You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

B&S 28Q777 crankcase vacuum line sucking oil up to fuel pump

#1

warreng5995

warreng5995

Hey all, first time poster.

My Dad has a Dixon 4515B ZTR mower that he got from his nephew... yeah its about 20 years old, I believe it to be a 2000 model

It has a Vanguard 15.5hp OHV engine #28Q777-0691-E1 (photo attached)

It all started... thats how most projects begin right ... with repairing the mower deck where it was rusting out only in the front section, and I welded in new sheet metal and etc etc...

... with repairing the mower deck where it was rusting out only in the front section, and I welded in new sheet metal and etc etc...

In any case, engine had an oil leak that had kept slowly getting worse, so wanted to get that fixed too. Appeared to be dipstick tube seal. Went to replace it, and when doing so I began cleaning all the old oil off the mower frame etc. Began to see oil going up the side of the block up under the engine cover, realized it must be the crankshaft seal under flywheel. Went to replace that, while doing so had the carb and air intake off. Happened to look into the intake side of the head and saw it was thickly coated in baked on oil . Long story short, ended up removing engine, complete tear down, found a thick layer of baked on oil (carbon buildup) all inside of head, top of piston, valves covered (not even sure if they were closing fully) etc. Oil in bottom of case was about a 1/2" of thick gel like sludge.The apparent problem was the bottom piston ring was stuck bad with a good amount of carbon build up, oil ring was stuck but came lose fairly easily when I began to mess with it.Top ring was moved ok, but there was build up in the groove. Seemed obvious that oil had been blowing by up into head.

. Long story short, ended up removing engine, complete tear down, found a thick layer of baked on oil (carbon buildup) all inside of head, top of piston, valves covered (not even sure if they were closing fully) etc. Oil in bottom of case was about a 1/2" of thick gel like sludge.The apparent problem was the bottom piston ring was stuck bad with a good amount of carbon build up, oil ring was stuck but came lose fairly easily when I began to mess with it.Top ring was moved ok, but there was build up in the groove. Seemed obvious that oil had been blowing by up into head.

After getting everything completely disassembled and several days worth of cleaning until all parts were spotless... all internal parts looked good. No scoring on cylinder sleeve nor piston, crank and cam had no scoring and no real wear, all teeth were sharp and square (not worn). Cam pressure release looked and operated just fine. Governor gearing was perfect, no wear, operated fine. etc etc .Got full engine gasket and seal kit, ring set, full carb rebuild kit including new float and float bowl (after cleaning found a tiny pin hole in old bowl). Rebuilt entire engine, including deglazing cylinder sleeve, lapping valves, as well as checking head and block for "flatness" using a slab of granite I keep in the shop. Used engine assembly lube on crank, cam, rod connector, pin, etc etc etc. Torqed everything to B&S specs as listed in their service manual, including the head in correct 3 rounds of increasing torque to final spec, and in correct order.

Reinstalled engine onto mower, and finished up installing carb, starter ect. Filled with conventional 10w30 oil and new B&S filter.

Took mower out for a short run, seemed to run good but not the power that it should have had. When engaging electric clutch for mower deck, engine bogged down significantly before coming back up to speed. When cutting any grass that was thick at all or "taller" than the rest, could hear the engine bog. At first thought maybe governor tab might needed adjusting (carb doesn't really have any adjustments but one) etc. Brought mower in and parked it as I didn't have the time that day.

Fast forward to two days ago, my Dad took mower out cut for about 20 min (just to test as grass isn't tall just beginning to grow), I could hear the mower bogging some as before etc. UPS truck shows up at our gate, my Dad drives down shuts mower off. UPS leaves, mower cranks but will not restart, doesn't even try to hit. I was in the shop, heard it, walked down to see what the problem was. Couldn't see any reason, thought maybe it either wasn't getting fuel or it was flooded. Tried some starter fluid in the air intake, nothing... must be flooded. Towed it back up to the shop. Started to pull plug when I noticed some fluid in the vacuum line going from crankcase breather to the fuel pump (I use the 1/4" silicone transparent fuel lines on anything I replace now days due to issues I've had with the old style lines, which is why I could see the fluid in the line). Took line off fuel pump, poured it out into my hand and it appears to be a mix of oil and gas. Ok... fuel pump membrane must have a hole in it. Checked oil, level was good and no indication of the presence of gas. Bought new fuel pump and air filter (even though the one on it was fairly new). Ran again... more fluid in vacuum line, but this time it was only oil.

Spoke again with Kevin who owns my local Stihl dealer, I buy most of my small engines parts, saws, etc from him as they are good people to work with and knowledgeable.The only other thing he (and myself) could think of is if the crank case breather spring was broke or something blocking it etc. Replaced crankcase breather with new. Ran again for a few min, line clear. Seemed like it fixed that issue, but engine still didn't have the power it should.

Today decided to recheck valve clearances, they were a bit off, and I will say they sure are touchy... finally was satisfied I had the clearances correct. Took mower out, power was much improved... but still bogged some. Wanted to run it longer, get engine up to full temp etc. Mowed about 20 min or so. Brought back into shop, oil was back in the vacuum line yet again, and engine would not restart.

I'm out of ideas... just doesn't make sense to me. If I hadn't just replaced the head gasket and etc, I would say a blown head gasket was possibly the issues. And that it was pushing a bit of pressure into crankcase. which in turn was pushing the oil through the breather. But I just did the headgasket with everything else with all brand new B&S parts.

Any input would be much appreciated

Edit: Just thought I would note that Italics button works, but "Bold" text doesn't appear to be working on here for some reason...

My Dad has a Dixon 4515B ZTR mower that he got from his nephew... yeah its about 20 years old, I believe it to be a 2000 model

It has a Vanguard 15.5hp OHV engine #28Q777-0691-E1 (photo attached)

It all started... thats how most projects begin right

In any case, engine had an oil leak that had kept slowly getting worse, so wanted to get that fixed too. Appeared to be dipstick tube seal. Went to replace it, and when doing so I began cleaning all the old oil off the mower frame etc. Began to see oil going up the side of the block up under the engine cover, realized it must be the crankshaft seal under flywheel. Went to replace that, while doing so had the carb and air intake off. Happened to look into the intake side of the head and saw it was thickly coated in baked on oil

After getting everything completely disassembled and several days worth of cleaning until all parts were spotless... all internal parts looked good. No scoring on cylinder sleeve nor piston, crank and cam had no scoring and no real wear, all teeth were sharp and square (not worn). Cam pressure release looked and operated just fine. Governor gearing was perfect, no wear, operated fine. etc etc .Got full engine gasket and seal kit, ring set, full carb rebuild kit including new float and float bowl (after cleaning found a tiny pin hole in old bowl). Rebuilt entire engine, including deglazing cylinder sleeve, lapping valves, as well as checking head and block for "flatness" using a slab of granite I keep in the shop. Used engine assembly lube on crank, cam, rod connector, pin, etc etc etc. Torqed everything to B&S specs as listed in their service manual, including the head in correct 3 rounds of increasing torque to final spec, and in correct order.

Reinstalled engine onto mower, and finished up installing carb, starter ect. Filled with conventional 10w30 oil and new B&S filter.

Took mower out for a short run, seemed to run good but not the power that it should have had. When engaging electric clutch for mower deck, engine bogged down significantly before coming back up to speed. When cutting any grass that was thick at all or "taller" than the rest, could hear the engine bog. At first thought maybe governor tab might needed adjusting (carb doesn't really have any adjustments but one) etc. Brought mower in and parked it as I didn't have the time that day.

Fast forward to two days ago, my Dad took mower out cut for about 20 min (just to test as grass isn't tall just beginning to grow), I could hear the mower bogging some as before etc. UPS truck shows up at our gate, my Dad drives down shuts mower off. UPS leaves, mower cranks but will not restart, doesn't even try to hit. I was in the shop, heard it, walked down to see what the problem was. Couldn't see any reason, thought maybe it either wasn't getting fuel or it was flooded. Tried some starter fluid in the air intake, nothing... must be flooded. Towed it back up to the shop. Started to pull plug when I noticed some fluid in the vacuum line going from crankcase breather to the fuel pump (I use the 1/4" silicone transparent fuel lines on anything I replace now days due to issues I've had with the old style lines, which is why I could see the fluid in the line). Took line off fuel pump, poured it out into my hand and it appears to be a mix of oil and gas. Ok... fuel pump membrane must have a hole in it. Checked oil, level was good and no indication of the presence of gas. Bought new fuel pump and air filter (even though the one on it was fairly new). Ran again... more fluid in vacuum line, but this time it was only oil.

Spoke again with Kevin who owns my local Stihl dealer, I buy most of my small engines parts, saws, etc from him as they are good people to work with and knowledgeable.The only other thing he (and myself) could think of is if the crank case breather spring was broke or something blocking it etc. Replaced crankcase breather with new. Ran again for a few min, line clear. Seemed like it fixed that issue, but engine still didn't have the power it should.

Today decided to recheck valve clearances, they were a bit off, and I will say they sure are touchy... finally was satisfied I had the clearances correct. Took mower out, power was much improved... but still bogged some. Wanted to run it longer, get engine up to full temp etc. Mowed about 20 min or so. Brought back into shop, oil was back in the vacuum line yet again, and engine would not restart.

I'm out of ideas... just doesn't make sense to me. If I hadn't just replaced the head gasket and etc, I would say a blown head gasket was possibly the issues. And that it was pushing a bit of pressure into crankcase. which in turn was pushing the oil through the breather. But I just did the headgasket with everything else with all brand new B&S parts.

Any input would be much appreciated

Edit: Just thought I would note that Italics button works, but "Bold" text doesn't appear to be working on here for some reason...

Attachments

#2

ILENGINE

ILENGINE

Some oil in the line to the fuel pump may be normal due to no way to stop oil from getting into the line.. the power issue and non restarting could be a partially sheared flywheel key.

#3

B

Bellcrank

B

Bellcrank

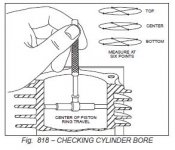

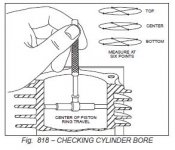

Did you ever run this engine before tear down ? Sounds like it's been rode hard and put away wet. Maybe it's worn out. Bore Diameter 3.4365 in. (87.29 mm) / Bore reject 3.4395 in. (87.36 mm) / Bore Out-Of-Round .0015 in. (.04 mm)

#4

B

Born2Mow

B

Born2Mow

Did you replace the fuel pump vacuum line with new "SAE J30 fuel hose" while you were re-assembling everything ? It's common that after 20 years this vacuum line has small leaks in it. Small leaks turn the vacuum hose into an impromptu "breather hose", and would allow crankcase oil into the hose. Small leaks in this hose will also keep the engine starved for fuel because the pump is not working with full pumping force. This would explain the engine's "low power" condition.

After 20 years on an air-cooled engine all your "rubber" parts are going to be shot. This list commonly includes hoses, o-rings and oil seals. First they harden. Then they crack. Then they leak.

After 20 years on an air-cooled engine all your "rubber" parts are going to be shot. This list commonly includes hoses, o-rings and oil seals. First they harden. Then they crack. Then they leak.

#5

StarTech

StarTech

With a 2000 engine it should have been mic'ed. Most likely the cylinder is both tapered and out of round which means that it need to go to .020 over if it was worn pass this. Just using a flex hone is also a mistake as it only makes things worst. Plus did you make sure you ordered the correct rings as they changed them in April 2001?

Side note the service manual still has the old cylinder torque spec of 220 in-lbs and the current torque spec is now 250 in-lbs. You also pay special attention the web area between the cylinder and the push rod galley as this where these engines blow head gaskets commonly.

Side note the service manual still has the old cylinder torque spec of 220 in-lbs and the current torque spec is now 250 in-lbs. You also pay special attention the web area between the cylinder and the push rod galley as this where these engines blow head gaskets commonly.

#6

warreng5995

warreng5995

Hi all thanks for the replies. Didn't get any emails that anyone had replied.

Anyway, try to answer everyone:

I tried my very best to assembly the flywheel and key very carefully, and torqued it to spec. I don't think that is the issue, as when it is cold, it starts right up fine. But I will look at it if I take the engine covers back off.

I didn't know about the torque spec change, I'll have to go look at the service manual I have and see the spec it gave, as that is the torque I set it too. And if I remember right, I *believe* it was 220. If that it what the manual I have states, I'll step it up to the 250 see what that does. I had thought about going higher recently, but didn't want to strip the threads out of the block. If they raised the torque spec, then compression leakage is most likely why they would have done so.

And yes that web area is the weakest point of these OHV gaskets. Just replaced one on another mower that I got for free as it would put out a literal cloud of smoke that you couldn't see through (due to the blown head gasket), and that is exactly where it blew out too. That mower doesn't have a mower deck, but since fixed it works great to pull my yard trailer I built

Additional Question: Is there a way to know if the muffler is partially blocked??? I read somewhere that this could cause similar issues. But it appears that the exhaust flow is normal. I may just pull the muffler off and see what happens.

Thanks for all the input and information everyone. I will go through some of these tomorrow if I have time to work on it. Once I go through the list, I'll report back if anything changed for better or worse.

Anyway, try to answer everyone:

I'm not sure how oil is the line is normal, I thought that is what the crank case breather was supposed to stop? Also if there is enough oil to block the line wouldn't that stop, or at least hinder, the vacuum to run the fuel pump? In which case would either cause no fuel to get through, or possibly cause the engine to run lean?Some oil in the line to the fuel pump may be normal due to no way to stop oil from getting into the line.. the power issue and non restarting could be a partially sheared flywheel key.

I tried my very best to assembly the flywheel and key very carefully, and torqued it to spec. I don't think that is the issue, as when it is cold, it starts right up fine. But I will look at it if I take the engine covers back off.

Yeah, we ran it for a couple seasons. Did all maintenance when we got it, and changed oil and filters regularly. Never saw the sludge and other until I took it apart though. My Dads nephew (my cousin) bought it from an auction... and yes there were issues from the beginning, but most seemed small and I was able to keep it running. The one that I couldn't fix was a light "knocking" or pinging sound. Part of it ended up being the spot welds holding the baffle inside the muffler had broke, I cut it open rewelded it, and welded the muffler back together (that was about 2 years ago when we first got it). Thought that had taken care of the sound, but could still hear a light pinging coming from the crankcase. It doesn't seem to have this sound now though. The bore being out of spec could be possible. I didn't measure it, as I didn't really have any tool that could do so. A T-Bore hole gauge would have worked, but don't have one and didn't realize at the time that some cheapos could be found.Did you ever run this engine before tear down ? Sounds like it's been rode hard and put away wet. Maybe it's worn out. Bore Diameter 3.4365 in. (87.29 mm) / Bore reject 3.4395 in. (87.36 mm) / Bore Out-Of-Round .0015 in. (.04 mm)

I did replace the vacuum line, as well as all other fuel lines. But not with SAE hose, I used transparent silicone fuel hose. Thats why I could see the oil in the line. With oil going into that line, I also thought that it blocking the vacuum to the fuel pump could be part of the power issues. I did replace all gaskets, all seals, and etc with all brand new. As you said, 20 years old all those type parts are going to be hard and cracking.Did you replace the fuel pump vacuum line with new "SAE J30 fuel hose" while you were re-assembling everything ? It's common that after 20 years this vacuum line has small leaks in it. Small leaks turn the vacuum hose into an impromptu "breather hose", and would allow crankcase oil into the hose. Small leaks in this hose will also keep the engine starved for fuel because the pump is not working with full pumping force. This would explain the engine's "low power" condition.

After 20 years on an air-cooled engine all your "rubber" parts are going to be shot. This list commonly includes hoses, o-rings and oil seals. First they harden. Then they crack. Then they leak.

The new rings were the correct part number as per the engine date code according to B&S, and they are B&S brand rings too. I didn't even know they sold oversized rings for these... manual never mentioned it and I hadn't replaced rings on a small engine before. Yeah, I should have found a way to measure the cylinder bore. As I said up above, didn't have the tools, didn't know I could have gotten some cheap, and also there are no machine shops out here so had no where to get it measured either.With a 2000 engine it should have been mic'ed. Most likely the cylinder is both tapered and out of round which means that it need to go to .020 over if it was worn pass this. Just using a flex hone is also a mistake as it only makes things worst. Plus did you make sure you ordered the correct rings as they changed them in April 2001?

Side note the service manual still has the old cylinder torque spec of 220 in-lbs and the current torque spec is now 250 in-lbs. You also pay special attention the web area between the cylinder and the push rod galley as this where these engines blow head gaskets commonly.

I didn't know about the torque spec change, I'll have to go look at the service manual I have and see the spec it gave, as that is the torque I set it too. And if I remember right, I *believe* it was 220. If that it what the manual I have states, I'll step it up to the 250 see what that does. I had thought about going higher recently, but didn't want to strip the threads out of the block. If they raised the torque spec, then compression leakage is most likely why they would have done so.

And yes that web area is the weakest point of these OHV gaskets. Just replaced one on another mower that I got for free as it would put out a literal cloud of smoke that you couldn't see through (due to the blown head gasket), and that is exactly where it blew out too. That mower doesn't have a mower deck, but since fixed it works great to pull my yard trailer I built

Additional Question: Is there a way to know if the muffler is partially blocked??? I read somewhere that this could cause similar issues. But it appears that the exhaust flow is normal. I may just pull the muffler off and see what happens.

Thanks for all the input and information everyone. I will go through some of these tomorrow if I have time to work on it. Once I go through the list, I'll report back if anything changed for better or worse.

#7

StarTech

StarTech

The only thing I had clogged mufflers on has been 2 cycles but anything can happen.

Yes the manual wasn't written with a novice in mind. If in the rear you will find that if cylinder has .004" of wear over the standard cylinder size you need to hone it to .020 over. As said this cant done with a flex but is instead done using a rigid hone with the correct stones. Ridge hones prevents the stones from just following the current taper and/or oval.

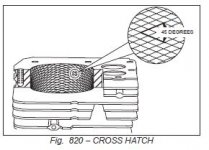

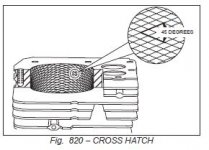

Aluminum cylinders 280 grit (nothing of coarser grit). Cast iron lined 180 grit (can use 80 grit for quick take to near .015 over then switch to 180 grit). You must create a crosshatch pattern of 45 degrees. Also while honing keep the rpm down under 300 rpm especially with aluminum to prevent galling and use honing oil. Smaller the diameter the slower.

If it does comes to oversizing then you will need both the OS piston and ring set.

Yes the manual wasn't written with a novice in mind. If in the rear you will find that if cylinder has .004" of wear over the standard cylinder size you need to hone it to .020 over. As said this cant done with a flex but is instead done using a rigid hone with the correct stones. Ridge hones prevents the stones from just following the current taper and/or oval.

Aluminum cylinders 280 grit (nothing of coarser grit). Cast iron lined 180 grit (can use 80 grit for quick take to near .015 over then switch to 180 grit). You must create a crosshatch pattern of 45 degrees. Also while honing keep the rpm down under 300 rpm especially with aluminum to prevent galling and use honing oil. Smaller the diameter the slower.

If it does comes to oversizing then you will need both the OS piston and ring set.

#8

B

Born2Mow

• Oil in the clear hose is not a sign of anything, other than that the hose is connected to the engine's sump.

That's all I got.

B

Born2Mow

• No experience with that type hose, but even if it only lasted a month there should be no vacuum leaks and the "low fuel delivery due to loss of vacuum" reduced to a non-issue. Still could be a tiny hole in the pump's diaphragm, but the I agree the hose should be 100% fixed. Good call.I did replace the vacuum line, as well as all other fuel lines. But not with SAE hose, I used transparent silicone fuel hose. That's why I could see the oil in the line. With oil going into that line, I also thought that it blocking the vacuum to the fuel pump could be part of the power issues. I did replace all gaskets, all seals, and etc with all brand new.

• Oil in the clear hose is not a sign of anything, other than that the hose is connected to the engine's sump.

That's all I got.

#9

warreng5995

warreng5995

I've rebuilt car engines and such, so I understand the procedures. I also did a bit of research on the differences for a small engine as well. I just wasn't going to go have it bored out if it was off. But I should have measured it to see how far out of spec it was, as if it was too far then I should have just junked the mower. The only reason I even did the engine rebuild, is because of all the other work I had already put into the mower.The only thing I had clogged mufflers on has been 2 cycles but anything can happen.

Yes the manual wasn't written with a novice in mind. If in the rear you will find that if cylinder has .004" of wear over the standard cylinder size you need to hone it to .020 over. As said this cant done with a flex but is instead done using a rigid hone with the correct stones. Ridge hones prevents the stones from just following the current taper and/or oval.

Aluminum cylinders 280 grit (nothing of coarser grit). Cast iron lined 180 grit (can use 80 grit for quick take to near .015 over then switch to 180 grit). You must create a crosshatch pattern of 45 degrees. Also while honing keep the rpm down under 300 rpm especially with aluminum to prevent galling and use honing oil. Smaller the diameter the slower.

View attachment 55788View attachment 55789

If it does comes to oversizing then you will need both the OS piston and ring set.

#10

warreng5995

warreng5995

Its the type of line often used on trimmers, chainsaw, etc. They just use a much smaller size. In any case, I know there may be oil vapor/residue in the line. But I think I'm getting so much oil in the line that it is slowing the vacuum to the fuel pump. With the engine off, there is about 1" of oil (in length) in the lowest part of the line. In any case, if that's not the issue then hopefully its one of the other things that I can fix.• No experience with that type hose, but even if it only lasted a month there should be no vacuum leaks and the "low fuel delivery due to loss of vacuum" reduced to a non-issue. Still could be a tiny hole in the pump's diaphragm, but the I agree the hose should be 100% fixed. Good call.

• Oil in the clear hose is not a sign of anything, other than that the hose is connected to the engine's sump.

That's all I got.

#11

warreng5995

warreng5995

Ok, a bit of an update.

I looked at the vacuum line today and about 1.5 to 2 inches of it was filled with oil (see first photo attached). ILENGINE & Born2Mow both of you said oil in the line may be normal. So I figured ok, lets not drain the line and leave the oil there and try to start it and see what happens. With the choke on, cranked it over and it fired right up.

So, I figured I might as well as pull the dipstick and see how much pressure it was pushing. Pulled the dipstick, and a light spray of oil did come out until I put my hand and paper towel over it. I could feel some air but didn't seem more than what I thought would be normal. After holding the paper towel over it for 5 or 10 seconds, I removed it and replaced the dip stick. There was some oil spray on the towel, but not soaked or anything. Oil level has stayed at the full mark this whole time.

Just for a comparison, I went out back to my other mower with B&S (16.5hp) and did the same thing. it actually sprayed more oil into my paper towel than this one did. But I am pretty sure it doesn't have a oil pump (but is "splash lube" only - I could be wrong about this though) as it doesn't have an oil filter like this engine does.

Back to this Vanguard, I ran the engine and let it come up to full temp, I watched the head and some other points with a infrared "laser" thermometer to see if I could find any abnormal hot spots. The hottest point on the head was near the spark plug, with temps around 280 to 300 f. The hottest spot I could find on the muffler was 680F at one point. Most of the muffler was around 450 to 500 f. Oil filter stayed between 122 and 130 f, as did the crankcase next to the filter. Valve cover got up to about 135 f. Other parts of the head and case were much cooler due to the air flow from the flywheel "cooling fan". I think the float bowl on the carb was around 110 f.

I will add there is no odd sounds or anything. It doesn't surge or etc. Runs smoothly.

Now that it was at full temp, I pulled the dipstick again and the air and oil spray seemed exactly the same as when I first started it. So no difference there.

Finally I turned off engine... let it sit for about 2 minuets or so. Tried to restart, it didn't want to, it chugged a bit, I let off the key and it chugged a few more times on its own but then picked back up to normal engine speed. So I ran it a few more minutes, and turned it off again. This time i let is sit about 5 minutes. Tried to restart, Nothing. Didn't even try to hit. Tried to restart it a few more times, letting it sit a minute or two between attempts, but never hit. Same as it did the other day.

I didn't have any more time to mess with it today, so that's all I was able to test.

But in short, it appears that the oil in the vacuum line isn't the issue, as it was that way today when I started the engine cold, and it fired right up just fine. So I guess that part is "solved" and appears to be a non-issue.

At this point, I don't think I'm getting piston blow by or bypass on the head gasket. As cold and hot both seemed to be the same with my mediocre "dip stick test".

I can't do a proper compression test on this engine, because it has the compression release on the cam shaft so it is easier to start. Which this compression release "lobe" doesn't move out of the way until the engine is running and the centrifugal force moves it. So from what I can see and understand, due to this compression release the compression PSI will never show correctly when just cranking the engine over. If anyone can confirm or refute this, please feel free to post such.

With that said, I did check my service manual StarTech and it listed 220 in-lbs as you said the old versions did. So when I have the time to pull the covers, intake/carb and etc. I may up the torque on the head to 250 in-lbs as per your suggestion.

So in the end with what little I was able to "test" today.... Why does the engine start cold just fine and seems to run "normally" and smoothly... but once hot when you shut it down for a few min, it won't restart?? Could this still be an issue with compression? Vapor lock in carb, but only after the engine cools?? Or...??? ?

?

Thanks All

I looked at the vacuum line today and about 1.5 to 2 inches of it was filled with oil (see first photo attached). ILENGINE & Born2Mow both of you said oil in the line may be normal. So I figured ok, lets not drain the line and leave the oil there and try to start it and see what happens. With the choke on, cranked it over and it fired right up.

So, I figured I might as well as pull the dipstick and see how much pressure it was pushing. Pulled the dipstick, and a light spray of oil did come out until I put my hand and paper towel over it. I could feel some air but didn't seem more than what I thought would be normal. After holding the paper towel over it for 5 or 10 seconds, I removed it and replaced the dip stick. There was some oil spray on the towel, but not soaked or anything. Oil level has stayed at the full mark this whole time.

Just for a comparison, I went out back to my other mower with B&S (16.5hp) and did the same thing. it actually sprayed more oil into my paper towel than this one did. But I am pretty sure it doesn't have a oil pump (but is "splash lube" only - I could be wrong about this though) as it doesn't have an oil filter like this engine does.

Back to this Vanguard, I ran the engine and let it come up to full temp, I watched the head and some other points with a infrared "laser" thermometer to see if I could find any abnormal hot spots. The hottest point on the head was near the spark plug, with temps around 280 to 300 f. The hottest spot I could find on the muffler was 680F at one point. Most of the muffler was around 450 to 500 f. Oil filter stayed between 122 and 130 f, as did the crankcase next to the filter. Valve cover got up to about 135 f. Other parts of the head and case were much cooler due to the air flow from the flywheel "cooling fan". I think the float bowl on the carb was around 110 f.

I will add there is no odd sounds or anything. It doesn't surge or etc. Runs smoothly.

Now that it was at full temp, I pulled the dipstick again and the air and oil spray seemed exactly the same as when I first started it. So no difference there.

Finally I turned off engine... let it sit for about 2 minuets or so. Tried to restart, it didn't want to, it chugged a bit, I let off the key and it chugged a few more times on its own but then picked back up to normal engine speed. So I ran it a few more minutes, and turned it off again. This time i let is sit about 5 minutes. Tried to restart, Nothing. Didn't even try to hit. Tried to restart it a few more times, letting it sit a minute or two between attempts, but never hit. Same as it did the other day.

I didn't have any more time to mess with it today, so that's all I was able to test.

But in short, it appears that the oil in the vacuum line isn't the issue, as it was that way today when I started the engine cold, and it fired right up just fine. So I guess that part is "solved" and appears to be a non-issue.

At this point, I don't think I'm getting piston blow by or bypass on the head gasket. As cold and hot both seemed to be the same with my mediocre "dip stick test".

I can't do a proper compression test on this engine, because it has the compression release on the cam shaft so it is easier to start. Which this compression release "lobe" doesn't move out of the way until the engine is running and the centrifugal force moves it. So from what I can see and understand, due to this compression release the compression PSI will never show correctly when just cranking the engine over. If anyone can confirm or refute this, please feel free to post such.

With that said, I did check my service manual StarTech and it listed 220 in-lbs as you said the old versions did. So when I have the time to pull the covers, intake/carb and etc. I may up the torque on the head to 250 in-lbs as per your suggestion.

So in the end with what little I was able to "test" today.... Why does the engine start cold just fine and seems to run "normally" and smoothly... but once hot when you shut it down for a few min, it won't restart?? Could this still be an issue with compression? Vapor lock in carb, but only after the engine cools?? Or...???

Thanks All

Attachments

#13

warreng5995

When cold, it starts and runs fine... until you turn it off for 5 min.

Before I re-adjusted the valves it had a very noticeable amount of power loss under load, but after the last adjustment power is improved (although its still less than it should be).

I just thought about something... what if its just a coincidence?? What I mean is, what if it not restarting when hot doesn't have anything to with the rebuild itself... and instead the issue just happened to occur during the time period of this rebuild?

Most of the time I really dismiss anything as "coincidence"... but what if the coil is breaking down?? Starts fine when cold... but once the engine is hot, the coil could be overheating to the point it has weak spark when hot??? It has to have some spark or it wouldn't run at all when the engine is hot. But once you turn the engine off, and the engine cools down enough. It takes a full powered spark to restart, but if the coil is still too hot and still has a weak spark, you get a hot engine no start condition???

Starts fine when cold... but once the engine is hot, the coil could be overheating to the point it has weak spark when hot??? It has to have some spark or it wouldn't run at all when the engine is hot. But once you turn the engine off, and the engine cools down enough. It takes a full powered spark to restart, but if the coil is still too hot and still has a weak spark, you get a hot engine no start condition???

Does this seem plausible? Anyone have a opinion?

warreng5995

Yep, no hard turn over or anything. It just cranks and cranks, but doesn't even try to hit.Question. When it doesn't restart, does it spin normally while cranking?

When cold, it starts and runs fine... until you turn it off for 5 min.

Before I re-adjusted the valves it had a very noticeable amount of power loss under load, but after the last adjustment power is improved (although its still less than it should be).

I just thought about something... what if its just a coincidence?? What I mean is, what if it not restarting when hot doesn't have anything to with the rebuild itself... and instead the issue just happened to occur during the time period of this rebuild?

Most of the time I really dismiss anything as "coincidence"... but what if the coil is breaking down??

Does this seem plausible? Anyone have a opinion?

#14

B

bertsmobile1

B

bertsmobile1

Spend $ 20 & get a red in line spark tester

No flashing = dud coil or kill wire shorting

Remove will wire from coil

Flashes red = short in wiring or faulty safety switch.

If it only does it when the blades are on suspect the reverse switch.

No flashing = dud coil or kill wire shorting

Remove will wire from coil

Flashes red = short in wiring or faulty safety switch.

If it only does it when the blades are on suspect the reverse switch.

#15

ILENGINE

ILENGINE

The oil is colleting in your vacuum line due to the sag. The line should run downhill from the fuel pump into the fitting on the breather to prevent oil pooling in the line. I am wondering if you are not loosing spark when the engine gets hot. heat sinking the ignition module.

#16

warreng5995

starts and runs when cold, continues to run when hot. After its hot, if you turn off engine for 5 minutes, it won't Re-Start.

warreng5995

its not switches nor kill wire.Spend $ 20 & get a red in line spark tester

No flashing = dud coil or kill wire shorting

Remove will wire from coil

Flashes red = short in wiring or faulty safety switch.

If it only does it when the blades are on suspect the reverse switch.

starts and runs when cold, continues to run when hot. After its hot, if you turn off engine for 5 minutes, it won't Re-Start.

#17

warreng5995

ignition module, possible. hadn't thought about that either. its mounted on a "plate" via one of the starter bolts.

warreng5995

ok, i'll try to see if there is a way to re-run the line. the carb and choke rods are in the way.The oil is colleting in your vacuum line due to the sag. The line should run downhill from the fuel pump into the fitting on the breather to prevent oil pooling in the line. I am wondering if you are not loosing spark when the engine gets hot. heat sinking the ignition module.

ignition module, possible. hadn't thought about that either. its mounted on a "plate" via one of the starter bolts.

#18

ILENGINE

ILENGINE

The ignition module is what you are calling the coil. Don't confuse it with the regulator/rectifier for the charging system which could be located next to the starter.ok, i'll try to see if there is a way to re-run the line. the carb and choke rods are in the way.

ignition module, possible. hadn't thought about that either. its mounted on a "plate" via one of the starter bolts.

#19

B

Born2Mow

The EPA has made all engine builders lean out their engines. This started this about 1988. They have gotten progressively leaner in stages, which is why many motorcycles now have fuel injection. If they have their way, look for electronic fuel injection on mowers in the next 10 years, or all-electric mowers mandated by law.

When everything is "perfect" your engine is running on a very minimal amount of fuel. Should anything happen to the float level or the jet size, then there won't be enough fuel to start a hot engine without using the choke.

Enter ethanol loaded fuels. When these are left in the carb for any length of time, the alcohol attracts water. The alcohol and water mixture leaves a very thin layer of (usually dark brown) "varnish" on everything.... including the inside of the jets. This makes the jet smaller on its fuel metering orifice... which in turn further leans out the fuel mixture. It's not much, but it's enough. The engine seems to run correctly, but it's really starved for fuel. Thus, the only way a hot engine will start is by using the choke.

Since the engine seems to run OK, I wouldn't open the carb. In your shoes I'd start using a "fuel stabilizer" AND carb cleaner, such as StarTron. The stabilizer will work to prevent future problems by keeping the alcohol in solution with the gasoline, and the cleaner will work to clean out any varnish that has accumulated. And it will do this while you run the engine on your regular schedule.

I implement this plan in my shop by treating the fuel in the BIG cans as soon as I bring it home from the gettin' place. In this way the StarTron works its way into my chain saw, leaf blower, weed whacker, my Exmark and both my walk-behinds. And the plan works. None of my equipment ever has carb or fuel issues.

Hope this helps.

B

Born2Mow

In my experience this is due to coating of the jets.Why does the engine start cold just fine and seems to run "normally" and smoothly... but once hot when you shut it down for a few min, it won't restart?? Could this still be an issue with compression? Vapor lock in carb, but only after the engine cools?? Or...????

The EPA has made all engine builders lean out their engines. This started this about 1988. They have gotten progressively leaner in stages, which is why many motorcycles now have fuel injection. If they have their way, look for electronic fuel injection on mowers in the next 10 years, or all-electric mowers mandated by law.

When everything is "perfect" your engine is running on a very minimal amount of fuel. Should anything happen to the float level or the jet size, then there won't be enough fuel to start a hot engine without using the choke.

Enter ethanol loaded fuels. When these are left in the carb for any length of time, the alcohol attracts water. The alcohol and water mixture leaves a very thin layer of (usually dark brown) "varnish" on everything.... including the inside of the jets. This makes the jet smaller on its fuel metering orifice... which in turn further leans out the fuel mixture. It's not much, but it's enough. The engine seems to run correctly, but it's really starved for fuel. Thus, the only way a hot engine will start is by using the choke.

Since the engine seems to run OK, I wouldn't open the carb. In your shoes I'd start using a "fuel stabilizer" AND carb cleaner, such as StarTron. The stabilizer will work to prevent future problems by keeping the alcohol in solution with the gasoline, and the cleaner will work to clean out any varnish that has accumulated. And it will do this while you run the engine on your regular schedule.

I implement this plan in my shop by treating the fuel in the BIG cans as soon as I bring it home from the gettin' place. In this way the StarTron works its way into my chain saw, leaf blower, weed whacker, my Exmark and both my walk-behinds. And the plan works. None of my equipment ever has carb or fuel issues.

Hope this helps.

#20

StarTech

StarTech

Fuel injection via throttle bodies is already here especially on v-twins. Briggs, Kawasaki, and Kohler all have fuel injected engines. Even Robin/Subaru even tried it on singles years ago. An example of the Robin is the EX21-EFI which they finally reverted back carburetors because they had so much problems with it.

#21

warreng5995

As far as ethanol goes, I don't buy ethanol fuel just for some of the reasons you listed. My local gas station is also a truck stop and they sell premium non-ethanol gasoline. Back about 5 years ago when I did buy ethanol, and even though I put some type of stabilizer in it, I kept having issues with my trimmers and chainsaw carbs, even a carb on a very small genset. Clean and rebuilt them, last for a while same issues. Bought new carbs, after a while, same issues. Switched to non-ethanol, haven't had any more problems.

I do use fuel stabilizer in anything engine that doesn't get used often or is going to be sitting more than a couple weeks. Also used it in the storage can if the fuel isn't going to be used directly. Haven't heard of startron before. But I do not like "stabil", its garbage in my opinion. I found a stabilizer called PRI-G for gasoline and PRI-D for diesel. Have used both for several years and it works well. From what I remember reading several years ago, its the same company that makes fuel stabilizer used in most ships.

In any case, like I said in my op, just got done with this full engine rebuild, full carb rebuild including all new jets, float, etc. I haven't ran the engine probably 1 hour in total since rebuild. All fresh fuel, clean tank, all new filters, new fuel pump, new fuel lines, new plug, etc.

Also the first time it wouldn't restart when hot (the first real time running it after rebuild), my Dad had tried it out for about 20 min cutting and shut it down when the UPS guy showed up. When it wouldn't restart I also thought it wasn't getting fuel, so I got some started fluid and shot it in the air intake, got nothing, not even a hit. Just like all the other times since when hot. So at that point I thought maybe the needle valve got stuck or something and might have flooded while he was talking to the UPS guy, towed it back up to the shop pulled plug, little glaze on the plug. cranked over engine, mist shot out of cylinder, but nothing out of the ordinary. So thats when I started trying to figure out what was going on before I ever posted here. Which at that time I thought it was related to the oil in the vacuum line going to the fuel pump, but have since ruled that out as a non-issue.

With that said, I could be wrong, but I really think its a weak coil at this point. When I get some time, I'm going to take the coil out and go buy a new B&S one from my local Stihl dealer. So we'll see what that does. I don't like throwing parts at an engine and see what sticks, but after everything else I've already rebuilt and replaced on this thing, might as well replace the coil too.

warreng5995

Fully agree about the ethanol and the EPA garbage. I wish the carbs were adjustable again... what the stupid EPA has forced to be done to them is as stupid as the new "no spill" fuel cans... along with many other things.In my experience this is due to coating of the jets.

The EPA has made all engine builders lean out their engines. This started this about 1988. They have gotten progressively leaner in stages, which is why many motorcycles now have fuel injection. If they have their way, look for electronic fuel injection on mowers in the next 10 years, or all-electric mowers mandated by law.

When everything is "perfect" your engine is running on a very minimal amount of fuel. Should anything happen to the float level or the jet size, then there won't be enough fuel to start a hot engine without using the choke.

Enter ethanol loaded fuels. When these are left in the carb for any length of time, the alcohol attracts water. The alcohol and water mixture leaves a very thin layer of (usually dark brown) "varnish" on everything.... including the inside of the jets. This makes the jet smaller on its fuel metering orifice... which in turn further leans out the fuel mixture. It's not much, but it's enough. The engine seems to run correctly, but it's really starved for fuel. Thus, the only way a hot engine will start is by using the choke.

Since the engine seems to run OK, I wouldn't open the carb. In your shoes I'd start using a "fuel stabilizer" AND carb cleaner, such as StarTron. The stabilizer will work to prevent future problems by keeping the alcohol in solution with the gasoline, and the cleaner will work to clean out any varnish that has accumulated. And it will do this while you run the engine on your regular schedule.

I implement this plan in my shop by treating the fuel in the BIG cans as soon as I bring it home from the gettin' place. In this way the StarTron works its way into my chain saw, leaf blower, weed whacker, my Exmark and both my walk-behinds. And the plan works. None of my equipment ever has carb or fuel issues.

Hope this helps.

As far as ethanol goes, I don't buy ethanol fuel just for some of the reasons you listed. My local gas station is also a truck stop and they sell premium non-ethanol gasoline. Back about 5 years ago when I did buy ethanol, and even though I put some type of stabilizer in it, I kept having issues with my trimmers and chainsaw carbs, even a carb on a very small genset. Clean and rebuilt them, last for a while same issues. Bought new carbs, after a while, same issues. Switched to non-ethanol, haven't had any more problems.

I do use fuel stabilizer in anything engine that doesn't get used often or is going to be sitting more than a couple weeks. Also used it in the storage can if the fuel isn't going to be used directly. Haven't heard of startron before. But I do not like "stabil", its garbage in my opinion. I found a stabilizer called PRI-G for gasoline and PRI-D for diesel. Have used both for several years and it works well. From what I remember reading several years ago, its the same company that makes fuel stabilizer used in most ships.

In any case, like I said in my op, just got done with this full engine rebuild, full carb rebuild including all new jets, float, etc. I haven't ran the engine probably 1 hour in total since rebuild. All fresh fuel, clean tank, all new filters, new fuel pump, new fuel lines, new plug, etc.

Also the first time it wouldn't restart when hot (the first real time running it after rebuild), my Dad had tried it out for about 20 min cutting and shut it down when the UPS guy showed up. When it wouldn't restart I also thought it wasn't getting fuel, so I got some started fluid and shot it in the air intake, got nothing, not even a hit. Just like all the other times since when hot. So at that point I thought maybe the needle valve got stuck or something and might have flooded while he was talking to the UPS guy, towed it back up to the shop pulled plug, little glaze on the plug. cranked over engine, mist shot out of cylinder, but nothing out of the ordinary. So thats when I started trying to figure out what was going on before I ever posted here. Which at that time I thought it was related to the oil in the vacuum line going to the fuel pump, but have since ruled that out as a non-issue.

With that said, I could be wrong, but I really think its a weak coil at this point. When I get some time, I'm going to take the coil out and go buy a new B&S one from my local Stihl dealer. So we'll see what that does. I don't like throwing parts at an engine and see what sticks, but after everything else I've already rebuilt and replaced on this thing, might as well replace the coil too.

#22

B

Born2Mow

B

Born2Mow

StarTron was originally developed for boaters. As much trouble as Ethanol caused in mowers and trimmers, it nearly killed the pleasure boat industry due to the proximity of water 24/7. It's a stabilizer AND cleaner, which is far better than a simple stabilizer, like Stabil. As long as you're already buying a fuel additive, it certainly wouldn't hurt to try a different one. It's certainly no more costly.

This is not a comment on your carb rebuilding skills. Please don't take it that way. What I'm saying is that carbs made in the last 15 years are VERY complex instruments, with as many as 4 stages of jetting for a variable-speed engine. It's extremely difficult for anyone to clean all the passageways without an ultrasonic cleaner and a tremendous amount of time.

I really hope the new coil fixes your issue. But if not, then maybe you'll remember this post.

All the best.

This is not a comment on your carb rebuilding skills. Please don't take it that way. What I'm saying is that carbs made in the last 15 years are VERY complex instruments, with as many as 4 stages of jetting for a variable-speed engine. It's extremely difficult for anyone to clean all the passageways without an ultrasonic cleaner and a tremendous amount of time.

I really hope the new coil fixes your issue. But if not, then maybe you'll remember this post.

All the best.

#23

warreng5995

I'm no pro by any means, I've just learned over the years what works for me, as I repair all my own stuff, whether it is mowers, 2-cycles, motorcycle, or cars/trucks. Can't afford to pay someone else to do it. And tbh I'd rather do most things myself, at least I know what was actually done... even if I do it wrong the first time and figure it out later, maybe then I'll know how to fix it lol ?

warreng5995

no offense taken ?, carb bodies are something else to clean sometimes with all the tiny passages and such, and it does take a good amount of time to clean and rebuild them. Smaller the carb the worse they are. But have been using an ultrasonic cleaner in recent years, which does help a lot. Besides the sonic cleaning itself, I also like usings its heater to warm up the distilled water (which I always use when cleaning carbs as I have well water) pretty good, as that seems to help clean a lot better too. Add in some sonic cleaner "soap" and I also add in some Mean Green Industrial Strength (which is difficult to find these days) when ever I'm cleaning carbs, and all together it does a pretty good job. I usually run a carb through several 30 min cycles (as 30 min is the longest cycle my cleaner will set for...?), just depending on what else I'm doing in the shop or how quickly I need the carb done. Then when it comes out of the cleaner, I use my air compressor to blow out all the passages.StarTron was originally developed for boaters. As much trouble as Ethanol caused in mowers and trimmers, it nearly killed the pleasure boat industry due to the proximity of water 24/7. It's a stabilizer AND cleaner, which is far better than a simple stabilizer, like Stabil. As long as you're already buying a fuel additive, it certainly wouldn't hurt to try a different one. It's certainly no more costly.

This is not a comment on your carb rebuilding skills. Please don't take it that way. What I'm saying is that carbs made in the last 15 years are VERY complex instruments, with as many as 4 stages of jetting for a variable-speed engine. It's extremely difficult for anyone to clean all the passageways without an ultrasonic cleaner and a tremendous amount of time.

I really hope the new coil fixes your issue. But if not, then maybe you'll remember this post.

All the best.

I'm no pro by any means, I've just learned over the years what works for me, as I repair all my own stuff, whether it is mowers, 2-cycles, motorcycle, or cars/trucks. Can't afford to pay someone else to do it. And tbh I'd rather do most things myself, at least I know what was actually done... even if I do it wrong the first time and figure it out later, maybe then I'll know how to fix it lol ?

#24

J

JMK1038

J

JMK1038

I had two mowers that had oil coming back to the carburator and in each the float valve was stuck and the gas was filling the crankcase and forcing the oil out.Hi all thanks for the replies. Didn't get any emails that anyone had replied.

Anyway, try to answer everyone:

I'm not sure how oil is the line is normal, I thought that is what the crank case breather was supposed to stop? Also if there is enough oil to block the line wouldn't that stop, or at least hinder, the vacuum to run the fuel pump? In which case would either cause no fuel to get through, or possibly cause the engine to run lean?

I tried my very best to assembly the flywheel and key very carefully, and torqued it to spec. I don't think that is the issue, as when it is cold, it starts right up fine. But I will look at it if I take the engine covers back off.

Yeah, we ran it for a couple seasons. Did all maintenance when we got it, and changed oil and filters regularly. Never saw the sludge and other until I took it apart though. My Dads nephew (my cousin) bought it from an auction... and yes there were issues from the beginning, but most seemed small and I was able to keep it running. The one that I couldn't fix was a light "knocking" or pinging sound. Part of it ended up being the spot welds holding the baffle inside the muffler had broke, I cut it open rewelded it, and welded the muffler back together (that was about 2 years ago when we first got it). Thought that had taken care of the sound, but could still hear a light pinging coming from the crankcase. It doesn't seem to have this sound now though. The bore being out of spec could be possible. I didn't measure it, as I didn't really have any tool that could do so. A T-Bore hole gauge would have worked, but don't have one and didn't realize at the time that some cheapos could be found.

I did replace the vacuum line, as well as all other fuel lines. But not with SAE hose, I used transparent silicone fuel hose. Thats why I could see the oil in the line. With oil going into that line, I also thought that it blocking the vacuum to the fuel pump could be part of the power issues. I did replace all gaskets, all seals, and etc with all brand new. As you said, 20 years old all those type parts are going to be hard and cracking.

The new rings were the correct part number as per the engine date code according to B&S, and they are B&S brand rings too. I didn't even know they sold oversized rings for these... manual never mentioned it and I hadn't replaced rings on a small engine before. Yeah, I should have found a way to measure the cylinder bore. As I said up above, didn't have the tools, didn't know I could have gotten some cheap, and also there are no machine shops out here so had no where to get it measured either.

I didn't know about the torque spec change, I'll have to go look at the service manual I have and see the spec it gave, as that is the torque I set it too. And if I remember right, I *believe* it was 220. If that it what the manual I have states, I'll step it up to the 250 see what that does. I had thought about going higher recently, but didn't want to strip the threads out of the block. If they raised the torque spec, then compression leakage is most likely why they would have done so.

And yes that web area is the weakest point of these OHV gaskets. Just replaced one on another mower that I got for free as it would put out a literal cloud of smoke that you couldn't see through (due to the blown head gasket), and that is exactly where it blew out too. That mower doesn't have a mower deck, but since fixed it works great to pull my yard trailer I built

Additional Question: Is there a way to know if the muffler is partially blocked??? I read somewhere that this could cause similar issues. But it appears that the exhaust flow is normal. I may just pull the muffler off and see what happens.

Thanks for all the input and information everyone. I will go through some of these tomorrow if I have time to work on it. Once I go through the list, I'll report back if anything changed for better or worse.

#25

D

donens2018

D

donens2018

Reading the posts, couldn't find any reference to the having done a compression test. When the new rings were put in, did the cylinder show scoring? As someone suggested, I would hook up spark tester and run it. Look for any signs of missing or poor ignition. Also, I would check for oil breather for blockage or sludge.

#26

StarTech

StarTech

The problem is these engines have an ACR which limits the compression to 60-90 psi. In order to get a valid compression reading ti would require adjust the vavle clearance until the ACR is no longer effective. But there is one problem that as the electric starters are too weak to turn the engine through the compression stroke. Briggs recommends doing leak down tests instead when a compression problem is suspected.Reading the posts, couldn't find any reference to the having done a compression test. When the new rings were put in, did the cylinder show scoring? As someone suggested, I would hook up spark tester and run it. Look for any signs of missing or poor ignition. Also, I would check for oil breather for blockage or sludge.

#27

E

ezcruisn71

E

ezcruisn71

The clear fuel line you are using going to the fuel pump might be some of your problem! This line will collapse and therefore won't work for the fuel pump correctly! That fuel line should be a ridged black double core rubber line. If it collapses it will not operate the fuel pump correctly!I had two mowers that had oil coming back to the carburator and in each the float valve was stuck and the gas was filling the crankcase and forcing the oil out.

#28

E

ezcruisn71

E

ezcruisn71

Snowmobiles use the same type of fuel pump and they will not work correctly with the clear fuel line either.The clear fuel line you are using going to the fuel pump might be some of your problem! This line will collapse and therefore won't work for the fuel pump correctly! That fuel line should be a ridged black double core rubber line. If it collapses it will not operate the fuel pump correctly!

#29

S

sterobinson

S

sterobinson

I'm pretty sure there's a Reed valve under the flywheel that goes bad and that's why you have oil in the vacuum tube.

#30

E

ezcruisn71

E

ezcruisn71

The fuel line I am talking about comes off the Engine. It is the pulse line to the pump. This must be dual core rubber line. The other lines can be clear lineSnowmobiles use the same type of fuel pump and they will not work correctly with the clear fuel line either.

#31

Scrubcadet10

Scrubcadet10

My kawasaki Mule uses a vacuum pump, i have the clear line on it and it works great.

Polyuerthane

Polyuerthane

#33

S

Sdmcarlson

S

Sdmcarlson

So your engine crankcase is getting pressure inside it from somewhere. As oil is splashed around inside, that increase in pressure is pushing oil through the breather line that goes to your fuel pump. So, where can the pressure come from? Well, as the piston moves up and down, it creates positive and negative pressures in there. This is usually relatively low pressure differences because the size of the crankcase and the distance of the piston motion. Any oil usually goes through breather and back into engine through galley.

So, in your case, I'm guessing as the piston goes to top of stroke to compress fuel/air mixture (or exhaust stroke as well), and some of that is getting by and pressurizing the crankcase - loss of power also. If that engine has a oil filler tube, you may feel the blow-by. How does it get past? Either the, as you said, the head gasket, valves not closing, or the rings. Harbor Freight has a cheap cylinder pressure tester. I dunno the specs but seems 90 to 120ish psi should be good.

I'd do a leak down test next.

Good luck

So, in your case, I'm guessing as the piston goes to top of stroke to compress fuel/air mixture (or exhaust stroke as well), and some of that is getting by and pressurizing the crankcase - loss of power also. If that engine has a oil filler tube, you may feel the blow-by. How does it get past? Either the, as you said, the head gasket, valves not closing, or the rings. Harbor Freight has a cheap cylinder pressure tester. I dunno the specs but seems 90 to 120ish psi should be good.

I'd do a leak down test next.

Good luck

#34

warreng5995

warreng5995

yep, as I said that in some previous posts, I thought about that at one point. But the oil isn't being thinned down, don't see or smell any fuel in the oil either.I had two mowers that had oil coming back to the carburator and in each the float valve was stuck and the gas was filling the crankcase and forcing the oil out.

#35

warreng5995

When I first broke it down, yes there was a lot of sludge in the bottom of the sump pan. But after breakdown I spent several days cleaning **everything**, including the whole crankcase, nearly spotless. So no sludge now.

I also have replaced crankcase breather, fuel pump, air filter, fuel filter, oil filter, fuel lines, rings, all gaskets and seals, sparkplug, valves lapped, complete rebuild on carb, and probably some more things that I can't remember right now. All parts are all B&S OEM. (except the fuel pump that I just replaced a few days ago while troubleshooting is an Oregon)

The fuel tank was also removed and cleaned out.

After I readjusted the valves again this last time, and spent like an hour doing so before I was completely satisfied.The power was decently improved from what it was, but its not 100%.

Leak down test is possible, haven't done that yet. Might try it when I get time.

Also Cylinder and piston were clean, no scoring at all. New B&S rings.

don't remember seeing any valve or opening under the flywheel, other than the crankshaft seal of course. The vacuum line goes to the crankcase breather, which I also just replaced, but it is on the side of the case down toward the bottom behind the carb.

don't remember seeing any valve or opening under the flywheel, other than the crankshaft seal of course. The vacuum line goes to the crankcase breather, which I also just replaced, but it is on the side of the case down toward the bottom behind the carb.

I know the vacuum line. I thought about that, watched and felt of it with engine running and didn't see any flexing of the line at all. If I didn't have a clear line on there, I wouldn't even know there was any oil in the line to begin with. Further, with the engine running, the oil seems to stick back only on the walls of the line, fuel pump runs fine. I may change the line to a regular black fuel hose just to see if there is a difference in running, have no way to see inside a regular black fuel line to see if the oil is still present though.

At this point I think this is a non-issue, and was mostly just my observation of not seeing it before because I had been running a regular black hose fuel line previously.

At this point my main issue is, it will start when engine is cold every time, it will continue to run even after engine is hot and up to full temp. But once you turn the engine off, and leave it off for around 5 min or so, it won't restart. Doesn't even hit, and I've ruled out "not getting fuel". And it is getting air. So its either compression or spark.

With that said I believe it is a weak ignition coil. Although its working, and will start a cold engine, when the coil itself is also cold. Once the engine gets hot and the coil is hot, when the engine cools down some the coil is still too hot and has a weak spark. And therefore doesn't have a strong enough spark to restart the "cooler" engine.

It will however restart a Hot engine. As in have the engine running up to full temp. Turn off engine, wait only a few seconds, restart engine. But if the engine sits for 5 min or so, it won't restart until its basically cold.

So a weak coil is my theory. We'll see what happens. I don't have a spark tester at the moment, but I am getting one. I have removed plug previously and reconnected the coil wire to it, grounded plug back to the block and cranked the engine, it does have spark. Just how strong of a spark when the coil is hot is the question..?

As soon as I get time I'm going remove cover and etc, remove coil and go buy a new one. I've replaced about everything else anyway, might as well replace the coil too as it may even be the original for all I know.

When I get time, I will try to do a leak down test and see what results that gets.

Thanks Everyone for All the Info and Replies! ?

?

Will update when I have more

warreng5995

Reading the posts, couldn't find any reference to the having done a compression test. When the new rings were put in, did the cylinder show scoring? As someone suggested, I would hook up spark tester and run it. Look for any signs of missing or poor ignition. Also, I would check for oil breather for blockage or sludge.

As I said in previous posts, my Dad bought this mower from his nephew who bought it from an auction.... We ran it for a couple seasons, but there always seemed to be something I had to fix all the time to keep it running. Fast forward, I basically have rebuilt the entire mower. Including a complete full engine rebuild, hasn't been run maybe an hour.So your engine crankcase is getting pressure inside it from somewhere. As oil is splashed around inside, that increase in pressure is pushing oil through the breather line that goes to your fuel pump. So, where can the pressure come from? Well, as the piston moves up and down, it creates positive and negative pressures in there. This is usually relatively low pressure differences because the size of the crankcase and the distance of the piston motion. Any oil usually goes through breather and back into engine through galley.

So, in your case, I'm guessing as the piston goes to top of stroke to compress fuel/air mixture (or exhaust stroke as well), and some of that is getting by and pressurizing the crankcase - loss of power also. If that engine has a oil filler tube, you may feel the blow-by. How does it get past? Either the, as you said, the head gasket, valves not closing, or the rings. Harbor Freight has a cheap cylinder pressure tester. I dunno the specs but seems 90 to 120ish psi should be good.

I'd do a leak down test next.

Good luck

When I first broke it down, yes there was a lot of sludge in the bottom of the sump pan. But after breakdown I spent several days cleaning **everything**, including the whole crankcase, nearly spotless. So no sludge now.

I also have replaced crankcase breather, fuel pump, air filter, fuel filter, oil filter, fuel lines, rings, all gaskets and seals, sparkplug, valves lapped, complete rebuild on carb, and probably some more things that I can't remember right now. All parts are all B&S OEM. (except the fuel pump that I just replaced a few days ago while troubleshooting is an Oregon)

The fuel tank was also removed and cleaned out.

After I readjusted the valves again this last time, and spent like an hour doing so before I was completely satisfied.The power was decently improved from what it was, but its not 100%.

Did we do a leak-down on this?

Yep, what StarTech said above, Can't do a compression test on this engine, as it has a compression release built into the camshaft to make it easier to start. That compression release doesn't move out of the way until centrifugal force overcomes it when the engine is running. So using a compression tester only gives a false reading at best.The problem is these engines have an ACR which limits the compression to 60-90 psi. In order to get a valid compression reading ti would require adjust the vavle clearance until the ACR is no longer effective. But there is one problem that as the electric starters are too weak to turn the engine through the compression stroke. Briggs recommends doing leak down tests instead when a compression problem is suspected.

Leak down test is possible, haven't done that yet. Might try it when I get time.

Also Cylinder and piston were clean, no scoring at all. New B&S rings.

humm...I'm pretty sure there's a Reed valve under the flywheel that goes bad and that's why you have oil in the vacuum tube.

The clear fuel line you are using going to the fuel pump might be some of your problem! This line will collapse and therefore won't work for the fuel pump correctly! That fuel line should be a ridged black double core rubber line. If it collapses it will not operate the fuel pump correctly!

Snowmobiles use the same type of fuel pump and they will not work correctly with the clear fuel line either.

The fuel line I am talking about comes off the Engine. It is the pulse line to the pump. This must be dual core rubber line. The other lines can be clear line

I know the vacuum line. I thought about that, watched and felt of it with engine running and didn't see any flexing of the line at all. If I didn't have a clear line on there, I wouldn't even know there was any oil in the line to begin with. Further, with the engine running, the oil seems to stick back only on the walls of the line, fuel pump runs fine. I may change the line to a regular black fuel hose just to see if there is a difference in running, have no way to see inside a regular black fuel line to see if the oil is still present though.

At this point I think this is a non-issue, and was mostly just my observation of not seeing it before because I had been running a regular black hose fuel line previously.

At this point my main issue is, it will start when engine is cold every time, it will continue to run even after engine is hot and up to full temp. But once you turn the engine off, and leave it off for around 5 min or so, it won't restart. Doesn't even hit, and I've ruled out "not getting fuel". And it is getting air. So its either compression or spark.

With that said I believe it is a weak ignition coil. Although its working, and will start a cold engine, when the coil itself is also cold. Once the engine gets hot and the coil is hot, when the engine cools down some the coil is still too hot and has a weak spark. And therefore doesn't have a strong enough spark to restart the "cooler" engine.

It will however restart a Hot engine. As in have the engine running up to full temp. Turn off engine, wait only a few seconds, restart engine. But if the engine sits for 5 min or so, it won't restart until its basically cold.

So a weak coil is my theory. We'll see what happens. I don't have a spark tester at the moment, but I am getting one. I have removed plug previously and reconnected the coil wire to it, grounded plug back to the block and cranked the engine, it does have spark. Just how strong of a spark when the coil is hot is the question..?

As soon as I get time I'm going remove cover and etc, remove coil and go buy a new one. I've replaced about everything else anyway, might as well replace the coil too as it may even be the original for all I know.

When I get time, I will try to do a leak down test and see what results that gets.

Thanks Everyone for All the Info and Replies!

Will update when I have more

#36

R

RMD

R

RMD

That's High crank case pressure due to blow by on the rings. So its worn rings, or ring clearance. That would account for the oil leak from the dipstick as well. Oil cannot travel up the vacuum line to the pump any other way. It also accounts for the oil on the intake as well from the crank case breather. Oil would only pass here if the breather valve was stuck open or crank case pressure was raised.

You also must know you cannot replace rings in a worn barrel as the barrel will be oval and the rings round. Hence blow by. So unless you have checked the barrel for round, honed the barrel even new rings will not seal.

You also must know you cannot replace rings in a worn barrel as the barrel will be oval and the rings round. Hence blow by. So unless you have checked the barrel for round, honed the barrel even new rings will not seal.

#37

B

Brian - Modern Mower

B

Brian - Modern Mower

HOLY COW. I am surprised by the responses.

I run a repair shop, and am a Briggs master technician. you are describing a typical problem. so typical, i could not believe the responses. you have too much crankcase pressure. normally, at a shop, we hook up a crankcase pressure gauge at the dip stick to see what the pressure is. the tool is called a manometer. the crankcase needs to show negative pressure (a vacuum) and, you are describing all of the typical symptoms of positive pressure. there are a few things that cause that, but the most likely suspect is a blown head gasket. second would be a breather valve that's not working, and third would be blow by past the rings, but that's the most rare.

BTW, i have worked on perhaps 1000 machines in the last year.

the crank case is building up pressure, and forcing oil out of all sorts of places. if i was a betting type, I'd bet its a head gasket.

I run a repair shop, and am a Briggs master technician. you are describing a typical problem. so typical, i could not believe the responses. you have too much crankcase pressure. normally, at a shop, we hook up a crankcase pressure gauge at the dip stick to see what the pressure is. the tool is called a manometer. the crankcase needs to show negative pressure (a vacuum) and, you are describing all of the typical symptoms of positive pressure. there are a few things that cause that, but the most likely suspect is a blown head gasket. second would be a breather valve that's not working, and third would be blow by past the rings, but that's the most rare.

BTW, i have worked on perhaps 1000 machines in the last year.

the crank case is building up pressure, and forcing oil out of all sorts of places. if i was a betting type, I'd bet its a head gasket.

#38

L

lefty2cox

L

lefty2cox

I think he said in the original post that the head gasket and breather were both replaced.HOLY COW. I am surprised by the responses.

I run a repair shop, and am a Briggs master technician. you are describing a typical problem. so typical, i could not believe the responses. you have too much crankcase pressure. normally, at a shop, we hook up a crankcase pressure gauge at the dip stick to see what the pressure is. the tool is called a manometer. the crankcase needs to show negative pressure (a vacuum) and, you are describing all of the typical symptoms of positive pressure. there are a few things that cause that, but the most likely suspect is a blown head gasket. second would be a breather valve that's not working, and third would be blow by past the rings, but that's the most rare.