You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

HRU216K2 Rebuild

#1

N

neevo

N

neevo

Hello all! I’m the owner of an old HRU216K2 in Australia. I’ve been putting a lot of effort in to getting it back to running condition (it was very cheap but very rough when I bought it; a bit of a basket case).

So far I’ve been fixing up wear parts and replacing damaged or missing bits with genuine Honda parts (except for the wheels), like rebuilding the transmission, and now it’s running well.

I’ve had some challenges though that I’m keen to get some advice on.

1. I have a fuel leak at the carb. It wasn’t leaking before, but I stripped it, ran it through my ultrasonic cleaner and put it back on the mower and now it’s dripping fuel on the deck. Tried to knock the carb as I suspected it was something caught in the bowl but keen to hear if anyone else has some ideas on what to check? I did leave the fuel on so maybe that was my problem but it didn’t leak before when I did that.

2. I’ve been having problems with the motor bogging. It also had a misfire which a new plug cured and I also struggled with setting up the throttle control section (which was quite bent when I bought it). I also suspect I set the govenor wrong as I had no idea what I was doing. It was struggling with basic mows On standard height and as I’m trying to manage thatch it wouldn’t cope at all. Stalling a lot as I tried to take a cut with only 1 step down on the deck.

I set the govenor off a video that was linked off this site (to the Honda website). Push govenor arm right, inner rod to far right. Tighten.

That and I found a service manual link off this site too which gave some info on how to set control linkage. Throttle to fast, undo cable holder on control linkage and set the position so that it just engages the choke. Tighten.

All seems well with the motor now. The revs are not high, actually very reasonable and I need to do another 1 notch down pass to see if there’s an improvement, but if anyone spots any errors in my thinking, please let me know.

If it still has a bogging issue I’m out of ideas.

So far I’ve been fixing up wear parts and replacing damaged or missing bits with genuine Honda parts (except for the wheels), like rebuilding the transmission, and now it’s running well.

I’ve had some challenges though that I’m keen to get some advice on.

1. I have a fuel leak at the carb. It wasn’t leaking before, but I stripped it, ran it through my ultrasonic cleaner and put it back on the mower and now it’s dripping fuel on the deck. Tried to knock the carb as I suspected it was something caught in the bowl but keen to hear if anyone else has some ideas on what to check? I did leave the fuel on so maybe that was my problem but it didn’t leak before when I did that.

2. I’ve been having problems with the motor bogging. It also had a misfire which a new plug cured and I also struggled with setting up the throttle control section (which was quite bent when I bought it). I also suspect I set the govenor wrong as I had no idea what I was doing. It was struggling with basic mows On standard height and as I’m trying to manage thatch it wouldn’t cope at all. Stalling a lot as I tried to take a cut with only 1 step down on the deck.

I set the govenor off a video that was linked off this site (to the Honda website). Push govenor arm right, inner rod to far right. Tighten.

That and I found a service manual link off this site too which gave some info on how to set control linkage. Throttle to fast, undo cable holder on control linkage and set the position so that it just engages the choke. Tighten.

All seems well with the motor now. The revs are not high, actually very reasonable and I need to do another 1 notch down pass to see if there’s an improvement, but if anyone spots any errors in my thinking, please let me know.

If it still has a bogging issue I’m out of ideas.

#2

B

bertsmobile1

B

bertsmobile1

It will only bog if

1) governor is not set properly

2) governor spring is in the wrong place

3) main jet is too big , engine will 8 stroke for a while

4) discharge chute is clogged ( very common with all Honda walk behinds).

5) blunt blades

6) air bleed to the float bowl is blocked.

1) governor is not set properly

2) governor spring is in the wrong place

3) main jet is too big , engine will 8 stroke for a while

4) discharge chute is clogged ( very common with all Honda walk behinds).

5) blunt blades

6) air bleed to the float bowl is blocked.

#3

N

neevo

Thanks bertsmobile1. Can you help me understand.

1. Did I set the govenor right based on the technique above?

2. Govenor spring is on the tightest setting (bottom hole). Not overly revving. Could the spring be worn out or is there other things I need to adjust in the control linkage?

3. Might see if I can check main jet with local shop. Is there a way to check jetting? Read in the service manual to warm engine, adjust to low idle, adjust pilot screw until higher revs are found, adjust back idle stop to normal low revs. Done.

4. That was an issue a few times. Forget to clean it out often because it’s so big.

5. Brand new genuine Honda blades

6. I would imagine that’s not an issue with the carb through the cleaner. Or should I take it apart more and clean some specific areas. Ill be grabbing a gasket kit for it anyway (as I suspect it doesn’t have a gasket on the float bowl) so might make sense to have another crack at it.

N

neevo

It will only bog if

1) governor is not set properly

2) governor spring is in the wrong place

3) main jet is too big , engine will 8 stroke for a while

4) discharge chute is clogged ( very common with all Honda walk behinds).

5) blunt blades

6) air bleed to the float bowl is blocked.

Thanks bertsmobile1. Can you help me understand.

1. Did I set the govenor right based on the technique above?

2. Govenor spring is on the tightest setting (bottom hole). Not overly revving. Could the spring be worn out or is there other things I need to adjust in the control linkage?

3. Might see if I can check main jet with local shop. Is there a way to check jetting? Read in the service manual to warm engine, adjust to low idle, adjust pilot screw until higher revs are found, adjust back idle stop to normal low revs. Done.

4. That was an issue a few times. Forget to clean it out often because it’s so big.

5. Brand new genuine Honda blades

6. I would imagine that’s not an issue with the carb through the cleaner. Or should I take it apart more and clean some specific areas. Ill be grabbing a gasket kit for it anyway (as I suspect it doesn’t have a gasket on the float bowl) so might make sense to have another crack at it.

#4

N

neevo

N

neevo

Cut the grass tonight and I can say the mowers power is a lot more consistent. I wasn’t trying to take deep cuts, simply cutting to the lowest setting I used last time.

I could hear the motor labouring on occasion but not once did I fear it would bog down to the point of stalling.

Would prefer a few more revs though as I think that would help a lot, plus it seems like the revs are pretty low on full throttle.

Anyone know how to increase the max speed when the throttle linkage is against the choke mechanism? The govenor spring is also on the lowest hole so no more adjustment there either. Could my spring have lost tension with old age?

I could hear the motor labouring on occasion but not once did I fear it would bog down to the point of stalling.

Would prefer a few more revs though as I think that would help a lot, plus it seems like the revs are pretty low on full throttle.

Anyone know how to increase the max speed when the throttle linkage is against the choke mechanism? The govenor spring is also on the lowest hole so no more adjustment there either. Could my spring have lost tension with old age?

#5

B

bertsmobile1

B

bertsmobile1

Most Hondas run at 3000 rpm to 3200 rpm.

The lower revs is one of the reason they sound so quiet which is a selling point.

Yes your governor spring could be stretched.

IF you have one with a blade brake or flywheel brake then they could be dragging a little

Sounds silly but check you have the blades on the right way up.

Are you running 2 or 4 blades ?

If 4 blades then it makes a difference when you run 4 high lift rather than a pair of each.

Some throttle assemblies have an adjustment on the choke some don't I am not familiar enough with the various domestic Hondas to remember which is what.

Some also have 2 governor springs

The lower revs is one of the reason they sound so quiet which is a selling point.

Yes your governor spring could be stretched.

IF you have one with a blade brake or flywheel brake then they could be dragging a little

Sounds silly but check you have the blades on the right way up.

Are you running 2 or 4 blades ?

If 4 blades then it makes a difference when you run 4 high lift rather than a pair of each.

Some throttle assemblies have an adjustment on the choke some don't I am not familiar enough with the various domestic Hondas to remember which is what.

Some also have 2 governor springs

#6

N

neevo

Bought a new governor spring. Old one was slightly stretched but not that much, maybe 6mm or so. New one installed. Still on lowest hole (most stretch) and revs picked up a little bit but not a huge amount.

Also purchased a new carb gasket kit and installed. Bowl gasket, black plastic thing in the carb (new oring) and 2 new washers on bowl bolts. Appears to not be leaking anymore. Also blew out all the holes with m compressor.

Blade brake isn’t dragging. I pulled the lever and the blades spin freely. Asssume that’s what’s supposed to happen.

Blade curves are facing [strike]up.[/strike]

I’m running 4 blades. 2 with small sweeps and 2 with larger.

I did take some time to look at the throttle control on a HRU216M2 (mines a K2) in the shop and it looks like my control setup is the same. Although mine doesn’t work the same so I suspect it’s a bit out of adjustment from being abused, bent etc.

Might not be a problem but as an example. My choke has 2 levers hitting each other at the beginning vs being a stop at the end.

N

neevo

Most Hondas run at 3000 rpm to 3200 rpm.

The lower revs is one of the reason they sound so quiet which is a selling point.

Yes your governor spring could be stretched.

IF you have one with a blade brake or flywheel brake then they could be dragging a little

Sounds silly but check you have the blades on the right way up.

Are you running 2 or 4 blades ?

If 4 blades then it makes a difference when you run 4 high lift rather than a pair of each.

Some throttle assemblies have an adjustment on the choke some don't I am not familiar enough with the various domestic Hondas to remember which is what.

Some also have 2 governor springs

Bought a new governor spring. Old one was slightly stretched but not that much, maybe 6mm or so. New one installed. Still on lowest hole (most stretch) and revs picked up a little bit but not a huge amount.

Also purchased a new carb gasket kit and installed. Bowl gasket, black plastic thing in the carb (new oring) and 2 new washers on bowl bolts. Appears to not be leaking anymore. Also blew out all the holes with m compressor.

Blade brake isn’t dragging. I pulled the lever and the blades spin freely. Asssume that’s what’s supposed to happen.

Blade curves are facing [strike]up.[/strike]

I’m running 4 blades. 2 with small sweeps and 2 with larger.

I did take some time to look at the throttle control on a HRU216M2 (mines a K2) in the shop and it looks like my control setup is the same. Although mine doesn’t work the same so I suspect it’s a bit out of adjustment from being abused, bent etc.

Might not be a problem but as an example. My choke has 2 levers hitting each other at the beginning vs being a stop at the end.

#7

N

neevo

N

neevo

Well this is embarrassing!!!!!

My blades were on upside down :O

I was wondering from m the beginning why this mower didn’t cut as good as my cheap old Victa and also why it felt like I needed to mow so high. Turns out I’ve been cutting with the twists on the blades!

I have no doubt this will improve things significantly.

My blades were on upside down :O

I was wondering from m the beginning why this mower didn’t cut as good as my cheap old Victa and also why it felt like I needed to mow so high. Turns out I’ve been cutting with the twists on the blades!

I have no doubt this will improve things significantly.

#8

B

bertsmobile1

B

bertsmobile1

Don't be embarrassed as we have all done it.

A particular problem when you remove the blade disc to fit the blades.

And the Powertorq is the best mower engine ever made by a very long margin.

The problem is Victa & the CSIRO ( joint project ) made them too good so they no not exhibit drastic "I need servicing" symptoms, so no one ever services them.

So over the years the 4 O rings go hard, the governor diaphragm goes hard & stiff as does the decompressor diaphragm.

Takes very little work to return one to almost new condition.

Only real Achillies heel is the steel pressings used from 2010 on which is way too thin any prone to rust at the left side handle mount.

To add to that the 4 blade mulch disc gives the best cut of any walk behind , particularly when used with the extra wide heavy duty blades.

A particular problem when you remove the blade disc to fit the blades.

And the Powertorq is the best mower engine ever made by a very long margin.

The problem is Victa & the CSIRO ( joint project ) made them too good so they no not exhibit drastic "I need servicing" symptoms, so no one ever services them.

So over the years the 4 O rings go hard, the governor diaphragm goes hard & stiff as does the decompressor diaphragm.

Takes very little work to return one to almost new condition.

Only real Achillies heel is the steel pressings used from 2010 on which is way too thin any prone to rust at the left side handle mount.

To add to that the 4 blade mulch disc gives the best cut of any walk behind , particularly when used with the extra wide heavy duty blades.

#9

N

neevo

N

neevo

My Victa certainly cut beautifully. It was 13 years old when I sold it a week ago and still ran strong.

Hopefully my Honda will cut a little cleaner now that the blades are the right way!

Hopefully my Honda will cut a little cleaner now that the blades are the right way!

#10

B

bertsmobile1

B

bertsmobile1

Hondas will give a much better cut down here than they do in the USA cause we have swing back blades on a disc so we get better air flow under the deck.

On short grass it will cut on par with your Victa, a bit better than the 2 blade but not as good as the 4 blade Victa with the mulch disc.

On very log grass the chute will choke on the volume of grass.

If yours clogs regularly fit 2 pair of high lift blades but beware the double high lifts will pack near 3 times as much grass in the catcher and will cause the front wheels to lift off the ground.

Most of my Commercial customers run the double high lifts because they can usually do a complete yard on a single catcher ( emptying time = money lost ) and it also gives a better cut on dense grass & allows them to cut wet grass.

It will not cut wet grass so don't bother trying, unless you fit the double high lift.

Use 10W 40 mower oil ( Gripskie & Sons get it blended ) and change it every second season along with the blades.

Being a big blade you can take them off & sharpen them if you like but they must be balanced to within 5g of each other.

You can reuse the bolts if you are just sharpening the blades but you must not reuse the 10mm nylock nut as they work themselves loose.

And do them up with a small tension wrench, correct tension on D shaped bolts is very very important

My commercial clients all use bulk after market blades, but they will change them several times a week at this time of year.

They reuse the bolts till it shows signs of wear but they all replace the nuts every time.

If yours is fittted with the less than useless square side filter, make sure you keep a few spare as they clog very quickly cutting very dry summer grass or mulching winter leaves.

If you have a side fliter without the prefilter, go to a honda shop & buy the support plate and a couple of prefilters.

At least 2/3 of the call outs for Honda push mowers ends up being a clogged prefilter.

The strait foam ones can be washed in shampoo and refitted when fully dry.

If you have a top filter, buy a couple of prefilters ( foam wraps ) for the same reason.

On short grass it will cut on par with your Victa, a bit better than the 2 blade but not as good as the 4 blade Victa with the mulch disc.

On very log grass the chute will choke on the volume of grass.

If yours clogs regularly fit 2 pair of high lift blades but beware the double high lifts will pack near 3 times as much grass in the catcher and will cause the front wheels to lift off the ground.

Most of my Commercial customers run the double high lifts because they can usually do a complete yard on a single catcher ( emptying time = money lost ) and it also gives a better cut on dense grass & allows them to cut wet grass.

It will not cut wet grass so don't bother trying, unless you fit the double high lift.

Use 10W 40 mower oil ( Gripskie & Sons get it blended ) and change it every second season along with the blades.

Being a big blade you can take them off & sharpen them if you like but they must be balanced to within 5g of each other.

You can reuse the bolts if you are just sharpening the blades but you must not reuse the 10mm nylock nut as they work themselves loose.

And do them up with a small tension wrench, correct tension on D shaped bolts is very very important

My commercial clients all use bulk after market blades, but they will change them several times a week at this time of year.

They reuse the bolts till it shows signs of wear but they all replace the nuts every time.

If yours is fittted with the less than useless square side filter, make sure you keep a few spare as they clog very quickly cutting very dry summer grass or mulching winter leaves.

If you have a side fliter without the prefilter, go to a honda shop & buy the support plate and a couple of prefilters.

At least 2/3 of the call outs for Honda push mowers ends up being a clogged prefilter.

The strait foam ones can be washed in shampoo and refitted when fully dry.

If you have a top filter, buy a couple of prefilters ( foam wraps ) for the same reason.

#11

N

neevo

N

neevo

Great info (exactly why I joined here so I could find some experts), really appreciate you helping me out.

Funny you mention the nylocks, I could put them back on with my fingers, so I’ll take them off and replace them. Cheap insurance as I don’t want one of them loosening themselves off. Have a torque wrench (small one), so I’ll find the right torque and do it properly.

I don’t have the square filter, I have a elongated round one with paper inside and foam on the outside. Also has a snorkel on handlebars but I’ve noticed foam part of filter is already pretty clogged. I oiled it lightly.

Should I remove the foam and clean regularly? What’s the prefilter you’re referring to? Would that go in the snorkel on the handlebars?

I don’t cut wet grass so no issues there.

Funny you mention the nylocks, I could put them back on with my fingers, so I’ll take them off and replace them. Cheap insurance as I don’t want one of them loosening themselves off. Have a torque wrench (small one), so I’ll find the right torque and do it properly.

I don’t have the square filter, I have a elongated round one with paper inside and foam on the outside. Also has a snorkel on handlebars but I’ve noticed foam part of filter is already pretty clogged. I oiled it lightly.

Should I remove the foam and clean regularly? What’s the prefilter you’re referring to? Would that go in the snorkel on the handlebars?

I don’t cut wet grass so no issues there.

#12

B

bertsmobile1

B

bertsmobile1

Don't oil the foam they go on dry.

Take it off, wash it in shampoo & return it when dry.

The foam is the prefilter and should be fitted DRY.

Get some extra ones so you always have a clean one on hand.

With a snorkel the filters should go about 5 or more years unless the tube has a leak in it.

Nut tension is 38 NM and correct, if you can thread them on past the insert by hand, they are beyond their useful service life.

38 nm is nowhere near tight enough to stop the nuts loosening in service and f done up tight enougn to stop loosening, they will be too tight to allow the blade to swing.

Take it off, wash it in shampoo & return it when dry.

The foam is the prefilter and should be fitted DRY.

Get some extra ones so you always have a clean one on hand.

With a snorkel the filters should go about 5 or more years unless the tube has a leak in it.

Nut tension is 38 NM and correct, if you can thread them on past the insert by hand, they are beyond their useful service life.

38 nm is nowhere near tight enough to stop the nuts loosening in service and f done up tight enougn to stop loosening, they will be too tight to allow the blade to swing.

#13

N

neevo

N

neevo

Gotcha!

You wouldn’t have any idea how the throttle control plate should be setup too would you? Mine was bent when I got it and so I straightened it out but when I was looking at a new 216M2 in the shop yesterday it had the same setup but operated differently.

The difference is how the choke engages. On mine I have 2 levers that rub against each other as the choke engages. On the new one in the shop this acts as a stop at the end of the choke action (doesn’t rub).

Photos:

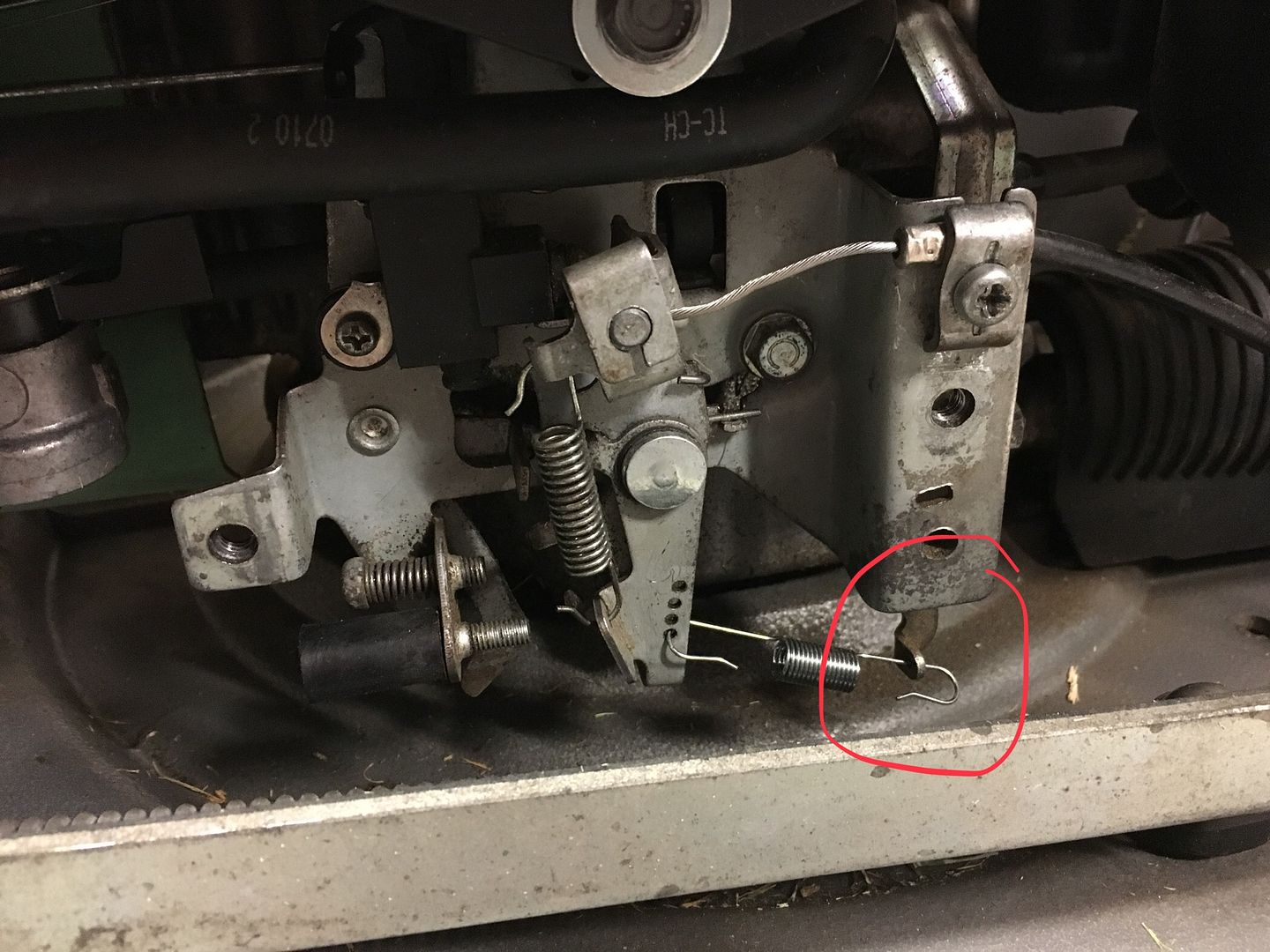

This is stop position:

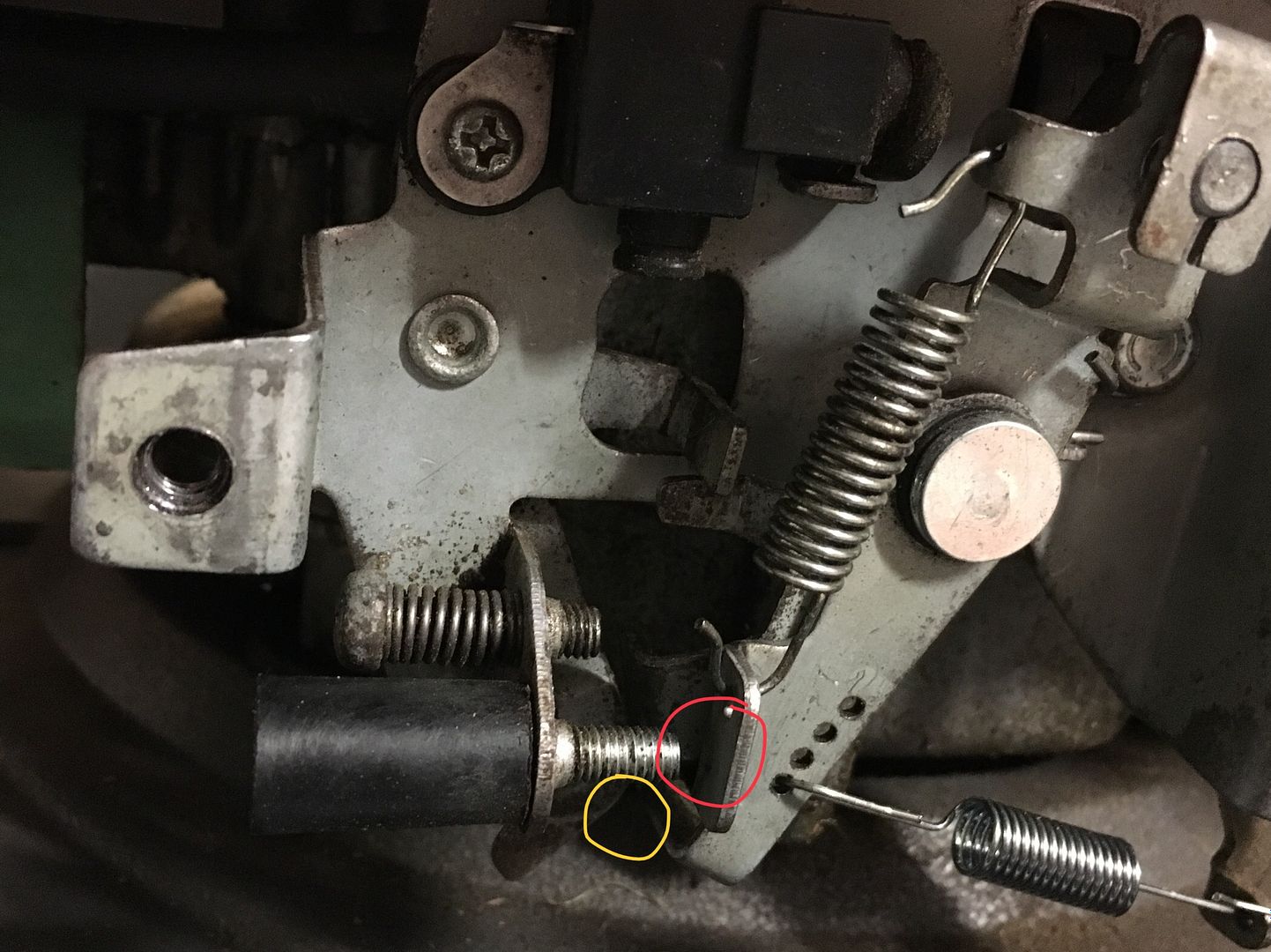

Low speed throttle position. The one in the shop had the spring with no slack. Mine has slack:

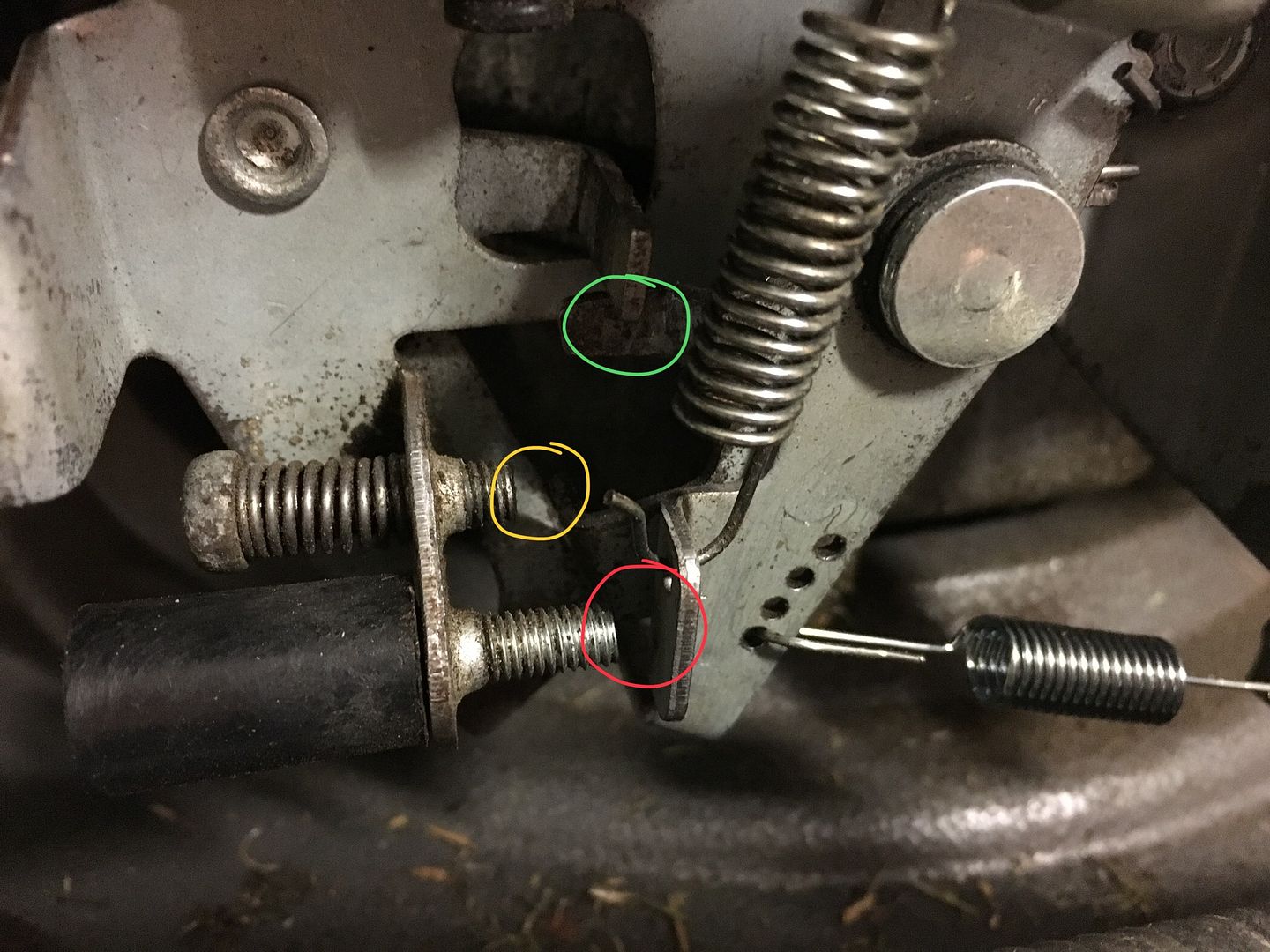

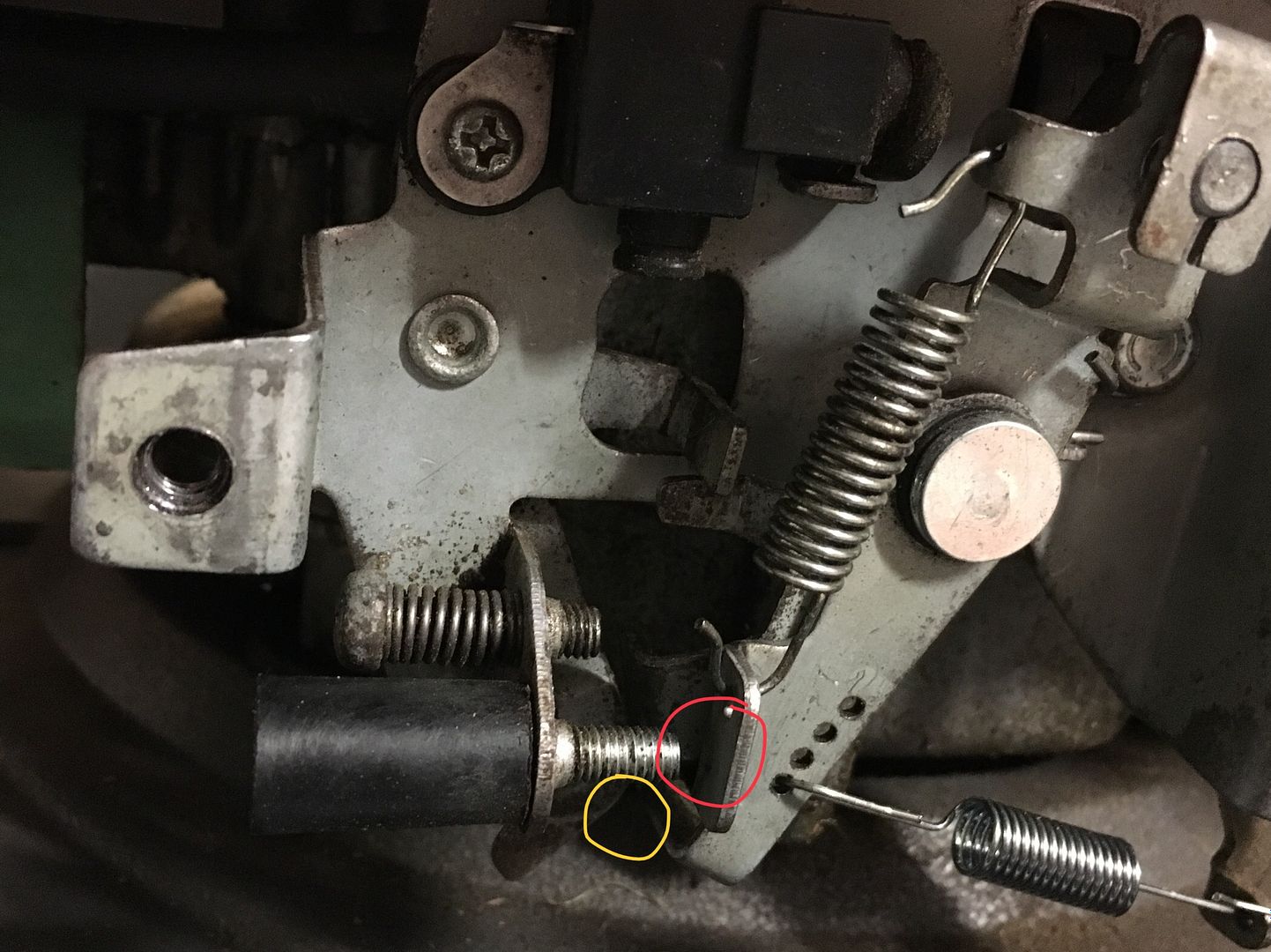

Full throttle position. I set this so that the choke mechanism just starts to engage. Red circle shows that the throttle stop is a long way from engaging. Yellow circle shows the lower arm of the choke mechanism is already engaging the throttle arm:

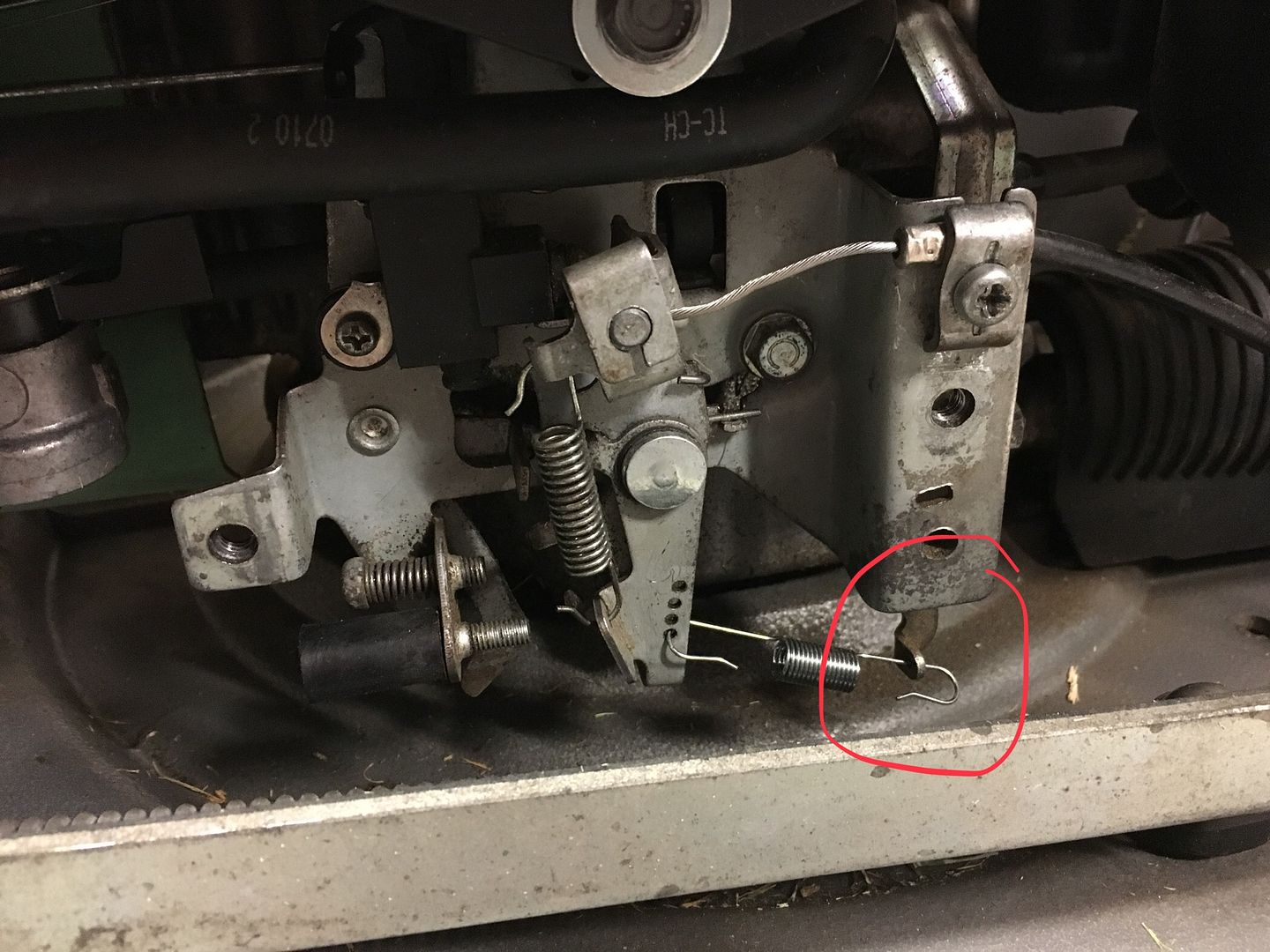

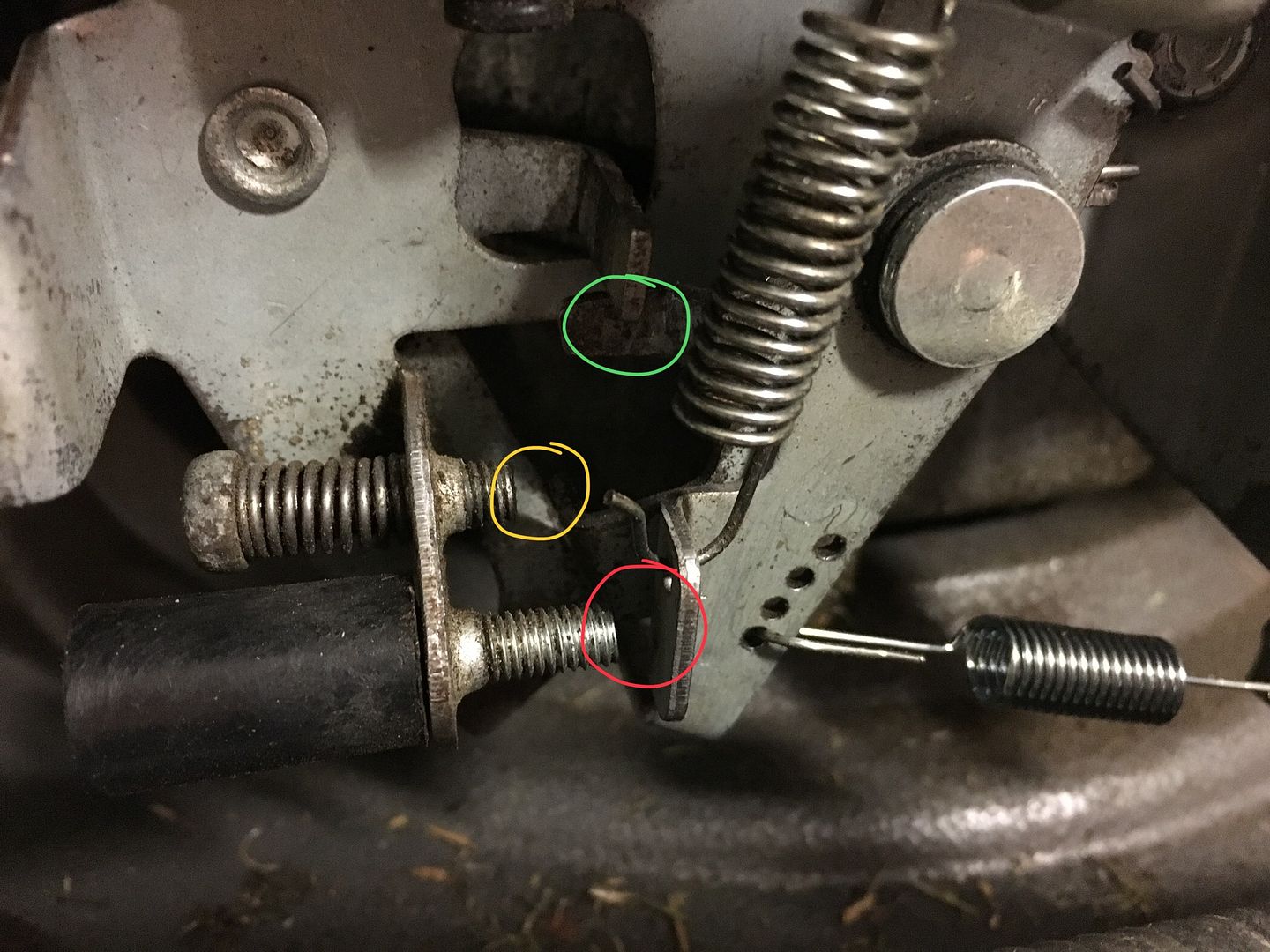

Choke at full. Choke butterfly is fully engaged in the carb but the choke stop (yellow) isn’t anywhere close to engaging the arm.

Maybe I’m over thinking it as the mower seems to run fine and should cut much better now the blades are on the right way!

The mower always fires first time and just on full throttle. Haven’t needed to use choke at all.

Pre filter has been removed, cleaned and put back. Bit damp so I’ll be dry easily by end of the day.

You wouldn’t have any idea how the throttle control plate should be setup too would you? Mine was bent when I got it and so I straightened it out but when I was looking at a new 216M2 in the shop yesterday it had the same setup but operated differently.

The difference is how the choke engages. On mine I have 2 levers that rub against each other as the choke engages. On the new one in the shop this acts as a stop at the end of the choke action (doesn’t rub).

Photos:

This is stop position:

Low speed throttle position. The one in the shop had the spring with no slack. Mine has slack:

Full throttle position. I set this so that the choke mechanism just starts to engage. Red circle shows that the throttle stop is a long way from engaging. Yellow circle shows the lower arm of the choke mechanism is already engaging the throttle arm:

Choke at full. Choke butterfly is fully engaged in the carb but the choke stop (yellow) isn’t anywhere close to engaging the arm.

Maybe I’m over thinking it as the mower seems to run fine and should cut much better now the blades are on the right way!

The mower always fires first time and just on full throttle. Haven’t needed to use choke at all.

Pre filter has been removed, cleaned and put back. Bit damp so I’ll be dry easily by end of the day.

#14

B

bertsmobile1

B

bertsmobile1

Something there is wrong there but I can not bring the correct set up to mind.

If that cable slides through the outer easily then it is the wrong cable or you are missing an adjuster at the handlebar end.

That cable build up water in the dip between the engine & handlebars and naturally rusts solid.

I replace a lot of them.

Lube it with Tri-Flow ( or similar ) from a push bike shop. Do not use WD 40 or oil as some of them are nylon linned and WD 40 softens the nylon.

Not enough stretch in the governor spring at full throttle which is why it seems to be running slow.

If that cable slides through the outer easily then it is the wrong cable or you are missing an adjuster at the handlebar end.

That cable build up water in the dip between the engine & handlebars and naturally rusts solid.

I replace a lot of them.

Lube it with Tri-Flow ( or similar ) from a push bike shop. Do not use WD 40 or oil as some of them are nylon linned and WD 40 softens the nylon.

Not enough stretch in the governor spring at full throttle which is why it seems to be running slow.

#15

N

neevo

N

neevo

I think the cables fine. It’s old I suspect but seems like the original one. It has the adjuster at the handlebars and catches perfectly in the lower cable holder.

Somethings not right with it. I’ll see how it cuts next time. If it doesn’t struggle I’ll forget it, if it continues to have issues I’ll need to revisit again.

Somethings not right with it. I’ll see how it cuts next time. If it doesn’t struggle I’ll forget it, if it continues to have issues I’ll need to revisit again.