years and I've worked with all kinds of connectors, including molex. That's why I'm asking to see it!]

#18

D

Dirtbmw20

Cavity part# T24167 and terminal part# U46662, solve my problems with this issue. I do not have pics.

D

Dirtbmw20

I'm sorry, I missed your comment about direct wire. Can you please confirm with a pic or a part no of the switch or the cavity what you are dealing with? Is it the one I mentioned using the spade terminals or is it something that uses the round pins and sockets as Boobala indicated. He mentioned 'molen'. That's a typo. He's referring to a 'Molex' type connector. That's a manufacturer name and they have been around forever and you can buy individual pins and sockets at electronics suppliers like Mouser, Digikey, Newark, etc. They are very common. The question is whether the 'standard' molex pins are used in the JD cavity. If I can just see a pic of exactly what you are looking for I can probably give you more help.

So, for this next comment I'll assume I was wrong about the spade terminal connector and instead it's a molex connector. I've assembled a boatload of molex connectors over the years and it's not uncommon for a male or female insert to pop out of the cavity. If you look closely at the insert, there are two "nibs", one on each side of the insert. When it is pushed into the cavity, those 'snap' in to retain it. If those are bent in, they won't grab. You can take an Xacto knife and gently bend them back out and push the insert back in and get it to grab. I mention this as you may not need to replace and can repair instead.

Sorry to belabor the issue, but my confusion is what type of connection you are dealing with in the first place. If you could provide a pic of the connector and of the pin that fell out, that would be helpful and I can point you to specific part numbers. If in fact it's molex pins you are looking for(and they are the standard ones), there's a good chance I have what you need in my shop and I can just send them to you! [I've been designing, building, and repairing electronics for the better part of 50 years and I've worked with all kinds of connectors, including molex. That's why I'm asking to see it!]

Cavity part# T24167 and terminal part# U46662, solve my problems with this issue. I do not have pics.

#19

T

Telesis

T

Telesis

Looks like you'll be up and running in no time. Glad JoeM had the info you needed. Let us know how you make out!

#20

J

James stark

J

James stark

I have no power to my hour meter of starter motor on my l110 I turned it off TRY to restart cutting field with try get a build fix it can bad ignition switch or a solenoid cause no power