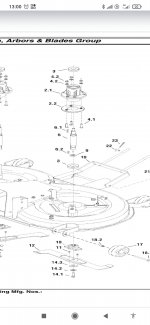

Not familiar with this particular assembly

However from the IPL I would get a short socket headed cap screw to replace the blade bolt

Flip the housing over and lay into the cap screw

If you can get your hands on a demolition hammer or air hammer the job will be a lot easier as the 10,000 + little taps a minute works a lot better and does a lot less damage than a massive big blow with a heavy hammer

I grind down one of the pointed tools to a flattish end that will go into the hole in the cap screw

The I lean heavy on the toll and pull the trigger

It is very important that the tool never looses contact with the surface or it will do what chisels do

In come really stubborn cases I have mounted the spindles & air hammer in my press and put about 1/2 ton on it before pulling the trigger.

Some can take days to get out but most will give up after an hour or so .

You can do the same from the top but to do it properly you need to put the nut back on or make a blind threaded hole is a block of steel and strike it to protect the end of the shaft

Some times all you can do is work both ends , hit the exposed shaft with a fine wire brush to polish it then flip the spindle over and do the same to the other end

I had some Ariens Zoom spindles that had to be done that way . Each flip only got about .020" to .040" more movement so it was an all night job.

Also beware that the bearings used in steel spindle housing are often C3 because they are an interfearance fit in the housing which you can do with steel & not with alloy housings.

I got caught out ( should have known better ) doing one a while back & the crush on the std bearings prevented the shaft spinning freely .