You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Houston, we've got a problem

#1

S

send2den

S

send2den

2011 54" Fas Trac Super Duty w/26HP Kawasaki. Bought new in "11". Great mower. Love it. BUT. Last year it developed a problem with the electrical system. Started blowing the 10A safety circuit fuse during cranking. Actually it wouldn't even attempt to crank, it would just pop the fuse at key turn. My initial assumption is somewhere I'm shorting out. I've checked the wiring on the 10A side (physically, not with a meter) for pinches, cuts or any other abnormalities and see nothing. Had cut about 6 yards this year with no issue until again yesterday. Very intermittent in nature. Never know when it's gonna hit. I kinda think it happens more when the engine is hot and the mower has been stopped for a few minutes. That was the m.o. yesterday. I forgot to mow a patch, went back to get the mower back out of the garage and it popped at key turn. I know it's not a real good thing to do but I can pop in a 15A fuse in it's place and it will start. I've gone through 2 or 3 10A at a time trying to crank it when it starts, so I pop in a 15 and I at least get the job done. Don't like it, but what are you gonna do? The 10A circuit has a seat switch, clutch switch, neutral switch and some start relays. I really don't know where to start troubleshooting the thing with a meter. I guess my question here is twofold. 1) Any ideas on where/how to start T/Sing the wiring and 2) Anybody else here had that history or heard of that history with this particular mower? I'm going broke on fuses, but I need to get the damn thing figured out before I start burning something up. Thanks for ANY ideas.

#2

B

bertsmobile1

B

bertsmobile1

If it pops a fuse at the turn of the key you have a dead short.

It will be in one of the safety switches.

On start up power goes from the ignition switch, through the PTO switch through the brake switch then to the solenoid.

On a seperate circuit 12 V goes to the fuel shut off solenoid which can chaff and gets overlooked because it is not part of the starting circuit.

One of the five is giving you greif.

It will be in one of the safety switches.

On start up power goes from the ignition switch, through the PTO switch through the brake switch then to the solenoid.

On a seperate circuit 12 V goes to the fuel shut off solenoid which can chaff and gets overlooked because it is not part of the starting circuit.

One of the five is giving you greif.

#3

S

send2den

S

send2den

Thanks for the info bert. I think we are in agreement to it being a short, but if is it intermittent in nature can it be a "dead short"? If I were to take an ohms reading or check conductivity between 2 points in the circuit a dead short would be there always wouldn't it? Depending on when I check it, it may or may not show up. Maybe take and ohms reading between points (I have an electrical schematic) and giggle the wires or something? I've not done much electrical troubleshooting on lawn mower units. so is this something that I could try? The schematic goes like this 10A fuse (which runs in parallel to the 15A fuse circuit) >2wires come off the fuse in parallel (1 wire goes to the seat switch on out to the start relays) The other wire branching off from the fuse goes through a Clutch Switch (Is this what you are calling the PTO switch? It is involved with the 15A circuit) > to another switch which is not labeled on the schematic >a Neutral Switch> Same Start Relay >Starter solenoid. One thing I have actually thought about doing is going into the garage, turning out all the lights and have the ole lady turn the key switch and see if I can see a spark and where it is coming from.LOL. Hey, it might work. But as far as T/Sing, is that how you would advise to check? Point A to point B, maybe giggle a wire. Check to ground? Ohms out a switch? Relay? Also if my thinking about this happening when the mower is hot and tries to be restarted, could that be some sort of clue? Hey, just to check that theory and possibly give it more legs, I just went to the garage and cranked it. Started like a champ. It's been 8+ hours since I mowed with it. I'm really high right now on it being a "hot" mower condition, maybe 75% sure. Any other ideas are extremely appreciated.

#4

B

bertsmobile1

B

bertsmobile1

If you have a circuit diagram then please post it to the forum.

There is more than 1 tennor in this chior and it helps if we all sing from the same song sheet.

All of the switches are simple on off switches, either normally off or normally on.

Some with 4 wires have both types together in one switch and can go short internally.

What I do now is to locate all the switches and bypass each one with patch cords pluged into the sockets the switch nornally goes into.

I make these cords out of thin wire so if there is a dead short they just melt and do not do more damage to the wiring.

If the mower works OK then the problem is in one of the switches and if the problem persists the problem is in the wiring.

I feel you are harbouring more than one gremlin in your mower.

Ohm meters tend to give unreliable results and a big wattage test lamp works a lot better as it draws a bit of juice so wires that are just touching will give up the ghost.

I use that method on motorcycles using an old headlamp globe as you don't need to be watching the meter and can keep your eyes on where you are poking probes.

There is more than 1 tennor in this chior and it helps if we all sing from the same song sheet.

All of the switches are simple on off switches, either normally off or normally on.

Some with 4 wires have both types together in one switch and can go short internally.

What I do now is to locate all the switches and bypass each one with patch cords pluged into the sockets the switch nornally goes into.

I make these cords out of thin wire so if there is a dead short they just melt and do not do more damage to the wiring.

If the mower works OK then the problem is in one of the switches and if the problem persists the problem is in the wiring.

I feel you are harbouring more than one gremlin in your mower.

Ohm meters tend to give unreliable results and a big wattage test lamp works a lot better as it draws a bit of juice so wires that are just touching will give up the ghost.

I use that method on motorcycles using an old headlamp globe as you don't need to be watching the meter and can keep your eyes on where you are poking probes.

#5

S

send2den

S

send2den

Working on uploading the schematic file. In my technologically challenged world and given that I'm not a spring chicken anymore, this may take a while. I've got a pic, just got to get it cut to a size that this site can approve, yet not get too squeezed down that you can't see it. Bear with me. :laughing:

#6

S

send2den

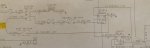

This is the best I could do on the schematic. Let's see if it even shows up.

Hey, it worked. I have no idea what the switch is that is on the top 10A wire just past the clutch switch. I'll have to investigate. Like bert says, there looks to be about 5 switches/relays that could be the issue, unless I got a pinched wire somewhere. I traced the wiring bundle down before and saw no abnormalities. This "hot mower" scenario should be a help, but not sure how a hot mower would cause the difference in the circuit between a short a not a short unless it is getting an insulation melt on a wire. I never smell anything. Could be totally off track with that line of thought, but it does seem to happen more on a hot mower after stopping. Guess I'll go to TSing this baby tomorrow.

Will just keep it here with the schematic.

Question 1) Should I show continuity on those 2 start relays between points 85 and 86? Both show resistence but not continuity. Is this normal?

S

send2den

This is the best I could do on the schematic. Let's see if it even shows up.

Hey, it worked. I have no idea what the switch is that is on the top 10A wire just past the clutch switch. I'll have to investigate. Like bert says, there looks to be about 5 switches/relays that could be the issue, unless I got a pinched wire somewhere. I traced the wiring bundle down before and saw no abnormalities. This "hot mower" scenario should be a help, but not sure how a hot mower would cause the difference in the circuit between a short a not a short unless it is getting an insulation melt on a wire. I never smell anything. Could be totally off track with that line of thought, but it does seem to happen more on a hot mower after stopping. Guess I'll go to TSing this baby tomorrow.

Will just keep it here with the schematic.

Question 1) Should I show continuity on those 2 start relays between points 85 and 86? Both show resistence but not continuity. Is this normal?

#7

S

send2den

S

send2den

bert or anybody else, do you know if I should be showing continuity between points 85 and 86 on the start relays? I have an ohms reading but no beep on my meter. Both the same.

So far have checked out the clutch switch contacts. OK. Seat switch. OK. They are all changing states and are showing continuity on the appropriate set of contacts when depressed/released. Still digging.

So far have checked out the clutch switch contacts. OK. Seat switch. OK. They are all changing states and are showing continuity on the appropriate set of contacts when depressed/released. Still digging.

#8

M

mechanic mark

M

mechanic mark

Intermittent problem, check all ground straps & cables by trying to move them by hand with force & see if one or more has vibrated loose.

Check for: failed carburetor solenoid diode, google: Hustler manuals, scroll down to Fastrac General Service Manual 121363 pages 7-1 & 2 for schematic.

Check for: failed carburetor solenoid diode, google: Hustler manuals, scroll down to Fastrac General Service Manual 121363 pages 7-1 & 2 for schematic.

#9

S

send2den

Will do mark. I pretty much went through the whole 10A circuit, checking for cut/pinched wires. Checked ignition switch, clutch switch, seat switch, both neutral switches (found out the one unmarked in the schematic is the right side, just not designated), both start relays, and wiring all around the starter and battery cables. One thing I did notice and don't know enough about it to say if it's no biggie or not, but a ground wire on the bottom of the starter. It runs from the small silver cannister which I assume is the starter solenoid, to the bigger black starter cannister which I assume is the other part of the starter. Anyway this ground looking wire is exposed and not insulated at all. Didn't know if this was normal or not. Bear with me guys, I'm still a learnin.lol. The thing started 3-4 times today as I moved it in the garage, but it never got hot. I went to the local Hustler guy in town and they really couldn't give me too much info other than to say they were $80.00 per hour labor if I wanted it fixed. I don't much care for that idea. lol. If I'm on the job, I can at worse case, pop a 15A in there to get it started, but I would rather not have to do that. If I can't figure this baby out, I may have to take her in and bite the bullet, this fall. Thanks for the input guys. If you can think of anything else to try, it would be much appreciated.

S

send2den

Intermittent problem, check all ground straps & cables by trying to move them by hand with force & see if one or more has vibrated loose.

Will do mark. I pretty much went through the whole 10A circuit, checking for cut/pinched wires. Checked ignition switch, clutch switch, seat switch, both neutral switches (found out the one unmarked in the schematic is the right side, just not designated), both start relays, and wiring all around the starter and battery cables. One thing I did notice and don't know enough about it to say if it's no biggie or not, but a ground wire on the bottom of the starter. It runs from the small silver cannister which I assume is the starter solenoid, to the bigger black starter cannister which I assume is the other part of the starter. Anyway this ground looking wire is exposed and not insulated at all. Didn't know if this was normal or not. Bear with me guys, I'm still a learnin.lol. The thing started 3-4 times today as I moved it in the garage, but it never got hot. I went to the local Hustler guy in town and they really couldn't give me too much info other than to say they were $80.00 per hour labor if I wanted it fixed. I don't much care for that idea. lol. If I'm on the job, I can at worse case, pop a 15A in there to get it started, but I would rather not have to do that. If I can't figure this baby out, I may have to take her in and bite the bullet, this fall. Thanks for the input guys. If you can think of anything else to try, it would be much appreciated.

#10

S

send2den

S

send2den

OK guys, I have a "lead". See what you think. I talked to a couple of people who were struck by the idea that my problem seemed more than likely happening on a "hot mower" condition. Had a few of them say to check the coils/wires because this is common. I pulled the wire off of 1 of 2 spark plugs and checked ohms while starting. The first plug I checked, the engine took some time to crank, but it did and I got the ohms reading (forget what it was right now, even though I wrote it down). Replaced it and did the same with the 2nd plug. The engine started pretty quickly and the ohms reading was a little different but nothing abnormally different. But here is where my "lead" comes from. As I reinstalled the front plug wire I noticed that it may have not been all the way seated. It's kinda in a bad place to get seated properly. I pushed on it extra hard and it "popped" into place. I'm like "SOB". Surely that wasn't it. I mowed the yard and let it sit for 15-20 minutes and tried cranking it again (which normally would blow a fuse) and it started right up. LOL. So my question is, do you guys think this is possible reason? Why during hot? Why the 10amp safety circuit fuse as opposed to the main 15amp fuse? Just because it pulls the whole system and the 10 amp gives up first? If this is it, will a loose ignition wire on a plug cause more amperage pull? I guess it probably does, but why not at initial start up? I'm thinking the little extra time to crank when the good wire to plug connection was pulled maybe explains it. It was relying on the loose wire to plug connection to start, thus a harder time cranking? What do you think? Fools Gold or is this a possibility. So far, it has worked once since finding.

#11

M

mechanic mark

M

mechanic mark

Good deal, pat yourself on the back. Plug wire connections are often overlooked. Next time you're in an auto parts store pick up a small tube of silicone dielectric grease for use on electrical parts, spark plug boots, etc.

https://www.amazon.com/Permatex-22058-Dielectric-Tune-Up-Grease/dp/B000AL8VD2 just an example

https://www.amazon.com/Permatex-22058-Dielectric-Tune-Up-Grease/dp/B000AL8VD2 just an example

#12

S

send2den

S

send2den

Thanks Mark. Just hoping this is the culprit. Just have to cut some more yards to find out I guess. This is the classic "Can't see the trees for the forest" scenario that I know all too well when dealing with electrical problems if it pans out to be correct. Won't be the first time I have looked like an idiot while TSing electrical problems, LOL. I will get some grease though. Excellent idea.

#13

S

send2den

S

send2den

OK, a year and a half later and I'm still here.LOL. Problem is still prevalent. Checked around town for hourly rates and decided on a guy here in town. These people deal with Hustler mowers and seem pretty reputable. Borrowed a trailer to get it over there. Explained the problem just like I have here on this site and let em have it. That was 4 weeks ago. Got a call today that my mower was ready. I asked the guy what they found as the culprit. Guy says they couldn't duplicate it. But they DID top off the fluids, c/o the fuel filter and put a new battery in it as they claim the battery was weak. The word from the tech was that the weak battery was probably the culprit of the fuse blowing. I thought "BS" but I didn't tell them "BS". I asked to talk to the tech, but they claimed he was elbow deep in hyd. oil and couldn't make it to the phone. He thought the weak battery was the culprit. LOL. Soooo, I ask the guy to ask the tech, if he ever changed out the 15amp fuse with the standard 10amp fuse when he tried to duplicate. The damn thing will start all day with the 15 amp fuse in it, so that would tell them nothing if they didn't change it to the original specced fuse. Guy couldn't remember. LOL.Sooooo, $150.00 and problem not solved. What more can a guy ask for? What I will do is probably take a 10 amp fuse with me. Check the mower when I get there. If it has the 15 amp fuse still in it I will really be pissed. I'll plug in the 10. load it up on the trailer, let it run while I go back in and shoot the sheet (warming up the mower). Go cut it off and try and restart. If it blows I'll have 2 options. Pack up and get the hell out of there or bring em out there and show em and say TRY AGAIN. Option 3 includes me keeping it on the trailer and trading it in on a new x series JD 4 wheel steer, I've been eyeballing. Gonna search threads here on that one. ANY ideas would be welcome at this point. Thanks.

#14

R

Rivets

R

Rivets

If you are sure that all wiring is in good condition and safety switches are good, I would get a new start relay and replace it, as relays can be affected by heat. If the problem still occurs, put the old relay back in and replace the kill relay. Replacing one relay at a time, just saves you buying two relays. I’ve only seen both relays going bad at the same time, once. If you want, you could just replace both from the start, just a little more $$$$. From your description, those are the only parts you are uncertain about. Spark plug wires have nothing to do with your problem, totally different electrical system, so cross that off as a possible cause. We both don’t know how the tech tried to solve the problem, but I would like to know if he tried different relays after bypassing the safety switches. This should not be a hard problem to solve, if the tech follows a good electrical troubleshooting procedure. Electrical troubleshooting can turn ones hair grey and cause one to drink, but with patience and a good understanding of electrical principles, plus a good procedure it can be done. If you like the unit, I would find the best electrical guy around, brand does not matter, and ask him if he would give it a try.

#15

S

send2den

S

send2den

Thanks rivets. May try that out after making sure the battery didn't solve the problem. LOL. Haven't yet figured out how I can say BS in a eloquent matter yet when I talk to them. Be nice if I could duplicate after I change the 15amp back to the 10 amp which I am just about sure they probably never even did. Could be wrong. Relays are fairly cheap. Friend of mine claims the 15 amp fuse in the safety circuit should not be a problem, but if it blows, it might be time to dive in again. Don't know if I can subscribe to that theory but he knows a hell of a lot more about outdoor equipment electric than I do.

#16

B

bertsmobile1

B

bertsmobile1

Yes , I am with Rivets on this one.

Forget about the mower shop and find an auto electrician.

One who only does repairs and does not sell air conditioning units , radios etc etc.

Take the wiring diagram with you and remind them that the cut out is a ground circuit .

Finding the correct wiring diagram is the hardest part.

They will have plenty of relays there to substitute with plus a lot better diagnostic gear and more experience in chasing up wiring problems.

Mower electrics & car electrics are exactly the same, except for the magneto ignition however a lot of emergency vehicles also ran a secondary magneto ignition system until the 90's, so an older technician should not have a problem with it.

I found a good one 30 miles away from my shop & he gets a lot of stuff from me to fix that is supposedly unrepairable.

Back before the flood of Chonda parts he had repaired at least 20 Honda starters for less than 10% of the replacement price.

The engine could have a 10A, 12A, 15 A, or 20A alternator depending upon which model got fitted so no a 15A fuse should not be a problem

Forget about the mower shop and find an auto electrician.

One who only does repairs and does not sell air conditioning units , radios etc etc.

Take the wiring diagram with you and remind them that the cut out is a ground circuit .

Finding the correct wiring diagram is the hardest part.

They will have plenty of relays there to substitute with plus a lot better diagnostic gear and more experience in chasing up wiring problems.

Mower electrics & car electrics are exactly the same, except for the magneto ignition however a lot of emergency vehicles also ran a secondary magneto ignition system until the 90's, so an older technician should not have a problem with it.

I found a good one 30 miles away from my shop & he gets a lot of stuff from me to fix that is supposedly unrepairable.

Back before the flood of Chonda parts he had repaired at least 20 Honda starters for less than 10% of the replacement price.

The engine could have a 10A, 12A, 15 A, or 20A alternator depending upon which model got fitted so no a 15A fuse should not be a problem

#17

S

send2den

S

send2den

Thanks Bert. I'll probably go over there today to talk with the manager or owner and tell them #1 I didn't necessarily run my unit in there to have "fluids topped off" or fuel filter changed out as well as a new battery, which seemed in good shape when I dropped it off. NONE of those things has a damn thing to do with fuses popping. #2 Ask them to just tell me the truth about not being able to find the problem. This "weak battery causing fuses to blow" is an insult to my intelligence and I'll never buy that as a viable option. #3 It was dropped off with the understanding that I was dealing with MORE THAN LIKELY an intermittent short somewhere in the electrical system and I wanted your guys to T/S, find and fix it. That's what I guess I'll say and I guess haul it the hell out of there. Check around for more people who can deal with this in my area. May even poke around on it some more if this weather here ever warms up a tad. 9 degrees right now, and my garage is not heated. What has happened here is the EXACT reason why I don't like taking my stuff to people to fix. This was my last alternative and was willing to just pay to have it fixed. I'm paying, but it's not fixed I am assuming.