You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Briggs 17.5 HP, OHC Engine Locks Up!

#1

brchad

brchad

ENGINE:

Briggs & Stratton, 17.5 HP

31C707 3346 G6

Code: 110224ZB 23882

Just as an introduction, I'm 70 and have been working on small engines since I was 10 years old. My employment background was sales and maintenance for two different pump companies in the Petro-Chem market .... specialty engineered centrifugal pumps for hazardous liquids (canned motor pumps and magnetic drive pumps.) With all that said.... I'm totally baffled by this problem with a Briggs & Stratton one cylinder engine! I've run out of ideas!

I've had the typical problem that's so prevalent on the web: the ridiculous compression release system and was fortunate enough to run across your instructions for setting the valves at 1/4" past TDC compression stroke. That saved me from replacing the third intake push rod and I began checking valves .... sometimes twice per season.

In spite of all my maintenance efforts, I had used the mower, shut it down.... went to restart it a week later and got the "lock up" when starting with a good battery. I tried setting and checking the valves about 10 times before I took the engine off and opened the sump. Sure enough.... there was those pieces of the compression release mechanism in the bottom of the case.

I purchased a new camshaft and installed it per factory manual.... lining up timing marks, etc. When I mounted it on the mower, I tried turning it CW by hand. It turned several revolutions and then FROZE (CLANK) in one place. I pulled the sump back off and saw that the timing marks (Crankshaft and Camshaft) were aligned .... piston about half way down. Just jammed. I stripped the engine down to the short block (not removing connecting rod, piston, counterweights, etc.) including the head. Took the head off, tappets out, rods out, etc. (New oil all over everything by the way.) I inspected the Crankshaft timing gear... I see no visible signs of wear. (I have a new one on order anyway.)

This is NOT the compression release problem.... where the engine hits the compression stoke and it's difficult to turn. When I say FROZE .... I mean it's JAMMED.... and will not turn forward period. The only way to unlock it, is to use channel-lock the shaft and turn it backwards. Then, if it's moved CW again .... it locks up.

Here's a weird piece of information: If I put the Camshaft in a random position (out of time in other words) the engine turns CW freely and doesn't gall up. Very strange.

Any suggestions, ideas, wild guesses, etc. would be great.

Thanks

Briggs & Stratton, 17.5 HP

31C707 3346 G6

Code: 110224ZB 23882

Just as an introduction, I'm 70 and have been working on small engines since I was 10 years old. My employment background was sales and maintenance for two different pump companies in the Petro-Chem market .... specialty engineered centrifugal pumps for hazardous liquids (canned motor pumps and magnetic drive pumps.) With all that said.... I'm totally baffled by this problem with a Briggs & Stratton one cylinder engine! I've run out of ideas!

I've had the typical problem that's so prevalent on the web: the ridiculous compression release system and was fortunate enough to run across your instructions for setting the valves at 1/4" past TDC compression stroke. That saved me from replacing the third intake push rod and I began checking valves .... sometimes twice per season.

In spite of all my maintenance efforts, I had used the mower, shut it down.... went to restart it a week later and got the "lock up" when starting with a good battery. I tried setting and checking the valves about 10 times before I took the engine off and opened the sump. Sure enough.... there was those pieces of the compression release mechanism in the bottom of the case.

I purchased a new camshaft and installed it per factory manual.... lining up timing marks, etc. When I mounted it on the mower, I tried turning it CW by hand. It turned several revolutions and then FROZE (CLANK) in one place. I pulled the sump back off and saw that the timing marks (Crankshaft and Camshaft) were aligned .... piston about half way down. Just jammed. I stripped the engine down to the short block (not removing connecting rod, piston, counterweights, etc.) including the head. Took the head off, tappets out, rods out, etc. (New oil all over everything by the way.) I inspected the Crankshaft timing gear... I see no visible signs of wear. (I have a new one on order anyway.)

This is NOT the compression release problem.... where the engine hits the compression stoke and it's difficult to turn. When I say FROZE .... I mean it's JAMMED.... and will not turn forward period. The only way to unlock it, is to use channel-lock the shaft and turn it backwards. Then, if it's moved CW again .... it locks up.

Here's a weird piece of information: If I put the Camshaft in a random position (out of time in other words) the engine turns CW freely and doesn't gall up. Very strange.

Any suggestions, ideas, wild guesses, etc. would be great.

Thanks

#2

EngineMan

I would remove the piston with connecting rod then see if you can turn it over without problems, if still jammed remove the camshaft and try again, (that is if you already haven't done so) if still jammed remove the push rods and try again, remove one item at a time that way hopefully you see where the problem is. (before removing the piston put a mark on it and on the top of the cylinder) am sure you know anyway. come back with your findings..!

EngineMan

ENGINE:

Briggs & Stratton, 17.5 HP

31C707 3346 G6

Code: 110224ZB 23882

Just as an introduction, I'm 70 and have been working on small engines since I was 10 years old. My employment background was sales and maintenance for two different pump companies in the Petro-Chem market .... specialty engineered centrifugal pumps for hazardous liquids (canned motor pumps and magnetic drive pumps.) With all that said.... I'm totally baffled by this problem with a Briggs & Stratton one cylinder engine! I've run out of ideas!

I've had the typical problem that's so prevalent on the web: the ridiculous compression release system and was fortunate enough to run across your instructions for setting the valves at 1/4" past TDC compression stroke. That saved me from replacing the third intake push rod and I began checking valves .... sometimes twice per season.

In spite of all my maintenance efforts, I had used the mower, shut it down.... went to restart it a week later and got the "lock up" when starting with a good battery. I tried setting and checking the valves about 10 times before I took the engine off and opened the sump. Sure enough.... there was those pieces of the compression release mechanism in the bottom of the case.

I purchased a new camshaft and installed it per factory manual.... lining up timing marks, etc. When I mounted it on the mower, I tried turning it CW by hand. It turned several revolutions and then FROZE (CLANK) in one place. I pulled the sump back off and saw that the timing marks (Crankshaft and Camshaft) were aligned .... piston about half way down. Just jammed. I stripped the engine down to the short block (not removing connecting rod, piston, counterweights, etc.) including the head. Took the head off, tappets out, rods out, etc. (New oil all over everything by the way.) I inspected the Crankshaft timing gear... I see no visible signs of wear. (I have a new one on order anyway.)

This is NOT the compression release problem.... where the engine hits the compression stoke and it's difficult to turn. When I say FROZE .... I mean it's JAMMED.... and will not turn forward period. The only way to unlock it, is to use channel-lock the shaft and turn it backwards. Then, if it's moved CW again .... it locks up.

Here's a weird piece of information: If I put the Camshaft in a random position (out of time in other words) the engine turns CW freely and doesn't gall up. Very strange.

Any suggestions, ideas, wild guesses, etc. would be great.

Thanks

I would remove the piston with connecting rod then see if you can turn it over without problems, if still jammed remove the camshaft and try again, (that is if you already haven't done so) if still jammed remove the push rods and try again, remove one item at a time that way hopefully you see where the problem is. (before removing the piston put a mark on it and on the top of the cylinder) am sure you know anyway. come back with your findings..!

#3

brchad

EngineMan -

Thank you for your response. I think we are on the same page regarding the process of troubleshooting mechanical equipment. For me, the three most important steps of the process are: 1.) Make sure you fully understand the nature of the problem... symptoms, timing, etc. 2) Double check ALL assumptions. (False assumptions can spoil and chance of success.) 3.) Investigate by process of elimination. What follows is a list, beginning with the occurrence of the problem to where I am as of now:

1. A couple or three years back.... while mowing (Troy-Bilt) the engine simply stopped. Simple investigation determined that the intake push rod was broken. I replaced the rod, set the valves but when trying to start, the engine would begin to turn and then lug. In short.... this is when I learned about what I see as a pathetic compression release system.... that I'm sure you are familiar with. (I couldn't believe that B&S had actually allowed that design on the market.) After resetting the valves at the 1/4 off TDC mark.... I was off and running. I then began to check the valve settings at least one or two times per season.

2. A few weeks ago.... I had the same experience.... this time it had run fine and I shut it down after mowing. When I tried to start it a week or so later.... lug again just as before. I first checked the battery (almost new), cables etc. Nope. So I immediately checked the valve settings. They seemed like perhaps they were a tad off.... so I reset them... again using the 1/4" off TDC. I set them perhaps 8 times. Still no luck.

3. Having read previously about the compression release system problems with the cam, I pulled the engine, removed the sump .... and BINGO .... there were the notorious broken pieces of the timing "spring lever" in the bottom of the case. I removed the cam.... and saw where the lever used to belong. I ordered a new cam, gaskets, etc.

4. While waiting for the parts, I thoroughly flushed the case with oil. I had kept the broken pieces, making sure I could account for any missing pieces that may have logged somewhere. Flushed the engine a second time and mopped it completely. Bear in mind that prior to this point... the starter would easily rotate the engine freely when the spark plug removed and by hand. When I installed the new cam.... I followed normal procedure to install and time.... cam and crankshaft gear timing marks lined up. This part may be critical: I noted that my attempt to place the crankshaft with the timing mark pointing toward the centerline of where the cam shaft goes .... I found it impossible to simply drop (wiggle) the cam into place. It was necessary to turn the crankshaft (CW when looking down at the flywheel) somewhat .... and offsetting the cam so that after it was installed and rotated, the timing marks would line up.

5. When everything looked all good.... having replaced and checked the governor setting .... new gasket, new seal .... lubed everything ... dropped the sump on .... wiggled the crankshaft and the sump fell into place. After having it all buttoned up was when I discovered that it would rotate (CW) somewhat.... then a CLANK ... and stop. If I rotated it backwards with channel locks it would break free. Regardless of how far I turned it in reverse.... it would still CLANK in the same place.

6. I removed the sump cover while the shaft was in the jammed position.... and noted that it was exactly when the timing marks were aligned.

7. At this point I began the process of elimination as noted in my original post. First removed the cam, of course.... and all turned fine without the cam. Replaced the cam.... CLANK. Removed the cam again... removed the rocker arms, push rods from the head and the valve tappets from the case. Everything still totally free with no cam. Installed the cam .... CLANK. I removed the head to watch the piston and movement appeared normal. (The head had the typical and expected amount of grime, easily removed and cleaned.)

8. I removed and inspected the crank shaft timing gear. It showed no visible signs of wear. Not assuming it was good.... sometimes it's difficult to see or feel a faulty part .... I ordered a new one, which will be arriving on Monday.

So... that is where I am in the process as of now. I will say that I seriously doubt that the new crankshaft timing gear will solve the problem.... but that's just an assumption! LOL!!

Again.... thank you for the response. One final step in my process came after fighting it for years. Don't be too proud to solicit advice! I continue to welcome ANY and ALL questions, comments or potential solutions.

Regards,

Bill

brchad

I would remove the piston with connecting rod then see if you can turn it over without problems, if still jammed remove the camshaft and try again, (that is if you already haven't done so) if still jammed remove the push rods and try again, remove one item at a time that way hopefully you see where the problem is. (before removing the piston put a mark on it and on the top of the cylinder) am sure you know anyway. come back with your findings..!

EngineMan -

Thank you for your response. I think we are on the same page regarding the process of troubleshooting mechanical equipment. For me, the three most important steps of the process are: 1.) Make sure you fully understand the nature of the problem... symptoms, timing, etc. 2) Double check ALL assumptions. (False assumptions can spoil and chance of success.) 3.) Investigate by process of elimination. What follows is a list, beginning with the occurrence of the problem to where I am as of now:

1. A couple or three years back.... while mowing (Troy-Bilt) the engine simply stopped. Simple investigation determined that the intake push rod was broken. I replaced the rod, set the valves but when trying to start, the engine would begin to turn and then lug. In short.... this is when I learned about what I see as a pathetic compression release system.... that I'm sure you are familiar with. (I couldn't believe that B&S had actually allowed that design on the market.) After resetting the valves at the 1/4 off TDC mark.... I was off and running. I then began to check the valve settings at least one or two times per season.

2. A few weeks ago.... I had the same experience.... this time it had run fine and I shut it down after mowing. When I tried to start it a week or so later.... lug again just as before. I first checked the battery (almost new), cables etc. Nope. So I immediately checked the valve settings. They seemed like perhaps they were a tad off.... so I reset them... again using the 1/4" off TDC. I set them perhaps 8 times. Still no luck.

3. Having read previously about the compression release system problems with the cam, I pulled the engine, removed the sump .... and BINGO .... there were the notorious broken pieces of the timing "spring lever" in the bottom of the case. I removed the cam.... and saw where the lever used to belong. I ordered a new cam, gaskets, etc.

4. While waiting for the parts, I thoroughly flushed the case with oil. I had kept the broken pieces, making sure I could account for any missing pieces that may have logged somewhere. Flushed the engine a second time and mopped it completely. Bear in mind that prior to this point... the starter would easily rotate the engine freely when the spark plug removed and by hand. When I installed the new cam.... I followed normal procedure to install and time.... cam and crankshaft gear timing marks lined up. This part may be critical: I noted that my attempt to place the crankshaft with the timing mark pointing toward the centerline of where the cam shaft goes .... I found it impossible to simply drop (wiggle) the cam into place. It was necessary to turn the crankshaft (CW when looking down at the flywheel) somewhat .... and offsetting the cam so that after it was installed and rotated, the timing marks would line up.

5. When everything looked all good.... having replaced and checked the governor setting .... new gasket, new seal .... lubed everything ... dropped the sump on .... wiggled the crankshaft and the sump fell into place. After having it all buttoned up was when I discovered that it would rotate (CW) somewhat.... then a CLANK ... and stop. If I rotated it backwards with channel locks it would break free. Regardless of how far I turned it in reverse.... it would still CLANK in the same place.

6. I removed the sump cover while the shaft was in the jammed position.... and noted that it was exactly when the timing marks were aligned.

7. At this point I began the process of elimination as noted in my original post. First removed the cam, of course.... and all turned fine without the cam. Replaced the cam.... CLANK. Removed the cam again... removed the rocker arms, push rods from the head and the valve tappets from the case. Everything still totally free with no cam. Installed the cam .... CLANK. I removed the head to watch the piston and movement appeared normal. (The head had the typical and expected amount of grime, easily removed and cleaned.)

8. I removed and inspected the crank shaft timing gear. It showed no visible signs of wear. Not assuming it was good.... sometimes it's difficult to see or feel a faulty part .... I ordered a new one, which will be arriving on Monday.

So... that is where I am in the process as of now. I will say that I seriously doubt that the new crankshaft timing gear will solve the problem.... but that's just an assumption! LOL!!

Again.... thank you for the response. One final step in my process came after fighting it for years. Don't be too proud to solicit advice! I continue to welcome ANY and ALL questions, comments or potential solutions.

Regards,

Bill

#4

EngineMan

EngineMan

When you go to put it back together refit the camshaft and remove the head and leave the push rods out, then try to see if you turn it in both directions, if so refit the push rods and head and try again, am thinking maybe the push rod(s) lifting too far up and pushing the valves or valve too far out and hitting the piston, so it maybe a wrong size push rod..!, try it with the arm-rockers off, come back and let us know. good-luck.

"6. I removed the sump cover while the shaft was in the jammed position.... and noted that it was exactly when the timing marks were aligned."

This would be near or at TDC

"6. I removed the sump cover while the shaft was in the jammed position.... and noted that it was exactly when the timing marks were aligned."

This would be near or at TDC

#5

Boobala

Boobala

Bill I am NOT doubting your competence or abilities OR that of anyone else posting on this thread, I expect you have the Briggs O/H manual, if not, here it is ........

https://drive.google.com/file/d/0B6NaqjIxWV1ybEN0LWo3azl6OUU/view

Hope you fix the issue and keep us posted.... Boobala

https://drive.google.com/file/d/0B6NaqjIxWV1ybEN0LWo3azl6OUU/view

Hope you fix the issue and keep us posted.... Boobala

#7

brchad

Thanks EngineMan -

I double checked the push rods.... same as the old ones.... same part number, etc. I already removed the head.... so no push rods.... no tappets. Still the same problem. So I can clearly see where the piston is. You did provide a clue here. Indeed, the timing marks are aligned, but I need to double check the piston position in the locked position with timing marks aligned. If I remember correctly, it is not at TDC .... but I have to double check. I'm not able to do it now... but will check it tomorrow after church and report back in early afternoon.

Thanks!

Bill

brchad

When you go to put it back together refit the camshaft and remove the head and leave the push rods out, then try to see if you turn it in both directions, if so refit the push rods and head and try again, am thinking maybe the push rod(s) lifting too far up and pushing the valves or valve too far out and hitting the piston, so it maybe a wrong size push rod..!, try it with the arm-rockers off, come back and let us know. good-luck.

"6. I removed the sump cover while the shaft was in the jammed position.... and noted that it was exactly when the timing marks were aligned."

This would be near or at TDC

Thanks EngineMan -

I double checked the push rods.... same as the old ones.... same part number, etc. I already removed the head.... so no push rods.... no tappets. Still the same problem. So I can clearly see where the piston is. You did provide a clue here. Indeed, the timing marks are aligned, but I need to double check the piston position in the locked position with timing marks aligned. If I remember correctly, it is not at TDC .... but I have to double check. I'm not able to do it now... but will check it tomorrow after church and report back in early afternoon.

Thanks!

Bill

#8

brchad

brchad

Boobala,

Hey.... my wife of 47 years doubts my competence and/or abilities all the time! I try to make it a point not to work when she is around!

Yes... thanks... I DO have the manual ... but thanks for the link. I'll check to see if it's the same version/revision, etc.

I appreciate the help.

Bill

Hey.... my wife of 47 years doubts my competence and/or abilities all the time! I try to make it a point not to work when she is around!

Yes... thanks... I DO have the manual ... but thanks for the link. I'll check to see if it's the same version/revision, etc.

I appreciate the help.

Bill

#9

brchad

All new gaskets.... all in place.

Thanks,

Bill

brchad

Check for all gaskets to be in place. Could be one not installed so not enough clearance.

All new gaskets.... all in place.

Thanks,

Bill

#10

brchad

Boobala -

Not to worry. My wife of 47 years doubts my competence and/or ability all the time. I make sure to work when she isn't around. LOL!

I do have the manual.... but I'll check to see if I have the current version.

Thanks,

Bill

brchad

Bill I am NOT doubting your competence or abilities OR that of anyone else posting on this thread, I expect you have the Briggs O/H manual, if not, here it is ........

https://drive.google.com/file/d/0B6NaqjIxWV1ybEN0LWo3azl6OUU/view

Hope you fix the issue and keep us posted.... Boobala

Boobala -

Not to worry. My wife of 47 years doubts my competence and/or ability all the time. I make sure to work when she isn't around. LOL!

I do have the manual.... but I'll check to see if I have the current version.

Thanks,

Bill

#12

B

bertsmobile1

B

bertsmobile1

Check the counterweight and the counterweight con rod.

It is in 2 pieces with a single bolt that can shear or bend or come loose.

In fact I see more counter weight failures than crank failures

Also check there is not a little piece of the compression release stuck in the counterweight.

You also could have had a small piece of metal lodge in the gear teeth

It is in 2 pieces with a single bolt that can shear or bend or come loose.

In fact I see more counter weight failures than crank failures

Also check there is not a little piece of the compression release stuck in the counterweight.

You also could have had a small piece of metal lodge in the gear teeth

#13

brchad

EngineMan -

Not sure I understand the question. At this point....as I said .... the engine is almost totally apart. The head is off.... the rods are out .... the tappets are removed. Did I miss something?

Per your earlier suggestion.... I will be checking shortly to verify the position of the piston when it jams.

Thanks,

Bill

brchad

That's fine.....so could a valve be open when the piston is at TDC..? (timing out)

EngineMan -

Not sure I understand the question. At this point....as I said .... the engine is almost totally apart. The head is off.... the rods are out .... the tappets are removed. Did I miss something?

Per your earlier suggestion.... I will be checking shortly to verify the position of the piston when it jams.

Thanks,

Bill

#14

brchad

berts -

Thank you. I had briefly "studied" the counterweight early on... but it certainly could be one of those faulty presumptions I mentioned earlier. That also applies to the potential of a counterweight piece stuck in the counterweight. If there's a small piece lodged in the gear teeth.... it would have to be microscopic .... I checked and cleaned it. (I will still be getting the new one tomorrow, just to be sure.)

I'll be getting back to you shortly on the first two points.

Bill

brchad

Check the counterweight and the counterweight con rod.

It is in 2 pieces with a single bolt that can shear or bend or come loose.

In fact I see more counter weight failures than crank failures

Also check there is not a little piece of the compression release stuck in the counterweight.

You also could have had a small piece of metal lodge in the gear teeth

berts -

Thank you. I had briefly "studied" the counterweight early on... but it certainly could be one of those faulty presumptions I mentioned earlier. That also applies to the potential of a counterweight piece stuck in the counterweight. If there's a small piece lodged in the gear teeth.... it would have to be microscopic .... I checked and cleaned it. (I will still be getting the new one tomorrow, just to be sure.)

I'll be getting back to you shortly on the first two points.

Bill

#15

brchad

brchad

Well guys.... it's NOT the crank gear. Installed the new one.... still locking up.

Looks like the next step is bertsmobile1's suggestion to check the counterweight system.

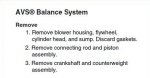

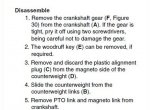

Unfortunately, my engine has the AVS Balance System.... so that means the counterweight bolt is located on the flywheel end. That means I'll have to pull the flywheel in order to access the bolt.

Tomorrow morning I am scheduled to have some pretty extensive oral surgery. (6-8 teeth pulled) Yuck!! So.... I have no idea how long it will be until I am able to get back into the engine.

In the meantime.... I want to thank everyone again for all of your suggestions and assistance. I'll be back to you as soon as I can eat Ice-cream!

Bill

Looks like the next step is bertsmobile1's suggestion to check the counterweight system.

Unfortunately, my engine has the AVS Balance System.... so that means the counterweight bolt is located on the flywheel end. That means I'll have to pull the flywheel in order to access the bolt.

Tomorrow morning I am scheduled to have some pretty extensive oral surgery. (6-8 teeth pulled) Yuck!! So.... I have no idea how long it will be until I am able to get back into the engine.

In the meantime.... I want to thank everyone again for all of your suggestions and assistance. I'll be back to you as soon as I can eat Ice-cream!

Bill

#16

brchad

brchad

UPDATE: Re: Briggs 17.5 HP, OHC Engine Locks Up!

Well, I survived my "Death by Dentist" experience and I was able to continue this "Engine Locks Up" adventure today.

Here is where I stand at this point:

As I mentioned earlier, I do believe that bertmobile1's suggestion to remove and inspect the counterbalance system (along with piston/rod in the process.)

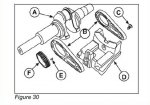

There are two different types of counterbalance systems for the 31C707 series. Earlier models use what B&S calls the "Synchro-Balance System" which is accessible by merely removing the bolt from the sump end. Later models utilize what B&S calls the "AVS System" which is somewhat more involved, since it requires removal of the flywheel. Of course.... my engine has the "AVS System!"

(Click thumbnail to enlarge)

The flywheel was a challenge (most are) but using a combination of different "tricks" I was able to pop it up and off without too much trouble. The next step was removal of the Connecting Rod bolts and cap. This is where I ran into a real challenge. I quickly realized that the bolts, with a round head, were torque bolts .... a T-40. I didn't have a decent T-40, so bought a new, good quality, 3/8"-T40. I noted that the torque spec for the bolt is 150 lb-in, so didn't expect it to be too difficult. WRONG!!! The first one was a real surprise. I started with a long handle ratchet ... and quickly saw that it was fruitless! I changed to a long pull bar and after a real struggle.... managed to crack it loose. The second one was even worse. I tried every trick in my bag to get that sucker off and nothing worked. I've worked on every size of engine... up to big block V-8's .... and NEVER ran across a bolt that tight.

I'm betting most of you can guess the outcome. Yep..... ace mechanic here, eventually, succeeded in buggering up the bolt head to the point where NO wrench is going to loosen it now!

So.... here I am ... back for more advice, suggestions, etc. I thought about vise grips... real tight .... pop with a mall. Alas, not able to get a firm grip with the vise grips. All I've been able to come up with is perhaps grinding off the bolt head.... sacrificing the rod, etc.

Any other ideas anyone? Again.... thanks for your help thus far!

Bill

Well, I survived my "Death by Dentist" experience and I was able to continue this "Engine Locks Up" adventure today.

Here is where I stand at this point:

As I mentioned earlier, I do believe that bertmobile1's suggestion to remove and inspect the counterbalance system (along with piston/rod in the process.)

There are two different types of counterbalance systems for the 31C707 series. Earlier models use what B&S calls the "Synchro-Balance System" which is accessible by merely removing the bolt from the sump end. Later models utilize what B&S calls the "AVS System" which is somewhat more involved, since it requires removal of the flywheel. Of course.... my engine has the "AVS System!"

(Click thumbnail to enlarge)

The flywheel was a challenge (most are) but using a combination of different "tricks" I was able to pop it up and off without too much trouble. The next step was removal of the Connecting Rod bolts and cap. This is where I ran into a real challenge. I quickly realized that the bolts, with a round head, were torque bolts .... a T-40. I didn't have a decent T-40, so bought a new, good quality, 3/8"-T40. I noted that the torque spec for the bolt is 150 lb-in, so didn't expect it to be too difficult. WRONG!!! The first one was a real surprise. I started with a long handle ratchet ... and quickly saw that it was fruitless! I changed to a long pull bar and after a real struggle.... managed to crack it loose. The second one was even worse. I tried every trick in my bag to get that sucker off and nothing worked. I've worked on every size of engine... up to big block V-8's .... and NEVER ran across a bolt that tight.

I'm betting most of you can guess the outcome. Yep..... ace mechanic here, eventually, succeeded in buggering up the bolt head to the point where NO wrench is going to loosen it now!

So.... here I am ... back for more advice, suggestions, etc. I thought about vise grips... real tight .... pop with a mall. Alas, not able to get a firm grip with the vise grips. All I've been able to come up with is perhaps grinding off the bolt head.... sacrificing the rod, etc.

Any other ideas anyone? Again.... thanks for your help thus far!

Bill

#17

I

ILENGINE

I

ILENGINE

Had one in the shop several years ago that did the exact same thing. Had to grind the head of the bolt off to get it apart. I now have some of those twisted spline looking bolt extractors, so maybe something like that would grip the rounded head and get it free.

#18

brchad

Checked on Google.... made a 5 minute drive to Advanced Auto and purchased the kit for $17.00:

https://shop.advanceautoparts.com/p/irwin-bolt-out-with-case-394001/9010233-P?searchTerm=bolt+extractor

Here's what the actual extractor looks like:

Attached the 1/2" extractor to my pull bar.... snugged it into place on the connector bolt.... a TAH DAH!! Popped loose with about a quarter turn!

Kudos to you ILENGINE!! Just goes to show you.... us old farts need to stay informed on new technology! LOL!!

Thanks a ton for the tip! Now.... back to work to see what else I can try to break! Ha!

Bill

brchad

Had one in the shop several years ago that did the exact same thing. Had to grind the head of the bolt off to get it apart. I now have some of those twisted spline looking bolt extractors, so maybe something like that would grip the rounded head and get it free.

Checked on Google.... made a 5 minute drive to Advanced Auto and purchased the kit for $17.00:

https://shop.advanceautoparts.com/p/irwin-bolt-out-with-case-394001/9010233-P?searchTerm=bolt+extractor

Here's what the actual extractor looks like:

Attached the 1/2" extractor to my pull bar.... snugged it into place on the connector bolt.... a TAH DAH!! Popped loose with about a quarter turn!

Kudos to you ILENGINE!! Just goes to show you.... us old farts need to stay informed on new technology! LOL!!

Thanks a ton for the tip! Now.... back to work to see what else I can try to break! Ha!

Bill

#19

I

ILENGINE

I

ILENGINE

That is the tool I was thinking of. Comes in handy when you need them. I have used my set to remove more than one allen head bolt on the camshaft cover of yamaha atv's and the lug nuts on an arctic cat atv. Seems like there has been other uses that I can't think of right now.

#20

brchad

brchad

UPDATE - Re: Briggs 17.5 HP, OHC Engine Locks Up!

Well... I now have the entire engine in parts!

I was pleasantly surprised at what I found. The piston/rings/rod were all in excellent shape. More importantly.... the crankshaft journals, throughout, were like new... no discoloration.... nice and smooth with minimal detectable wear.

Here's the good news.... arising from the bad. Inspection of the AVS counterbalance assembly was a different story. At first glance, I couldn't imagine that anything was wrong. WRONG! Upon closer inspection, the PTO side Counterweight Link appeared loose... and when I tried to rotate it on the crank, it would gall up in places. The one on the Flywheel end turned freely. When I removed the one on the PTO side, I immediately noted that the pin was discolored (black burn/wear marks) while the other side was nice and clean. My assumption at this point is that the pin and the link are both bad. This could certainly account for the "lock up" that brought me this far!

I ordered new Counterweight Links and Pins for both sides.... along with the two Connecting Rod bolts that were ruined... seals, gaskets, etc.

Thanks again to all who have helped me here. I really appreciate it.

The parts arrive on Thursday. I'll be back with the news sometime soon after.

Bill

Well... I now have the entire engine in parts!

I was pleasantly surprised at what I found. The piston/rings/rod were all in excellent shape. More importantly.... the crankshaft journals, throughout, were like new... no discoloration.... nice and smooth with minimal detectable wear.

Here's the good news.... arising from the bad. Inspection of the AVS counterbalance assembly was a different story. At first glance, I couldn't imagine that anything was wrong. WRONG! Upon closer inspection, the PTO side Counterweight Link appeared loose... and when I tried to rotate it on the crank, it would gall up in places. The one on the Flywheel end turned freely. When I removed the one on the PTO side, I immediately noted that the pin was discolored (black burn/wear marks) while the other side was nice and clean. My assumption at this point is that the pin and the link are both bad. This could certainly account for the "lock up" that brought me this far!

I ordered new Counterweight Links and Pins for both sides.... along with the two Connecting Rod bolts that were ruined... seals, gaskets, etc.

Thanks again to all who have helped me here. I really appreciate it.

The parts arrive on Thursday. I'll be back with the news sometime soon after.

Bill

#21

B

bertsmobile1

B

bertsmobile1

Sounds about right.

Counterweights outnumber rod failures about 4 : 1.

Good to ear you are getting somewhere.

However please do us a favour and don't quit your current job for open heart surgury :laughing:

Counterweights outnumber rod failures about 4 : 1.

Good to ear you are getting somewhere.

However please do us a favour and don't quit your current job for open heart surgury :laughing:

#22

brchad

brchad

#23

brchad

brchad

Sorry it's been a while since I reported back.... but I haven't had much time to work on the "Bloody Briggs" until the last few days.

Here's where we stand at the moment. GOOD NEWS!! The engine is assembled.... mounted to the mower. (The new lower seal... NOT leaking oil ... always my fear!) but MOST of all... the engine rotates freely... and the valve decompression (cam) is WORKING! YEAH!!! I should have the full results soon.

In the meantime.... I think I missed one STEP in my sage advice in an earlier post: "For me, the three most important steps of the process are: 1.) Make sure you fully understand the nature of the problem... symptoms, timing, etc. 2) Double check ALL assumptions. (False assumptions can spoil and chance of success.) 3.) Investigate by process of elimination."

I should have added another step: 4.) Make sure to remember where "things" came from.... so you can put them back in the same place! :ashamed:

I have the wiring harness all attached correctly.... not a big deal, right? There are two wires (clipped together) that run under the engine (I think). One actually branches off to TWO wires... one with a circular ground connection and a plastic connector. I know for certain where the ground connection goes.... and I know that the other plastic one goes to the carb shutoff. I'm damned if I can figure out where the other one goes.

The "other one" is a BLACK wire... with a two-wire white plastic connector. SHEESH! I've looked everywhere (forget B&S manual) ..... does ANYONE know what that wire is... and where it goes?

Thanks!

Bill (Thankfully NOT doing open heart surgery!)

Anyone know how this part "Intake Manifold Gasket 79608" fits.... or what it's for? It was installed "as built" when new.... but does that mean it actually belongs there.... or that it was installed correctly. If it does belong... I would assume that the manifold o-ring would need to seat onto the metal side and the gasket side to the intake? Again... forget about the manual... if it's in there.... I haven't found it.

Here's where we stand at the moment. GOOD NEWS!! The engine is assembled.... mounted to the mower. (The new lower seal... NOT leaking oil ... always my fear!) but MOST of all... the engine rotates freely... and the valve decompression (cam) is WORKING! YEAH!!! I should have the full results soon.

In the meantime.... I think I missed one STEP in my sage advice in an earlier post: "For me, the three most important steps of the process are: 1.) Make sure you fully understand the nature of the problem... symptoms, timing, etc. 2) Double check ALL assumptions. (False assumptions can spoil and chance of success.) 3.) Investigate by process of elimination."

I should have added another step: 4.) Make sure to remember where "things" came from.... so you can put them back in the same place! :ashamed:

I have the wiring harness all attached correctly.... not a big deal, right? There are two wires (clipped together) that run under the engine (I think). One actually branches off to TWO wires... one with a circular ground connection and a plastic connector. I know for certain where the ground connection goes.... and I know that the other plastic one goes to the carb shutoff. I'm damned if I can figure out where the other one goes.

The "other one" is a BLACK wire... with a two-wire white plastic connector. SHEESH! I've looked everywhere (forget B&S manual) ..... does ANYONE know what that wire is... and where it goes?

Thanks!

Bill (Thankfully NOT doing open heart surgery!)

Anyone know how this part "Intake Manifold Gasket 79608" fits.... or what it's for? It was installed "as built" when new.... but does that mean it actually belongs there.... or that it was installed correctly. If it does belong... I would assume that the manifold o-ring would need to seat onto the metal side and the gasket side to the intake? Again... forget about the manual... if it's in there.... I haven't found it.

#24

B

bertsmobile1

B

bertsmobile1

On the bottom of the carb is a fuel shut off solenoid which usually has a white plug with 2 wires.

One is +12 with the ignition on, the other is a ground wire, usually with a ring terminal on it that goes onto one of the engine cover retaining screws, under the cylinder which is not easy to get at with the engine in the mower.

One is +12 with the ignition on, the other is a ground wire, usually with a ring terminal on it that goes onto one of the engine cover retaining screws, under the cylinder which is not easy to get at with the engine in the mower.

#25

EngineMan

EngineMan

There is no reference of that type of gasket in the parts list for that engine that I can see, unless they modified it later from the parts list that I have, if the black wire is coming from the stator then it could be the AC out (lights) which is shown on the B&S electrical.

Attachments

#26

B

bertsmobile1

B

bertsmobile1

That is a restrictor gasket.

It is used to reduce the size of the carb venturi thus reducing the flow of air through the carb.

One of the ways they reduce the Hp of larger engines to make smaller Hp ones.

Toss it if there is one with a completely round hole in it.

It is used to reduce the size of the carb venturi thus reducing the flow of air through the carb.

One of the ways they reduce the Hp of larger engines to make smaller Hp ones.

Toss it if there is one with a completely round hole in it.

#27

Boobala

Boobala

Whenever I work on something, no matter if I have the manual or not, (unless it's really simple like changing a light-bulb..:laughing:..:laughing I always take pictures, BEFORE & during disassembly, it becomes my failing memory tool , really saved me headaches many times, as we all know, the manuals leave a lot to be desired ( but cost-wise) understandable, I TRY to relay that anybody doing a repair job.

I always take pictures, BEFORE & during disassembly, it becomes my failing memory tool , really saved me headaches many times, as we all know, the manuals leave a lot to be desired ( but cost-wise) understandable, I TRY to relay that anybody doing a repair job.

#28

Boobala

Here's a few pics of MY Briggs 17.5 OHV eng. wires, the 2 wires going under my starter (one black, one violet) are for the head-lights, hope this is of some help, ...

... ...

... ...

... ...

...

Boobala

Sorry it's been a while since I reported back.... but I haven't had much time to work on the "Bloody Briggs" until the last few days.

Here's where we stand at the moment. GOOD NEWS!! The engine is assembled.... mounted to the mower. (The new lower seal... NOT leaking oil ... always my fear!) but MOST of all... the engine rotates freely... and the valve decompression (cam) is WORKING! YEAH!!! I should have the full results soon.

In the meantime.... I think I missed one STEP in my sage advice in an earlier post: "For me, the three most important steps of the process are: 1.) Make sure you fully understand the nature of the problem... symptoms, timing, etc. 2) Double check ALL assumptions. (False assumptions can spoil and chance of success.) 3.) Investigate by process of elimination."

I should have added another step: 4.) Make sure to remember where "things" came from.... so you can put them back in the same place! :ashamed:

I have the wiring harness all attached correctly.... not a big deal, right? There are two wires (clipped together) that run under the engine (I think). One actually branches off to TWO wires... one with a circular ground connection and a plastic connector. I know for certain where the ground connection goes.... and I know that the other plastic one goes to the carb shutoff. I'm damned if I can figure out where the other one goes.

The "other one" is a BLACK wire... with a two-wire white plastic connector. SHEESH! I've looked everywhere (forget B&S manual) ..... does ANYONE know what that wire is... and where it goes?

Thanks!

Bill (Thankfully NOT doing open heart surgery!)

Anyone know how this part "Intake Manifold Gasket 79608" fits.... or what it's for? It was installed "as built" when new.... but does that mean it actually belongs there.... or that it was installed correctly. If it does belong... I would assume that the manifold o-ring would need to seat onto the metal side and the gasket side to the intake? Again... forget about the manual... if it's in there.... I haven't found it.

View attachment 34795

Here's a few pics of MY Briggs 17.5 OHV eng. wires, the 2 wires going under my starter (one black, one violet) are for the head-lights, hope this is of some help,

...

... ...

... ...

... ...

...

#29

brchad

Ahhhh Boobala to the rescue! Great idea about photos during dismantle! (I'm 70, but I think my memory is about 90+!)

See this picture I altered from your list. BINGO??

Much appreciated!

Bill

brchad

Here's a few pics of MY Briggs 17.5 OHV eng. wires, the 2 wires going under my starter (one black, one violet) are for the head-lights, hope this is of some help, View attachment 34801...View attachment 34802...View attachment 34803...View attachment 34804...View attachment 34805

Ahhhh Boobala to the rescue! Great idea about photos during dismantle! (I'm 70, but I think my memory is about 90+!)

See this picture I altered from your list. BINGO??

Much appreciated!

Bill

#30

Boobala

Boobala

GREAT ! Bill, glad to be of help, yep, I'm up there too! turn 71 on Dec. 14th, thanks for the credence on my pics, this is exactly why I tell folks to do the same !! I had the hood off cleaning the machine to sell it, that's why the conn. was swingin in the breeze, I REALLY wish I knew how to add the arrows and circles to my pics, I'm just not very savvy with my puter, (just enough to be dangerous) ( LOL ) anyway I'm following your progress and can't wait till it's runnin again, hoping you keep us up-dated all the way through . Have a GREAT day, ...later ... Boobala

#33

brchad

My neighbor doesn't need a mower! His yard is weeds. It automatically dies in the fall. (I get free seed from him every spring... CRAB GRASS!!!)

By the way..... I believe that's "Okey Dokey" .... at least where I come from! https://www.phrases.org.uk/meanings/264800.html

brchad

Did ya buy your neighbor a beer for him loaning ya his mower .?? Now if we can get YOUR'S to run everything will be Hokey-Dokey !! ..

View attachment 34845

AHhhh just bustin your chops Bill, Glad to see it running and sounds good too! Please keep us updated !

My neighbor doesn't need a mower! His yard is weeds. It automatically dies in the fall. (I get free seed from him every spring... CRAB GRASS!!!)

By the way..... I believe that's "Okey Dokey" .... at least where I come from! https://www.phrases.org.uk/meanings/264800.html

#34

Boobala

you're absolutely right Bill, Okey-Dokey it is ! I must have have been thinking about Hunky-Dory !! ..:laughing:..:laughing:

Boobala

View attachment 34846

My neighbor doesn't need a mower! His yard is weeds. It automatically dies in the fall. (I get free seed from him every spring... CRAB GRASS!!!)

By the way..... I believe that's "Okey Dokey" .... at least where I come from! https://www.phrases.org.uk/meanings/264800.html

you're absolutely right Bill, Okey-Dokey it is ! I must have have been thinking about Hunky-Dory !! ..:laughing:..:laughing:

#35

Boobala

Boobala

OK Bill, since ya caught ME, in a "senior-moment" , turn-about is fair play ! In your thread header, you have ... Briggs 17.5 HP, OHC Engine Locks UP! I didn't know Briggs made a 17.5 HP OHC engine, BUT, .. They do make a 17.5 OHV AND I had 2 of them till I sold one to my wife's grandson this past summer, here's a few pics, to check out, .... ( doncha just LOVE when old folks drag out their "family-albums" ( LOL ) ...

...

... ...

... ...

... ...

... ...

... ...

...

...

... ...

... ...

... ...

... ...

...

...

... ...

... ...

... ...

... ...

... ...

... ...

... ...

... ...

... ...

... ...

...

#36

brchad

Hey..... I really hate to do this.... BUT ..... from your own attached photos ..... Image #2

Follow the magic BLUE arrow ..... me thinks it says 17.5 HP OHV!

brchad

OK Bill, since ya caught ME, in a "senior-moment" , turn-about is fair play ! In your thread header, you have ... Briggs 17.5 HP, OHC Engine Locks UP! I didn't know Briggs made a 17.5 HP OHC engine, BUT, .. They do make a 17.5 OHV .....

Hey..... I really hate to do this.... BUT ..... from your own attached photos ..... Image #2

Follow the magic BLUE arrow ..... me thinks it says 17.5 HP OHV!

#37

Boobala

AHA !! RE-read my post ! I stated OHV ..OVER HEAD VALVE ... you.. in your HEADER stated OHC ..OVER HEAD CAM

The header ... the VERY TOP line of your posting page !!

Boobala

Hey..... I really hate to do this.... BUT ..... from your own attached photos ..... Image #2

Follow the magic BLUE arrow ..... me thinks it says 17.5 HP OHV!

AHA !! RE-read my post ! I stated OHV ..OVER HEAD VALVE ... you.. in your HEADER stated OHC ..OVER HEAD CAM

The header ... the VERY TOP line of your posting page !!

#38

brchad

brchad

#39

Boobala

Boobala

#40

brchad

I was pretty smart when I was married 47 years ago! I planned in advance. All I have to remember is her birthday.... we were married on mine!

HAPPY THANKSGIVING EVERYONE!

(Click Me!)

Blessings!

Bill

brchad

NO SERIOUS PROBLEM !! at our age, " Everything " is forgiven, ... excepting the Wife's Birthday and your Wedding Anniversary !!

View attachment 34886

I was pretty smart when I was married 47 years ago! I planned in advance. All I have to remember is her birthday.... we were married on mine!

HAPPY THANKSGIVING EVERYONE!

(Click Me!)

Blessings!

Bill