GentlemanFahmah

Active Member

- Joined

- May 5, 2010

- Threads

- 5

- Messages

- 74

OK this topic was very interesting to me, and I took the opportunity to send it to a friend who is a mechanical and metallurgical genius and here's his reply which is VERY interesting:

I know that my Land Pride mower uses bushings around the bolt to nest the blade perfectly centered so that its balanced. I assume that this one does too but maybe not and perhaps that IS the problem right there.

I'd get a bushing for this as per original spec, and I'd make darn sure you have that blade properly centered and tight in this nest.

My mower blades are all hardened steel and if these are "el cheapo" aftermarket blades, then they might be prone to flex that could contribute too.

So #1, do you have that bushing spacer that goes around the shaft of the bolt to take up the space in the hole of the blade?

#2 - use original OEM Kubota blades, or a KNOWN safe equal. You hurl one of these babies off the mower and out the side chute when a car is driving by or a kid walking by and it's going to be a sad day.

1)

From: Rob

Sent: Thursday, September 01, 2011 6:21 AM

To: Ken

Subject: Ok, this needs Ken's diagnostic brain

http://www.lawnmowerforum.com/general-mower-discussion/5418-kubota-middle-blade-breaks.html

This is very intriguing to me and I'm at a loss except to think that the blades originally on the mower were inferior and had a design flaw. If anyone can pinpoint a theoretical cause, I think it's you.

So, what do you think? I think it has to be a blade problem but you see stuff like this frequently and might better understand the physics of what would do this.

This is pretty interesting.

Rob

2)

From: Ken

Sent: Thursday, September 01, 2011 11:06 AM

To: Rob

Subject: RE: Ok, this needs Ken's diagnostic brain

The only way it could break in that short of time is from fatigue due to harmonics. His gearbox bearings / gears will be next in line for catastrophic failure.

I am not a member so I can't look at the photos of the breaks.

There was a good suggestion for measuring the blade at 180 degree rotations to see if the quill was bent.

Also, I know this is counter intuitive, but if he ran with a lighter blade this would push the natural frequency up and likely out of the range of the rotational frequency of the mower.

At present, he either needs to slow the motor speed down or speed it up to avoid the critical frequency of the blade.

Ken

-------I copied and emailed him the pics you posted and here's his final reply-------------

3)

From: Rob

Sent: Thursday, September 01, 2011 8:54 AM

To: Ken

Subject: RE: Ok, this needs Ken's diagnostic brain

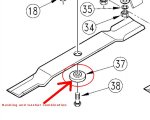

[photo of mandril and remaining blade center with bolt looking up]

This tells the story (the guy takes pictures of all the wrong angles!!)

This is a classic fatigue failure from bending UP and DOWN. The original crack started in the dark colored areas and the final failure was a complete fracture (light colored areas).

The original crack had time enough to rust and looks like the crack started on the top surface and propagated downward with would mean the bending was oriented downward at the tip of the blade.

[photo of center of blade and bolt looking down]

This photo shows fretting corrosion.

Not enough clamping force to deal with the vibration of the blade doing the harmonic dance . . .

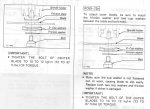

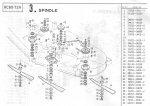

Also the bolt hole is huge compared to the bolt. Presumably there is a bushing that centers the blade on the shaft / quill . . . if not, that would explain the problem right there.

Ken

I know that my Land Pride mower uses bushings around the bolt to nest the blade perfectly centered so that its balanced. I assume that this one does too but maybe not and perhaps that IS the problem right there.

I'd get a bushing for this as per original spec, and I'd make darn sure you have that blade properly centered and tight in this nest.

My mower blades are all hardened steel and if these are "el cheapo" aftermarket blades, then they might be prone to flex that could contribute too.

So #1, do you have that bushing spacer that goes around the shaft of the bolt to take up the space in the hole of the blade?

#2 - use original OEM Kubota blades, or a KNOWN safe equal. You hurl one of these babies off the mower and out the side chute when a car is driving by or a kid walking by and it's going to be a sad day.